Patents

Literature

40results about How to "Ensure level dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

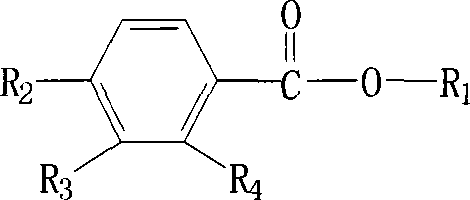

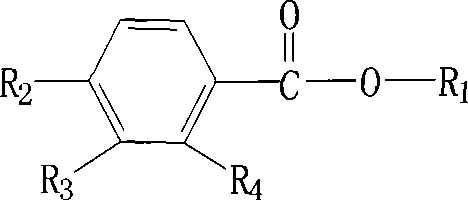

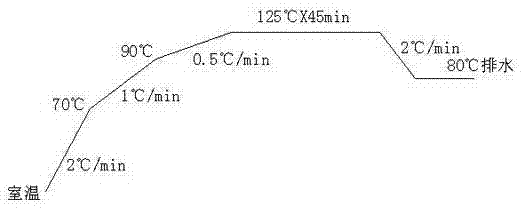

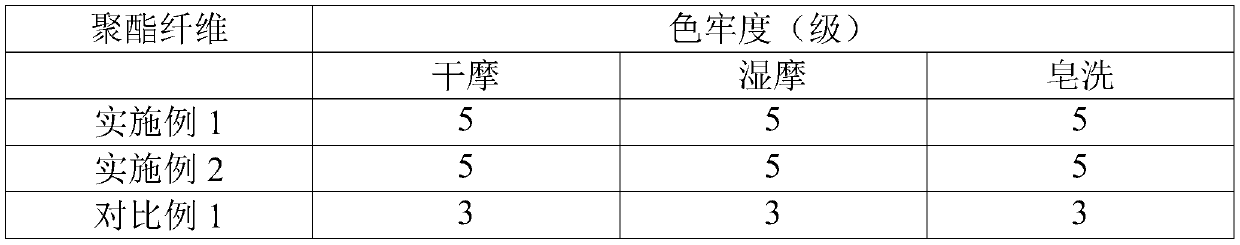

Polyester fiber disperse dye low-temperature coloring accelerant BENTE and technique

ActiveCN101446047AFacilitated DiffusionImproving the dyeing performance of disperse dyesDyeing processSurface-active agentsColor temperature

The invention discloses a polyester fiber disperse dye low-temperature coloring accelerant BENTE and a technique. The accelerant BENTE comprises the following components by the weight percentage: 85 to 97 percent of organic compound BLB and 3 to 15 percent of compound emulsifier. The compound emulsifier comprises the components with the following weight percentage: 98 to 60 percent of hydrophilic nonionic surface active agent, 0 to 30 percent of hydrophobic nonionic surface active agent, and 2 to 10 percent of assistant emulsifier. The coloring technique thereof is as follows: 0.1 to 5 percent (o.w.f) of disperse dye and 1 to 10 percent (o.w.f) of the accelerant BENTE are dyed under the temperature between 50 and 60 DEG C with the pH value of 4.5 to 7 and a bath ratio of 1:10 to 1:50; the temperature is raised to the temperature between 90 and 110 DEG C at a speed of 2 DEG C / min and then the temperature is maintained for 60 and 80 min. The coloring technique not only is convenient to be used, but also endows the coloring benefit of the coloring stage of the polyester fiber disperse dye, lowering the coloring temperature and reduces pollution and cost.

