Low-color-difference polyester super-soft ultrafine yarn and preparation method thereof

A technology of ultra-fine yarn and polyester, applied in the direction of single-component polyester rayon, dyeing method, rayon manufacturing, etc., can solve the problems of dye color point, not easy to wash off, hinder liquid flow circulation, etc., to achieve glossy soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

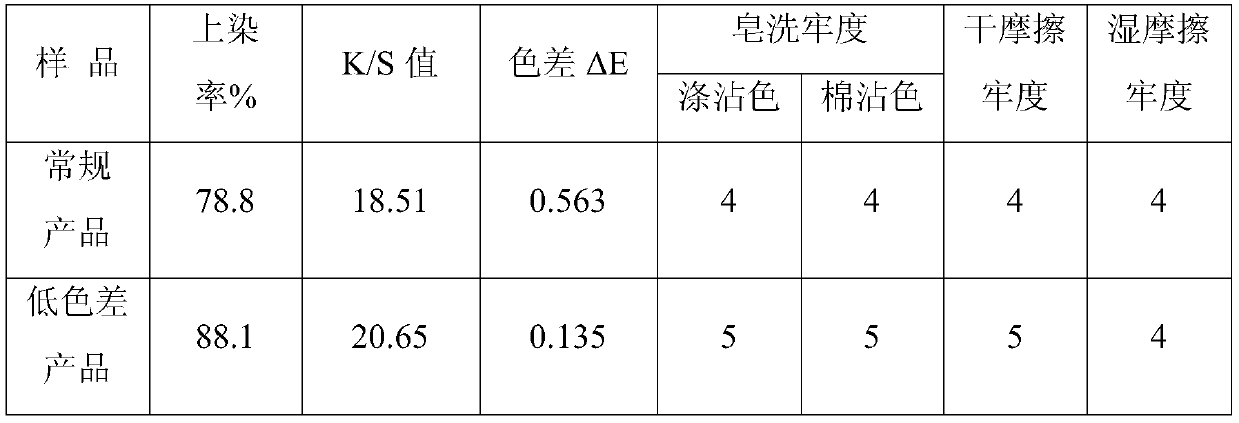

Embodiment 1

[0070] A method for preparing low-chromatic-difference polyester ultra-soft ultra-fine filaments, the main process comprising:

[0071] (1) Preparation of catalyst magnesium ethylene glycol:

[0072] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 6V, the cathode current density is 150mA, and electrolyze for 10 hours at 50°C. Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0073] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0074] Esterification reaction:

[0075] Use terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 1.2:1, add anti-ether agent sodium acetat...

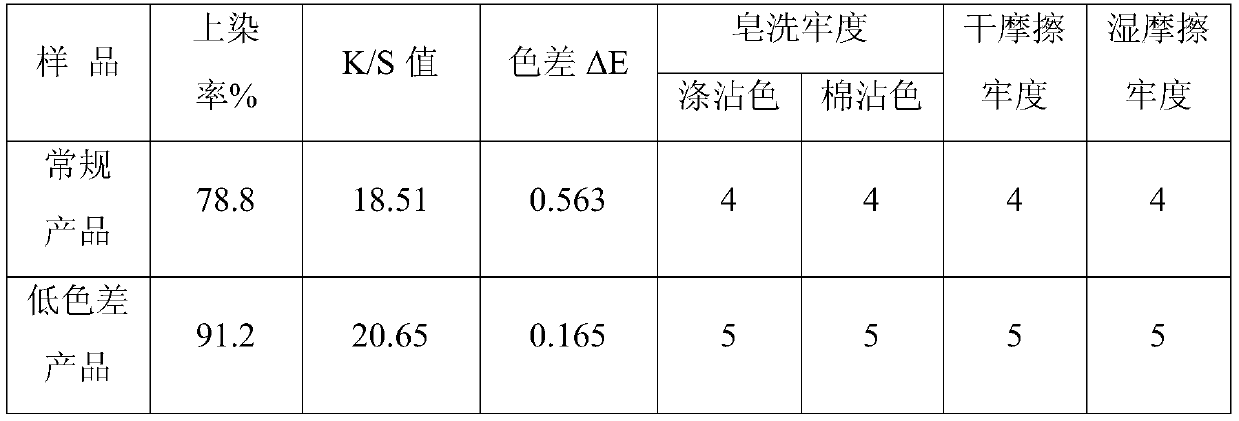

Embodiment 2

[0092] A method for preparing low-chromatic-difference polyester ultra-soft ultra-fine filaments, the main process comprising:

[0093] (1) Preparation of catalyst magnesium ethylene glycol:

[0094] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 10V, the cathode current density is 200mA, electrolyze at 60°C for 12 hours, after the electrolysis ends Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0095] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0096] Esterification reaction:

[0097] Using terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 2.0:1, adding an...

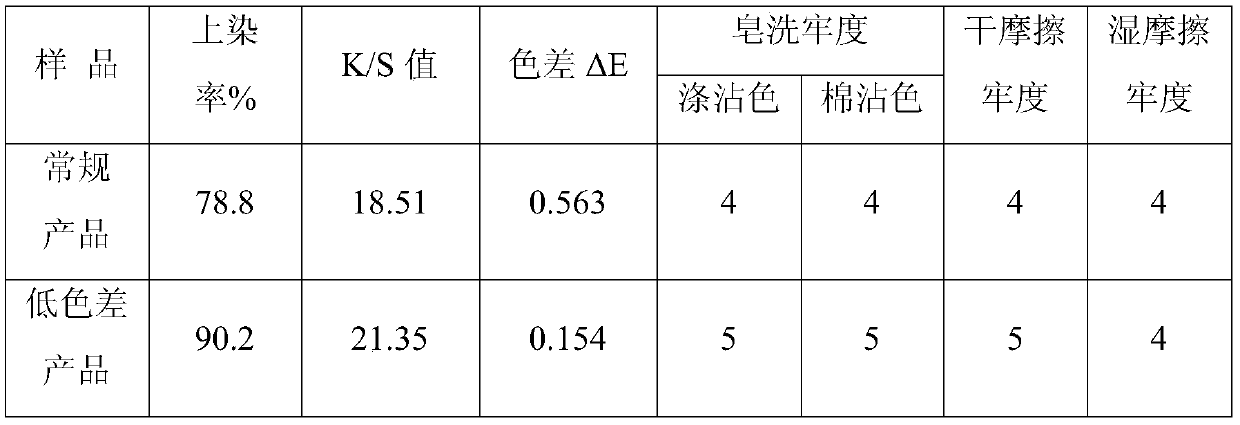

Embodiment 3

[0114] A method for preparing low-chromatic-difference polyester ultra-soft ultra-fine filaments, the main process comprising:

[0115] (1) Preparation of catalyst magnesium ethylene glycol:

[0116] Add ethylene glycol into the single-chamber electrolytic cell, the supporting electrolyte is magnesium chloride, the metal magnesium block is the anode, and the cathode is graphite; connect direct current, the initial voltage is 7V, the cathode current density is 160mA, and electrolyze for 11 hours at 55°C. Take out the electrode to obtain a white suspension; filter under reduced pressure, wash the white solid with absolute ethanol, and dry to obtain magnesium ethylene glycol;

[0117] (2) Preparation of polyester, including esterification reaction and polycondensation reaction:

[0118] Esterification reaction:

[0119] Using terephthalic acid and ethylene glycol as raw materials, the molar ratio of ethylene glycol to terephthalic acid is 1.5:1, adding anti-ether agent sodium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com