Dyeing and finishing process of coffee-yarn blended and knitted fabric

A technology of coffee yarn and fabric, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, textiles and papermaking, etc. It can solve the problems of same-color dyeing influence, swimming migration, fiber friction and washing fastness decline, etc. , to achieve the effect of good air permeability and good color fastness to rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

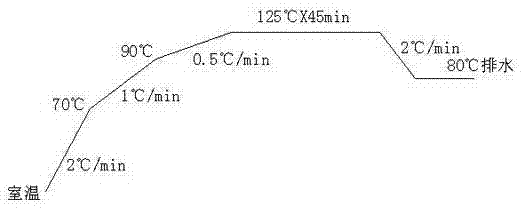

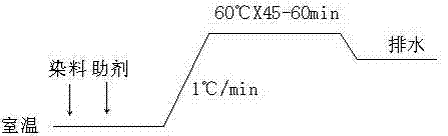

[0064] A kind of dyeing and finishing process of coffee yarn blended fabric of the present invention, its process flow is as follows: gray cloth - pretreatment - dyeing - soaping - softening - finishing - inspection - finished product, wherein:

[0065] 1. Gray cloth: the gray cloth is made of coffee yarn blended fabric. In this embodiment, coffee yarn and viscose fiber blended fabric are used, wherein: the blended ratio of coffee yarn and viscose fiber is 30-70%: 70-30% to obtain 26-40S Coffee and viscose blended yarns are used as raw materials to weave knitted fabrics with a width of 150-170 cm and a weight of 150-200 gsm.

[0066] 2. Pre-processing:

[0067] In order to ensure that the coffee yarn and viscose fiber in the blended fabric can be dyed uniformly and in the same color in the subsequent dyeing process, a mild refining process is adopted in the pre-treatment process to make the pre-treatment more uniform and transparent, which is convenient for the subsequent dyei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com