Patents

Literature

48 results about "Epoxy putty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy putty refers to a group of room-temperature-hardening substances used as space-filling adhesives. Exact compositions vary according to manufacturer and application. They are stored until use as two components of clay-like consistency. Kneading the two components into each other creates an exothermic chemical reaction that activates the substance for use by catalyzing an epoxide polymerisation reaction. Unlike many other types of glues, an epoxy adhesive can fill gaps and even be molded into a structural part. Some makers claim in advertising that one can drill and tap their cured products, and that they quickly cure "hard as steel" (as measured by Shore rating), though they are much weaker than steel in tensile strength and shear strength.

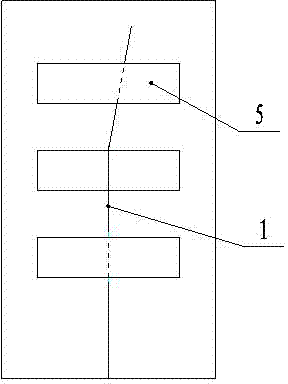

Construction method for reinforcing concrete structure by using carbon fibers

The invention relates to a construction method for reinforcing a concrete structure by using carbon fibers, belonging to the technical field of building constructions. The construction method comprises the following construction steps of: (1) carrying out a concrete foundation treatment; (2) coating priming paint; (3) carrying out incomplete part repair by utilizing epoxy putties; (4) sticking carbon fiber sheets; and (5) curing. The construction method disclosed by the invention has the advantages of simple and rapid construction, no need of any clamp, mould plate and support and low construction cost, and is suitable for each type of reinforced concrete structure or reinforcement and enhancement of the member, reinforced concrete structures, such as bridges, industrial and civil buildings and special structures, high-rise structures, impounding reservoirs, jars, culverts, tunnels, wharfs and harbors and the like, and is also suitable for the repair and enhancement of the structures.

Owner:云南巨和建设集团有限公司

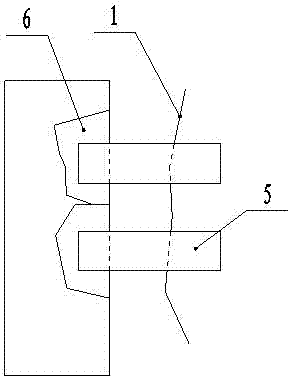

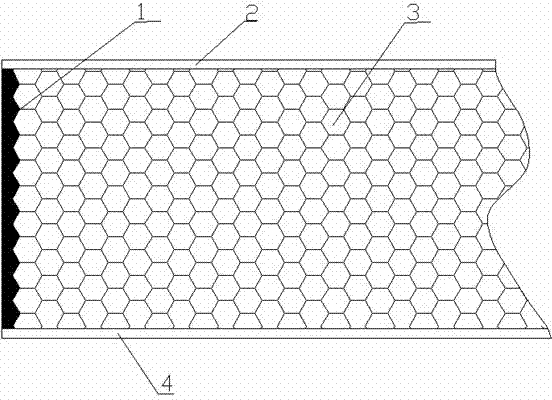

Edge sealing structure of honeycomb sandwich shelter wallboard, and edge sealing method thereof

InactiveCN103590532AImprove lateral pressure resistanceImprove rigiditySynthetic resin layered productsBuilding componentsHoneycombEngineering

The invention relates to an edge sealing structure of a honeycomb sandwich shelter wallboard, and an edge sealing method thereof. The edge sealing structure is low-density epoxy putty composed of an epoxy resin and a lightweight filler. The invention also relates to an edge sealing method of the honeycomb sandwich shelter wallboard by adopting the edge sealing structure. The edge sealing structure has a low cost, can substantially improve the side compression resistance and the whole rigidity of a honeycomb sandwich panel, and has frame reinforcing and waterproof sealing effects. The method is simple to operate, and is especially suitable for the rapid edge sealing treatment of a part with any shape in any positionof a honeycomb sandwich shelter wallboard after random perforation.

Owner:衡阳泰豪通信车辆有限公司

Surface treatment method for composite material blade of helicopter

The invention discloses a surface treatment method for a composite material blade of a helicopter, and belongs to the technical field of the surface treatment of composite materials. The method is characterized by solving the problems of falling, cracking and aging of a coating during the use of the composite material blade by improving the conventional surface treatment technology for the composite material. Normal temperature slight corrosion technology of metal is used on leading edge coating iron of the composite material blade for solving the problem of surface chemical treatment of the composite material blade before the leading edge coating iron is painted. The method comprises the following steps of: filling pinholes on the surface of the composite material blade with epoxy putty;coating an epoxy primer to enhance the bonding force of the paint layer; coating a wash primer to solve the problem of the bonding force between the leading edge coating iron and the paint layer; andcoating a polyurethane finish. Compared with the prior art, the method of the invention solves the problem of the surface chemical treatment of the composite material blade before the leading edge coating iron is painted, so that the problem of paint peeling of the leading edge coating iron of the composite material blade is solved.

Owner:HARBIN

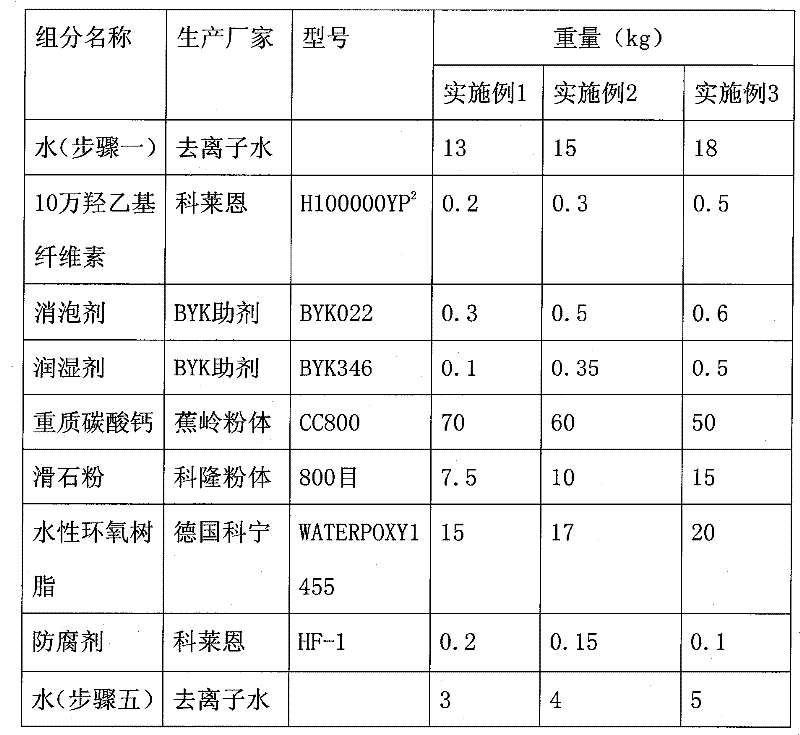

Aqueous epoxy putty, and preparation and use method thereof

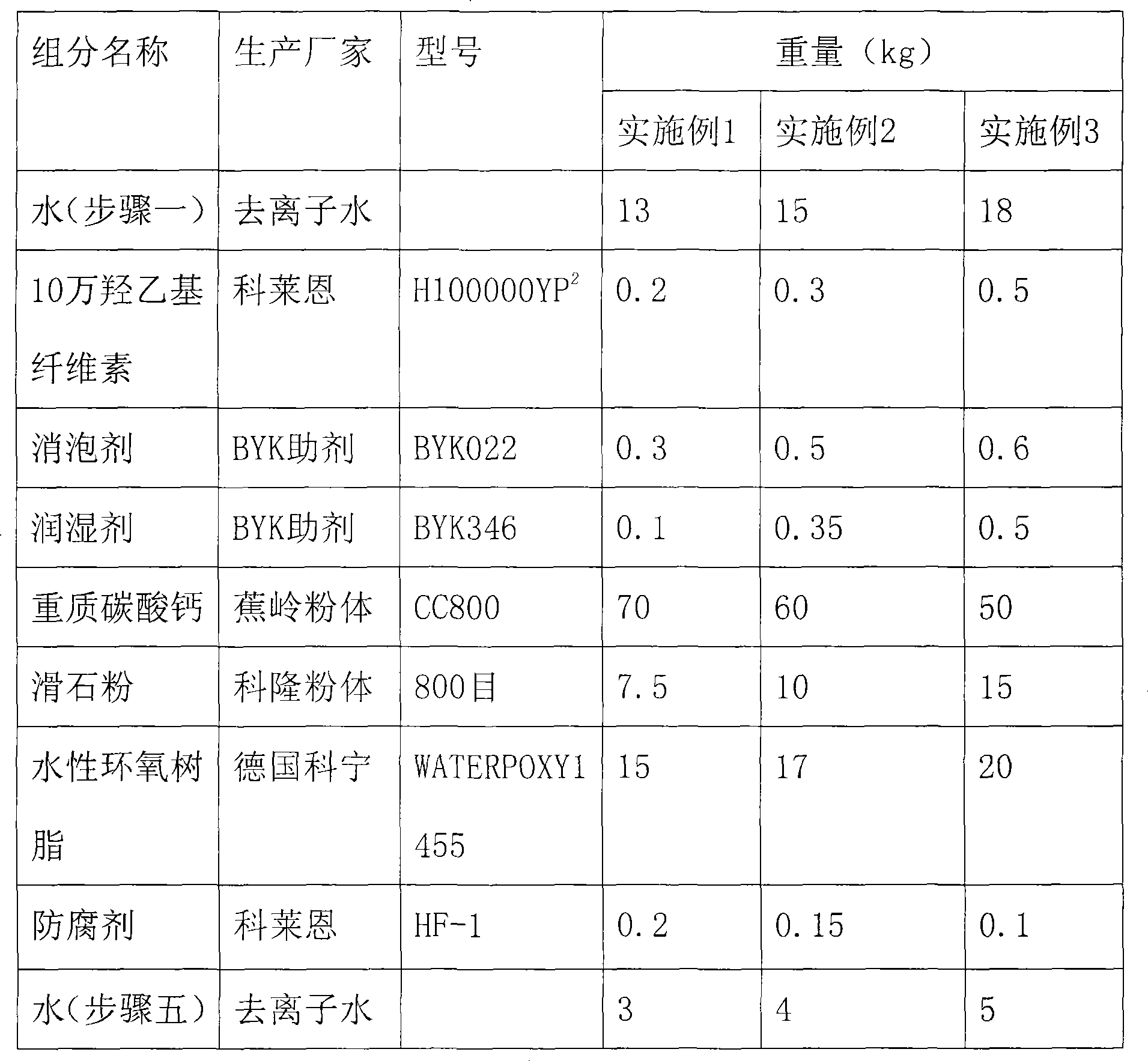

The invention relates to an aqueous epoxy putty and a preparation method thereof. The preparation method comprises the following steps: 1. 13 to 18 weight portions of water is added with 0.2 to 0.5 weight portion of thickening agent under the stirring at the speed of 500 to 800 revolutions / minutes, is stirred and is fully dissolved; 2. 0.3 to 0.6 weight portion of a defoaming agent and 0.1 to 0.5 weight portion of wetting agent are sequentially added into the mixture and are evenly stirred; 3. 50 to 70 weight portions of powdered whiting and 7.5 to 15 weight portions of talcum powder are added into the mixture; under the rotational speed of 500 to 800 revolutions / minute, all composition are mixed; and if water is too little to stir the compositions evenly, 3 to 5 weight portions of an aqueous epoxy resin is added into the mixture, is stirred for 5 to 8 minutes till the fineness is between 30 and 40 microns at the rotational speed of 1,200 to1,500 revolutions / minute; 4. at the middle rotational speed, the residual amount of the aqueous epoxy resin is fully replenished to 15 to 20 weight portions totally and is evenly stirred; and 5. the mixture is continuously added with 0.1 to 0.2 weight portion of antiseptic and 3 to 5 weight portions of water, is stirred for 7 to 19 minutes at low speed, and is filtered to obtain the aqueous epoxy putty. According to weight ratio of 6 to 4, an aqueous epoxy curing agent and water are mixed to obtain a special matched curing agent; and according to weight ratio of 20 to 1, the aqueous epoxy putty and the curing agent are mixed for use. The aqueous epoxy putty can solve the problem that oily paint dissolves a polystyrene plate due to the fact that an aqueous epoxy primer is leaked to paint or the thickness of the painted primer does not meet the requirement, and can well decorate and protect a coating layer.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

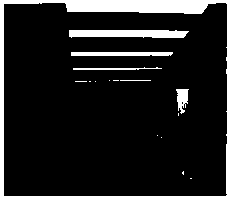

Hydraulic building compound anti-seepage system and system forming method

ActiveCN107829406AImprove bindingIncrease elasticityAnti-corrosive paintsFilling pastesElastomerWater flow

The invention provides a compound anti-seepage system. A primer layer and a membrane waterproof layer are formed in sequence on the surface of concrete of a hydraulic building, wherein the primer layer comprises a first coating and / or an epoxy putty layer and a second coating. The first coating is epoxy primer for the base surface of damp or dry concrete; the second coating is polyurethane primer;and the membrane waterproof layer is made of a polymer elastomer material. A silica sand layer is additionally arranged between the first coating and / or the epoxy putty layer and the second coating,and / or, the membrane waterproof layer is additionally provided with a finishing coat layer. The invention further provides an anti-seepage and protective method for the concrete surface. The binding force between the compound anti-seepage system provided by the invention and the concrete surface is high, elasticity is good, and the compound anti-seepage system is resistant to erosion and abrasion,capable of being adapted to a damp and low-temperature construction environment of hydraulic buildings such as a dam, a water delivery tunnel, a box culvert, a channel and a pipe, long-term dipping in water and the use environment of high-speed water flow erosion and is free of being softened and falling, safe and environmentally friendly.