Owner:浙江云中马股份有限公司

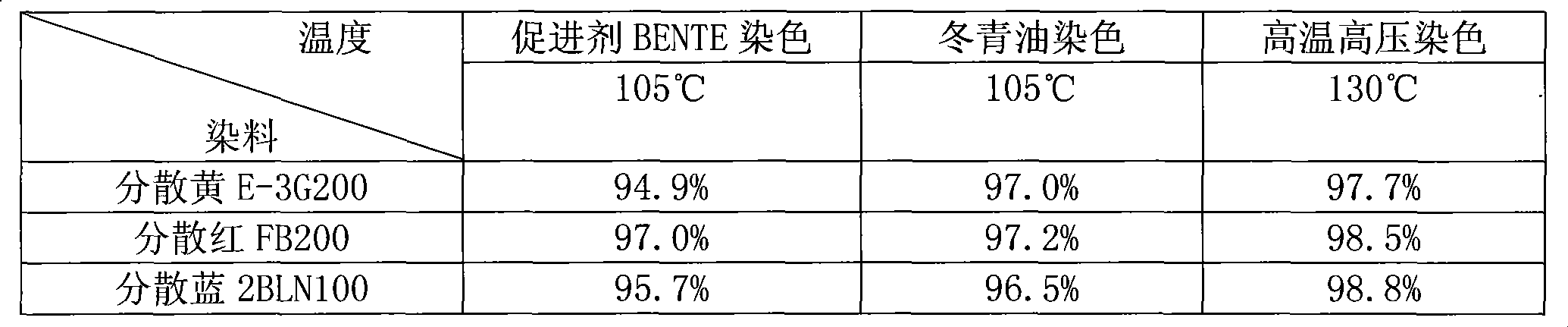

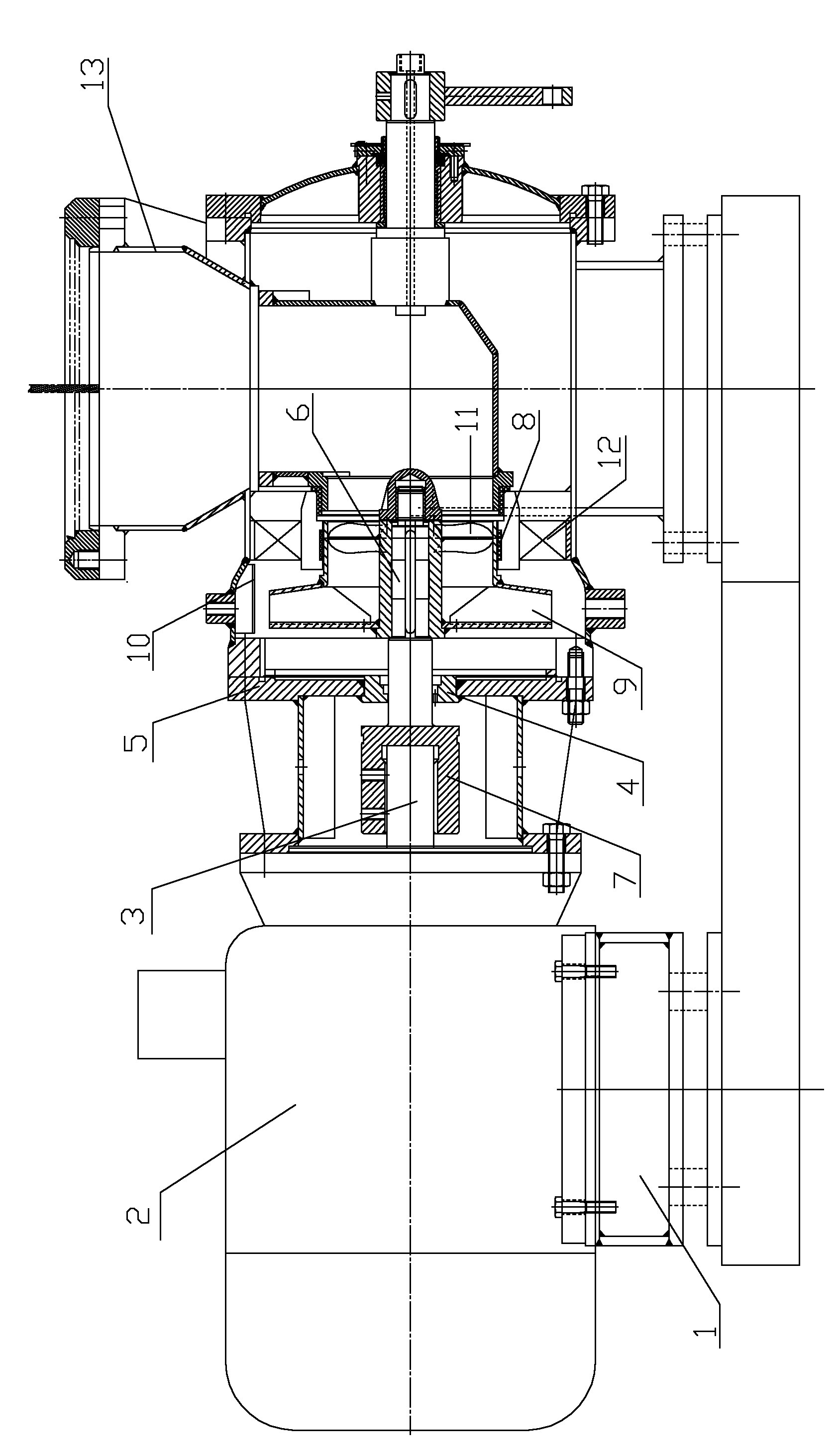

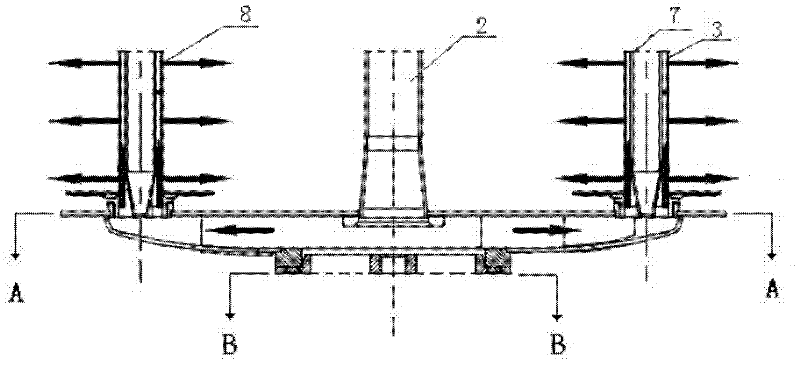

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

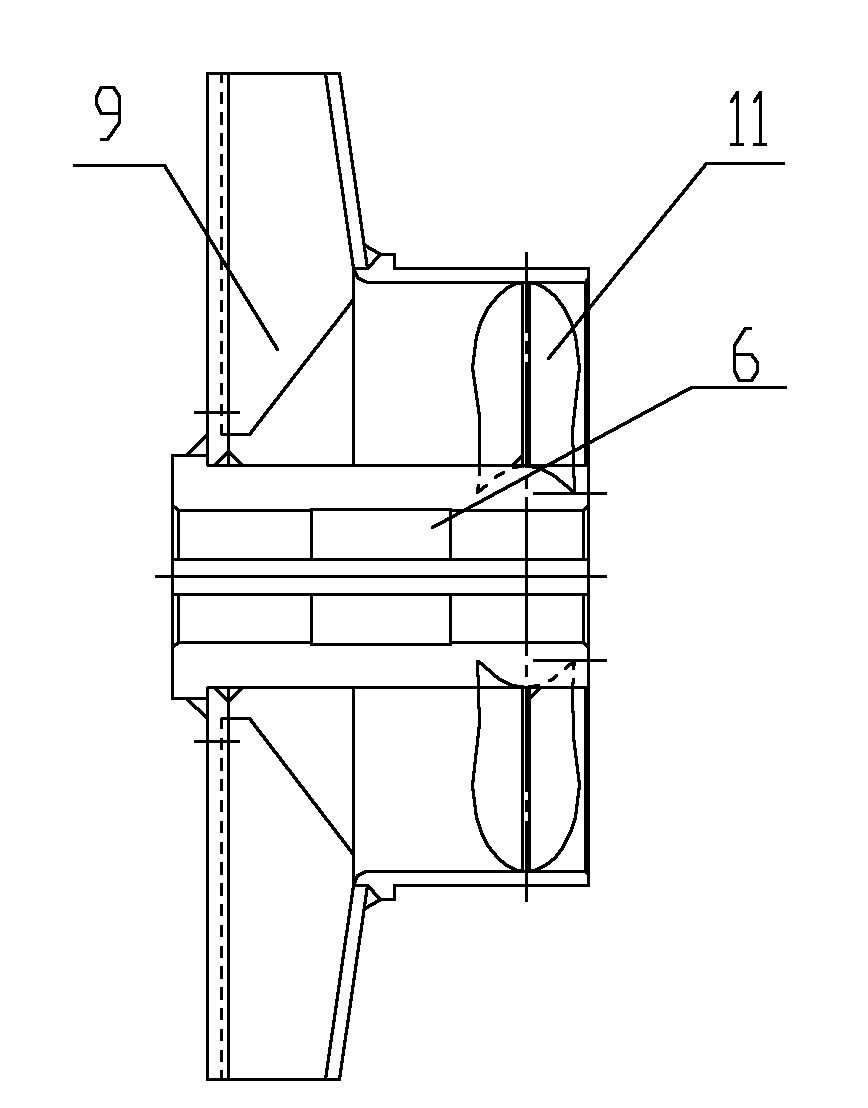

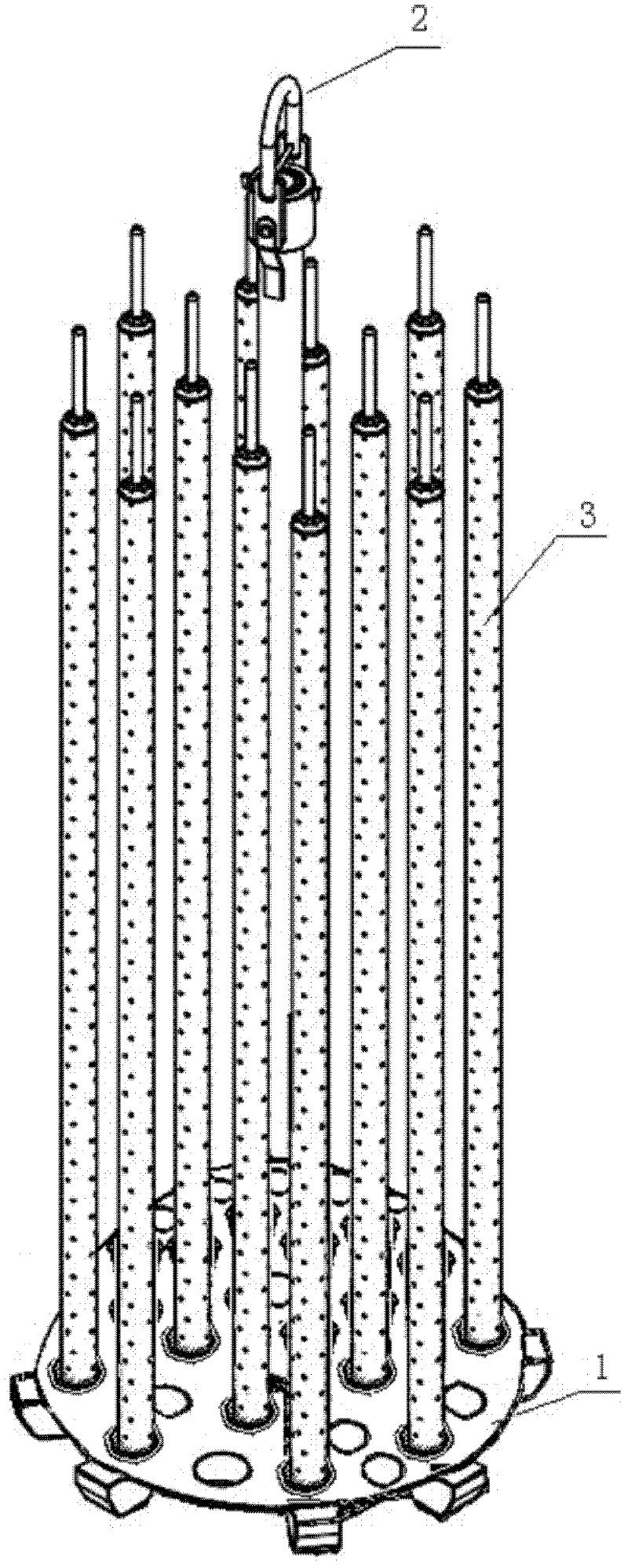

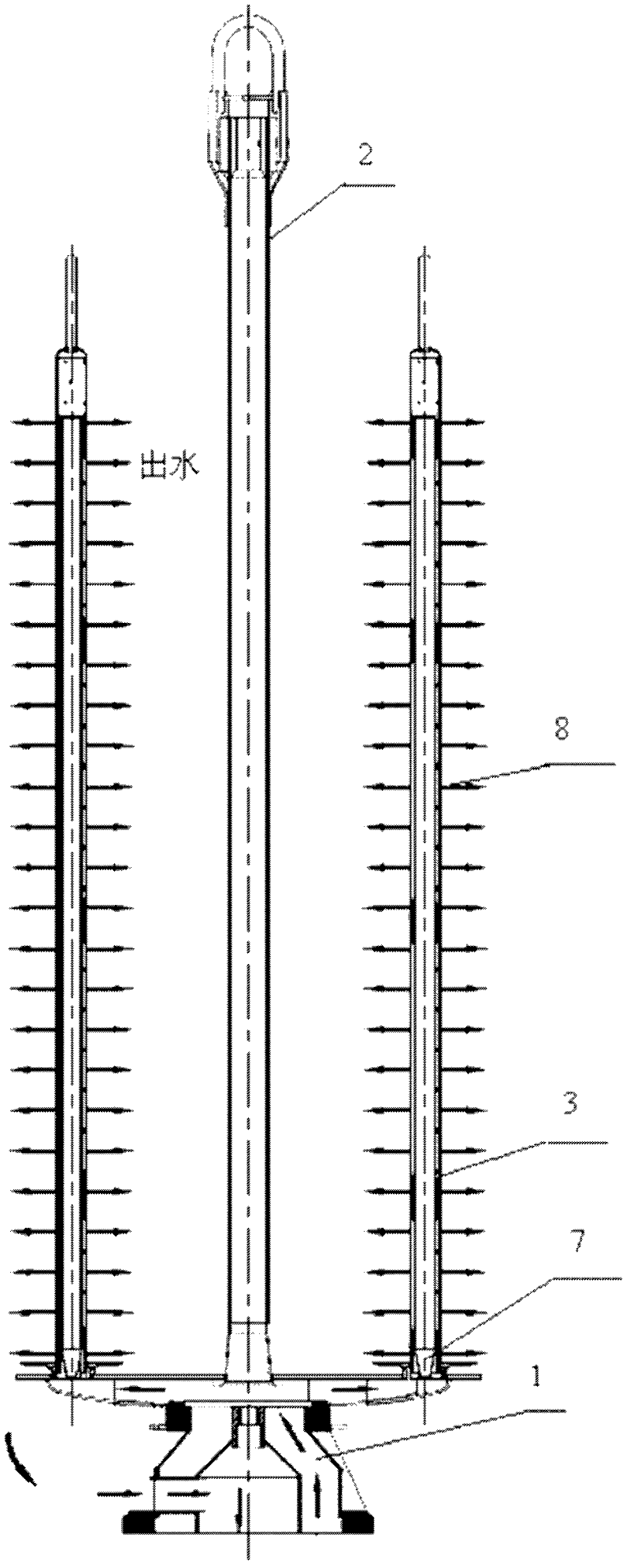

A creel device for an ultra-low liquor ratio yarn dyeing machine

InactiveCN102296436AReduce the cross-sectional areaGuaranteed coaxialityTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentWater bathsYarn

The invention discloses a creel device of a yarn dyeing machine with an ultra-low bath ratio, which comprises a sand table, a suspender and a yarn rod, wherein the upper surface of the sand table is in a disk shape; the lower end of the sand table is in a cavity structure; the yarn rod is in a hollow barrel structure; a water drum is arranged in the barrel of the yarn rod and is in a hollow or solid columnar structure; the center line of the yarn rod and the center line of the water drum are same; the ratio of the hollow internal diameter of the yarn rod and the external diameter of the waterdrum is 10:7-9; and the barrel of the yarn rod is evenly provided with a plurality of water outlets along the circumference of horizontal cross sections of different heights. The hollow barrel of theyarn rod disclosed by the invention is provided with the water drum, which is favorable for reducing the volume of dye liquor in the yarn rod and for reducing a water bath ratio; under the same main pump power, the water drum is favorable for improving the practical lift of a pipeline relatively, the flow rate of the dye liquor in the yarn rod is improved, the levelling property of cheeses of upper layers and lower layers can be better guaranteed, and the one-time success rate for dyeing is improved; and from the bottom to the top, the water outlets on the barrel of the yarn rod at the outer side of the water drum are thicker at the higher place of the yarn rod, which is favorable for realizing the purpose of even dye transfer.

Owner:高勋绿色智能装备(广州)有限公司

Production process for anti-ultraviolet radiation fabric

InactiveCN104404709AEnsure level dyeingWeft knittingHeating/cooling textile fabricsUltravioletUltraviolet radiation

The invention discloses a production process for an anti-ultraviolet radiation fabric. The production process comprises the following steps of sorting, weaving, preprocessing, dyeing, dewatering and shaping. By selecting reasonable technological parameters and agents, the anti-ultraviolet radiation fabric with stable protective properties can be obtained; meanwhile, different agents are added to improve the functionality and wearing comfort.

Owner:JIANGSU SUNSHINE GRP CO LTD

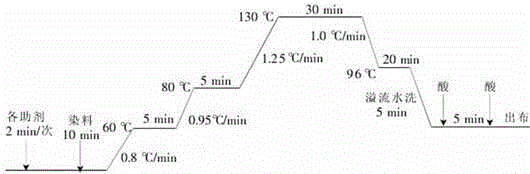

Dyeing and finishing process of coffee-yarn blended and knitted fabric

ActiveCN104727163ARealize medium and dark double dyeing processAccelerated adsorption and dispersionFibre treatmentDyeing processColour fastnessYarn

The invention discloses a dyeing and finishing process of a coffee-yarn blended and knitted fabric. The dyeing and finishing process is characterized by comprising the following steps: preparing grey fabric, pretreating, dyeing, soaping, softening and carrying out after finishing, wherein a mild pre-treatment degreasing process is adopted; and an active double-dyeing process of firstly dyeing, dispersing and dyeing is adopted to dye, so that the difficulty in dying with the same color of the blended and knitted fibers is solved; through control on a finishing agent and the amount of the finishing agent in the after finishing process of the coffee-yarn blended and knitted fabric, the problems of same color and different colors in the dyeing process of the coffee-yarn blended and knitted fabric are solved; good air permeability and relatively good rubbing fastness are obtained; and meanwhile, a plurality of efficacies that the coffee-yarn blended and knitted fabric is capable of absorbing stink, removing an odor, storing heat, keeping warm, absorbing moisture and drying quickly in an far infrared manner are taken into account.

