Low-color-difference polyester DTY (Draw Textured Yarn) and preparation method thereof

A polyester and chromatic aberration technology, applied in the direction of single-component polyester rayon, rayon manufacturing, melt spinning, etc., can solve the problems of color flower, hindering liquid flow circulation, not easy to wash off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

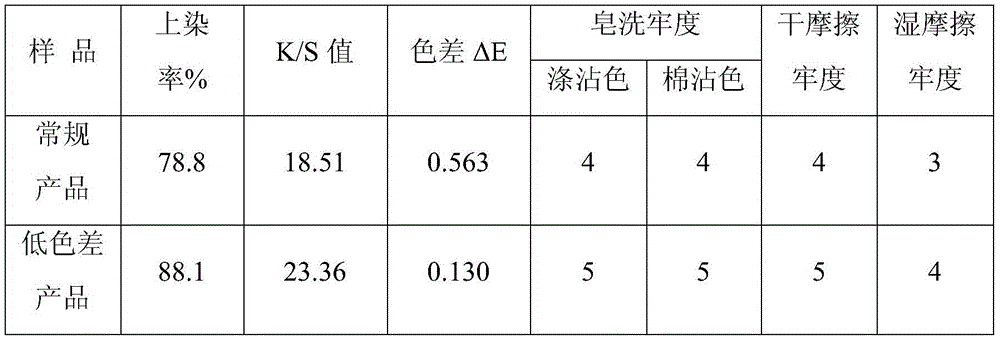

[0057] A kind of preparation method of polyester DTY yarn with low color difference of the present invention, terephthalic acid and ethylene glycol undergo esterification and polycondensation under the catalysis of the mixture of ethylene glycol magnesium and ethylene glycol antimony to obtain polyester, and then through Cut into pellets to obtain polyester chips, and then dissolve and wash the polyester chips to obtain polyester; then measure, extrude, cool, oil and wind to obtain POY filaments. Polyester DTY yarn with low color difference is made from POY yarn through wire guide tube, network, heating stretching, false twisting, heat setting and winding molding.

[0058] 1. Dye:

[0059] Disperse Brilliant Blue 2BLN, 5% (o.w.f)

[0060] 2. Dyeing process:

[0061] The fiber is dyed at 70-80°C for 10-15 minutes, the temperature rise rate is 1.0-2.0°C / min, the temperature is kept at 120-130°C for 40-60 minutes, the temperature is lowered, and the reduction cleaning is perfor...

Embodiment 1

[0074] A preparation method of low color difference polyester DTY yarn, the main process comprises:

[0075] (1) Preparation of catalyst magnesium ethylene glycol:

[0076] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 6V, the cathode current density is 150mA, and electrolyze for 10 hours at 50°C. Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0077] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0078] Esterification reaction:

[0079] Use terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 1.2:1, add anti-ether agent sodium acetate, the amount of sodium ace...

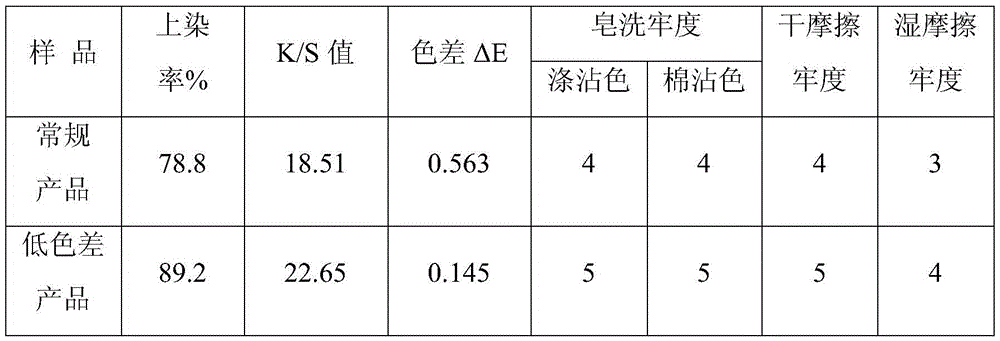

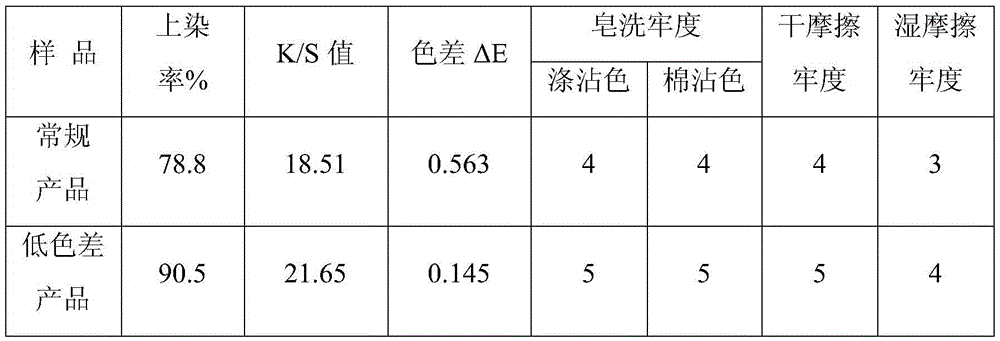

Embodiment 2

[0101] A preparation method of low color difference polyester DTY yarn, the main process comprises:

[0102] (1) Preparation of catalyst magnesium ethylene glycol:

[0103] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 10V, the cathode current density is 200mA, electrolyze at 60°C for 12 hours, after the electrolysis ends Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0104] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0105] Esterification reaction:

[0106] Using terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 2.0:1, adding anti-ether agent calcium ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| chromatic aberration | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com