Aqueous epoxy putty, and preparation and use method thereof

A technology of epoxy putty and water-based epoxy resin, applied in the field of coatings, can solve problems such as dissolution and failure to meet the requirements of oil-based paint, and achieve the effects of good adhesion, enhanced protection and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Prepare water-based epoxy putty main paint of the present invention:

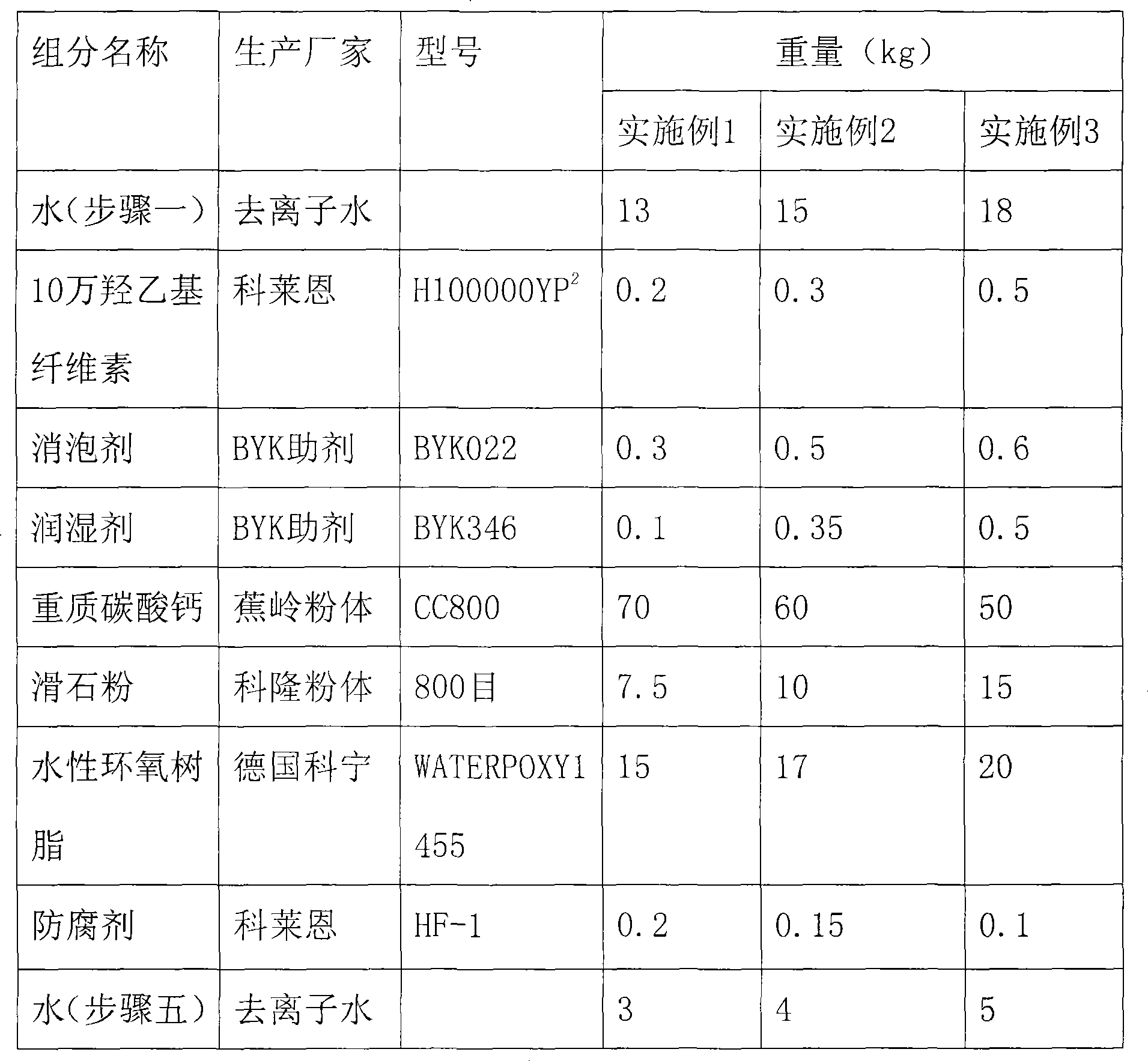

[0063] Get each component according to the weight listed in "Example 1" in Table 1, and the preparation method is as follows:

[0064] Step 1. Add 13 kg of water in the formula to the production tank, slowly add 0.2 kg of 100,000 hydroxyethyl cellulose under medium-speed stirring, and stir for 10-15 minutes until the 100,000 hydroxyethyl cellulose is completely dissolved.

[0065] Step 2. Add defoamer BYK022: 0.3kg and wetting agent BYK346: 0.1kg according to the weight ratio, and stir for 10-15 minutes until completely uniform.

[0066] Step 3. Add 70kg of heavy calcium carbonate and 7.5kg of talcum powder according to the weight ratio, and disperse at high speed for 20-30 minutes. Stir unevenly, add water-based epoxy resin WATERPOXY1455: about 3kg, after about 5-8min, turn to high speed to 1200-1500r / min, disperse for 20-30min, until the fineness is 30-40 microns, within this time range If the di...

Embodiment 2

[0072] With each component weight listed in " embodiment 2 " in table 1, repeat the method described in above-mentioned embodiment 1 (only each component weight changes), prepare waterborne epoxy putty main paint; Repeat curing in embodiment 1 The components, proportioning and preparation method of the agent were prepared to obtain the water-based epoxy putty curing agent; the main paint and the diluent were mixed uniformly according to 20:1, and then the water-based epoxy putty was obtained after construction and drying according to the method described in Example 1 paint film.

[0073] The routine performance testing results are shown in the corresponding data of "Example 2" in Table 2.

Embodiment 3

[0075] With each component weight listed in " embodiment 3 " in table 1, repeat the method described in embodiment 1 (only each component weight changes), prepare waterborne epoxy putty main paint; Repeat the curing agent in embodiment 1 Components, proportioning and preparation method to prepare a water-based epoxy putty curing agent; mix the main paint and diluent uniformly according to 20:1, then carry out construction and drying according to the method described in Example 1 to obtain a water-based epoxy putty paint film . The routine performance test results are shown in the corresponding data of "Example 3" in Table 2.

[0076] Table II

[0077] serial number Test items Example 1 Example 2 Example 3 1 Construction good excellent good 2 Grinding hand sandable Excellent sandability good 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com