Owner:浙江七色彩虹科技有限公司

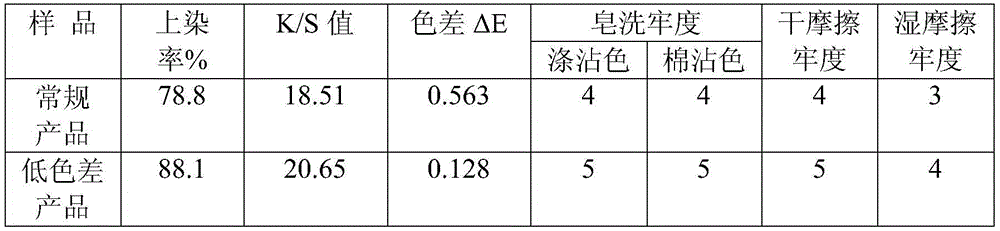

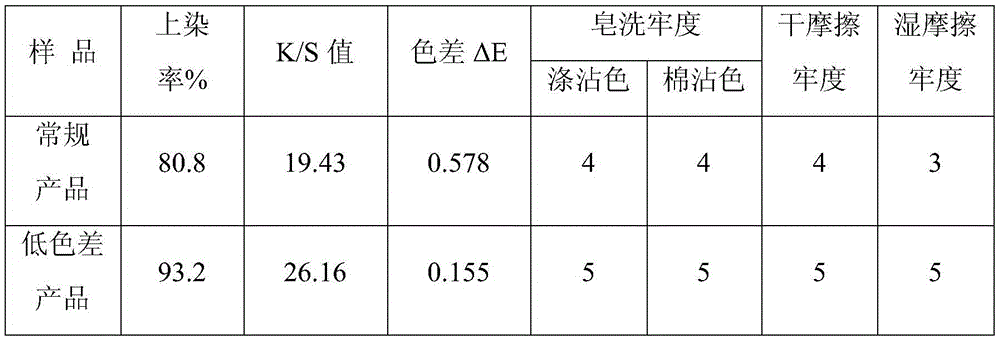

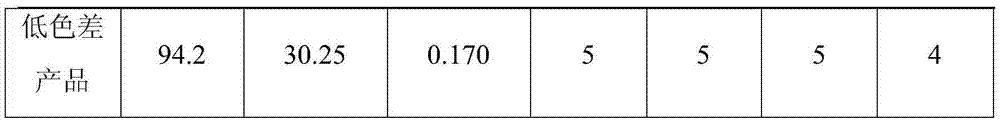

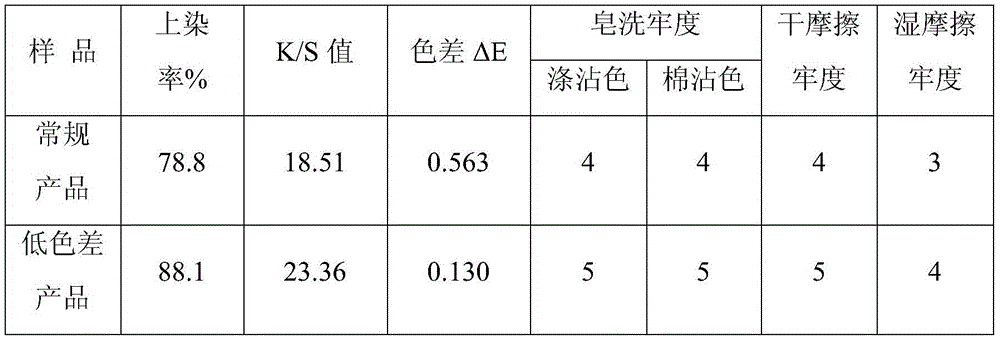

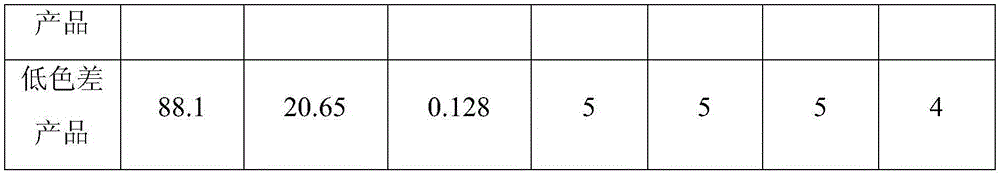

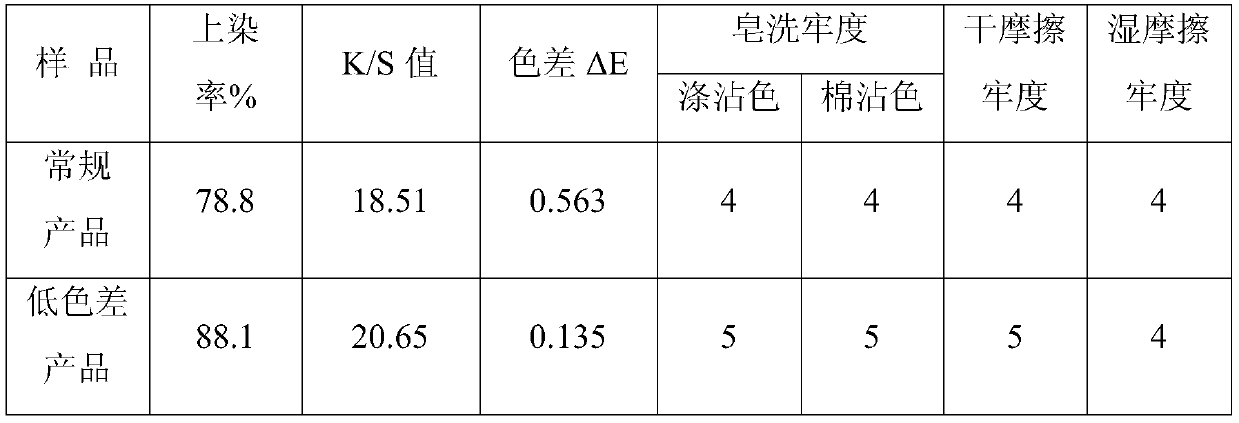

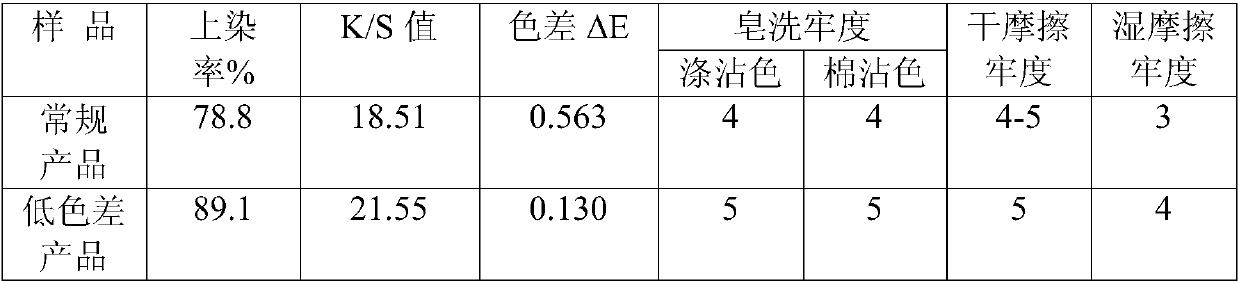

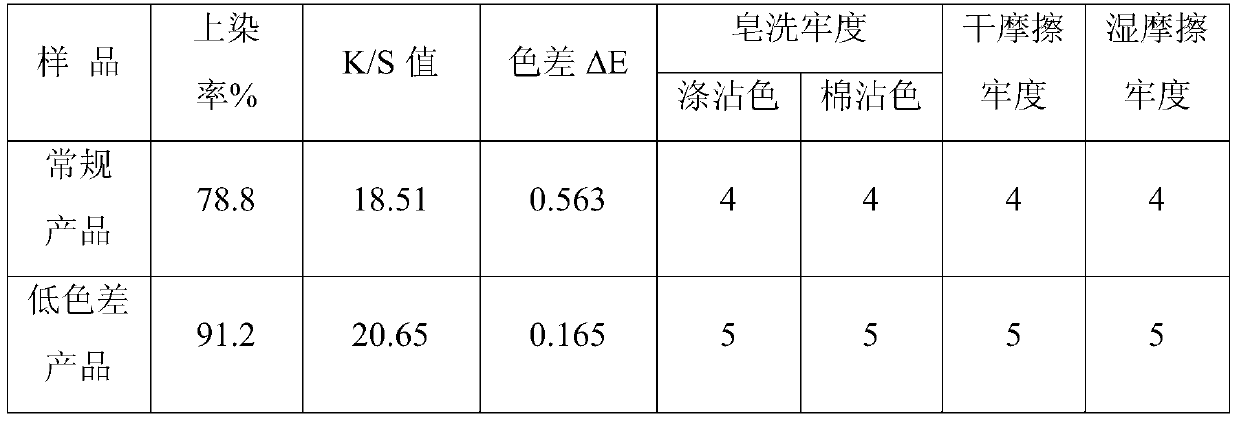

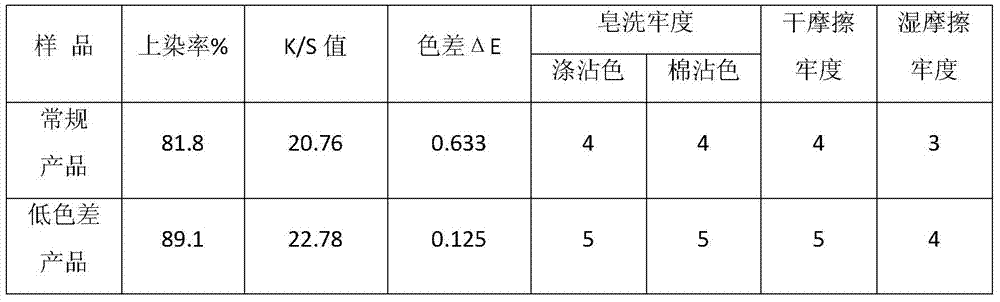

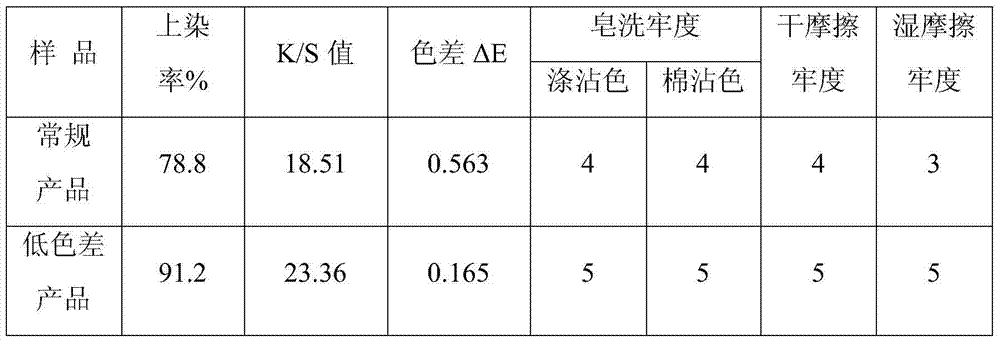

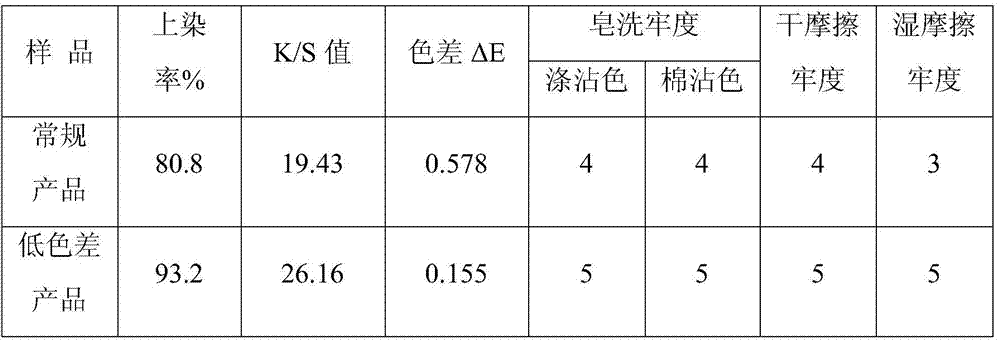

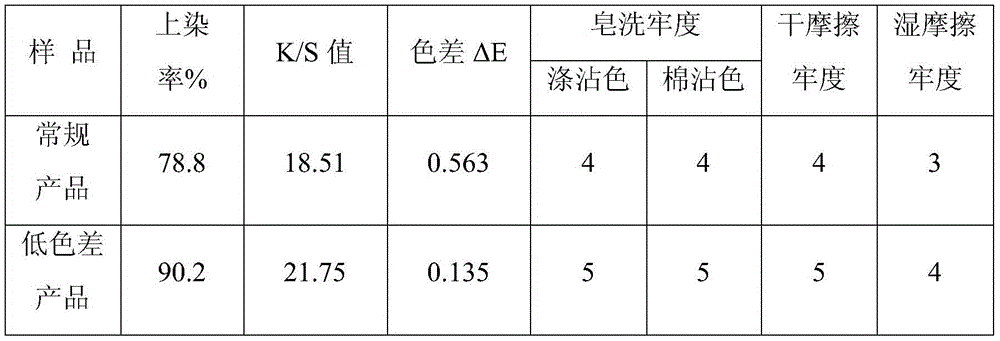

Low-chromatic-aberration polyester POY and preparation method thereof

ActiveCN105463619ASmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsPolyesterBreaking strength

The invention relates to a low-chromatic-aberration polyester POY and a preparation method thereof. The low-chromatic-aberration polyester POY is obtained through polyester spinning; the breaking strength of the high-dye-uptake polyester fiber POY is larger than or equal to 2.6 cN / dtex, the elongation at break is 100.0+ / -10.0%, and the chromatic aberration delta E is smaller than 0.200. According to the low-chromatic-aberration polyester POY and the preparation method thereof, ethylene glycol magnesium is milder, the thermal degradation coefficient is very small, side reactions caused in the reaction process are few, and generation of oligomers in the processing process is reduced; the mass percentage content of the oligomers is smaller than 0.5%, and the mass percentage content of diethylene glycol is smaller than 0.5%; the oligomers are decreased in the polymerizing process and are further decreased in the soluble washing process, and therefore in the polyester fiber dyeing and post processing heat setting processes, the quantity of the oligomers which migrate from the interior of the fiber to the exterior of the fiber is reduced, occurrence of color spots and strip patterns is reduced, and the fiber levelling property and crockfastness are guaranteed.

Owner:JIANGSU HENGLI CHEM FIBER

Warp-knitting dacron short pile fabric and weaving method thereof

InactiveCN107761242AShrinkage ControlNot easy to shrinkPattern makingWarp knittingFiberChemical treatment

The invention discloses a warp-knitting dacron short pile fabric and a weaving method thereof, and belongs to the technical field of warp-kitting fabric weaving. 50-75D of dacron FDY and dacron DTY composite filaments are adopted as pile yarn, 50D / 24F of polyester silk FDY or polyester silk DTY is adopted as bottom yarn, a two-comb or three-comb Tricot warp knitting machine conducts weaving to obtain gray fabric, then the procedures of pre-shaping, fuzzing process implementation, dyeing, drying, hot trimming and burnt-out are carried out, and after dehydration and drying for shaping are conducted, checking and packaging are carried out. By means of a chemical treatment method for dacron fibers, the effect of forming a three-dimensional pattern diversified in color and different in shape onthe fuzzing surface of the fabric is achieved, the gram weight of the fabric is low, and the fabric has better heat preservation performance and higher comfort degree.