Owner:李泽月

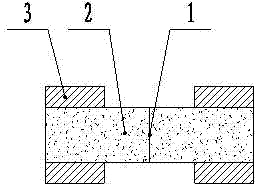

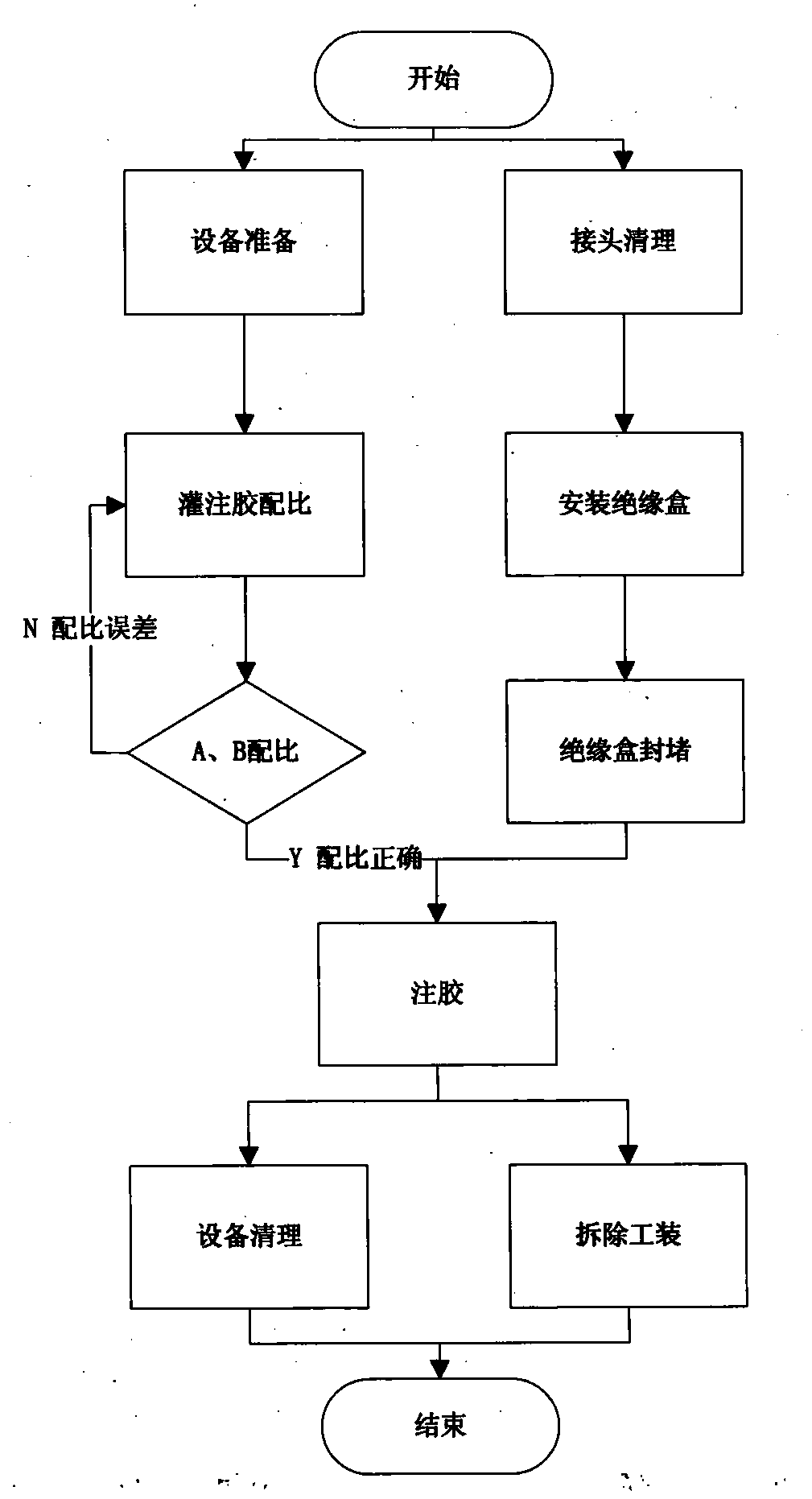

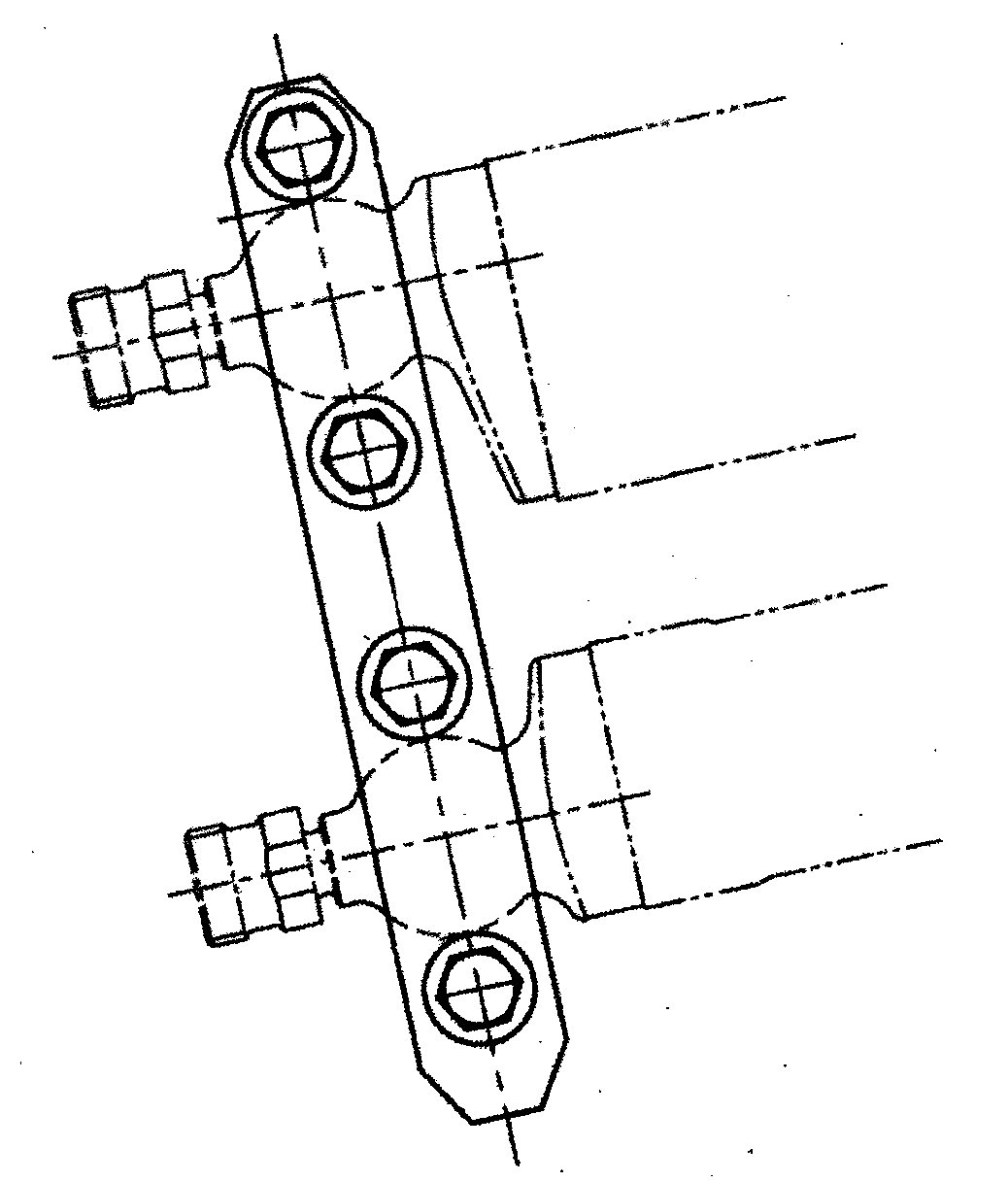

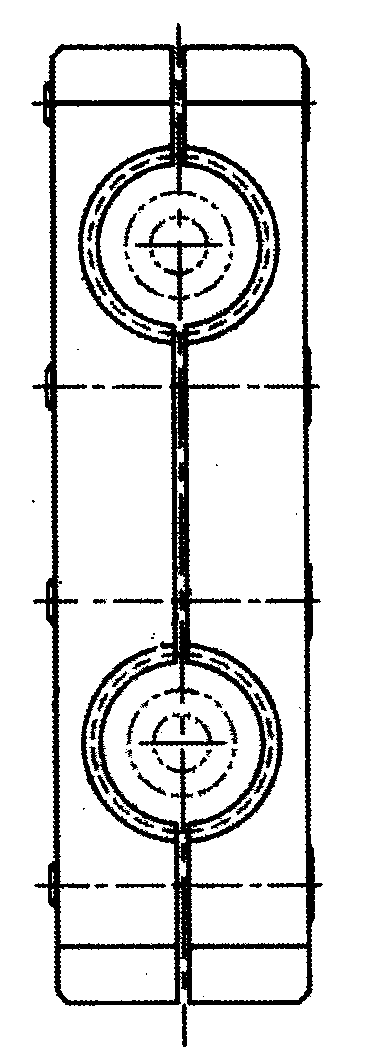

Epoxy potting method for insulation box on end portion of electric generator

ActiveCN103546000ASolve efficiency problemsSolve labor intensityApplying solid insulationRoom temperatureEngineering

The invention provides an epoxy potting method for an insulation box on an end portion of an electric generator. The method includes the steps of closing a connector through the mica insulation box and a tool, sealing the seam between the mica insulation box and the tool through epoxy putty, forming epoxy injection holes in the mica insulation box in advance, injecting potted epoxy into the epoxy injection holes through an epoxy potting device, solidifying the potted epoxy at the room temperature, and enabling the mica insulation box and the potted epoxy to form a whole after the tool is removed. The method overcomes the detects in the prior art, the insulation box obtained through the method is reliable in performance and simple in structure, production efficiency can be improved, labor intensity can be lowered, and the insulation effect is ensured.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

