Printing device of thermosensitive and thermal-transfer-printing printer

A thermal transfer printer and printing device technology, applied in printing and other directions, can solve the problems of slow speed and only printing monochrome graphics and texts, and achieve the effects of improving printing quality, shortening heating time, and increasing moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

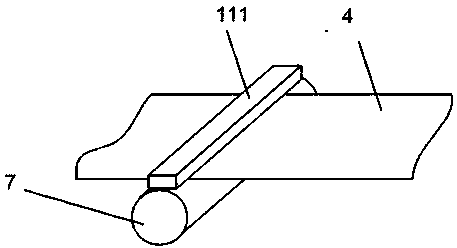

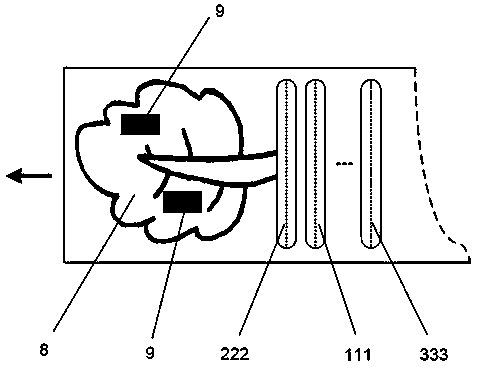

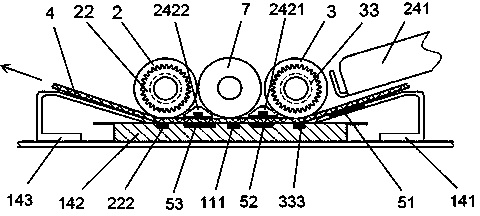

[0035] The printing device of a thermal printer. The print head consists of three parallel thermal print heads 111, 222, and 333. The three compression rubber rollers 2, 3, and 7 are mounted on the frame through bearings. The compression rubber roller will print The medium 4 is pressed against the print head; the pressing rubber roller is driven by a motor. The paper feeding ends of the three print heads are respectively provided with pre-heating zones 51, 52, 53. The pre-heating zones are installed on the paper guides 141, 142, and 143. The heating sheets used in the pre-heating zones are ceramic heating sheets.

[0036] The ceramic heating plate preheats the passing printing medium to an appropriate temperature and maintains a constant temperature. The temperature needs to be set according to the specific printing medium, which is generally higher than the ambient temperature but much lower than the temperature required for normal printing of the medium to increase the printing...

Embodiment 2

[0041] The difference from the first embodiment is that dual print heads are used in this embodiment. The print head is composed of two parallel thermal print heads 222 and 333. The print heads are respectively provided with pressing rubber rollers 2 and 3 to drive Gear 1 is connected to the drive motor, and the drive gear meshes with the outer ring gears of the two one-way bearing gears 22 and 33. The engagement directions of the inner and outer rings of the two one-way bearing gears are opposite. The compression rubber roller of the print head is fixedly connected.

[0042] Since the joining directions of the inner and outer rings of the two one-way bearings 22 and 33 are opposite, when the driving gear rotates counterclockwise, the outer ring of the second one-way bearing gear 22 on the left rotates clockwise, and the inner ring engages the follower; at this time, The outer ring of the first one-way bearing gear 33 on the right also rotates clockwise, and its inner ring is alw...

Embodiment 3

[0048] The difference from the second embodiment is that this embodiment is a printing device of a thermal transfer printer. There is a ribbon 6 passing between the printing medium 4 and the print head, and the ink on the ribbon is heated by the semiconductor printing head. On the printing medium 4, the printout is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com