Owner:JIANGSU ZHENYANG GROUP

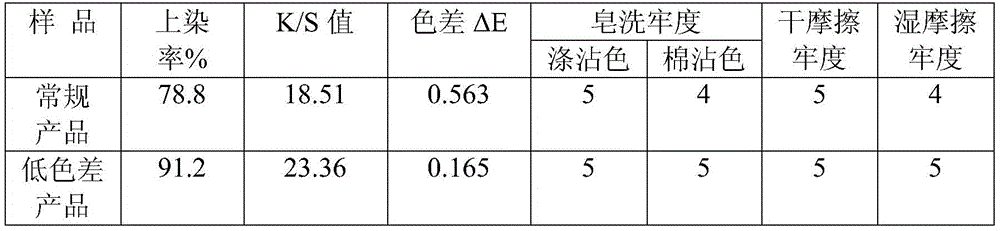

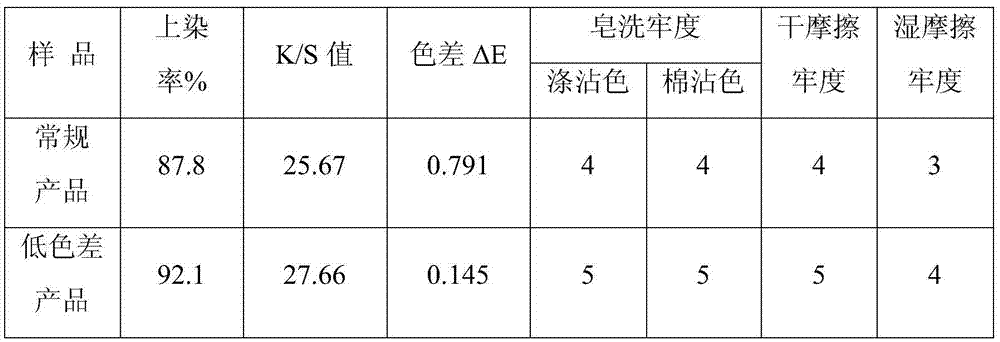

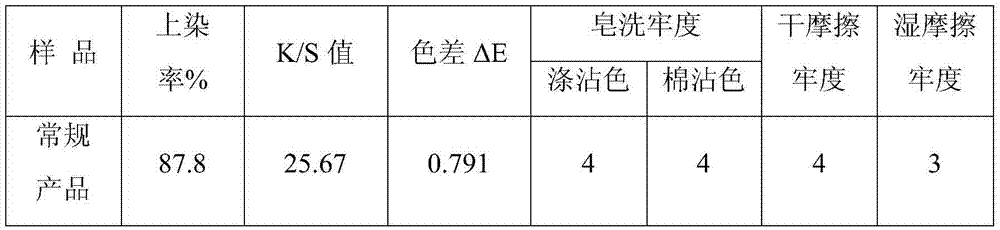

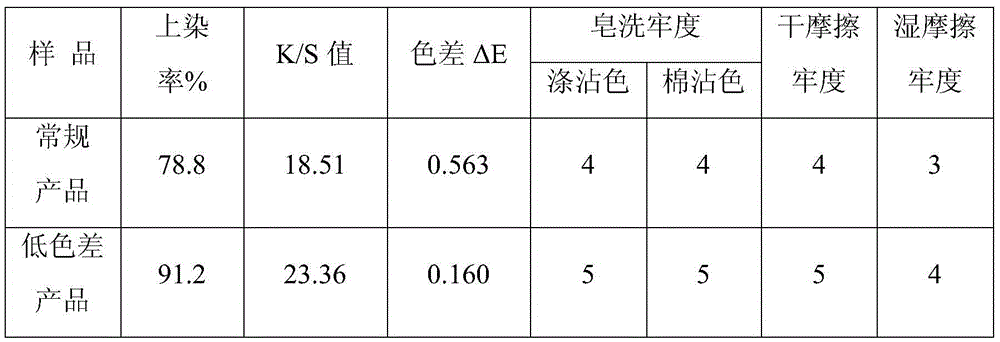

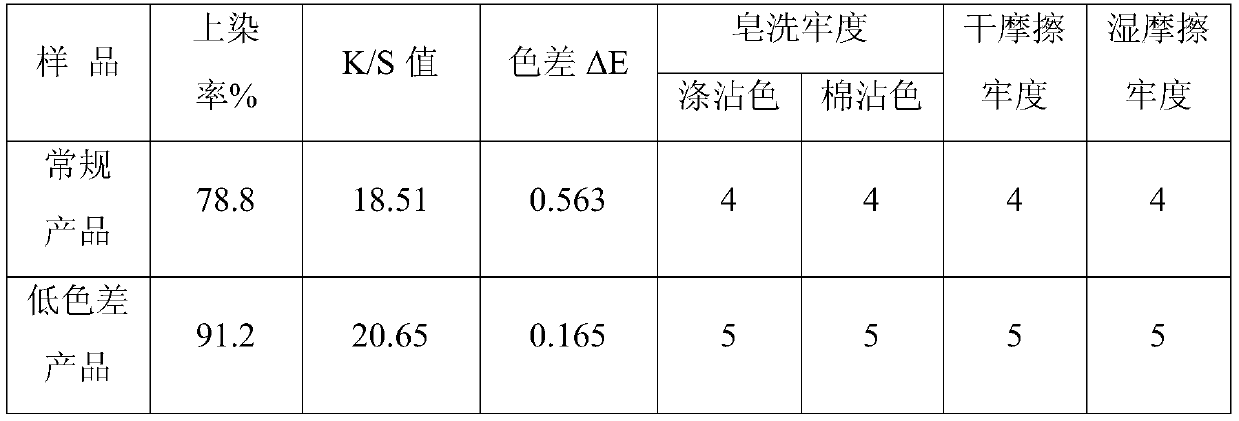

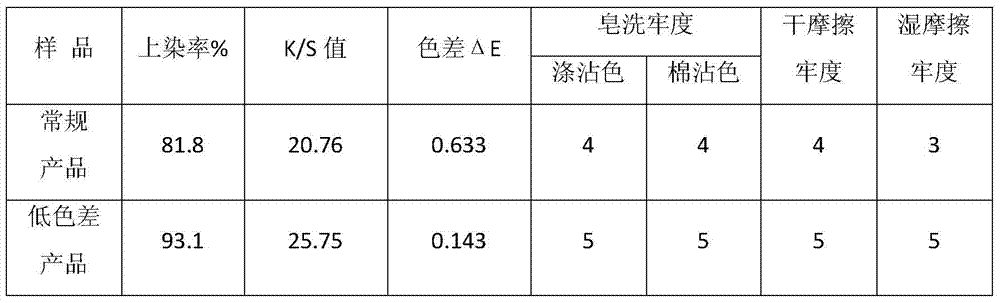

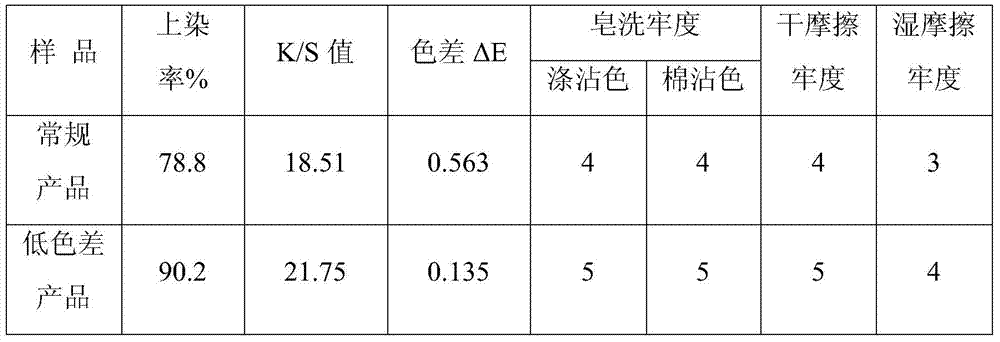

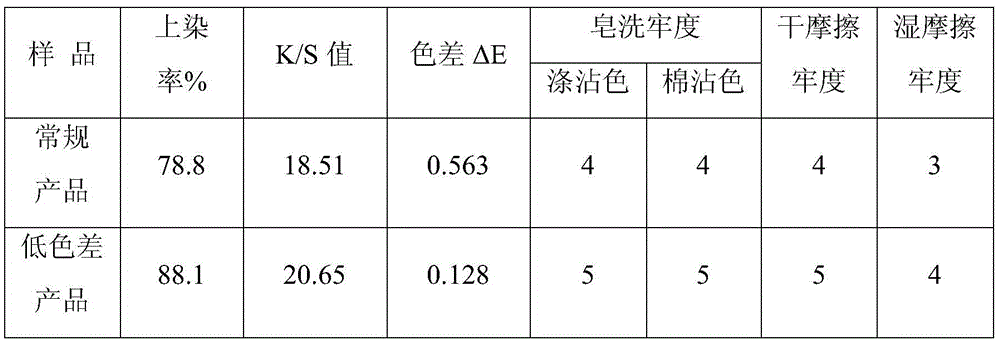

Low-color-difference polyester wool-like different-shrinkage complex yarn and preparation method thereof

ActiveCN105648570ASmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsPolyesterYarn

The invention relates to low-color-difference polyester wool-like different-shrinkage complex yarn and a preparation method thereof. The low-color-difference polyester wool-like different-shrinkage complex yarn is prepared through carrying out fiber intermingling on low-color-difference polyester POY (Pre-Oriented Yarn) and low-color-difference polyester FDY (Fully Drawn Yarn), wherein the low-color-difference polyester POY forms small yarn loops which surround the low-color-difference polyester FDY; the low-color-difference polyester POY and the low-color-difference polyester FDY are made from polyester through carrying out dissolving and washing and then carrying out spinning. The low-color-difference polyester wool-like different-shrinkage complex yarn has the rupture strength not lower than 3.0cN / dtex, the breaking elongation of 40.0+ / -3.0%, the crimp contraction of 5.50+ / -3.0%, the interlacing degree of 95+ / -5 / m, the fiber number of 150dtex to 300dtex and the color difference [delta]E smaller than 0.200. According to the low-color-difference polyester wool-like different-shrinkage complex yarn and the preparation method thereof, ethylene glycol magnesium is relatively mild and has a very small thermal degradation coefficient, and the oligomers are reduced during polymerization and are further reduced during washing, so that during the dyeing and postprocessing thermosetting of polyester fibers, the amount of the oligomers migrating to the outside of the fibers from the inside is reduced, the occurrence of color spots and streaks is reduced, and the level dyeability and rubbing fastness of the fibers are guaranteed.

Owner:JIANGSU HENGLI CHEM FIBER

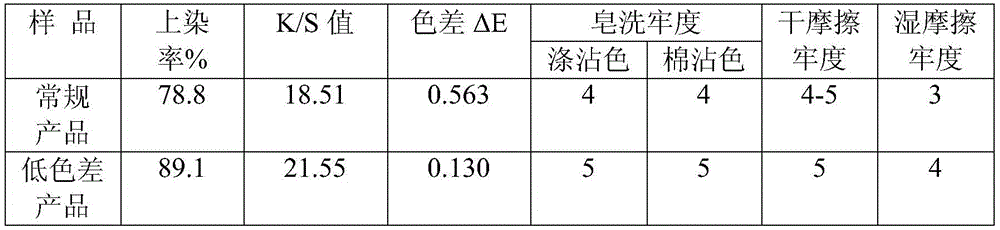

Low-color-difference polyester HOY (high oriented yarn) fibers and preparation method thereof

ActiveCN105442082ASmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to low-color-difference polyester HOY (high oriented yarn) fibers and a preparation method thereof. The low-color-difference polyester HOY fibers are prepared from spun polyester yarn, and the breaking strength of the polyester HOY fibers with high dye uptake is larger than or equal to 3.0 cN / dtex; the elongation at break is 50.0% plus or minus 4.0%, and the color difference delta E is smaller than 0.200. Ethylene glycol magnesium is relatively mild, the thermal degradation coefficient is small, fewer side reactions are caused in the reaction process, and generation of oligomers is reduced in the processing process; the mass percentage of oligomers is smaller than 0.5%, and the mass percentage of diethylene glycol is smaller than 0.5%; the oligomers are reduced in the polymerization process and further reduced in the dissolving process, accordingly, the quantity of the oligomers transferred from the inside of the fibers to the outside of the fibers is reduced in the processes of polyester fiber dyeing and post-processing thermal setting, colored patches and streaks are reduced, and the fiber leveling property and the rubbing fastness are guaranteed. The HOY fibers have lower crystallinity, the breaking elongation is larger and the initial modulus of the fibers is smaller, so that the fibers have good flexibility.

Owner:JIANGSU HENGLI CHEM FIBER

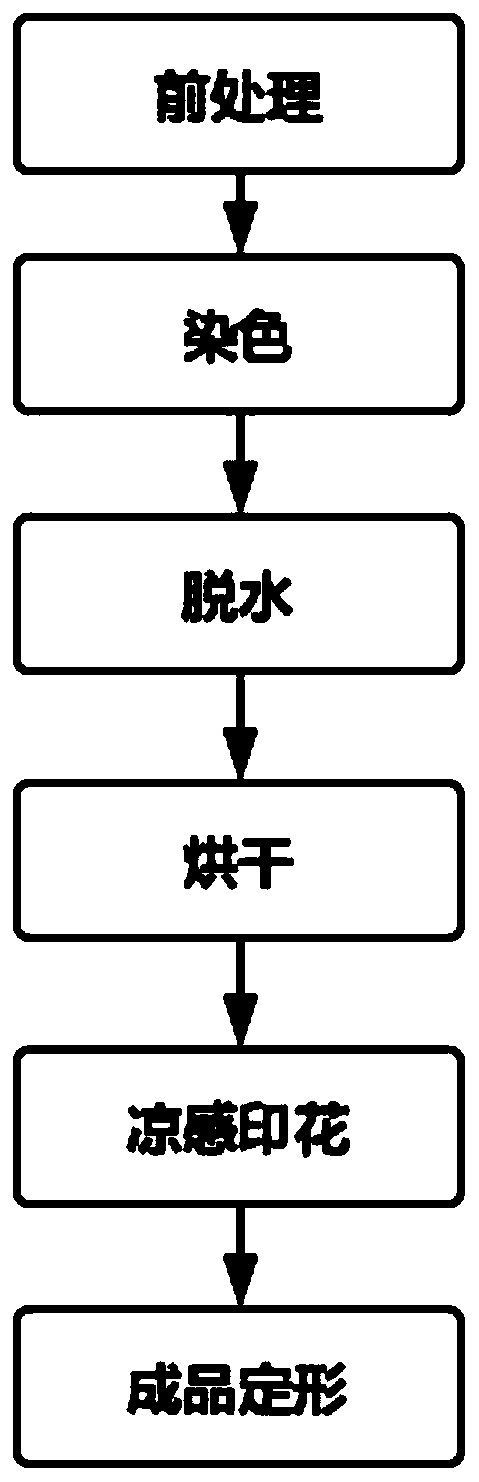

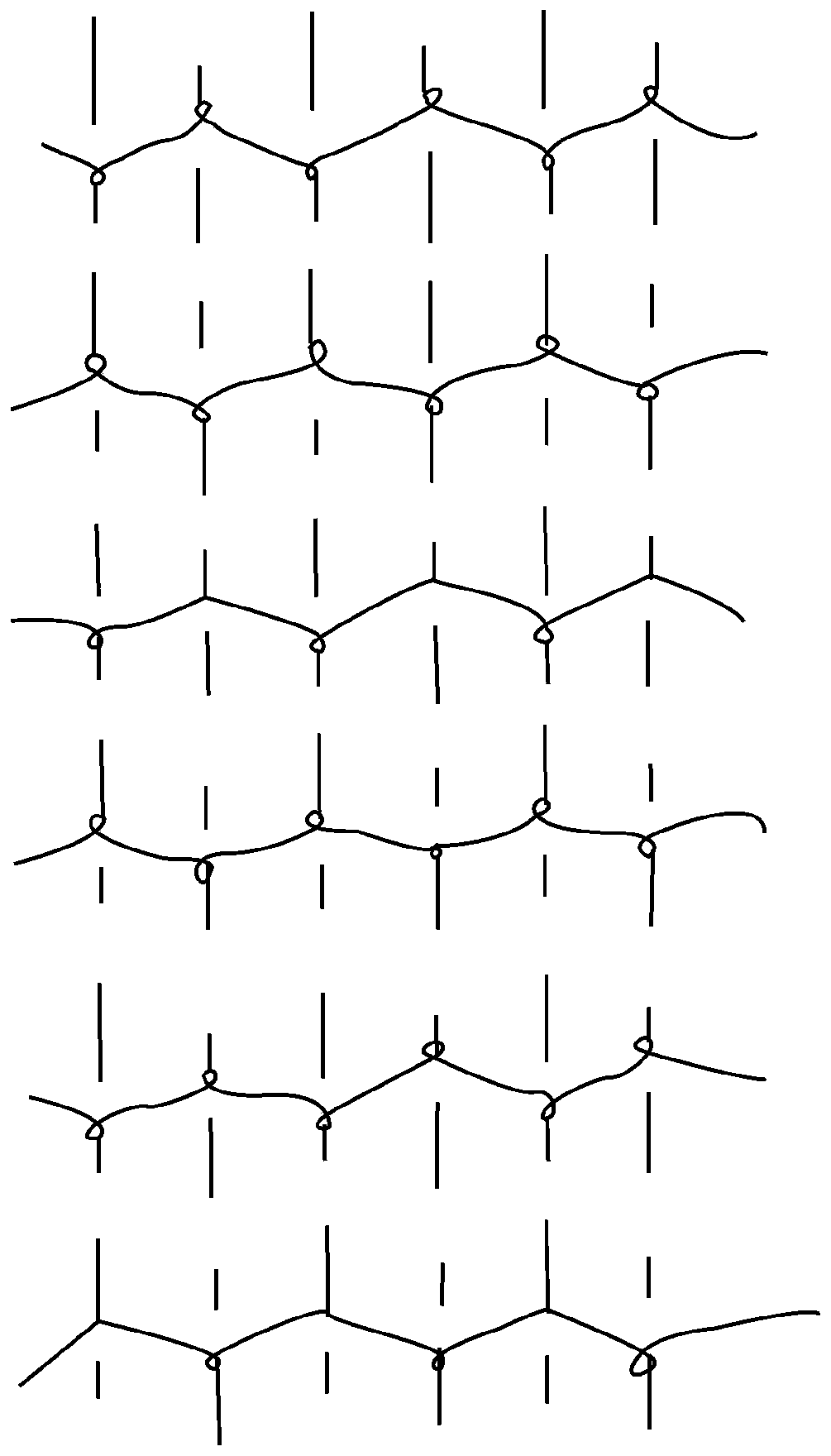

Preparation method of knitted fabric with moisture absorption and sweat releasing and continuous cool feeling functions