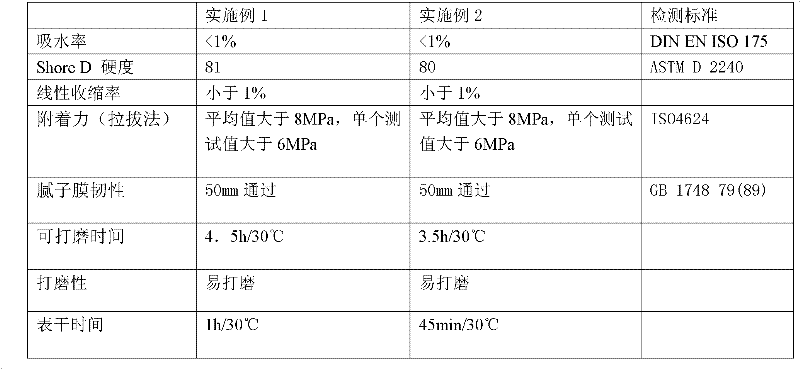

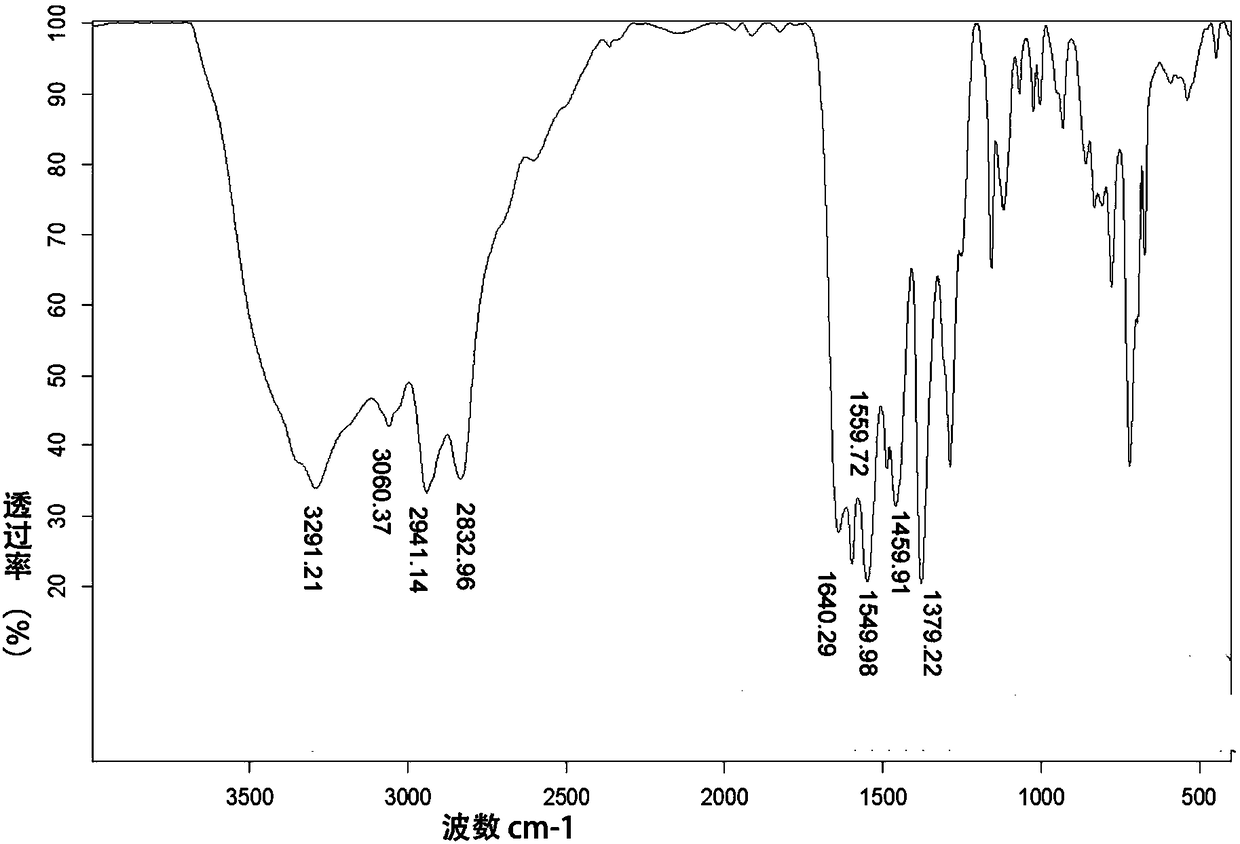

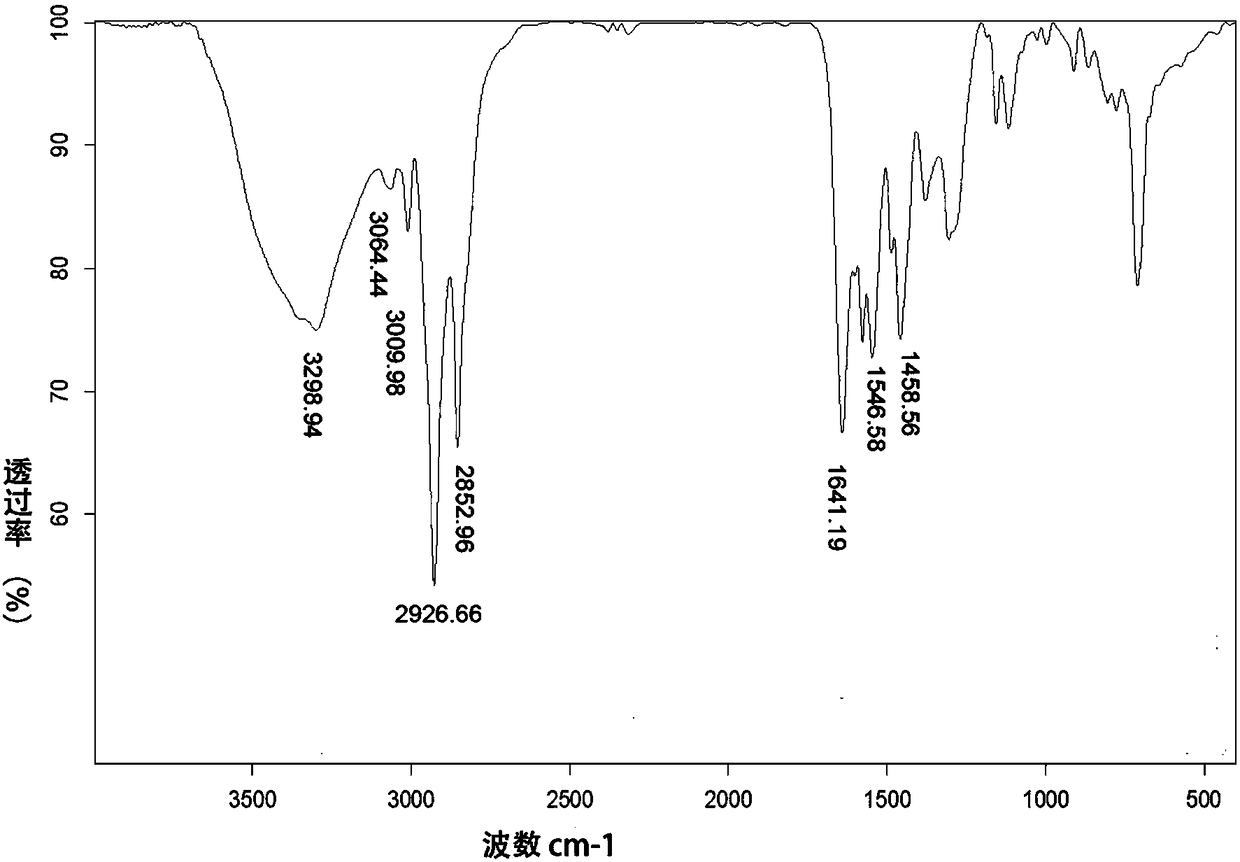

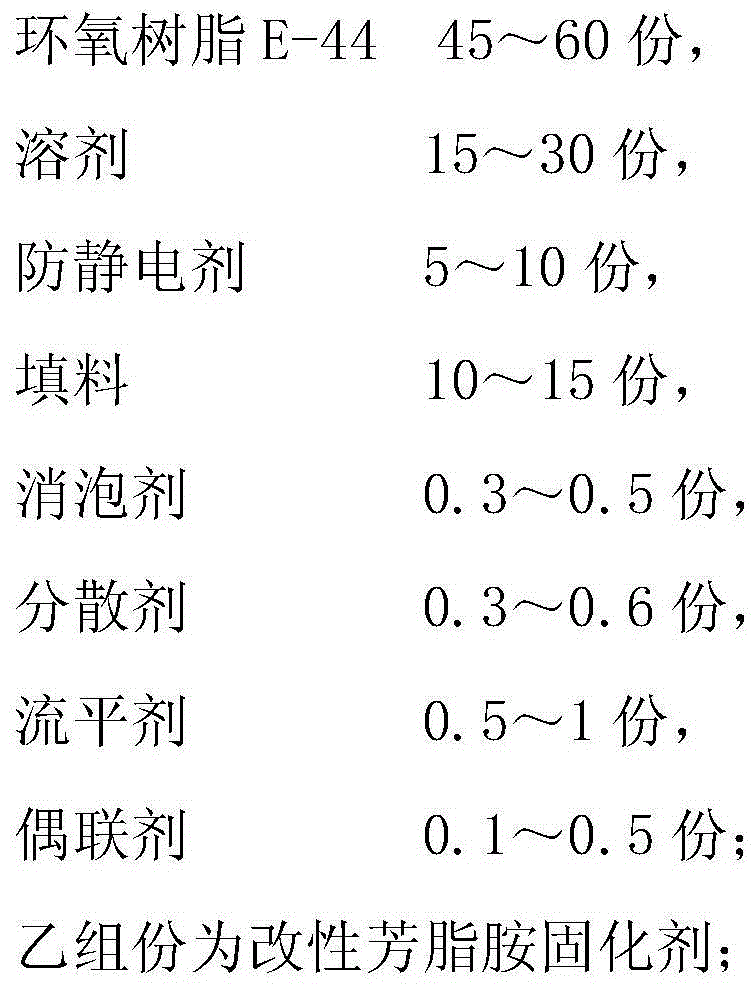

Epoxy ash for high performance megawatt wind turbine blades and preparation method thereof

The invention discloses a high-performance epoxy ash for megawatt wind power blades and a preparation method. The epoxy ash is formed by mixing a putty part and a curing agent part, wherein the mass composition of the putty part is: Epoxy resin 20-65%, reactive diluent 5-20%, pigment and filler 40-70%, wetting and dispersing agent 1-5%, leveling agent 0.1-5%, defoamer 1-4%, thixotropic The curing agent is 0.5-10%; the curing agent part is formed by mixing amine substances and thixotropic agents. The product of the invention has the advantages of convenient curing, strong adhesion, low shrinkage, excellent mechanical properties, good electrical properties, chemical stability and the like.

