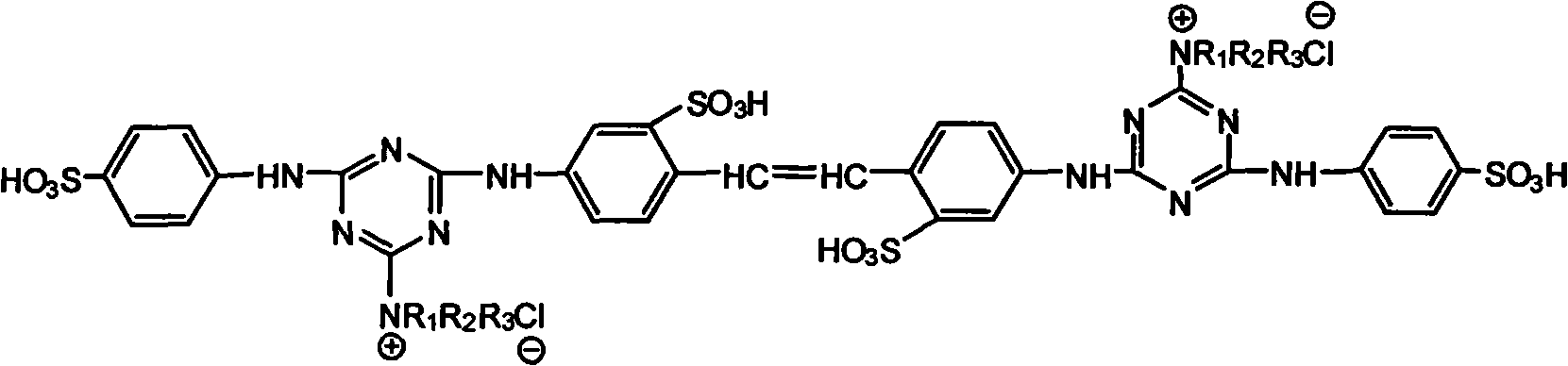

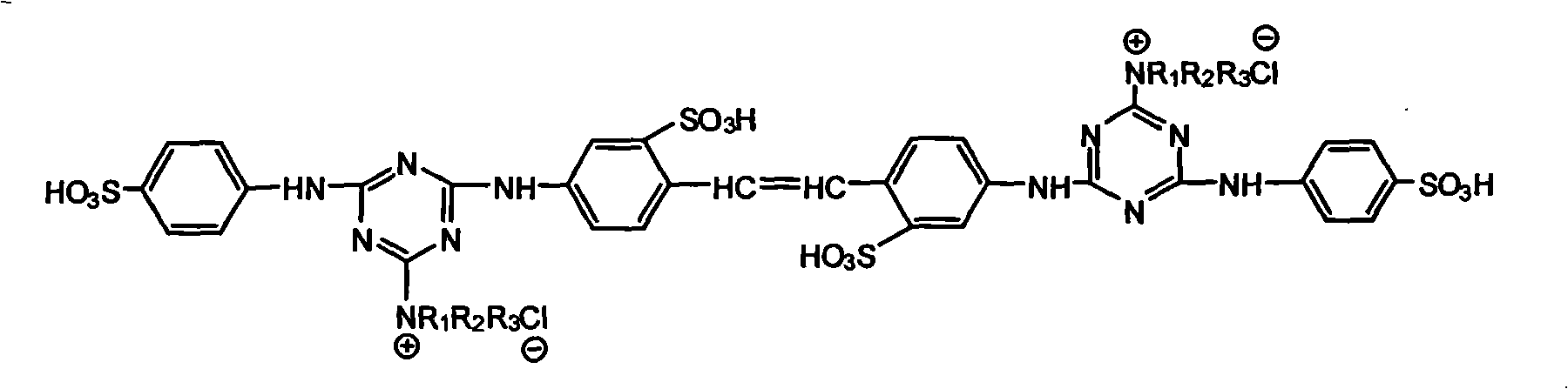

Amphiprotic triazine-DSD acid fluorescent whitener of tetra-sulfonic acid, synthesizing method thereof and applications

A technology of fluorescent whitening agent and tetrasulfonic acid, which is applied in the direction of adding luminescent/fluorescent substances, bleaching products, dyes of washing compositions, etc., can solve the problems of strong acid resistance, poor light fastness, easy precipitation, etc. Stable, good dye uptake, improved bonding and washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In a 500ml three-neck flask (ice-water bath), add a mixture of 60g deionized water and 180g ice and 7.40g cyanuric chloride, keep the temperature at 5°C, stir vigorously to disperse evenly, add 6.93g p-aminobenzenesulfonic acid, and adjust the pH value At about 2.0, react for 2.5 hours and then rise to about 10°C; raise the temperature to 40°C in a constant temperature water bath, add 7.39g of DSD acid, adjust the pH value to 3.5, react for 2.5h; then raise the temperature to 75°C, add 4.61g of N- Methylmorpholine, adjust the pH value to 7.5, react for 2.5 hours, and dry to obtain a solid product that is a quaternary ammonium salt-type fluorescent whitening agent, with a yield of 85.8%.

Embodiment 2

[0018] In a 500ml three-necked flask (ice-water bath), add a mixture of 60g deionized water and 180g ice and 7.40g cyanuric chloride, keep the temperature at 0°C, stir vigorously to disperse evenly, add 6.93g p-aminobenzenesulfonic acid, and adjust the pH value At about 2.0, react for 2.5 hours and then rise to about 10°C; raise the temperature to 45°C in a constant temperature water bath, add 7.39g of DSD acid, adjust the pH value to 4.5, and react for 2.5h; then raise the temperature to 85°C, add 4.69gN,N - Diethylethanolamine, adjust the pH value to 8.5, react for 2.5 hours, and dry to obtain a solid product that is a quaternary ammonium salt-type fluorescent whitening agent, with a yield of 82.7%.

Embodiment 3

[0020] In a 500ml three-neck flask (ice-water bath), add a mixture of 60g deionized water and 180g ice and 7.40g cyanuric chloride, keep the temperature at 5°C, stir vigorously to disperse evenly, add 6.93g p-aminobenzenesulfonic acid, and adjust the pH value At about 2.0, react for 2.5 hours and then rise to about 10°C; raise the temperature to 43°C in a constant temperature water bath, add 7.39g of DSD acid, adjust the pH value to 4.0, and react for 2.5h; then raise the temperature to 80°C, add 6.53g of N, N-diethanol glycine, adjust the pH value to 7.8, react for 2.5 hours, and dry to obtain a solid product that is a quaternary ammonium salt-type fluorescent whitening agent, with a yield of 81.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com