InactiveCN111058168AGood moisture absorptionFunction increaseWeft knittingDyeing processPolyesterColour fastness

The invention discloses a preparation method of a knitted fabric with moisture absorption and sweat releasing and continuous cool feeling functions. According to the preparation method, chemically andphysically modified polyester filaments are taken as raw materials, a weaving process and a dyeing and finishing process are adopted, and the knitted fabric is designed into a honeycomb or mesh double-sided tissue structure; and a printing paste is prepared by adopting a cool feeling finishing agent with strong cooling effect and water washing resistance, and the printing paste is transferred tothe fabric in a printing mode. The preparation method has the beneficial effects that by testing the basic performance, the burst strength, the color fastness, the moisture absorption quick-drying performance and the moisture absorption and cool feeling performance of the knitted fabric, the result shows that the knitted fabric has excellent moisture absorption and quick-drying performance, and iscapable of effectively relieving discomfort and wet cold feeling of people caused by damp sweat; and moreover, the knitted fabric also has excellent moisture absorption and cooling performance, and all performances meet standard values.

Owner:JIANGSU JINCHENZHEN TEXTILE

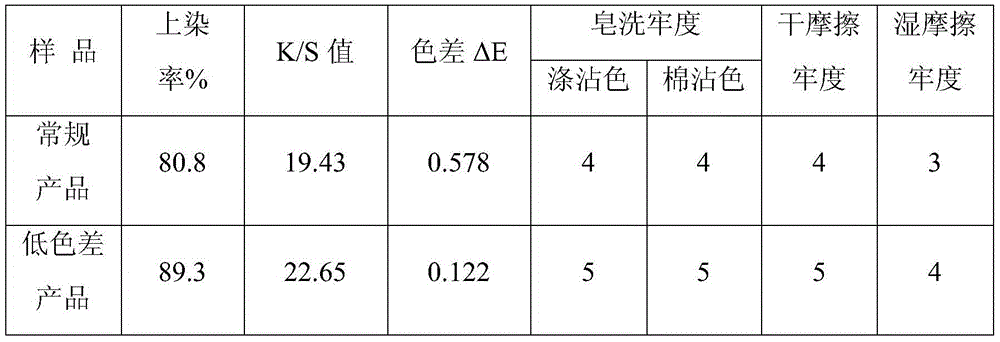

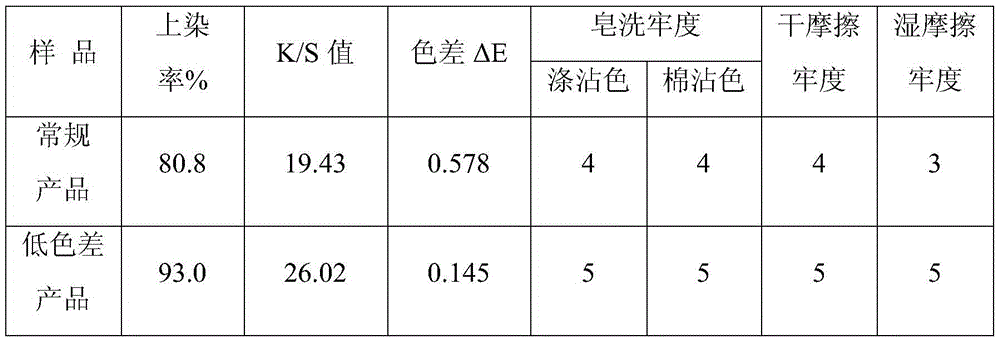

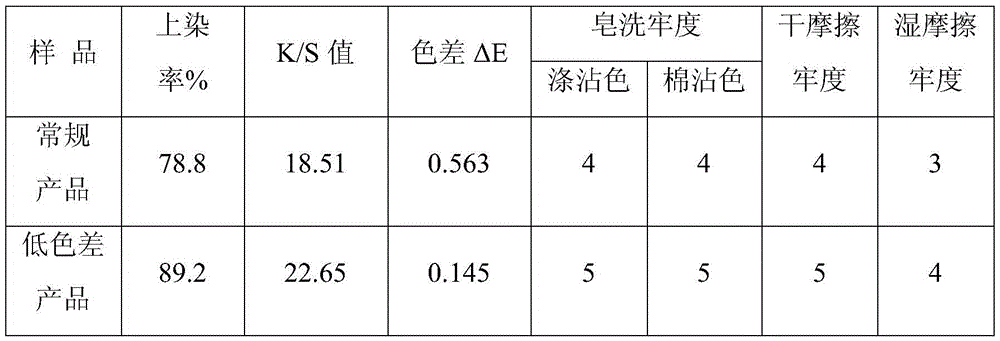

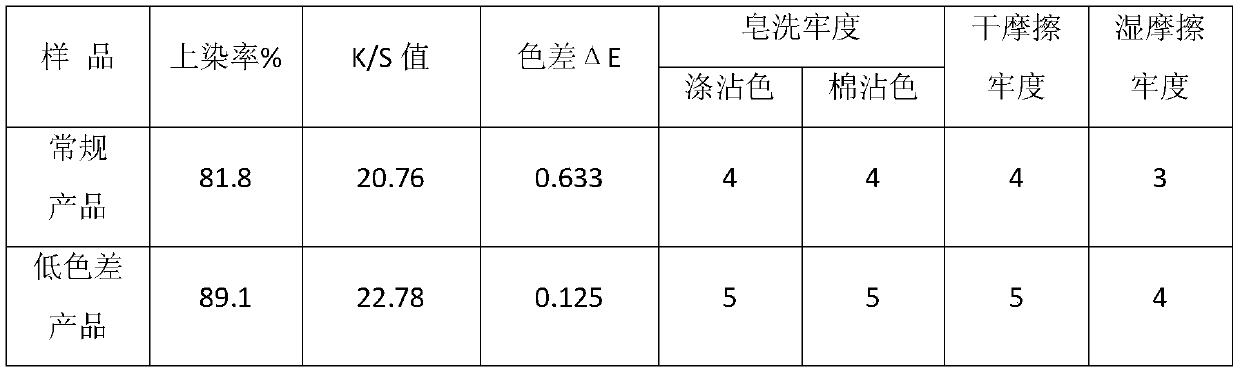

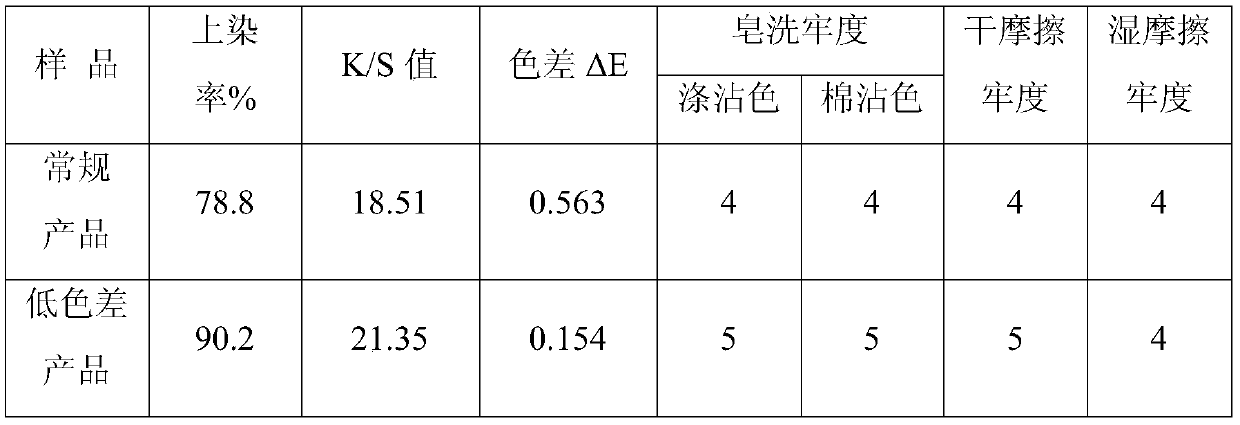

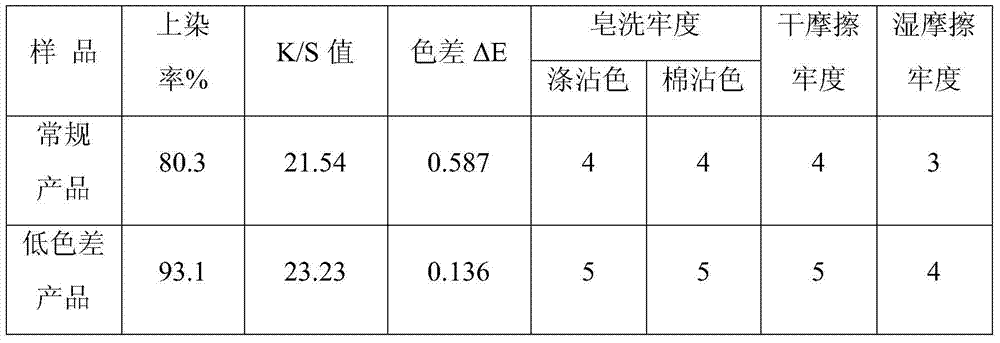

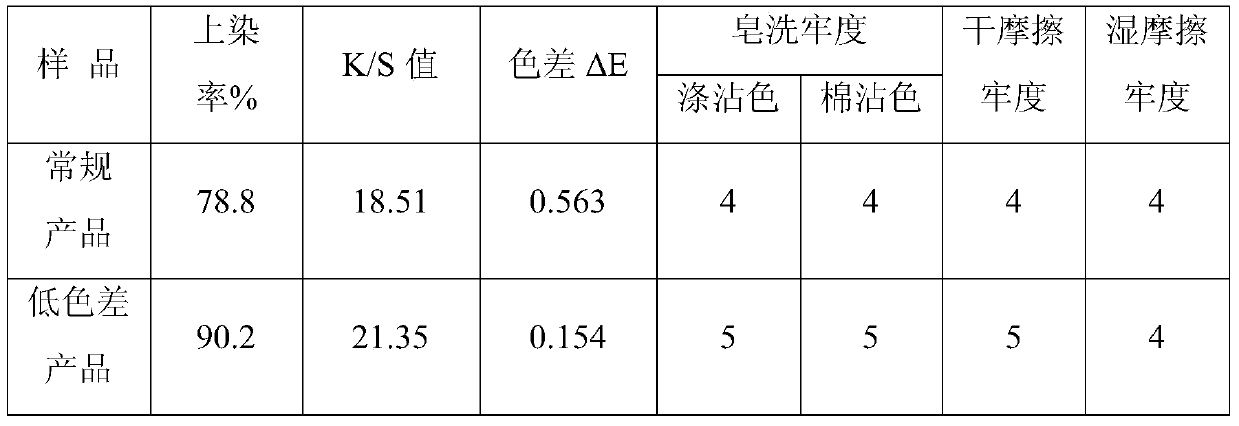

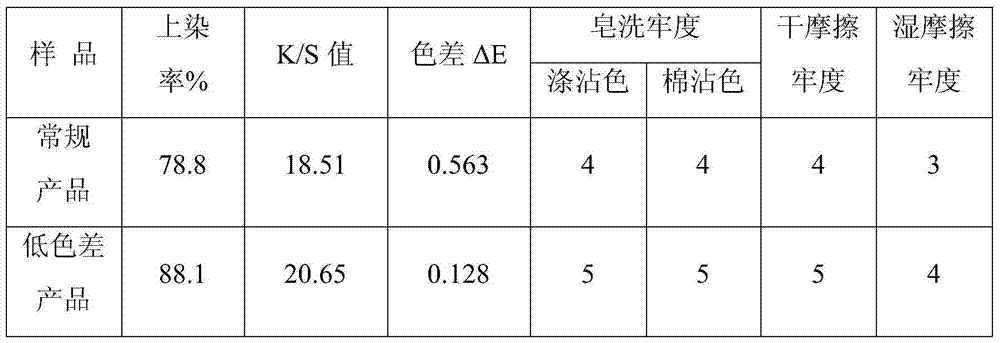

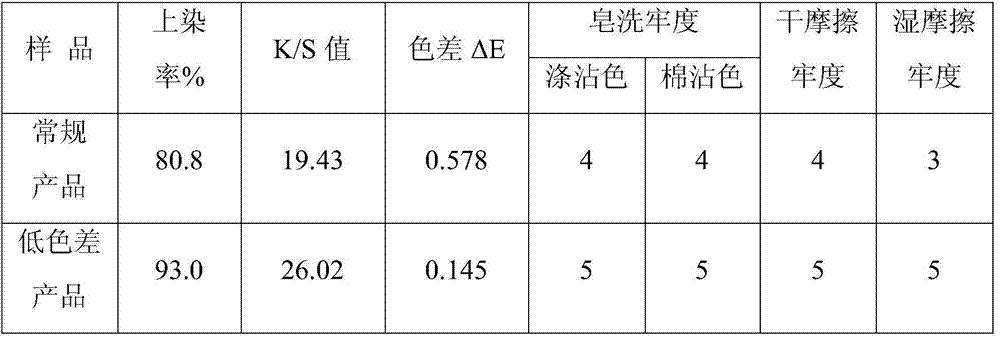

Low-color-difference polyester DTY (Draw Textured Yarn) and preparation method thereof

ActiveCN105648571ASmall coefficient of thermal degradationReduce generationMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention relates to low-color-difference polyester DTY (Draw Textured Yarn) and a preparation method thereof. The low-color-difference polyester DTY is prepared through carrying out spinning processing on polyester and has the rupture strength not lower than 1.9cN / dtex, the breaking elongation of 30.0+ / -5.0% and the color difference delta-E smaller than 0.200. According to the low-color-difference polyester DTY and the preparation method thereof, ethylene glycol magnesium is relatively mild, has a very small thermal degradation coefficient and causes less side reactions during reaction, so that the production of oligomers during processing is reduced; the mass percent of the oligomers is lower than 0.5%, and the mass percent of diethylene glycol is lower than 0.5%. The oligomers are reduced during polymerization and are further reduced during dissolving and washing, so that during the dyeing and postprocessing thermosetting of polyester fibers, the amount of the oligomers migrating to the outside of the fibers from the inside is reduced, the occurrence of color spots and streaks is reduced, and the level dyeability and rubbing fastness of the fibers are guaranteed.