Owner:江苏普兰纳涂料有限公司

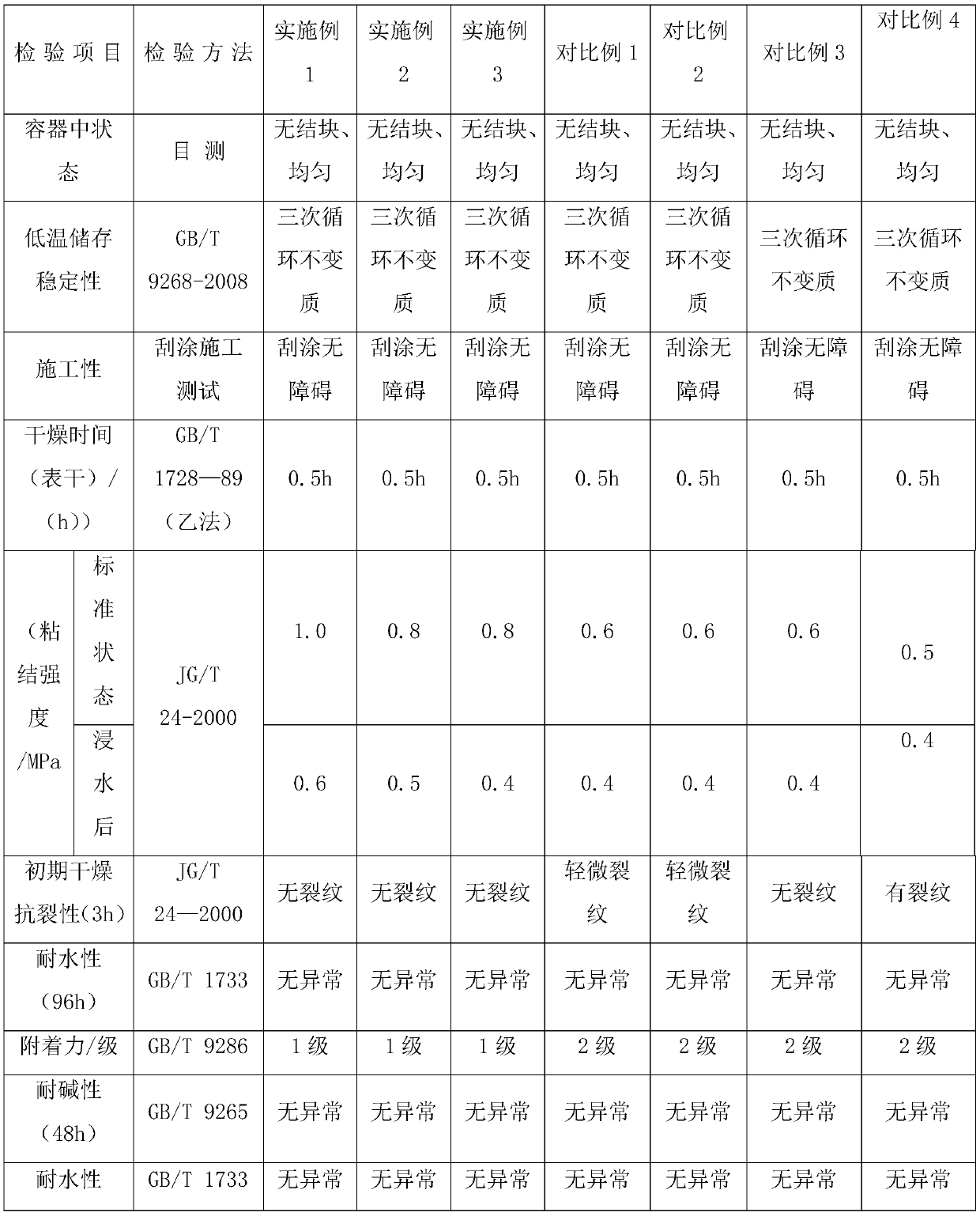

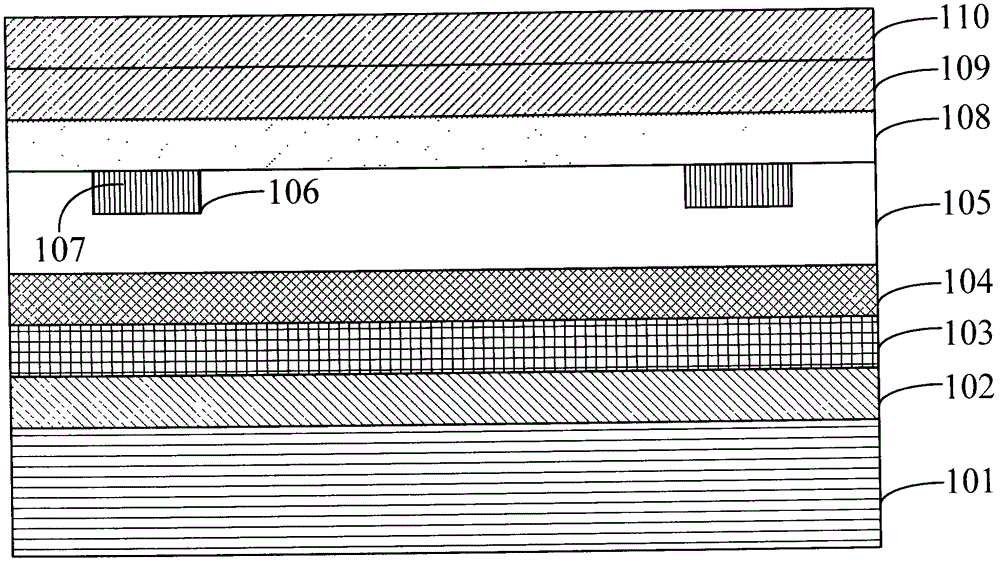

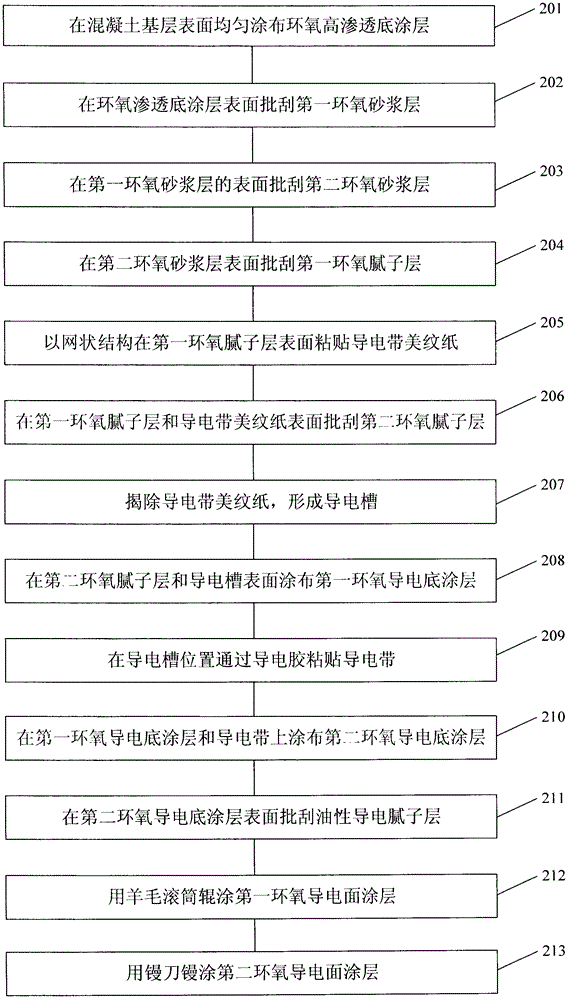

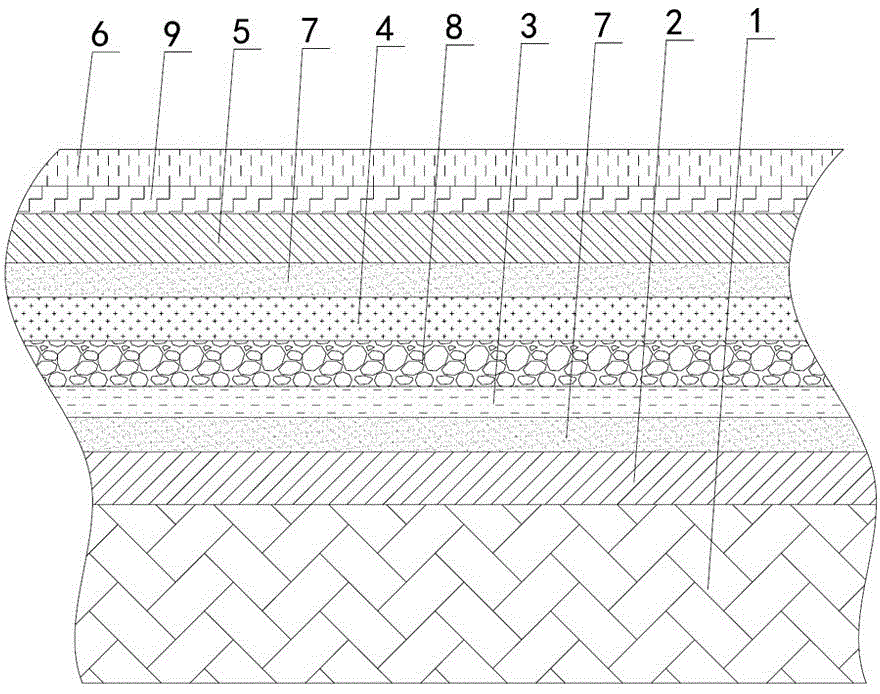

Antistatic type epoxy floor and manufacturing method thereof

InactiveCN103388394AWith pressureWear-resistantEpoxy resin coatingsElectrically-conductive paintsCarrying capacityPutty

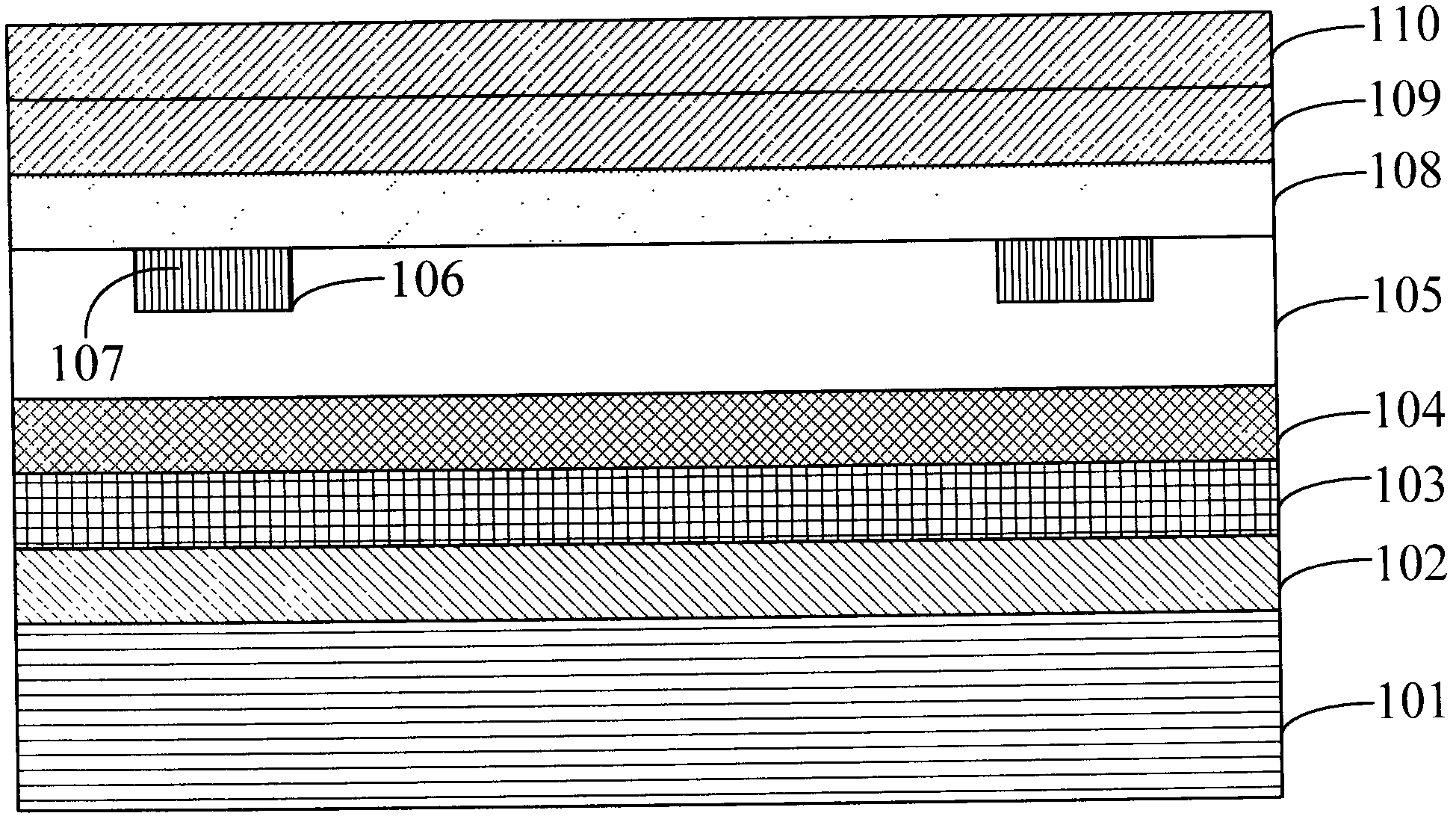

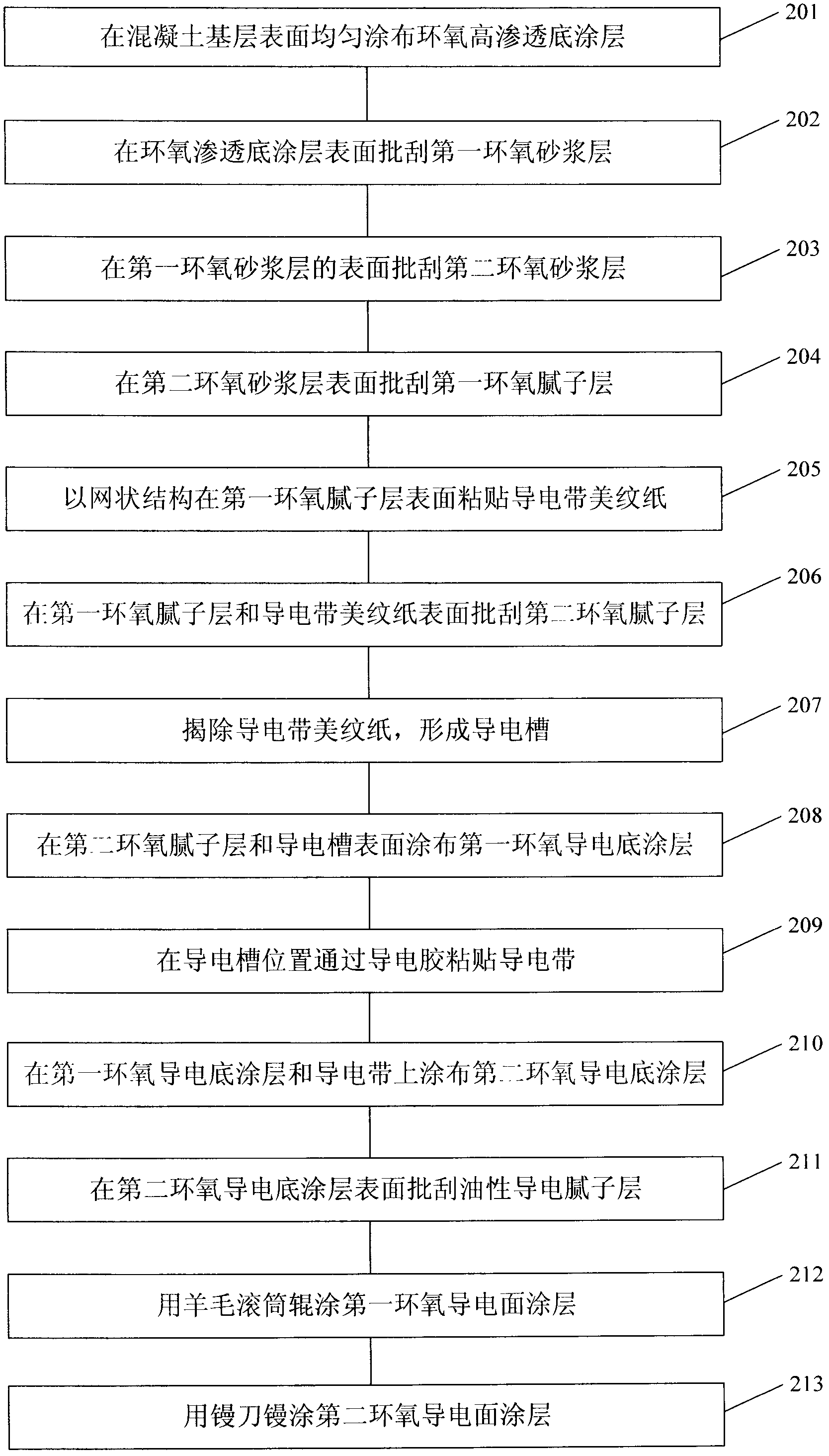

The invention discloses an antistatic type epoxy floor and a manufacturing method thereof. The antistatic type epoxy floor comprises a high-permeability epoxy bottom coating, a first epoxy mortar layer, a second epoxy mortar layer, an epoxy putty layer, a first epoxy conductive bottom coating, a conductive band, a second epoxy conductive bottom coating, an oily conductive putty layer, a first epoxy conductive face coating and a second epoxy conductive face coating. The antistatic type epoxy floor has the advantages of pressure resistance, abrasion resistance, strong adhesive force, stable conductive resistance value, large carrying capacity and the like. Even if the surface is abraded to a certain degree, the conductive band cannot be damaged, and the stability of the conductive system of the floor is ensured. Only the surface of the floor is coated, the floor can not be repaired to realize recycle. The production use and maintenance cost is reduced.

Owner:YANTAI DAJIE DIPING ENG CO LTD

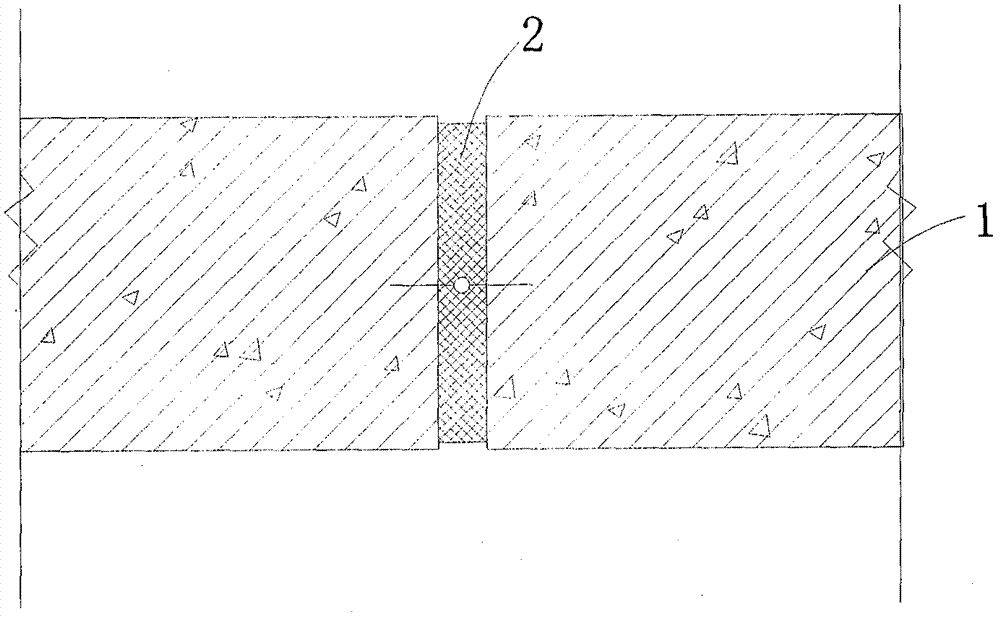

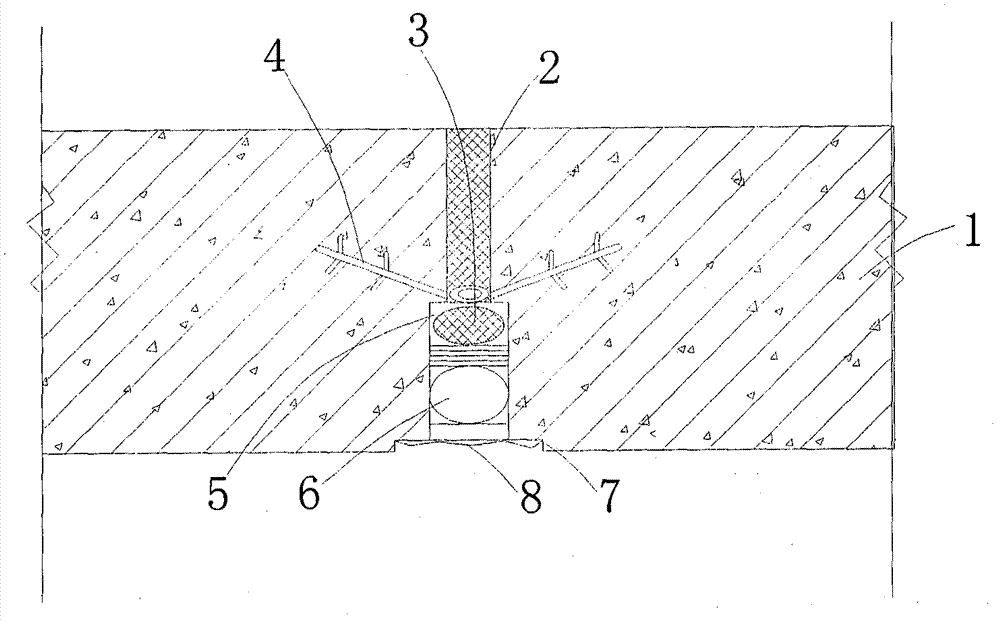

Deformation joint processing structure of top plate

InactiveCN107975153AReduce adverse effectsImprove waterproof performanceBuilding insulationsEngineeringEarth surface

