Water-based inkjet ink for inkjet printing and preparation method thereof

An inkjet ink and inkjet printing technology, which is applied in the field of water-based inkjet ink and its preparation, can solve the problems of poor fluency and stability, and achieve good weather resistance, good fluency, and excellent color expression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

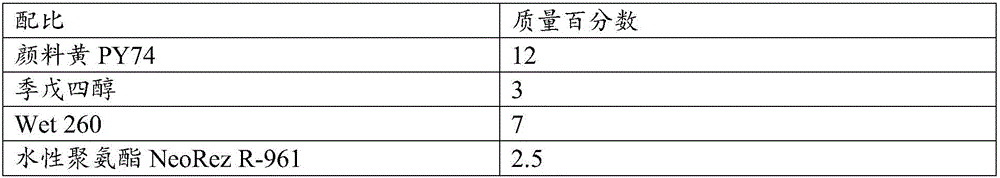

[0059] Table 1: Slurries

[0060]

[0061]

[0062] Table 2: Inkjet Inks

[0063] Proportion

mass percentage

yellow paste

15

polyethylene glycol 8000

8

preservatives

0.1

BYK 348

0.5

Water-based acrylic resin Joncryl 7159

6

0.5

Deionized water

margin

[0064] First configure the formula in Table 1: mix deionized water, defoamer BYK094, water-based PU resin NeoRez R-961, dispersant Wet260, and emulsification stabilizer pentaerythritol, stir well, then increase the stirring speed to 900rpm, and slowly add Pigment yellow, stir and disperse for 30 minutes after adding, and then put it into a nano grinder for grinding, select 0.1mm yttrium stabilized zirconia beads, the grinder speed is 1500rpm, the grinding time is 0.3h / kg, and the flow rate is 4kg / min; after grinding, After being centrifuged in a high-speed centrifuge, the centrifugal speed is 6500rpm, the flow ra...

Embodiment 2

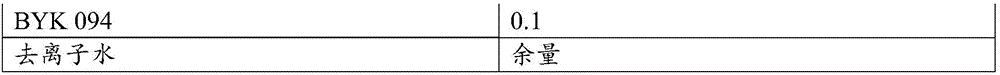

[0067] Table 3: Slurries

[0068]

[0069] Table 4: Inkjet Inks

[0070] Proportion

[0071] The preparation method is the same as in Example 1.

Embodiment 3

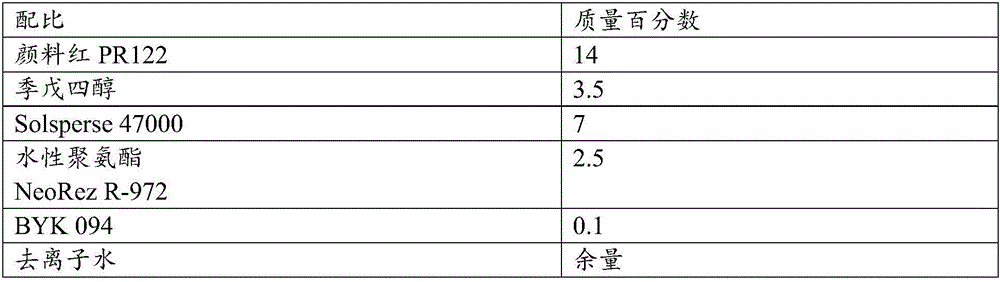

[0073] Table 5: Slurries

[0074] Proportion

[0075] Table 6: Inkjet Inks

[0076] Proportion

[0077] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com