Owner:JIANGSU HENGLI CHEM FIBER

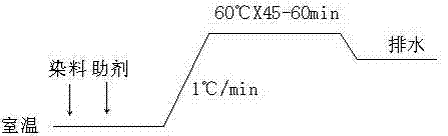

Jade green air-flow dyeing technology for single jersey

InactiveCN107083697AAvoid differences in dye adsorptionNo creasesBiochemical treatment with enzymes/microorganismsDyeing processAirflowDyeing

ThThe invention relates to jade green dyeing technology for single jersey. Hemming process is not needed and one process is omitted, based on dyeing technology, anhydrous sodium sulphate is added firstly and uniformly distributed on a cloth surface, in order to solve the problem of color spots; a smooth agent is added in order to eliminating the problem of fluffing or piling of fabrics due to stretching or friction by extraneous mechanical action; by means of matching relation of air quantity and linear velocity of cloth lifting rollers, after the fabric leaves a cloth guiding tube, an expansion process is provided, bundling position is continuously changed, so that folding parts can be rapidly expanded, creases of the fabric are not generated, and difference of dye adsorption generated at the crease parts is avoided. the fabric has good effects in the aspects of capillary effect, fineness, hand feeling, weight loss, and the like, and the technology saves time, auxiliary agents, and has low energy consumption and low emission; the technology enables the fabric to have better indices of each color fasteness and guarantees level-dyeing property; by means of control of dyeing time, the problems of uneven dyeing and the like due to bond breaking of dye after bond type reactions are prevented.

Owner:JIHUA 3543 KNITTING CLOTHING

Low-color-difference polyester superbright trilobal profiled yarn and preparation method thereof

ActiveCN105646857ASmall coefficient of thermal degradationReduce generationFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention relates to low-color-difference polyester superbright trilobal profiled yarn and a preparation method thereof. The low-color-difference polyester superbright trilobal profiled yarn is prepared through carrying out spinning on polyester and has the rupture strength not lower than 3.8cN / dtex, the breaking elongation of 33.0+ / -3.0% and the color difference [delta]E smaller than 0.200. According to the low-color-difference polyester superbright trilobal profiled yarn and the preparation method thereof, ethylene glycol magnesium is relatively mild, has a very small thermal degradation coefficient and causes less side reactions during reaction, so that the production of oligomers during processing is reduced; the mass percent of the oligomers is lower than 0.5%, and the mass percent of diethylene glycol is lower than 0.5%. The oligomers are reduced during polymerization and are further reduced during washing, so that during the dyeing and postprocessing thermosetting of polyester fibers, the amount of the oligomers migrating to the outside of the fibers from the inside is reduced, the occurrence of color spots and streaks is reduced, and the level dyeability and rubbing fastness of the fibers are guaranteed.

Owner:JIANGSU HENGLI CHEM FIBER

Dyeing pretreatment process for pineapple leaves-cotton blended knitted fabric

InactiveCN101608398AImprove dyeing performanceEnsure level dyeingBiochemical fibre treatmentSingeingChemistryDyeing

The invention provides a dyeing pretreatment process for pineapple leaves-cotton blended knitted fabric. The process is characterized by comprising the following steps: 1, soaking the pineapple leaves-cotton blended knitted fabric in oxygen bleaching solution at a temperature between 90 and 100 DEG C for 60 minutes; 2, soaking the blended knitted fabric in acetate solution at 50 DEG C for 10 minutes; 3, soaking the blended knitted fabric in soda solution at 80 DEG C for 30 minutes; and 4, feeding the blended knitted fabric into a KMM-260 singeing machine and performing gas singeing treatment,wherein the vehicle speed is 100 meters per minute, and the amount of oil is between 25 and 30. The process has the advantages of significantly promoting the dyeing properties of the pineapple leaves-cotton blended knitted fabric subjected to the pretreatment and guaranteeing color vividness, color fastness and level dyeing property thereof; in addition, the knitted fabric integrates the excellent performances of pineapple leaves and cotton and has a unique style.

Owner:DONGHUA UNIV +2

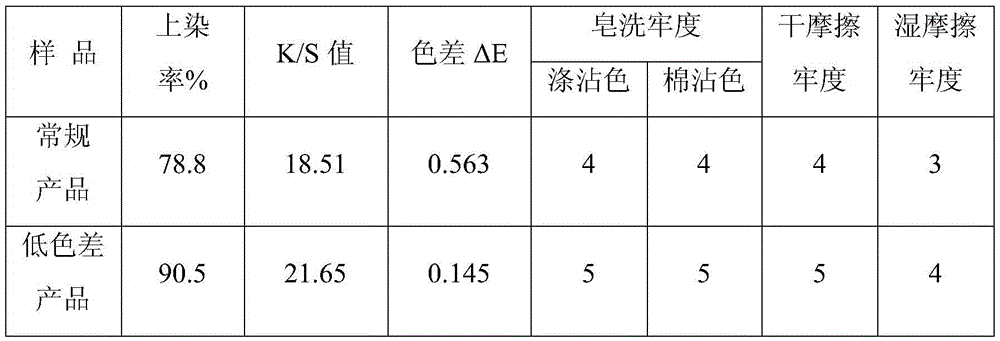

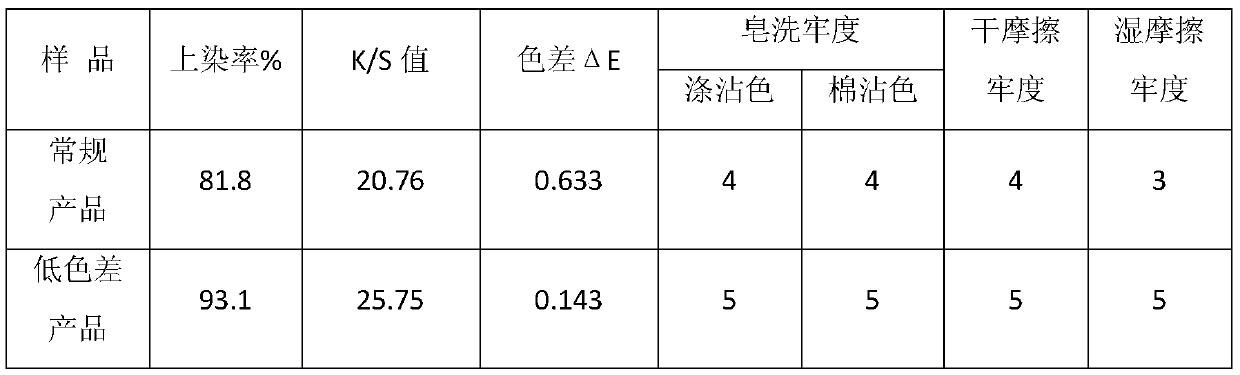

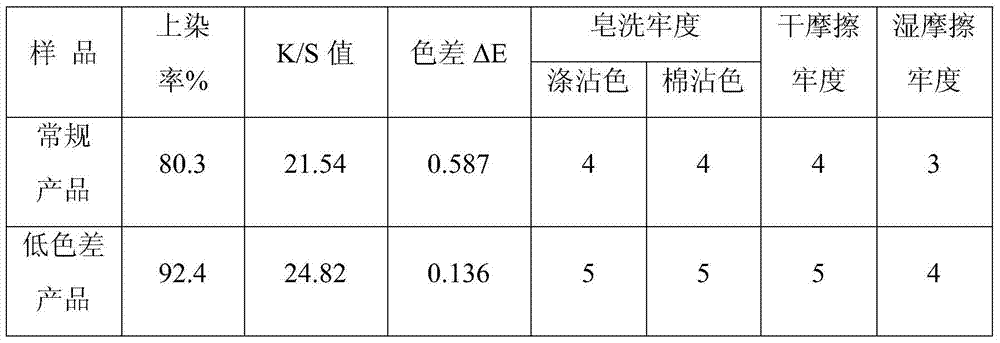

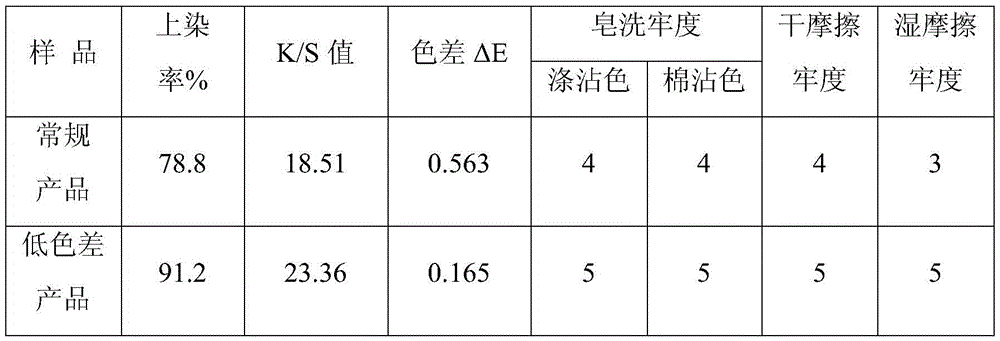

Low-color-difference polyester differential shrinkage composite yarn and preparation method thereof

ActiveCN105506774ASmall coefficient of thermal degradationReduce generationElectrolysis componentsElectrolytic organic productionYarnPolyester

The invention relates to low-color-difference polyester differential shrinkage composite yarn and a preparation method thereof. The low-color-difference polyester differential shrinkage composite yarn is obtained by compounding polyester POY (Partially Oriented Yarn) and polyester FDY (Fully Drawn Yarn); the polyester POY and the polyester FDY are obtained by spinning after dissolving-washing of polyester; the low-color-difference polyester differential shrinkage composite yarn is greater than or equal to 1.9cN / dtex in breaking strength, is 30.0+ / -5.0 percent in elongation at break, is 2.50+ / -3.0 percent in crimp contraction, is 20+ / -5 pieces per meter in interlacing degree, and is less than 0.200 in color difference deltaE. Ethylene glycol magnesium in the composite yarn is relatively mild and is very small in thermal degradation coefficient, oligomers produced in a polymerization process are reduced, and oligomers produced in a dissolving-washing process are further reduced, so that the occurrence of color spots and stripes in polyester fiber dyeing and post-processing heat setting is reduced, and the fiber levelling property and rubbing fastness are ensured. The differential shrinkage composite yarn has excellent shading performance, superior dyeing performance, high bulkiness and soft handfeel; meanwhile, a large quantity of loops exist on the surfaces of fibers, so that the aurora defect of chemical fiber yarn is overcome.

Owner:JIANGSU HENGLI CHEM FIBER

A production process for anti ultraviolet fabric of a showing shed awning cloth

A production process for anti ultraviolet fabric of a showing shed awning cloth is disclosed. The process includes selecting materials, braiding, pretreating, dyeing, sizing, beaming, leasing, attaching to a shaft, dehydrating and sizing. Through selection of reasonable process parameters and agents, the anti ultraviolet fabric with sable protection performance can be prepared, and addition of various auxiliary agents can improve functional and decorative properties.