The invention relates to a deformation joint processing structure of a top plate. The deformation joint processing structure comprises a concrete structure layer equipped with a deformation joint. Oneend of the deformation joint is provided with a joint grouting cavity which is chiseled. The joint grouting cavity is internally poured with a non-solidified liquid rubber water-stop belt. Two sidesof the deformation joint are connected with grouting slot drawing pipe cavities. The joint grouting cavity is sealed by an anti-seepage product and epoxy putty. The deformation joint processing structure has good water-proof performance. Additionally, structure performance is excellent. The protection effect is very evident and capable of effectively preventing rainwater from seeping into the deformation joint. The anti-deformation capability is high. Therefore, adverse influence of the earth surface upon the deformation joint is effectively reduced.

Owner:俞岳峰

Terrace construction technique

The invention discloses a terrace construction technique. The technique comprises base surface processing, mending, scrapping base coat, scrapping floating coat slurry, and scrapping putty layer and finish. The invention further discloses ingredients of epoxy putty and the floating coat slurry. According to the technique, the floating coat slurry has the advantages of good uniformity, high pressure resisting strength after being cured, better visual effect and long service life.

Owner:江苏恒建元建筑工程技术有限公司

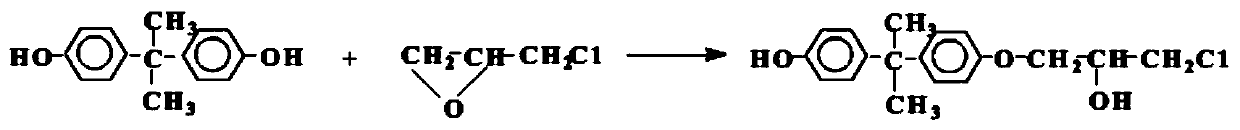

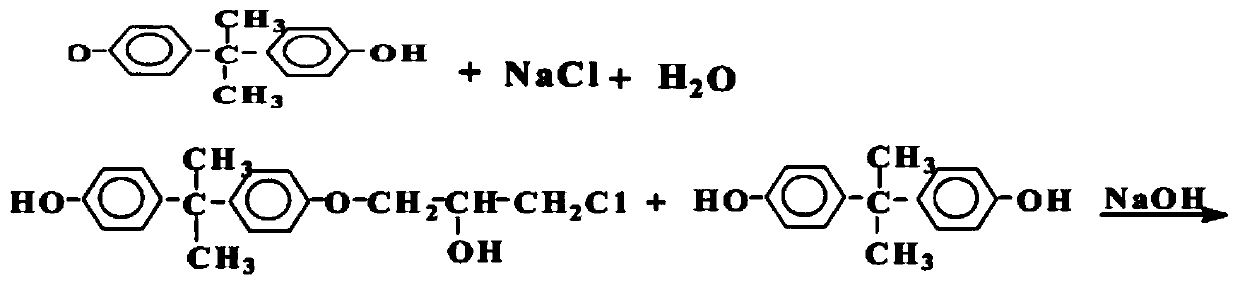

High-strength epoxy resin aqueous phase curing agent as well as preparation method and application thereof

The invention discloses a high-strength epoxy resin aqueous phase curing agent as well as a preparation method and an application thereof. The curing agent is obtained by mixing 70-95 wt% of phenolicamide, 5-30 wt% of diluent, 0-10 wt% of hexatomic ring containing amide amine and 0-5 wt% of phenolic tertiary amine at the room temperature of 20 DEG C to 100 DEG C, obtaining 100 parts by mass of anactive organic matter, adding 0-150 parts by mass of micrometer or nanometer pigment filler, mixing evenly, and cooling to the room temperature. The curing agent, a liquid epoxy resin or an epoxy resin, and a micrometer or nanometer inorganic filler compound are proportionally mixed, achieves excellent mechanical properties under the humid and underwater environment, and can be used to prepare awaterproof high pressure mould, a sealant, epoxy putty, a surfactant, an interface adhesive and an anticorrosive paint.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +4

Construction method for antistatic epoxy floor level

InactiveCN104387918AImprove conductivityLow costCovering/liningsEpoxy resin coatingsSurface finishBroom

The invention discloses a construction method for an antistatic epoxy floor level. The method comprises the following steps: (1) grinding, namely adding water, grinding and adjusting the flatness of a concrete foundation; (2) detecting, namely performing on-the-spot investigation and base detection on the concrete base; (3) cleaning, namely cleaning the surface of the concrete base by using a broom; (4) performing surface treatment, namely removing cement laitance, a curing agent and a demolding agent; (5) repairing; (6) applying base coat, namely performing blade coating on epoxy primer by using a sawtooth rubber scraper, and performing surface finishing by using an undercoat drum; (7) applying primary floating coat, namely performing blade coating on antistatic epoxy mortar by using the sawtooth rubber scraper and an electric trowelling machine; (8) applying secondary floating coat, namely performing blade coating on antistatic epoxy putty by using a flat rubber scraper; (9) performing batch coating, namely rolling antistatic conductive epoxy primer by using the undercoat drum; (10) applying topcoat, namely performing blade coating on epoxy top-coat by using the sawtooth rubber scraper, and performing surface finishing by using the undercoat drum; and (11) maintaining. The antistatic epoxy floor level disclosed by the invention is excellent in antistatic properties, easy and convenient to maintain and low in cost.

Owner:ZHONGSHA CONSTR GROUP

Water-based epoxy putty

InactiveCN102337050AHigh bond energyLower surface energyFilling pastesWater basedMechanical property

The invention discloses water-based epoxy putty, relating to the technical field of coating production in the chemical industrial field. The water-based epoxy putty is prepared by mixing a component A, a component B and a component C, wherein the component A is a high-performance modified water-based epoxy emulsion; the component B is a mixed modified amine curing agent; the component C is mixed dry powder consisting of cement and quartz powder; and the weight ratio of the component A to the component B to the component C is (15-18):1:(15-18). The aging resistance, heat resistance, oil resistance, water resistance, precipitation resistance, medium resistance and electrical performance of the putty are enhanced; and the water-based epoxy putty has high physical and mechanical properties and high chemical resistance, and can be applied to the protection of a cement concrete fundamental plane.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

Water-based terrace phase-change epoxy putty coating and preparation method thereof

InactiveCN110964408ARealize the control effectAvoid bulgingEpoxy resin coatingsFiberCrack resistance

The invention discloses a water-based terrace phase-change epoxy putty coating and a preparation method thereof. The water-based terrace phase-change epoxy putty coating is formed by compounding a component A, a component B and a component C; the component A comprises, by weight, 30-50 parts of a waterborne epoxy curing agent, 30-40 parts of deionized water, 0.1-0.3 part of a defoaming agent, 0.1-0.4 part of a dispersing agent, 0.2-0.6 part of a base material wetting agent, 0.8-1.2 parts of a leveling agent and 10-20 parts of a microcapsule phase change material; the component B comprises, byweight, 85-95 parts of waterborne epoxy resin and 5-15 parts of aliphatic glycidyl ether, and the aliphatic glycidyl ether meets the following requirements: (1) the viscosity at 40 DEG C is 3-7 mpa.s,and (2) the epoxy equivalent is 290-310 g / eq; and the component C comprises, by weight, 80-100 parts of 200-mesh quartz powder and 1.5-4.5 parts of a composite fiber. The addition of the microcapsulephase-change material and the composite fiber greatly improves the cracking resistance and adhesive force of the putty coating.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Aqueous epoxy putty

The invention discloses aqueous epoxy putty. The aqueous epoxy putty comprises, by mass, 5-10% of water, 35-40% of aqueous epoxy resin, 25-30% of calcined kaolin, 10-15% of heavy calcium carbonate, 10% of titanium dioxide, 2% of propylene glycol, 1% of an antifoaming agent, 1-1.5% of a film forming agent and a proper amount of a thickening agent. The epoxy emulsion and a jade surfactant are mixed to form a stable dilution system so that water resistance and chemical resistance of the aqueous epoxy putty are improved. The aqueous epoxy putty has low volatility, is environmentally friendly and does not produce pollution.

Owner:赵燕

Antistatic epoxy resin floor and manufacturing method

InactiveCN103388394BWith pressureWear-resistantEpoxy resin coatingsElectrically-conductive paintsPuttyEpoxy putty

The invention discloses an antistatic type epoxy floor and a manufacturing method thereof. The antistatic type epoxy floor comprises a high-permeability epoxy bottom coating, a first epoxy mortar layer, a second epoxy mortar layer, an epoxy putty layer, a first epoxy conductive bottom coating, a conductive band, a second epoxy conductive bottom coating, an oily conductive putty layer, a first epoxy conductive face coating and a second epoxy conductive face coating. The antistatic type epoxy floor has the advantages of pressure resistance, abrasion resistance, strong adhesive force, stable conductive resistance value, large carrying capacity and the like. Even if the surface is abraded to a certain degree, the conductive band cannot be damaged, and the stability of the conductive system of the floor is ensured. Only the surface of the floor is coated, the floor can not be repaired to realize recycle. The production use and maintenance cost is reduced.

