Traceable paper cups and bowls and preparation method thereof

A paper cup paper and paper bowl technology, which is applied in the field of permanent paper cup paper bowl and its preparation, can solve the problems of non-formed paper cup paper bowl production time, failure to achieve the expected effect of effective traceability, and hidden dangers of dietary health, so as to promote safety and quality improvement, the maintenance of people's health, and the effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

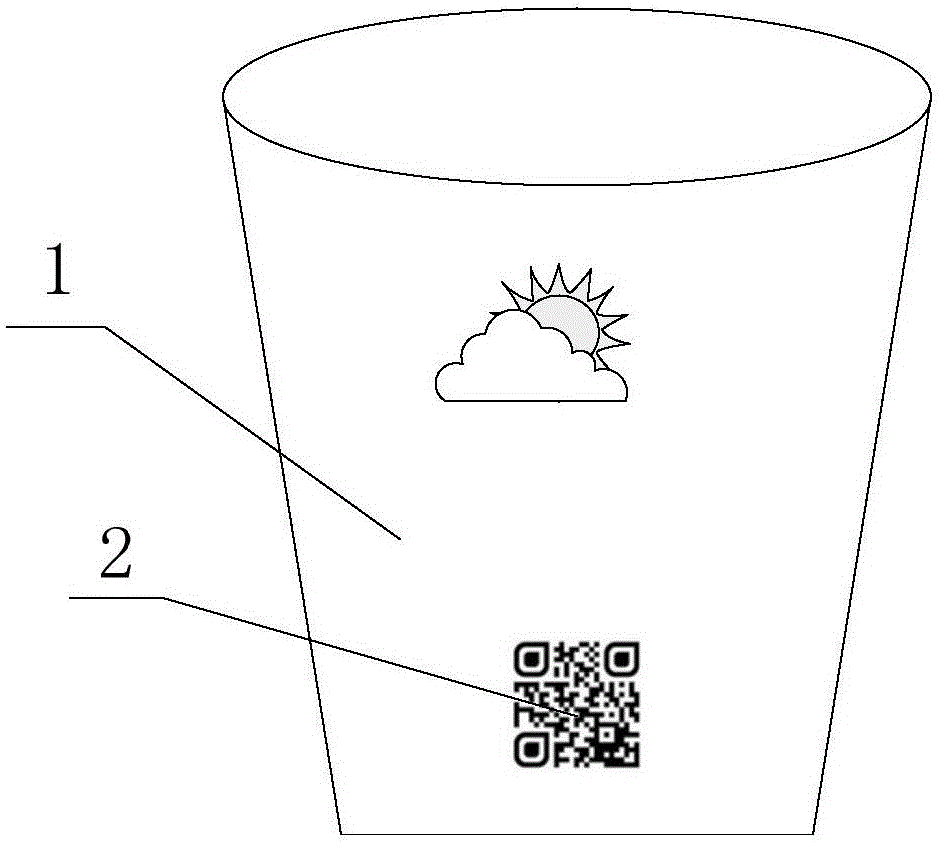

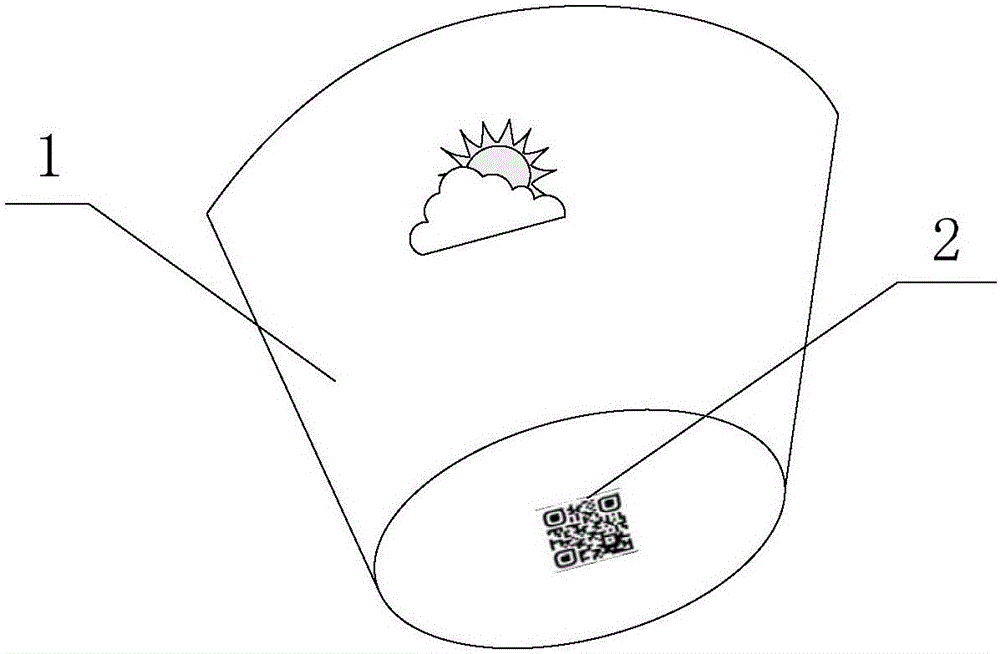

[0028] The traceable paper cup and paper bowl proposed by the present invention, figure 1 The paper cup and paper bowl with the traceability logo printed on the side shown, the traceability logo 2 is printed on the outer side of the paper