Owner:江阴力丰装饰有限公司

Environment-friendly reactive dye low-temperature salt-free dyeing method for cotton fabric

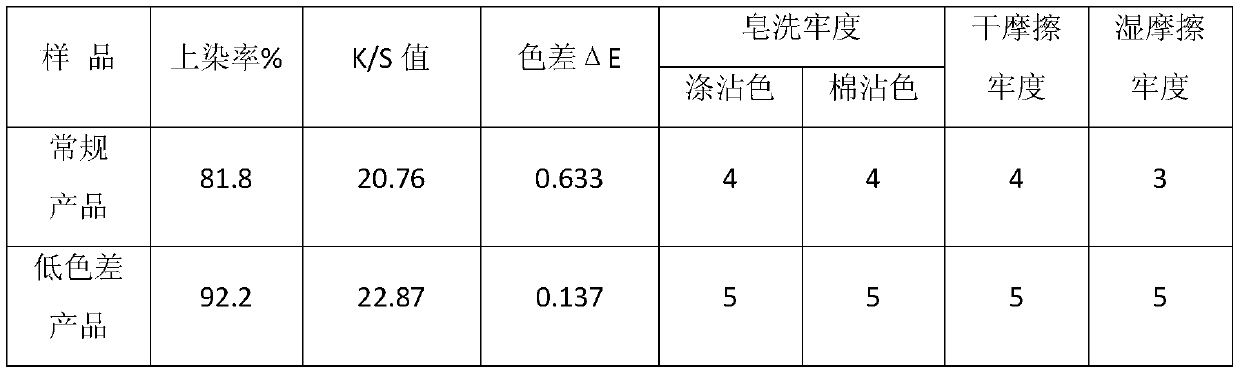

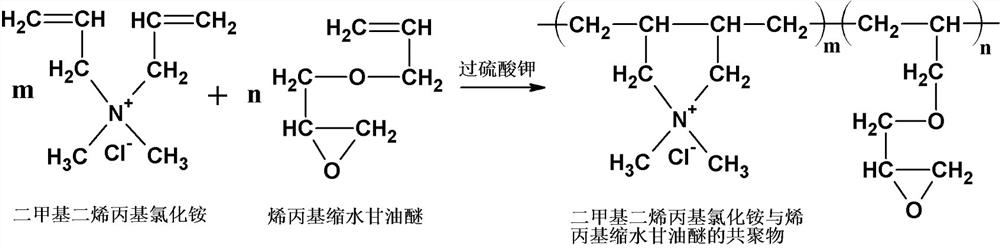

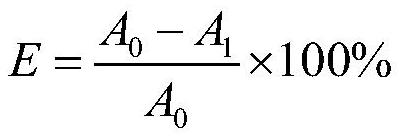

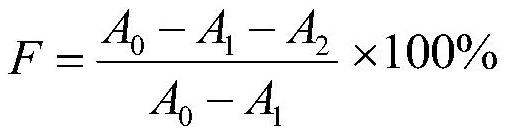

ActiveCN111636223AImprove overall utilizationModerate cationicityWater contaminantsDyeing processPotassium persulfateAllyl glycidyl ether

The invention relates to an environment-friendly reactive dye low-temperature salt-free dyeing method for cotton fabric. The environment-friendly reactive dye low-temperature salt-free dyeing method comprises the following steps of synthesis of a cationic polymer, modified treatment of the cotton fabric, dyeing, flocculation of dye wastewater, and the like. Under condition of taking potassium persulfate as an initiator, dimethyl diallyl ammonium chloride and allyl glycidyl ether are used to synthesize the cationic polymer; the cotton fabric is soaked into a cationic polymer aqueous solution ofcertain concentration to undergo modified treatment; and the modified cotton fabric can be dyed with reactive dye under a low-temperature salt-free condition, so that a dyeing rate and a color fixation rate of the dye are increased, and even dyeing is good. Water washing liquor of the modified cotton fabric is mixed with dyeing residual liquor and soaping liquor, and a little cationic polymer inthe solution is utilized for flocculating residual dyes in the dyeing wastewater, so that emission of printing and dyeing wastewater is greatly reduced, and practical production and environmental protection are facilitated.

Owner:QINGDAO UNIV

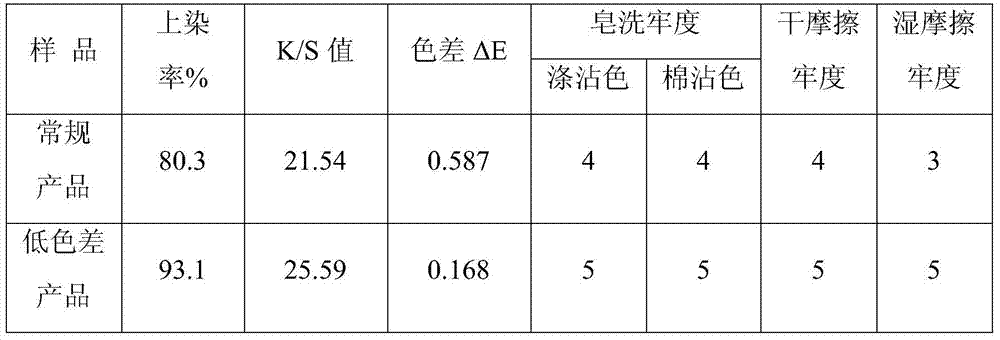

Low-color-difference polyester super-soft ultrafine yarn and preparation method thereof

ActiveCN105506775ASoft lusterSmall coefficient of thermal degradationDyeing processMelt spinning methodsMagnesiumColor difference

The invention relates to low-color-difference polyester super-soft ultrafine yarn and a preparation method thereof. The low-color-difference polyester super-soft ultrafine yarn is obtained by polyester spinning. A high-dye-uptake polyester fiber super-soft ultrafine yarn is greater than or equal to 3.8cN / dtex in breaking strength, is 35.0+ / -3.0 percent in elongation at break, is 0.20-0.50dtex in single yarn size, and is less than 0.200 in color difference deltaE. Ethylene glycol magnesium in the ultrafine yarn is relatively mild and is very small in thermal degradation coefficient, less side reactions are caused in a reaction process, and the production of oligomers in a processing process is reduced; oligomers produced in a polymerization process are reduced, and oligomers produced in a dissolving-washing process are further reduced, so that the quantity of the oligomers migrating from the insides to the outsides of fibers are reduced in polyester fiber dyeing and post-processing heat setting, the occurrence of color spots and stripes is reduced, and the fiber levelling property and rubbing fastness are ensured. The softness of a super-soft ultrafine polyester fiber is reflected by a very small yarn size and a small composite-yarn total size, and a fabric made of the super-soft ultrafine polyester fiber has very soft and fine handfeel, is soft in color and luster, and is comfortable and breathable.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of polyester ultra-bright trilobal profiled yarn with low color difference and preparation method thereof

ActiveCN105646857BSmall coefficient of thermal degradationReduce generationFilament/thread formingMonocomponent polyesters artificial filamentYarnPolyester

The invention relates to low-color-difference polyester superbright trilobal profiled yarn and a preparation method thereof. The low-color-difference polyester superbright trilobal profiled yarn is prepared through carrying out spinning on polyester and has the rupture strength not lower than 3.8cN / dtex, the breaking elongation of 33.0+ / -3.0% and the color difference [delta]E smaller than 0.200. According to the low-color-difference polyester superbright trilobal profiled yarn and the preparation method thereof, ethylene glycol magnesium is relatively mild, has a very small thermal degradation coefficient and causes less side reactions during reaction, so that the production of oligomers during processing is reduced; the mass percent of the oligomers is lower than 0.5%, and the mass percent of diethylene glycol is lower than 0.5%. The oligomers are reduced during polymerization and are further reduced during washing, so that during the dyeing and postprocessing thermosetting of polyester fibers, the amount of the oligomers migrating to the outside of the fibers from the inside is reduced, the occurrence of color spots and streaks is reduced, and the level dyeability and rubbing fastness of the fibers are guaranteed.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of low color difference polyester poy yarn and preparation method thereof

ActiveCN105463619BSmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsPolyesterBreaking strength

The invention relates to a low-chromatic-aberration polyester POY and a preparation method thereof. The low-chromatic-aberration polyester POY is obtained through polyester spinning; the breaking strength of the high-dye-uptake polyester fiber POY is larger than or equal to 2.6 cN / dtex, the elongation at break is 100.0+ / -10.0%, and the chromatic aberration delta E is smaller than 0.200. According to the low-chromatic-aberration polyester POY and the preparation method thereof, ethylene glycol magnesium is milder, the thermal degradation coefficient is very small, side reactions caused in the reaction process are few, and generation of oligomers in the processing process is reduced; the mass percentage content of the oligomers is smaller than 0.5%, and the mass percentage content of diethylene glycol is smaller than 0.5%; the oligomers are decreased in the polymerizing process and are further decreased in the soluble washing process, and therefore in the polyester fiber dyeing and post processing heat setting processes, the quantity of the oligomers which migrate from the interior of the fiber to the exterior of the fiber is reduced, occurrence of color spots and strip patterns is reduced, and the fiber levelling property and crockfastness are guaranteed.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of low color difference polyester imitation cotton type differential shrinkage composite yarn and its preparation method

ActiveCN105671675BSmall coefficient of thermal degradationReduce generationMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterChemistry

The invention relates to a low-color-difference polyester cotton-imitating different-shrinking composite filament and a preparation method thereof. The low-color-difference polyester cotton-imitating different-shrinking composite filament is a composite filament composed of a low-color-difference polyester POY filament and a low-color-difference polyester FDY filament through fiber blending. The low-color-difference polyester POY filament forms fine filament rings surrounding the low-color-difference polyester FDY filament. The low-color-difference polyester POY filament and the low-color-difference polyester FDY filament are formed by dissolving and washing polyester and performing spinning. The low-color-difference polyester cotton-imitating different-shrinking composite filament is not less than 2.0 cN / detx in breaking strength, is 18.0% + / - 3.0% in breaking elongation, is 4.8% + / - 3.0% in crimp contraction, is 15 / m + / - 5 / m in network degree and is less than 0.200 in color difference [delta]E. In the invention, magnesium ethylene glycolate is mild and is low in thermal degradation coefficient. In a polymerization process, oligomer is reduced and is further reduced during the dissolving and washing process, so that in the polyester fiber, after dying and during after-treatment thermal shaping, the migration amount of the oligomer from interior to exterior is reduced, thereby reducing color spots and bars and ensuring fiber level dyeing and friction fastness.

Owner:JIANGSU HENGLI CHEM FIBER

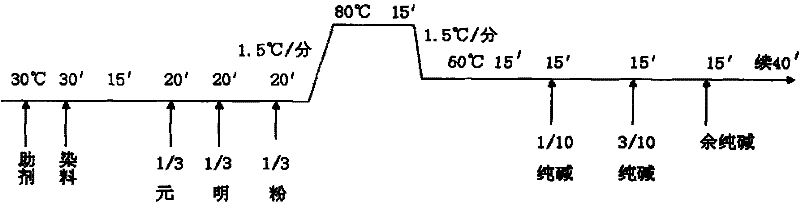

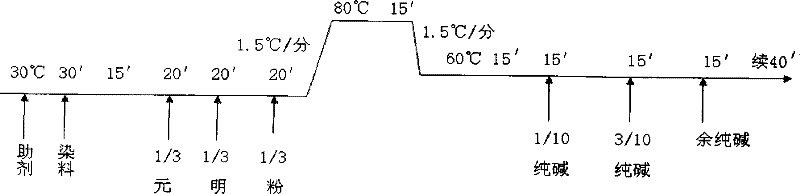

Processing method of copper ammonia filament yarn-dyed high-grade fabric

ActiveCN113737357AEnsure level dyeingHigh strengthHeating/cooling textile fabricsDyeing processPolymer sciencePolymer chemistry

The invention discloses a processing method of a copper ammonia filament yarn-dyed high-grade fabric. The method comprises the following technological processes of copper ammonia filament twisting, bobbin polyester thread coating, yarn loosening, yarn dyeing, weaving and gray fabric after-treatment. The yarn dyeing comprises a sodium carbonate pretreatment procedure and a dyeing procedure. A formula of a pretreatment agent adopted in the sodium carbonate pretreatment procedure comprises 2-4 g / L of a pretreatment refining agent, 2-4 g / L of sodium carbonate and 1-5 g / L of hydrogen peroxide with the mass concentration of 27.5%; the heat preservation temperature in the sodium carbonate pretreatment procedure is 80-110 DEG C, the heat preservation time is 30-60 minutes, and a bidirectional circulation mode is adopted for water flow. A reactive dye is adopted in the dyeing procedure, and a sodium carbonate solution with the concentration of 5-10 g / L is adopted as a color fixing agent for color fixation after dyeing. The processing method is high in yield, and the processed fabric is high in strength and physical test index, good in color uniformity, small in fiber damage, high in utilization rate, soft and smooth in hand feeling and elegant in gloss and is the first-choice fabric for high-grade clothes.

