Sand blasting and shot peening equipment

A shot peening and equipment technology, applied in metal processing equipment, spray guns, abrasive jet machine tools, etc., can solve the problems of workers with respiratory diseases, unsuitable for automated production, and labor-intensive workers. hidden dangers and the effect of improving shot peening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

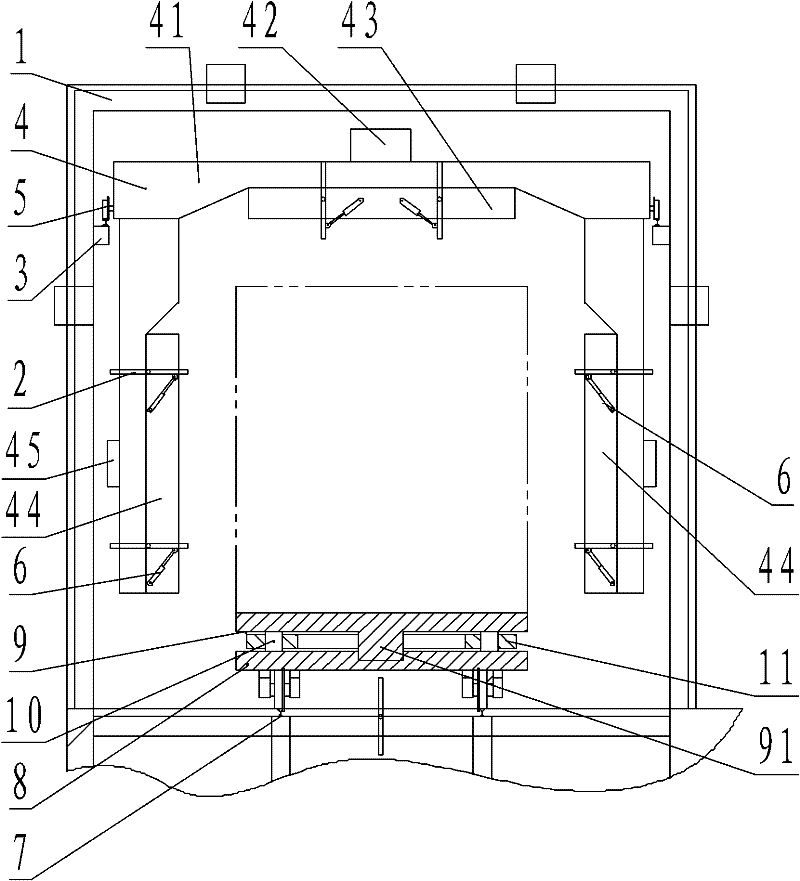

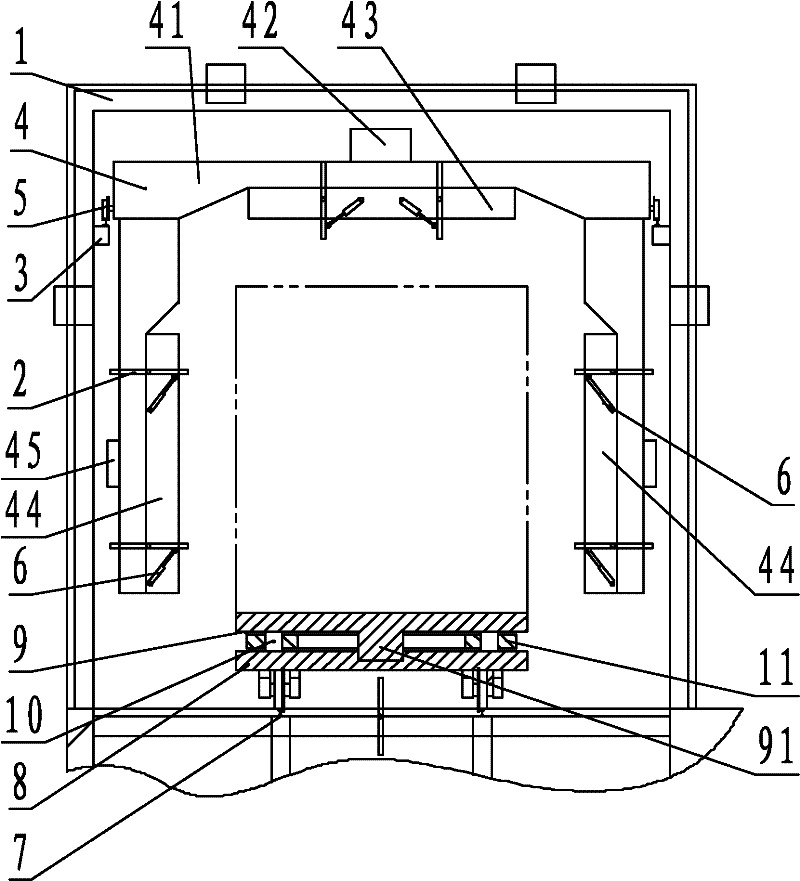

[0024] As shown in the figure, a sandblasting and peening equipment, the described sandblasting and peening equipment includes a chamber body 1 and a spray gun 2, and a group of gantry guide rails 3 are arranged on the upper part of the chamber, inside the chamber A gantry 4 is provided, and the gantry 4 cooperates with the gantry guide rail 3 through several sets of rollers 5. The beam 41 on the top of the gantry 4 is connected with a movable plate 43 through a cylinder 42, and the spray gun 2 is handed over to the movable plate 43. On the spray gun 2 and the movable plate 43 paper parts are provided with a start push rod 6, the two ends of the pneumatic push rod 6 are respectively connected with the spray gun and the movable plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com