Owner:YANTAI DAJIE DIPING ENG CO LTD

Aqueous epoxy putty, and preparation and use method thereof

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

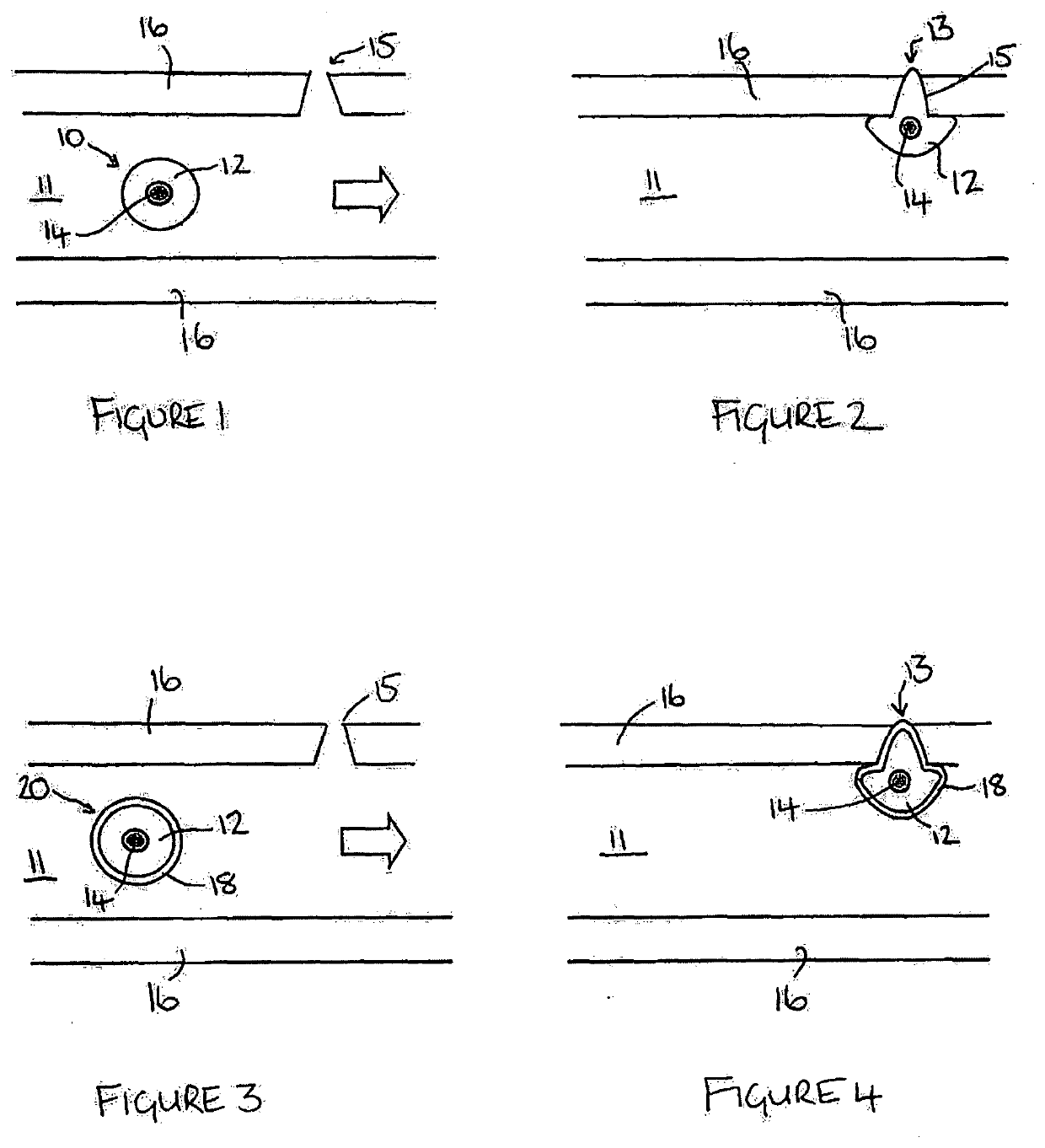

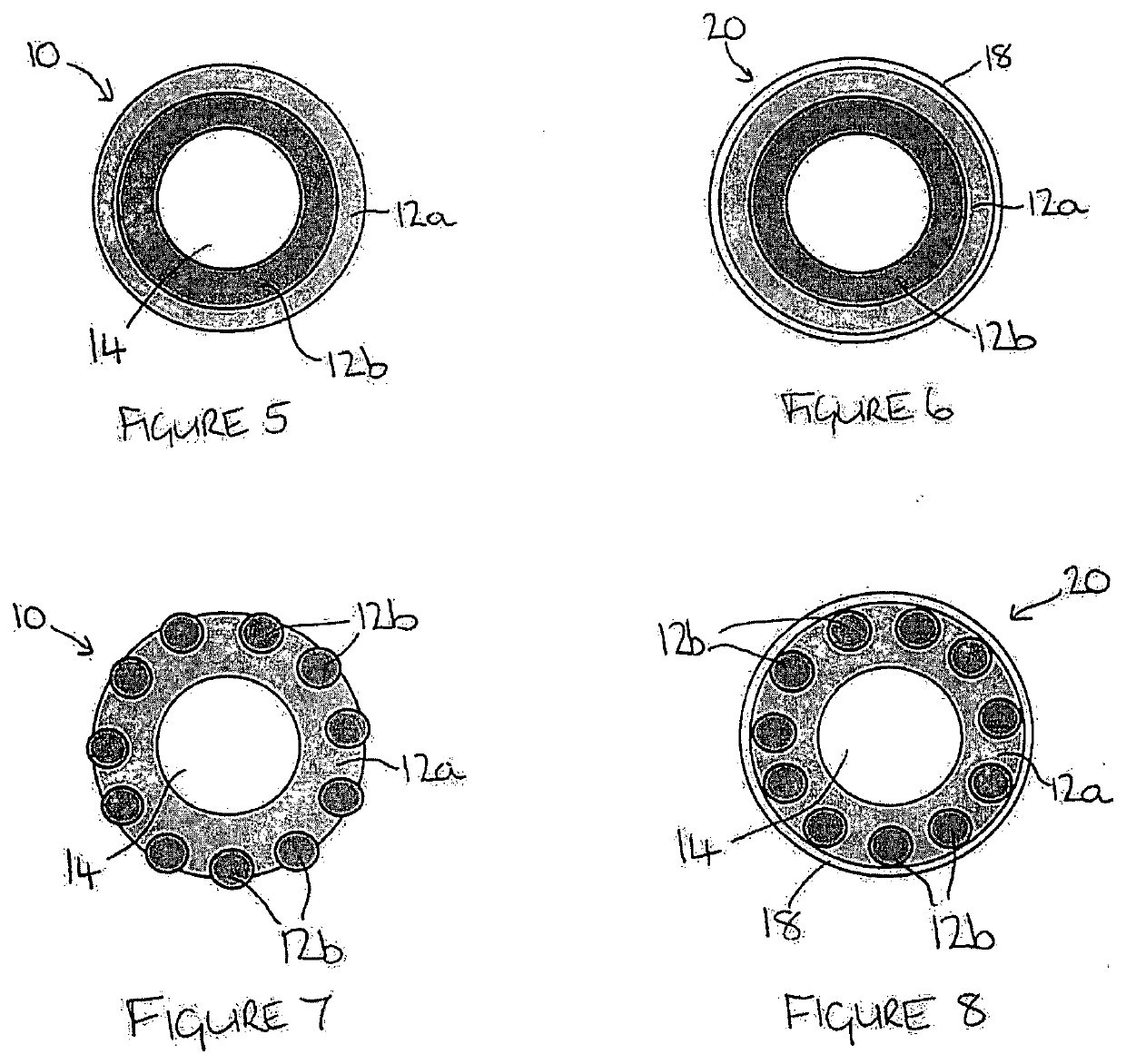

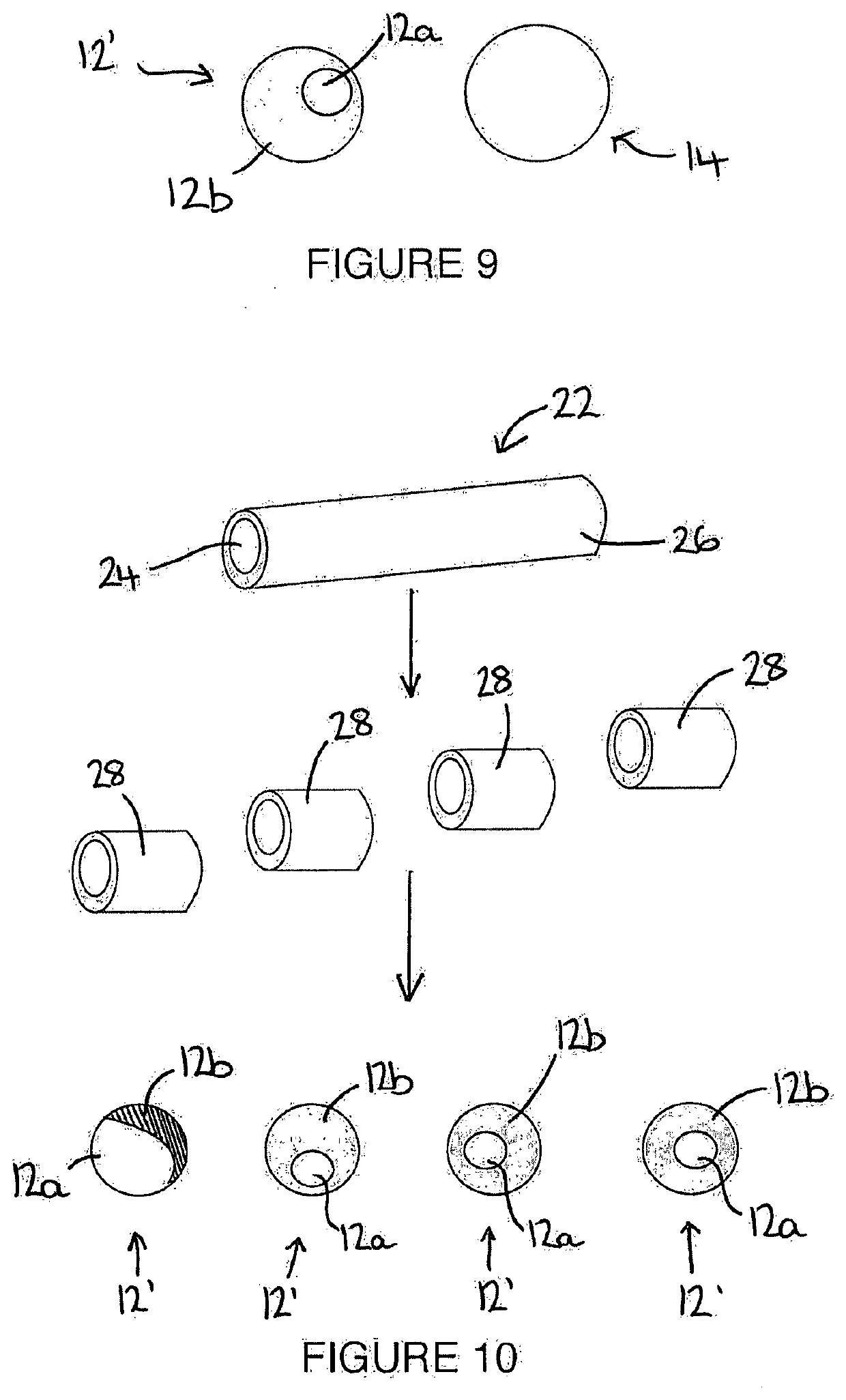

Sealing element

A sealing element (10) for use in a fluid-carrying pipeline (16) comprising a substantially central core (14) surrounded by a coating (12). The outer coating (12) is adapted to perform a partial extrusion through an opening (15) in a pipeline wall (16) to seal the opening (15). The density of the sealing element (10) is substantially the same as the density of the fluid (11) in the pipeline (16). The coating (12) comprises a two-part epoxy putty, and the core (14) is formed from a deformable material. A method of making the sealing element is also disclosed.

Owner:QINOV8 UK LTD

Method of repairing phosphoric acid equipment corroded

InactiveCN103921055AAvoid safety hazardsCompleteChemical/physical/physico-chemical processesConductive polymerPhosphoric acid

The invention discloses a method of repairing phosphoric acid equipment corroded and belongs to the technical field of corrosion and protection. The method includes the steps of 1, treating the base surface, namely cleaning the corroded base surface of a phosphoric acid device, cleaning with alkali, and wiping the base surface with detergent; 2, repairing defects, namely painting the base surface with epoxy primer, and repairing with epoxy putty or epoxy mortar; 3, performing conduction leveling, namely, after repairing the defects of a base, painting a conductive layer; 4, performing anti-corrosion isolating, namely, roughening and leveling the conductive layer to impart certain roughness to the conductive layer, cleaning the conductive layer, painting with primer, cement and a glued board, and checking the phosphoric acid device required. The method has the advantages that after the treatment, the corroded phosphoric acid device is repaired and the service life of the phosphoric acid device is prolonged.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

