Polyesteramide, preparation method thereof and fiber

A technology of polyester amide and amidation reaction, applied in the direction of single-component polyamide rayon, etc., can solve the problems of affecting the performance of subsequent fibers, yellowing of polyester amide slices, etc., and achieve outstanding performance, good elongation at break The effect of long rate and high dye uptake rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

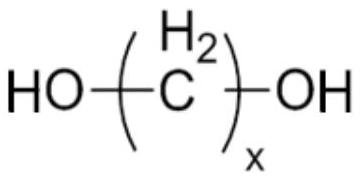

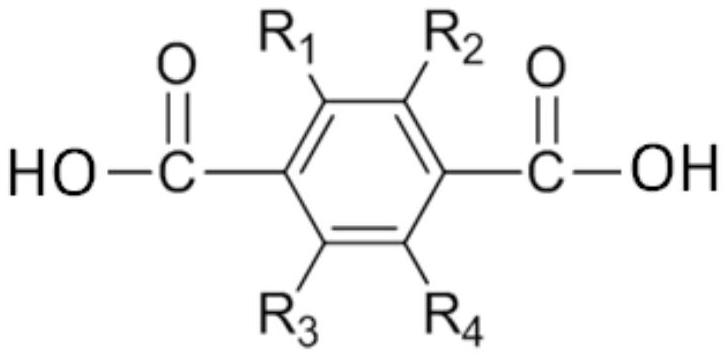

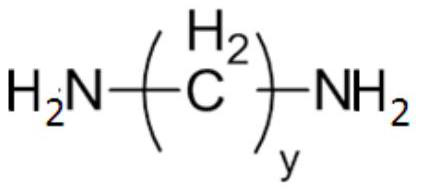

[0065]Under the condition of nitrogen protection, add 16.0kg terephthalic acid and 7.48kg ethylene glycol into a 100L esterification reaction kettle, add 7.8g ethylene glycol antimony catalyst, raise the temperature to about 260°C for reaction, and distill low Boiling point component, when the reaction is carried out for about 300 minutes, the low boiling point fraction reaches 98% of the theoretical amount, the esterification reaction is completed, and the stabilizer trimethyl phosphate 4.86g is added to the esterification reaction kettle, and then the prepared hexadiene Acid-pentamethylenediamine aqueous solution (mass concentration is 30%, wherein the mass of adipate-pentamethylenediamine salt is 480g), continue stirring at about 260°C for about 10 minutes. Then transfer the material in the esterification reaction kettle to the polycondensation reaction kettle under the condition of nitrogen protection, raise the temperature to 280°C, and evacuate to 1kPa, and after about 1 ...

Embodiment 2

[0067] Under the condition of nitrogen protection, add 16.0kg terephthalic acid and 7.48kg ethylene glycol into a 100L esterification reaction kettle, add 7.8g ethylene glycol antimony catalyst, raise the temperature to about 260°C for reaction, and distill low Boiling point component, when the reaction is carried out for about 300 minutes, the low boiling point fraction reaches 98% of the theoretical amount, the esterification reaction is completed, and the stabilizer trimethyl phosphate 4.86g is added to the esterification reaction kettle, and then the prepared hexadiene Acid-pentamethylenediamine aqueous solution (mass concentration is 50%, wherein the mass of adipic acid-pentamethylenediamine salt is 480g), continue stirring at about 260°C for about 10 minutes. Then transfer the material in the esterification reaction kettle to the polycondensation reaction kettle under the condition of nitrogen protection, raise the temperature to 280°C, and evacuate to 1kPa, and after abo...

Embodiment 3

[0069] Under the condition of nitrogen protection, add 16.0kg terephthalic acid and 7.48kg ethylene glycol into a 100L esterification reaction kettle, add 7.8g ethylene glycol antimony catalyst, raise the temperature to about 260°C for reaction, and distill low Boiling point component, when the reaction is carried out for about 300 minutes, the low boiling point fraction reaches 98% of the theoretical amount, the esterification reaction is completed, and the stabilizer trimethyl phosphate 4.86g is added to the esterification reaction kettle, and then the prepared hexadiene Acid-pentamethylenediamine aqueous solution (mass concentration is 70%, wherein the mass of adipic acid-pentamethylenediamine salt is 480g), continue stirring at about 260°C for about 10 minutes. Then transfer the material in the esterification reaction kettle to the polycondensation reaction kettle under the condition of nitrogen protection, raise the temperature to 280°C, and evacuate to about 1kPa, after a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com