Production process of cotton coated viscose uniform material

A production process, viscose yarn technology, applied in fabric surface trimming, heating/cooling fabric, dyeing method, etc., can solve the problems of poor fabric durability and practicability, poor moisture absorption and air permeability, etc., to increase coloring power, Ensure level dyeing and increase washing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The best embodiment of the present invention is as follows:

[0025] With 75% 150D viscose yarn and 25% 26 S Combed cotton yarn is used as raw material to weave double-sided Roman cloth structure on a 24G34" double-sided machine.

[0026] The woven fabric becomes a finished product through the dyeing process→dehydration process→opening process→drying process→heat setting finishing process→inspection process.

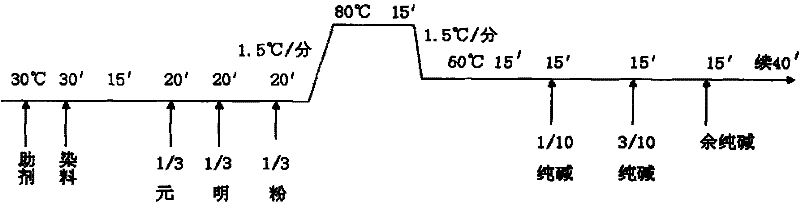

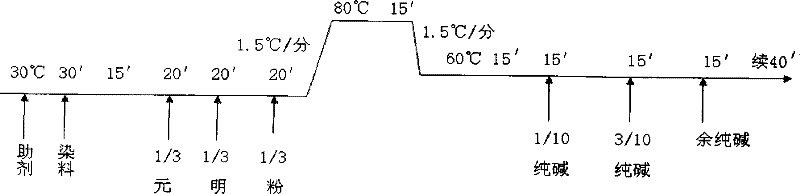

[0027] The dyeing process such as figure 1 Shown:

[0028] First, add the required auxiliary, which is a general-purpose dyeing auxiliary, such as G560 chelating dispersant, into the aqueous solution at 30°C, wait for 30 minutes before adding the required dye, such as the environmentally friendly product named Yongguang Yellow 3RS The sun-resistant and perspiration-resistant reactive dyes, after 15 minutes, add 1 / 3 of sodium su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com