Digital-printing active ink suitable for wide-width micro-piezoelectric printer

A technology of digital printing and reactive ink, applied in ink, application, household appliances and other directions, can solve the problems of narrow adaptability of different models, long production cycle, uneconomical and other problems, achieve excellent color expression, good washing fastness , the effect of good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

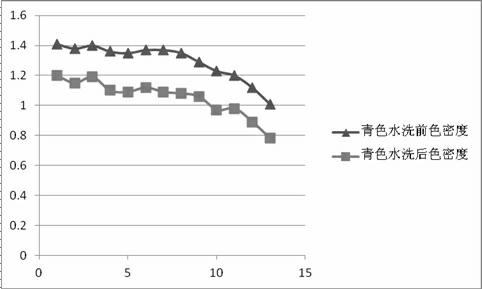

Embodiment 1

[0033] The active ink for digital printing suitable for wide-width micro piezoelectric printers of the present invention has a proportioning ratio as follows:

[0034] 10.0% by weight of reactive dye Everplus cyan G powder;

[0035] 15% by weight of glycerin, 1,2 propylene glycol, 1,2-hexanediol, diethylene glycol butyl ether, a mixture composed of 7:3:3:2 (weight);

[0036] 2% by weight trimethylolpropane;

[0037] 0.1% by weight GXL;

[0038] 0.02% by weight Tris (trishydroxymethylaminomethane);

[0039] 0.1 wt% ET-135;

[0040] 0.5% by weight SOLSPERSE S47000;

[0041] 1% by weight ethylene urea;

[0042] 71.28% by weight deionized water.

[0043] Preparation:

[0044] Put 15% by weight of glycerin, 1,2 propylene glycol, 1,2-hexanediol, and diethylene glycol butyl ether in a ratio of 7:3:3:2 (weight) into the reaction kettle, and then Add 2% by weight of trimethylolpropane, 0.1% by weight of GXL (20% of 1,2-benzisothiazolin-3-one in dipropylene glycol in water), 0.0...

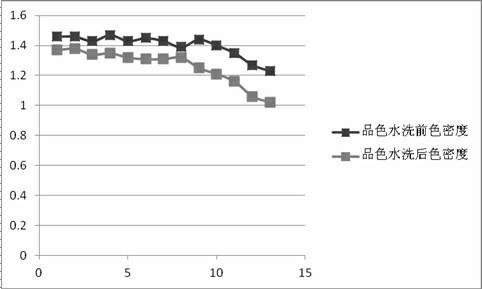

Embodiment 2

[0046] The active ink for digital printing suitable for wide-width micro piezoelectric printers of the present invention has a proportioning ratio as follows:

[0047] 10.0% by weight of reactive dye Everplus Red 6B powder;

[0048] 20.0% by weight of glycerin, 1,2 propylene glycol, 1,2-hexanediol, diethylene glycol butyl ether, a mixture composed of 10:3:3:4 (weight);

[0049] 1.0% by weight trimethylolpropane;

[0050] 0.05% by weight GXL;

[0051] 0.02% by weight Tris (trishydroxymethylaminomethane);

[0052] 0.1 wt% ET-135;

[0053] 1.0% by weight SOLSPERSE S47000;

[0054] 1.0% by weight urea;

[0055]66.83% by weight deionized water.

[0056] Preparation:

[0057] Put 20.0% by weight of glycerin, 1,2-propylene glycol, 1,2-hexanediol, diethylene glycol butyl ether, and a mixture of 10:3:3:4 (weight) into the reaction kettle, and then add 1.0 wt% Trimethylolpropane, 0.05 wt% GXL (20% 1,2-benzisothiazolin-3-one in dipropylene glycol in water), 0.02 wt% Tris (trishyd...

Embodiment 3

[0059] The active ink for digital printing suitable for wide-width micro piezoelectric printers of the present invention has a proportioning ratio as follows:

[0060] 12.0% by weight of reactive dye Everplus yellow 6G powder;

[0061] 15.0% by weight of glycerin, 1,2 propylene glycol, 1,2-hexanediol, diethylene glycol butyl ether, a mixture composed of 7:3:1:4 (weight);

[0062] 2.0% by weight trimethylolpropane;

[0063] 0.1% by weight GXL;

[0064] 0.02% by weight Tris (trishydroxymethylaminomethane);

[0065] 0.2 wt% ET-135;

[0066] 0.3% by weight SOLSPERSE S27000;

[0067] 5.0% by weight ethylene urea;

[0068] 65.38% by weight deionized water.

[0069] Preparation:

[0070] Put 15% by weight of glycerin, 1,2-propylene glycol, 1,2-hexanediol, diethylene glycol butyl ether, and a mixture of 7:3:1:4 (by weight) into the reaction kettle, and then add 2.0 wt% Trimethylolpropane, 0.1 wt% GXL (20% 1,2-benzisothiazolin-3-one in dipropylene glycol in water), 0.02 wt% Tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com