Owner:NINGBO YOUNGOR YINGCHENG UNIFORM +1

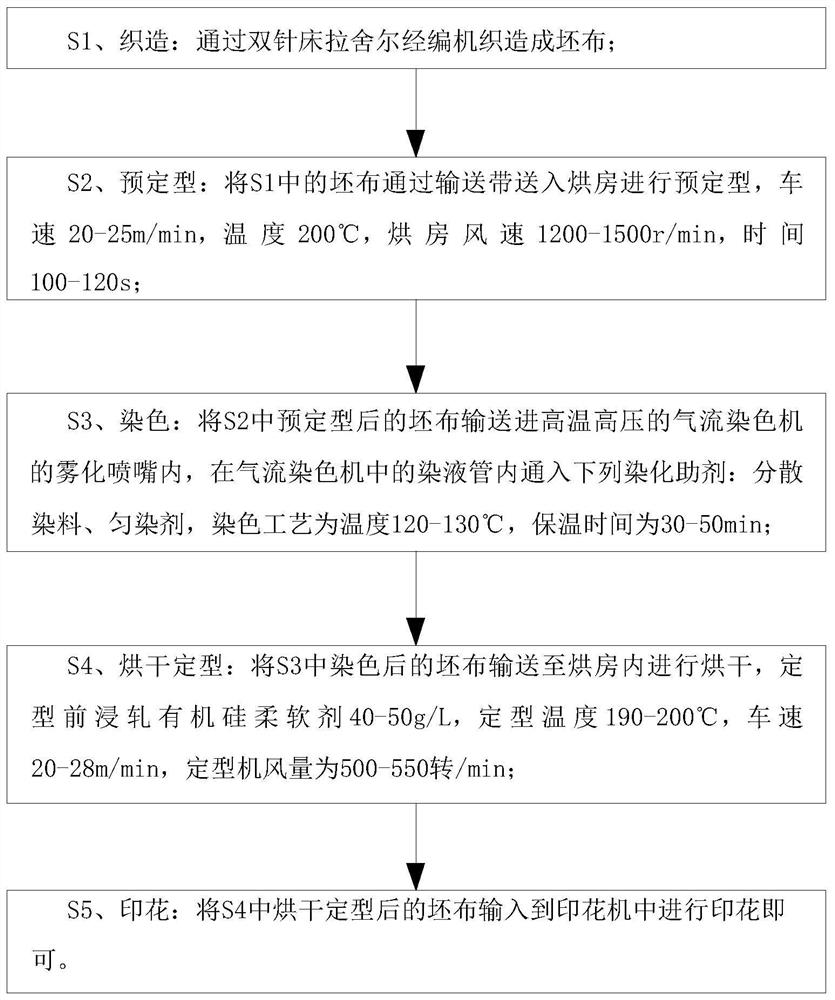

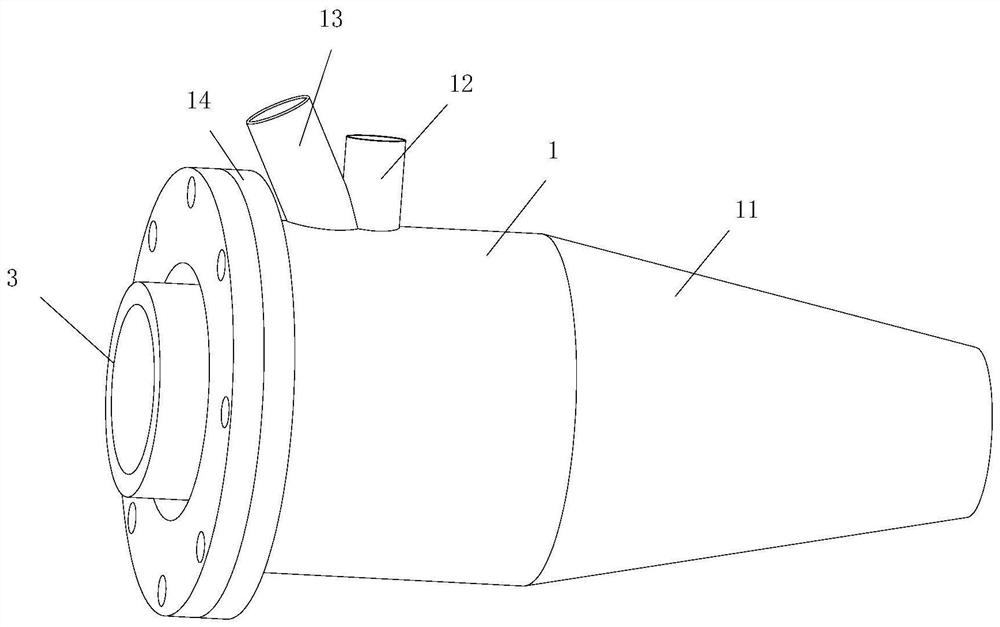

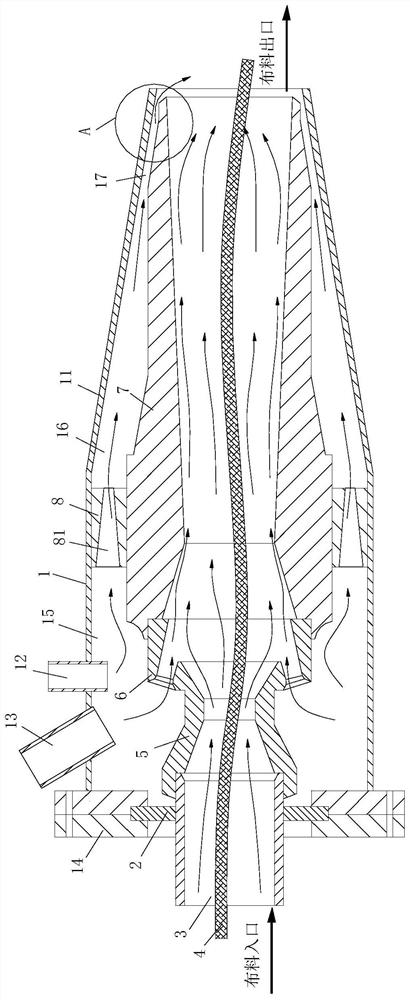

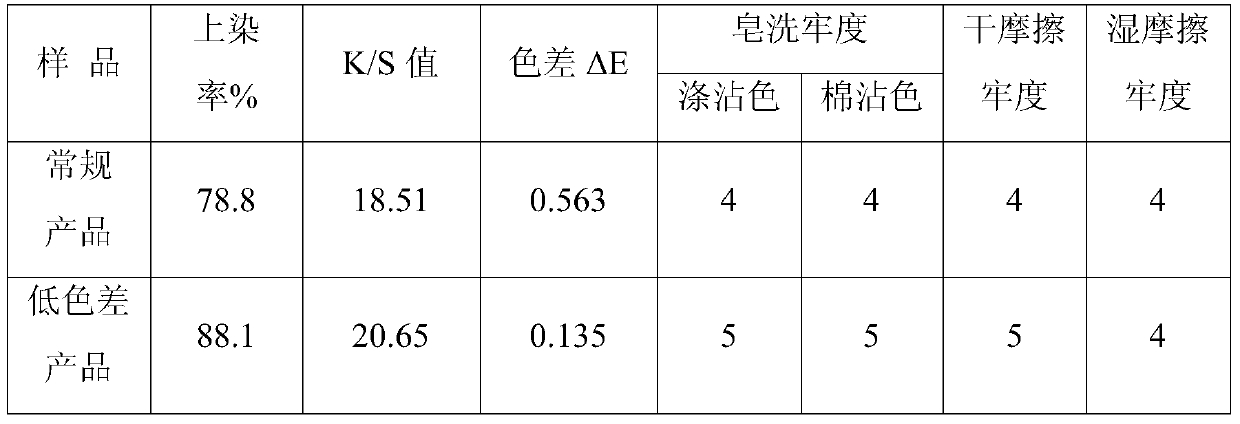

A process for thickening hand feeling of polyester printed fabric

ActiveCN111778650BLarge particle sizeFully atomizedTextile treatment machine partsWarp knittingDisperse dyeTextile printer

The invention relates to the technical field of textile production, in particular to a process for thickening the hand of polyester printed fabrics, comprising the following steps: S1, weaving: weaving into grey fabrics through a double-needle bed Raschel knitting machine; S2, presetting: The grey cloth in S1 is sent to the drying room through the conveyor belt for pre-forming, the vehicle speed is 20-25m / min, the temperature is 200°C, the air speed in the drying room is 1200-1500r / min, and the time is 100-120s; S3, dyeing: Pre-forming in S2 The finished grey fabric is transported into the atomizing nozzle of the high-temperature and high-pressure airflow dyeing machine, and the following dyeing auxiliaries are introduced into the dye liquor tube in the airflow dyeing machine: disperse dyes, leveling agents, and the dyeing process is at a temperature of 120-130°C, The holding time is 30-50min; it realizes the dyeing with the atomized dye solution twice before and after, so that the dyeing rate is good, the dyeing is uniform, and the dyeing property is improved. By continuously accelerating the high-speed airflow, the wound grey fabric can be fluffy and blown, which further improves the To ensure level dyeing performance, at the same time to ensure that the dyed grey fabric feels soft and thick.

Owner:宣城凯欧纺织有限公司

A kind of low chromatic aberration polyester ultra-soft ultra-fine yarn and preparation method thereof

ActiveCN105506775BSmall coefficient of thermal degradationReduce generationDyeing processMelt spinning methodsYarnPolyester

Owner:JIANGSU HENGLI CHEM FIBER

Color master batch capable of improving level dyeing property and preparation method of color master batch

InactiveCN110079060AEnsure level dyeingNo migration will occurMonocomponent polyesters artificial filamentDye addition to spinning solutionHydrophilic monomerDisperse dye

The invention discloses color master batch capable of improving the level dyeing property and a preparation method of the color master batch. Raw materials of the color master batch comprise carrier resin and super absorbent resin, wherein the super absorbent resin is a grafted copolymer formed by grafting starch or cellulose with at least two hydrophilic monomers, and a disperse dye is adsorbed in the super absorbent resin. The super absorbent resin is added to the color master batch and used for loading the disperse dye, countless 3D space network structures are distributed in the super absorbent resin formed by graft polymerization of the starch and at least two hydrophilic monomers, when the super absorbent resin is soaked in a suspension of the disperse dye, the disperse dye can enterthe 3D space network structures with water, and when the super absorbent resin is dried, water molecules are evaporated and the disperse dye is firmly locked in the super absorbent resin. When the color master batch is utilized for preparing polyester fibers, the disperse dye can be uniformly dispersed into the polyester fibers without migration, and therefore, the level dyeing property of the disperse dye is guaranteed to the greatest degree.

Owner:TONGXIANG HUACAI MASTERBATCH

A kind of low color difference polyester differential shrinkage composite yarn and its preparation method

ActiveCN105506774BSmall coefficient of thermal degradationReduce generationElectrolysis componentsElectrolytic organic productionYarnPolyester

The invention relates to a low-color difference polyester different-shrinkage composite yarn and a preparation method thereof. The low-color-difference polyester different-shrinkage composite yarn is obtained by compounding polyester POY yarn and polyester FDY yarn; the polyester POY yarn and polyester yarn Ester FDY yarn is obtained by spinning polyester after melting and washing. The breaking strength of the low-color difference polyester differential shrinkage composite yarn is ≥1.9cN / dtex, the elongation at break is 30.0±5.0%, and the crimp shrinkage rate is 2.50 ±3.0%, the degree of network is 20±5 / m; the color difference ΔE is less than 0.200; the magnesium ethylene glycol in the present invention is relatively mild, its thermal degradation coefficient is very small, the reduction of oligomers in the polymerization process, the dissolution and washing process The oligomers are further reduced, which reduces the occurrence of stains and streaks in polyester fiber dyeing and post-processing heat setting, and ensures fiber level dyeing and rubbing fastness. Different shrinkage composite yarn has excellent shading performance, excellent dyeing performance, high bulkiness and soft hand feeling, and because there are many loops on the surface of the fiber, it also eliminates the aurora defect of chemical fiber filaments.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of low color difference polyester dty bright yarn and preparation method thereof

ActiveCN105463618BSmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsBreaking strengthPolyester

The invention relates to a low-chromatic-aberration bright polyester DTY and a preparation method thereof. The low-chromatic-aberration bright polyester DTY is obtained through the steps that polyester is processed through soluble washing and then processed through melt spinning processing by special-shaped spinneret orifices; the breaking strength (cN / dtex) of the low-chromatic-aberration bright polyester DTY is larger than or equal to 4.0, the elongation at break (%) is 25.0+ / -2.5, the end section of the DTY is in the shape of a regular triangle, and the chromatic aberration delta E is smaller than 0.200. According to the low-chromatic-aberration bright polyester DTY and the preparation method thereof, ethylene glycol magnesium is milder, the thermal degradation coefficient is very small, side reactions caused in the reaction process are few, and generation of oligomers in the processing process is reduced; in the polyester fiber dyeing and post processing heat setting processes, the quantity of the oligomers which migrate from the interior of the fiber to the exterior of the fiber is reduced, occurrence of color spots and strip patterns is reduced, and the fiber levelling property and crockfastness are guaranteed. The bright polyester DTY has the real silk-like gloss and softness, the fabric bright sensation and the soft and elegant silk light sensation, has the excellent optical property, is thick and solid in fabric handfeel and good in bulkiness and air permeability and has the superbright flashing effect.

Owner:JIANGSU HENGLI CHEM FIBER

Production process of cotton coated viscose uniform material

InactiveCN101575763BWith comfortSun resistantWeft knittingHeating/cooling textile fabricsYarnViscose

The invention provides a process for manufacturing viscose yarn face and cotton back NBC protective school uniform material which is characterized by adopting an interlock structure and comprising the following components: 73-76 percent of 150D viscose yarn and 24-27 percent of combed cotton yarn, and environmental-friendly sunshine-resisting and sweat-resisting reactive dye is dyed into the viscose yarn face and cotton back NBC protective school uniform material. The viscose yarn face and cotton back NBC protective school uniform material is treated by water-proof finish aid, oil-proof finish aid and soil-releasing finish aidso that the water-proof finish aid, the oil-proof finish aid and the soil-releasing finish aid are adhered. The process comprises a weaving process, a dyeing process, a dehydration process, a width opening process, a drying process, a treatment process after heat setting and a test process. The viscose yarn face and cotton back NBC protective school uniform material manufactured by the inventive process has the characteristics of water-proof, oil-proof, soil-releasing properties, and the like and uneasy fluffiness and pilling. The invention can guarantee the level dyeing property and dye uptake of dye uptake fiber, increase colorizing force of the dye and improve the whole performance of the fabric.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

A kind of low chromatic aberration polyester wool-like type differential shrinkage composite yarn and preparation method thereof

ActiveCN105648570BSmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsFiberPolyester

Owner:JIANGSU HENGLI CHEM FIBER

Low-chromatic-aberration bright polyester DTY and preparation method thereof

ActiveCN105463618ASmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsPolyesterBreaking strength

The invention relates to a low-chromatic-aberration bright polyester DTY and a preparation method thereof. The low-chromatic-aberration bright polyester DTY is obtained through the steps that polyester is processed through soluble washing and then processed through melt spinning processing by special-shaped spinneret orifices; the breaking strength (cN / dtex) of the low-chromatic-aberration bright polyester DTY is larger than or equal to 4.0, the elongation at break (%) is 25.0+ / -2.5, the end section of the DTY is in the shape of a regular triangle, and the chromatic aberration delta E is smaller than 0.200. According to the low-chromatic-aberration bright polyester DTY and the preparation method thereof, ethylene glycol magnesium is milder, the thermal degradation coefficient is very small, side reactions caused in the reaction process are few, and generation of oligomers in the processing process is reduced; in the polyester fiber dyeing and post processing heat setting processes, the quantity of the oligomers which migrate from the interior of the fiber to the exterior of the fiber is reduced, occurrence of color spots and strip patterns is reduced, and the fiber levelling property and crockfastness are guaranteed. The bright polyester DTY has the real silk-like gloss and softness, the fabric bright sensation and the soft and elegant silk light sensation, has the excellent optical property, is thick and solid in fabric handfeel and good in bulkiness and air permeability and has the superbright flashing effect.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com