Aramid fiber antibacterial dyeing one-bath treatment method

A treatment method, aramid fiber technology, applied in dyeing, textiles and papermaking, etc., can solve problems affecting aramid fiber crystallization, lower product quality, complicated process, etc., achieve good color fastness to rubbing, no harmful gas emissions, The effect of dyeing effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare the dye solution according to the following process formula, put the dye solution and aramid fabric into the dyeing cup, then put the dyeing cup into the high-temperature dyeing machine, raise the temperature to 60°C, and keep it warm for 30 minutes to make the carrier and the fabric evenly interact. After the heat preservation is over, the temperature is raised to 130°C at 2°C / min, dyed for 60 minutes, and the temperature is lowered to 40°C after the dyeing is completed.

[0035] Process formula for dyeing and antibacterial treatment in the same bath:

[0036] cationic dye 2% (o.w.f.) Carrier / g·L -1

50 Silver nitrate / g.L -1

0 pH value 4.0 temperature / ℃ 130 time / min 60 bath ratio 1:50

[0037] .

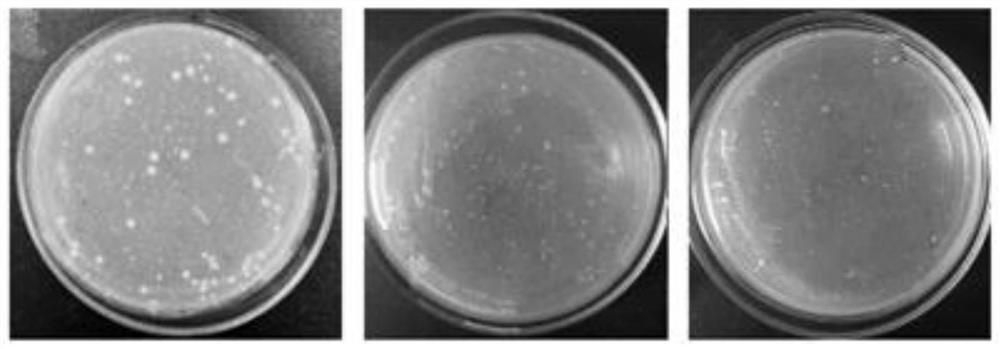

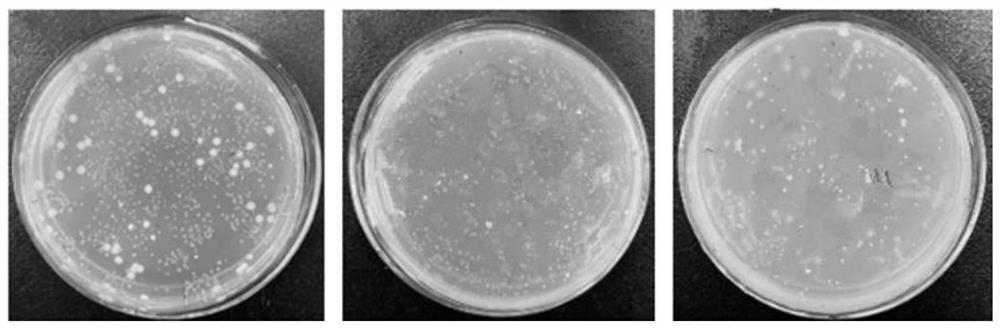

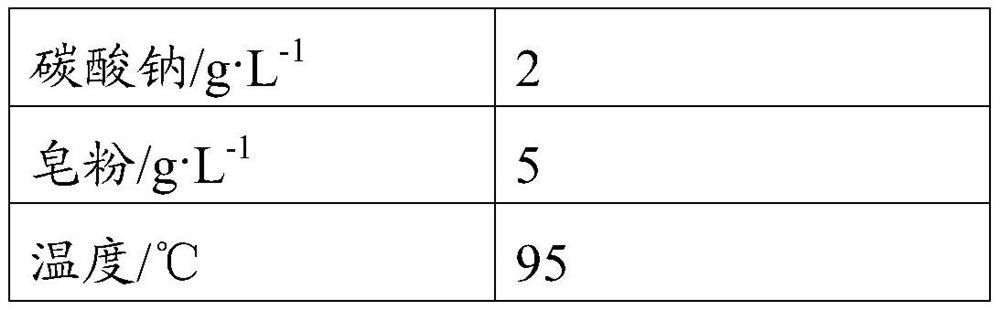

[0038] Finally, wash the dyed fabric with cold water and hot water. After washing, put the dyed fabric into a beaker and add the prepared soaping agent. Put the beaker in a w...

Embodiment 2

[0040] Prepare the dye solution according to the following process formula, put the dye solution and aramid fabric into the dyeing cup, then put the dyeing cup into the high-temperature dyeing machine, raise the temperature to 60°C, and keep it warm for 30 minutes to make the carrier and the fabric evenly interact. After the heat preservation is over, the temperature is raised to 130°C at 2°C / min, dyed for 60 minutes, and the temperature is lowered to 40°C after the dyeing is completed.

[0041] Process formula for dyeing and antibacterial treatment in the same bath:

[0042] cationic dye 2% (o.w.f.) Carrier / g·L -1

50 Silver nitrate / g.L -1

0.3 pH value 4.0 temperature / ℃ 130 time / min 60 bath ratio 1:50

[0043] .

[0044] Finally, wash the dyed fabric with cold water and hot water. After washing, put the dyed fabric into a beaker and add the prepared soaping agent. Put the beaker in a...

Embodiment 3

[0046] First, the aramid fabric is pretreated (10g / L degreaser, soaked at 95°C for 30min, after scouring, the temperature is lowered to 40°C, washed and dried); secondly, the antibacterial aramid dyed fabric is prepared by the cationic carrier dyeing method.

[0047] Process formula for dyeing and antibacterial treatment in the same bath:

[0048] cationic dye 2% (o.w.f.) Carrier / g·L -1

40 Sodium sulfate / g·L -1

50 Silver nitrate / g.L -1

0.6 pH value 4.0 temperature / ℃ 130 time / min 60 bath ratio 1:50

[0049] .

[0050] Finally, wash the dyed fabric with cold water and hot water. After washing, put the dyed fabric into a beaker and add the prepared soaping agent. Put the beaker in a water bath at 40°C, raise the temperature to 95°C and keep it warm for 25 minutes. After soaping, cool down to 60°C, wash the fabric in hot water and then in cold water, and finally put it in an oven for drying.

[0051] The dyed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com