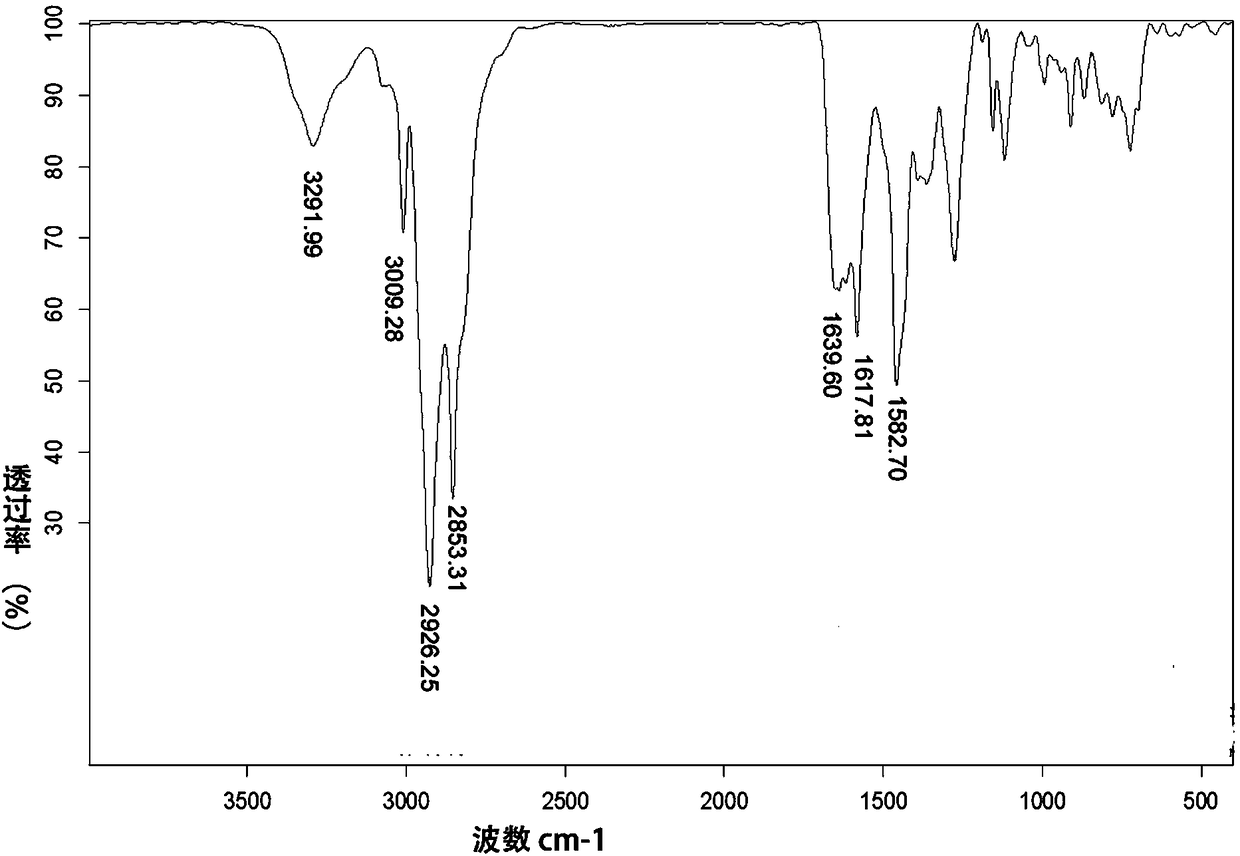

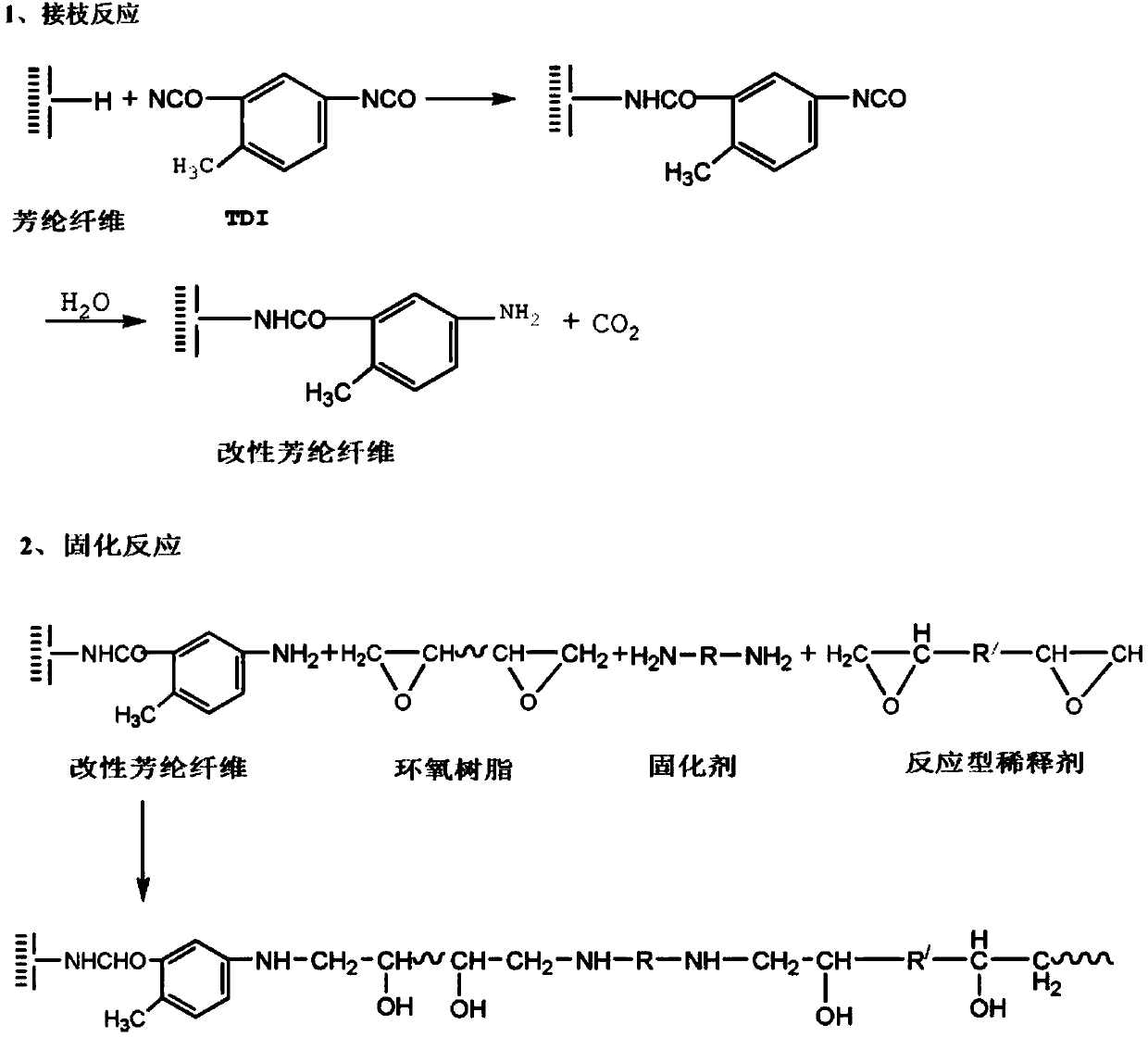

Flame-retardant epoxy putty, and preparation method and application thereof

ActiveCN110804335AIncrease crosslink densityImprove mechanical propertiesFilling pastesPolymer scienceToluene diisocyanate

The invention discloses a flame-retardant epoxy putty, and a preparation method and an application thereof. The flame-retardant epoxy putty is prepared from 20-60 wt% of epoxy resin, 1-10 wt% of modified aramid chopped fibers, 5-30 wt% of an epoxy curing agent, 1-20 wt% of a flame retardant, 5-20 wt% of an active diluents, 3-40 wt% of a filler, 0.5-5 wt% of an additive and 0-3 wt% of a pigment; and the modified aramid chopped fibers are obtained by modifying aramid chopped fibers with toluene diisocynate. The epoxy putty has excellent mechanical properties, heat resistance, flame retardancy and salt spray resistance, can improve the comprehensive properties of filled plates, has a wide application range, and can be used for filling splicing, inserts, edges and to-be-processed parts of honeycomb sandwich plates.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

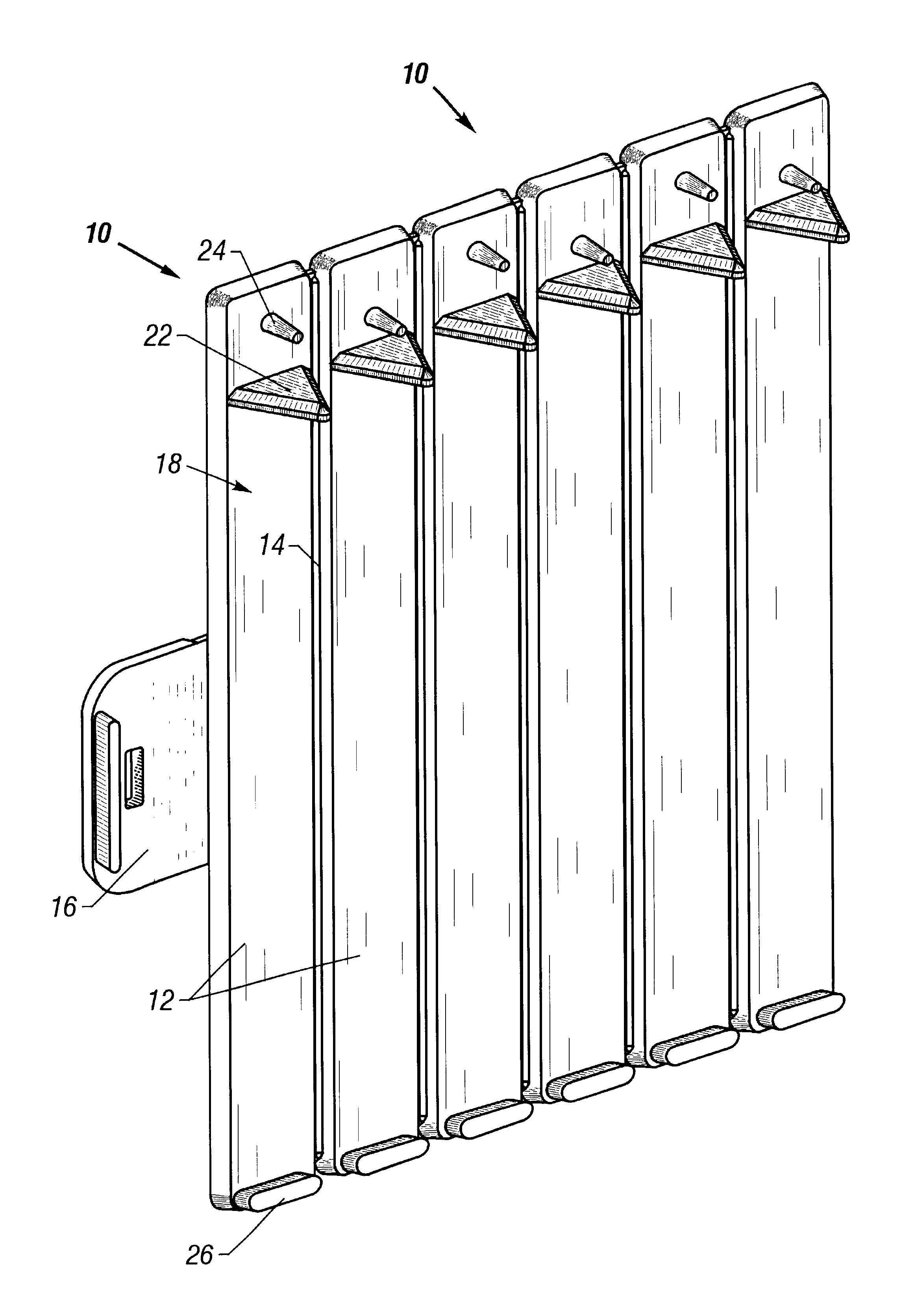

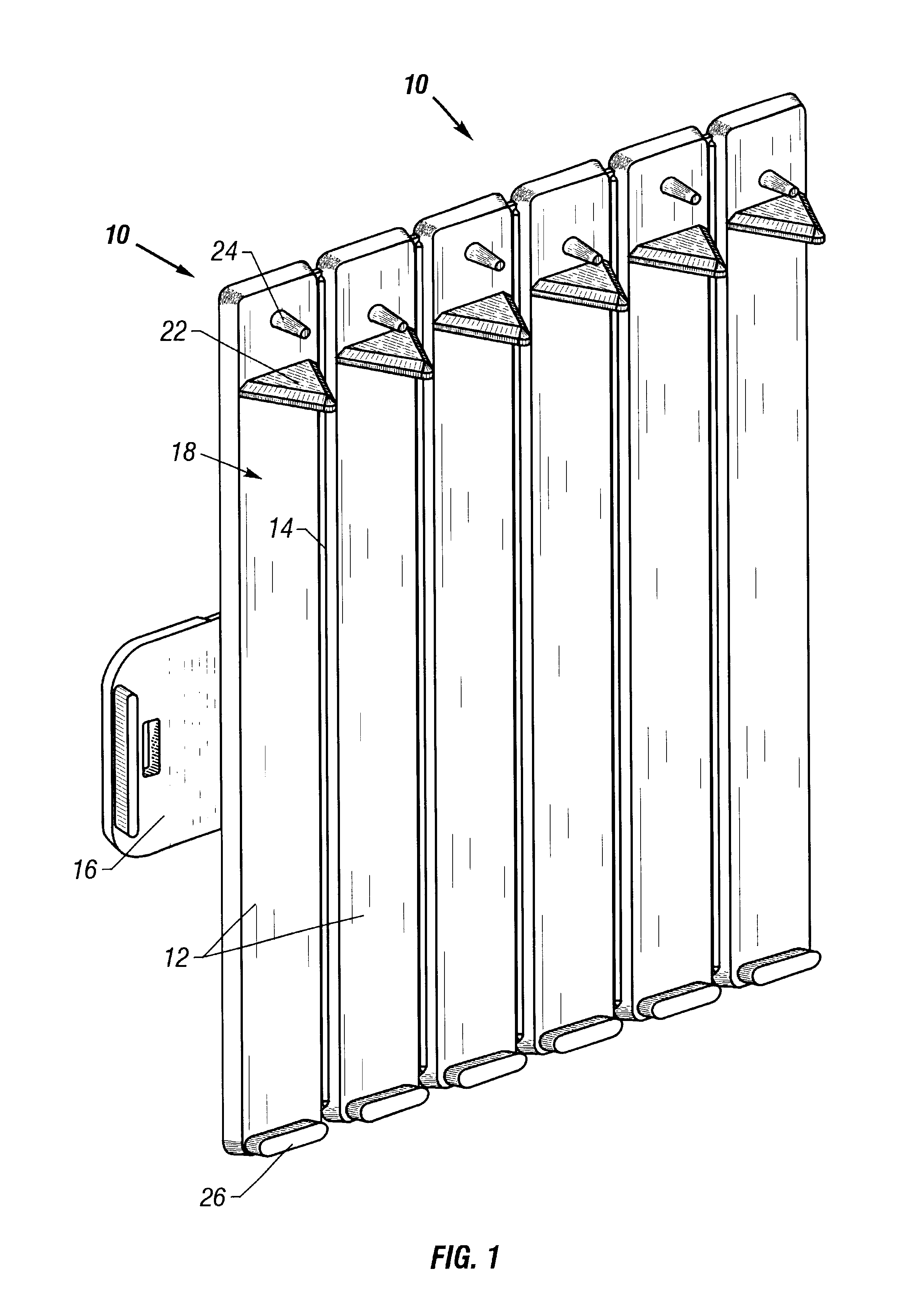

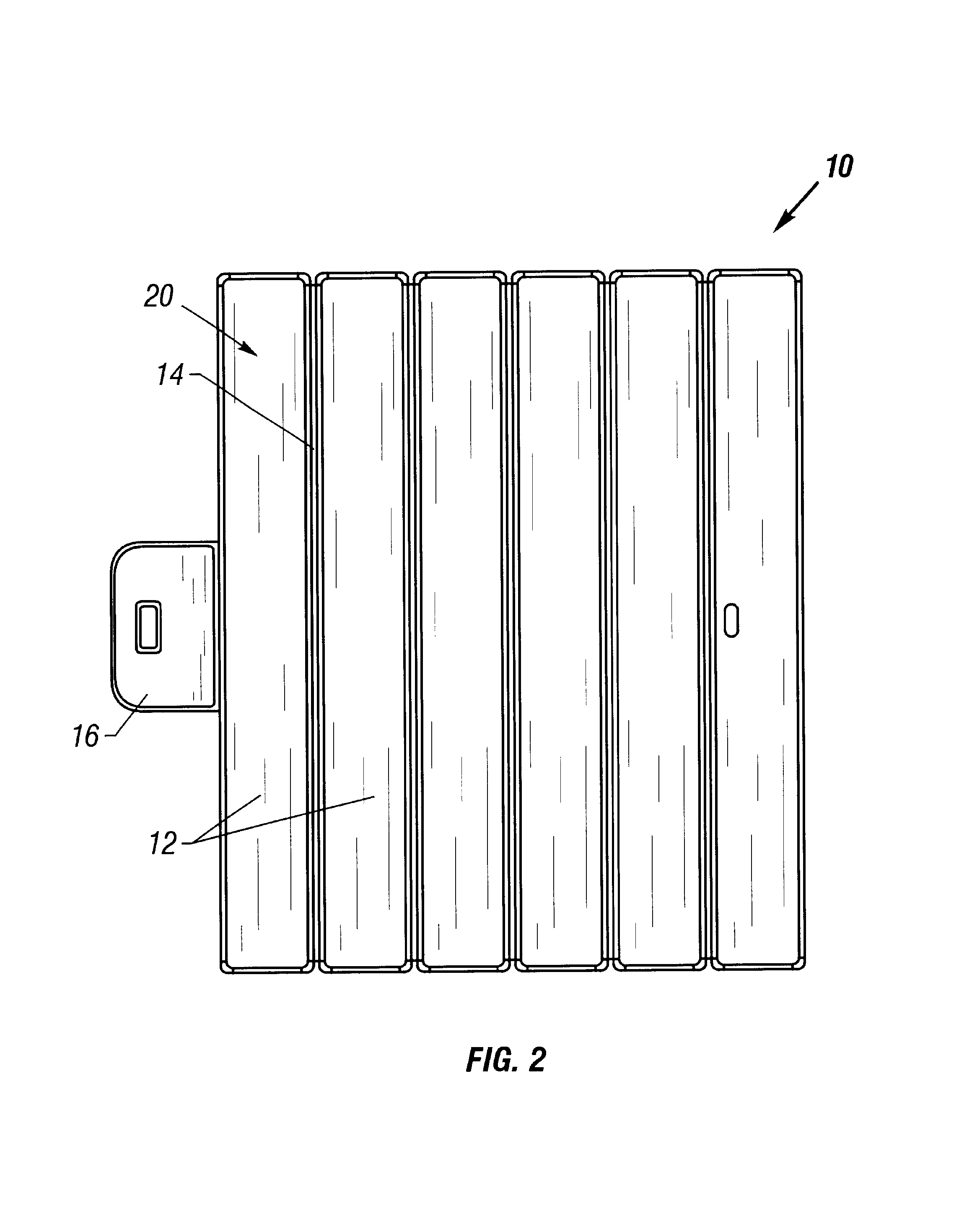

Epoxy putty stick holder

An epoxy putty stick holder which has a plurality of wall portions connected to each other by a flexible joint, able to wrap around and store an epoxy putty stick. The inner surfaces of the wall portions have a tooth portion which is used to cut-off a portion of the epoxy putty stick, and a peg portion that puncture the cut-off portion of the epoxy putty stick to initiate the chemical reaction in a two-port epoxy stick. A lip portion is also located on the inner surface of the wall portions to hold the unused portion of the epoxy stick within the holder between the lip portion and the tooth portion, when the holder is wrapped around the epoxy stick in the holder's closed position.

