Environment-friendly reactive dye low-temperature salt-free dyeing method for cotton fabric

A reactive dye and salt-free dyeing technology, applied in dyeing methods, chemical instruments and methods, water pollutants, etc., can solve the problems of affecting the dyeing effect, uneven modification, high cationic degree, etc., to avoid secondary pollution, good Level dyeing effect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

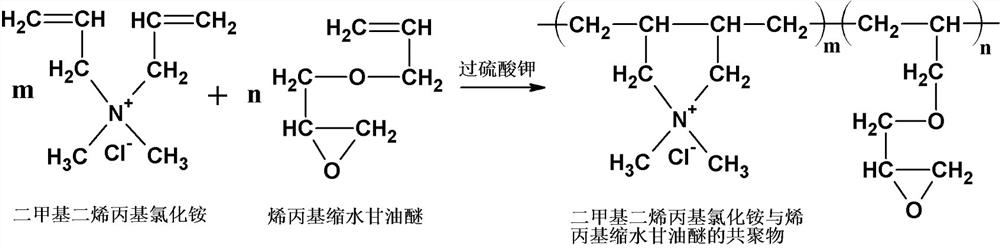

[0017] (1) Synthetic process of dimethyl diallyl ammonium chloride and allyl glycidyl ether copolymer

[0018] Weigh dimethyl diallyl ammonium chloride and allyl glycidyl ether according to a mass ratio of 7.5:1 and add them to a three-necked flask, then add potassium persulfate of 1% (mass percentage, the same below) of the total amount of monomers As an initiator, the temperature was raised to 90°C, stirred at constant temperature for 4 hours, cooled naturally to room temperature, acetone was added to precipitate the product, and vacuum-dried at 50°C.

[0019] (2) Cotton fabric modification process

[0020] The cationic polymer synthesized above was made into a cationic polymer aqueous solution with a concentration of 0.7g / L with deionized water, and sodium hydroxide solution was added to adjust its pH value to 13, and the cotton fabric was immersed in the solution with a bath ratio of 1:100. Keep at 25°C, stir slowly for 6h, take out and wash with water until neutral.

[...

Embodiment 2

[0029] (1) Synthetic process of dimethyl diallyl ammonium chloride and allyl glycidyl ether copolymer

[0030] Weigh dimethyl diallyl ammonium chloride and allyl glycidyl ether according to a mass ratio of 7.5:1 and add them to a three-necked flask, then add potassium persulfate of 1% of the total amount of monomers as an initiator, and heat up to 80 ℃, stirred and reacted at constant temperature for 6 hours, transferred to a small beaker and naturally cooled to room temperature, added acetone to precipitate the product, and dried under vacuum at 50 ℃.

[0031] (2) Cotton fabric modification process

[0032] The cationic polymer synthesized above was made into a cationic polymer aqueous solution with a concentration of 0.7g / L with deionized water, and sodium hydroxide solution was added to adjust its pH value to 13, and the cotton fabric was immersed in the solution with a bath ratio of 1:100. Keep at 25°C, stir slowly for 6h, take out and wash with water until neutral.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com