cup and paper bowl 1. figure 2 The bottom shown is a paper cup and paper bowl with a traceability logo printed on the bottom, and the traceability logo 2 is printed on the bottom of the paper cup and paper bowl 1. The traceability logo 2 is bound with information including the manufacturer, production batch, production date, and source of raw materials for later traceability display. Traceability ID 2 is a QR code with a unique ID. Those skilled in the art can understand that, in addition to the two-dimensional code, the traceability identifier 2 can of course also be other identifiers capable of binding traceability information.

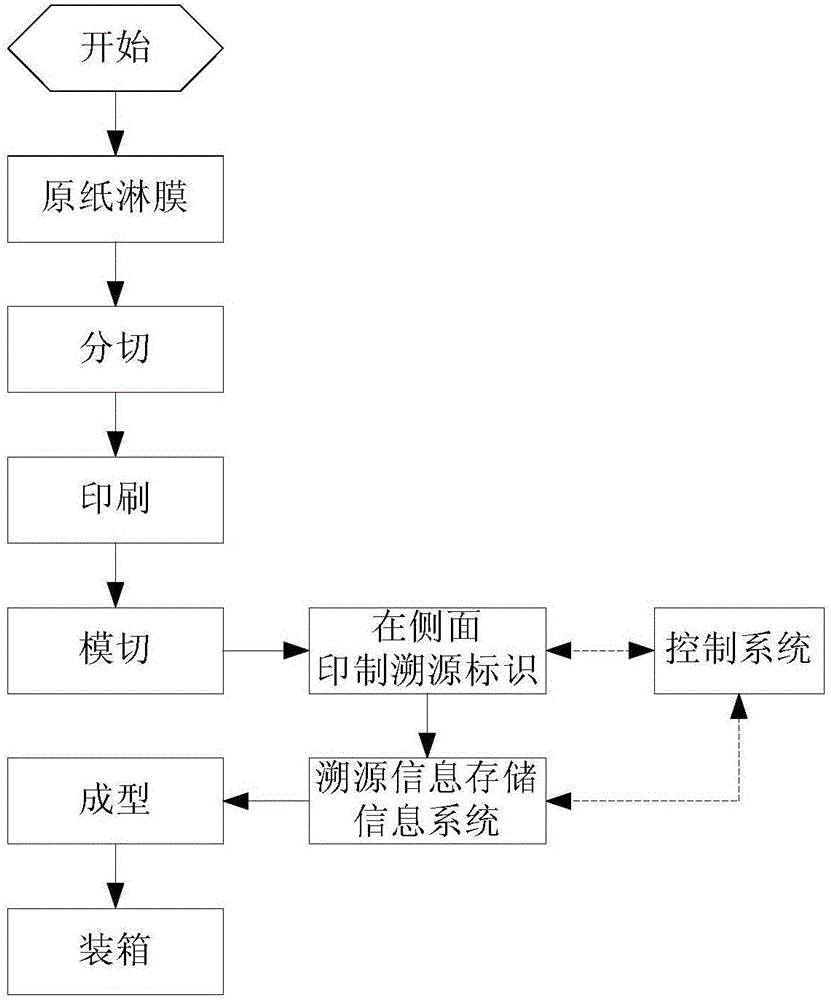

[0029] image 3 A preparation method of traceable paper cups and bowls is shown, including the following ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com