Owner:VAL A CHICAGO

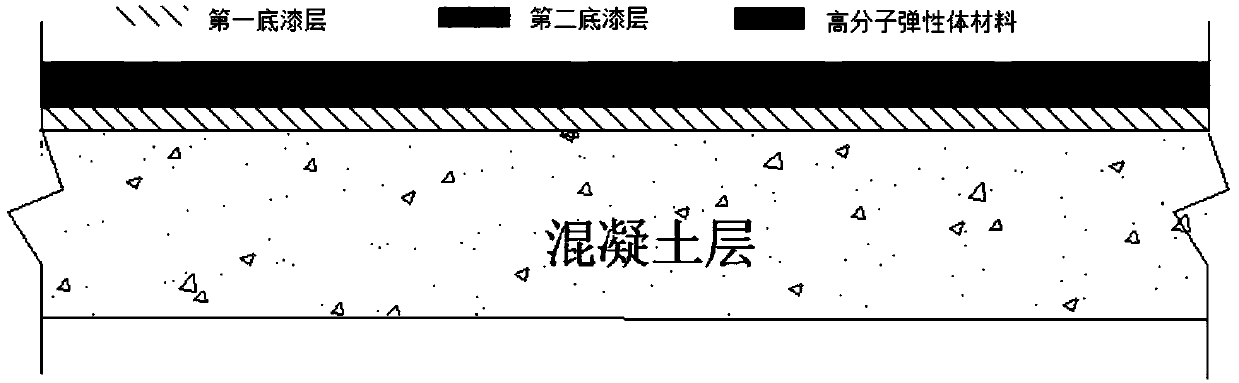

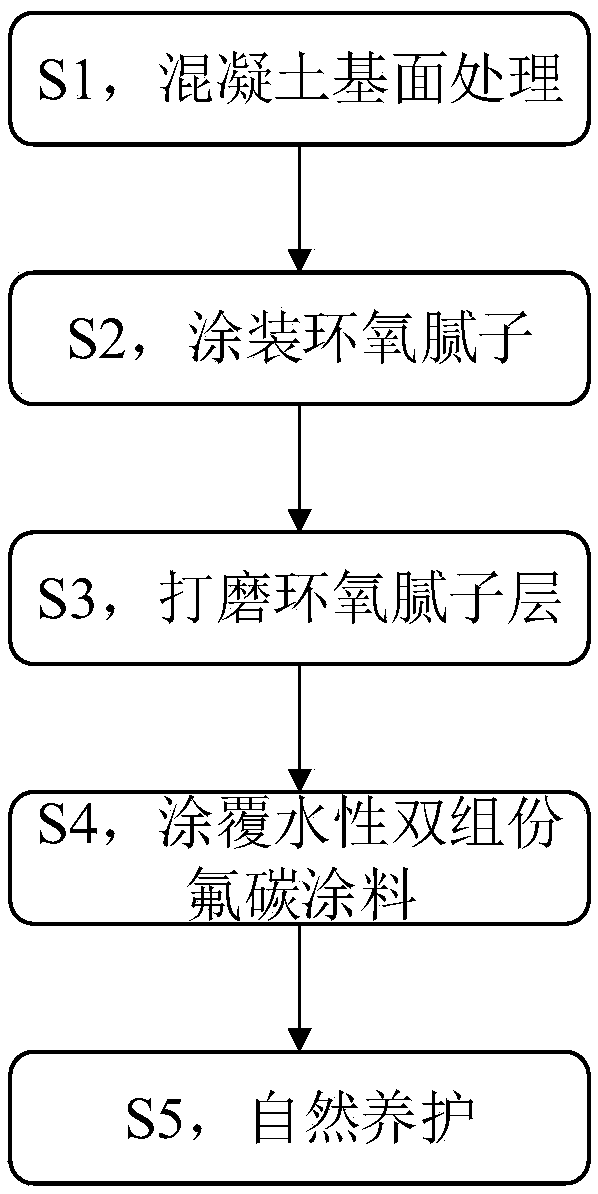

Isolating type coating and method for concrete repair and protection

InactiveCN109265197AImprove adhesionGuaranteed not to bubble or fall offAnti-corrosive paintsFilling pastesWater basedWeather resistance

The invention discloses an isolating type coating and method for concrete repair and protection. Epoxy putty is adopted, has good cohesive action with a concrete base material, and can be completely integrated with the concrete base material, so that a corrosive medium can be completely isolated, and the state where the coating does not foam and drop is guaranteed; the sealing effect is excellent,and the corrosion resistance is good, so that construction can be performed in a humid environment and a drying environment; surface coating water-based double-component fluorocarbon coating is usedfor bridge surface decoration and durability protection, and the formed coating has excellent adhesion, weather resistance, acid and alkaline resistance, and a self-cleaning effect, so that the concrete structure is free of maintenance for a long time. The isolating type coating and method for concrete repair and protection can repair a concrete base surface, and also can continuously isolate erosion, on concrete, of a corrosion factor, so that new and old concrete repair and protection problem is effectively solved, the safety, durability and decoration of the concrete structure are improved;and the coating is simple in system, convenient to construct, and environmentally friendly.

Owner:WUDA JUCHENG STRUCTURE CO LTD

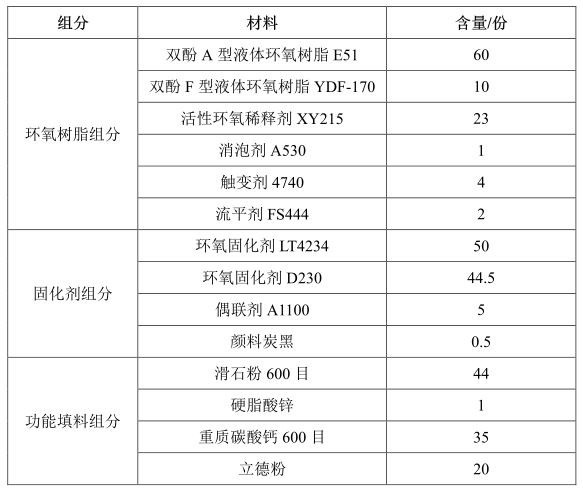

Solvent-free spraying type epoxy putty

InactiveCN112280361ALow viscosityImproved resistance to crystallizationFilling pastesPolymer scienceSolvent free

The invention discloses solvent-free spraying type epoxy putty. The solvent-free spraying type epoxy putty comprises an epoxy resin component, a curing agent component and a functional filler component, the epoxy putty has good bonding performance with concrete, shows excellent mechanical properties, does not contain volatile solvents, has nonvolatile matter content of 99% or more, is environmentally friendly, is beneficial to protection of the health of workers, can be used for spraying construction, has high construction efficiency, can adapt to construction of different base material shapesand adopts an airless spraying mode, and the maximum one-time forming thickness can reach 2mm; in addition, the epoxy putty product is in a three-component form, the filler is a single component, andno filler settlement risk exists in the storage period.

Owner:湖南固特邦土木技术发展有限公司

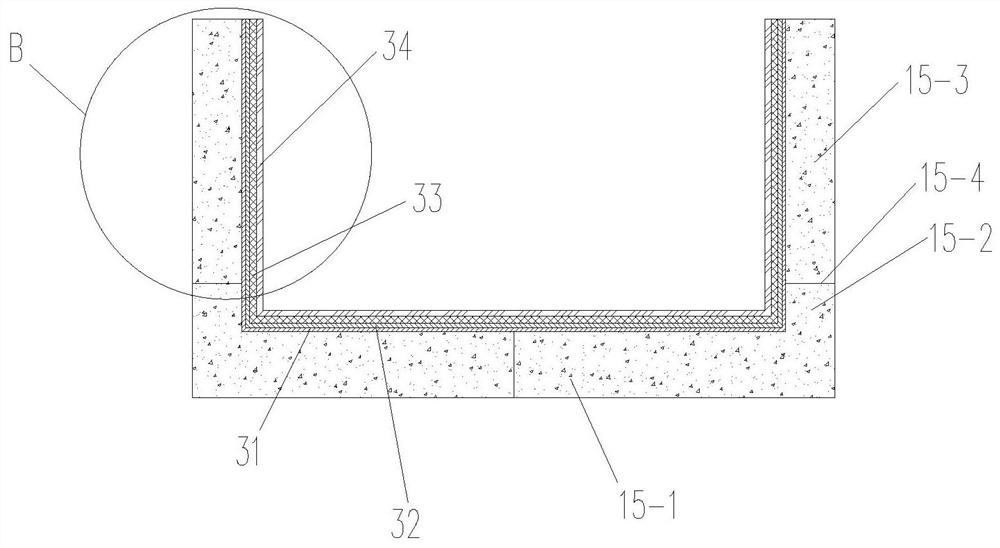

Anti-corrosion pool for solar cell panel production wastewater and construction method thereof

PendingCN111608260ASimple structureReasonable designCesspoolsGeneral water supply conservationGlass fiberWastewater

The invention discloses an anti-corrosion pool for solar cell panel production wastewater and a construction method thereof. The anti-corrosion pool includes a concrete base layer and a pool body, wherein the pool body comprises a pool baseplate and pool wall side walls; the concrete base layer extends out of the pool wall side walls; the pool wall side walls comprise guide walls integrated with the pool baseplate and pool walls arranged on the guide walls; construction joints are arranged on joints of the guide walls and the pool walls; the pool baseplate and the pool wall side walls are provided with a ground coat resin layer, a leveling resin layer, a glass fiber cloth layer and an epoxy putty layer from inside to outside in sequence; and the glass fiber cloth layer comprises multiple layers of glass fiber cloth. The construction method comprises the following steps of 1, pouring construction of the pool body; 2, grinding of the pool body; 3, water injection tests of the pool body;4, antiseptic treatment of the pool body; and 5, water injection test of the anti-corrosion pool. The anti-corrosion pool is reasonable in design, capable of adapting to the impact of the wastewater and avoiding the leakage of the anti-corrosion pool, and good in corrosion resistance.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS

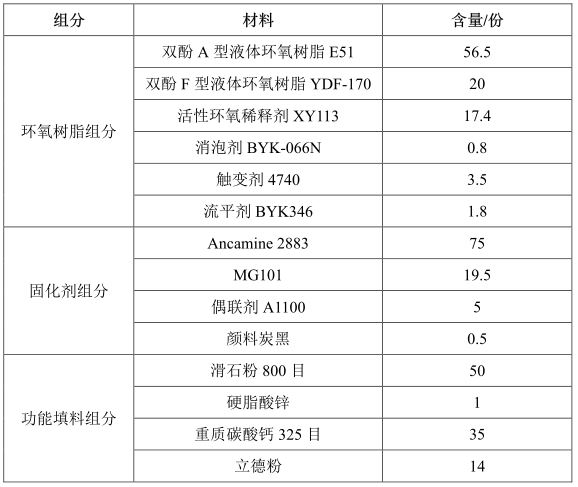

Anti-aging and anti-yellowing solvent-free epoxy putty and preparation method thereof

InactiveCN112759972AExcellent yellowing resistanceImprove appearance qualityFilling pastesEpoxy resin coatingsPolymer scienceSolvent free

The invention discloses anti-aging and anti-yellowing solvent-free epoxy putty and a preparation method thereof. The epoxy putty comprises a component A and a component B. The component A is composed of bisphenol A epoxy resin, a diluent, a silane coupling agent, a thixotropic agent, filler and titanium dioxide. The component B is prepared from a modified curing agent, a thixotropic agent, filler, carbon black and titanium dioxide; the component A and the component B are used according to the mass ratio of 2: (0.9-1.1), and the epoxy putty is obtained. The anti-aging and anti-yellowing solvent-free type epoxy putty is environment-friendly, non-toxic and low in VOC, has super-strong bonding strength with a concrete base material, is high in anti-aging performance, does not have a yellowing phenomenon under long-term ultraviolet irradiation, and can meet the corrosion prevention and decoration requirements of concrete infrastructures.

Owner:CARBON TECH CO LTD

Moisture-proof flooring structure and manufacturing method thereof

The invention relates to a moisture-proof flooring structure and a manufacturing method thereof. The moisture-proof flooring structure comprises a concrete surface layer, wherein the concrete surface layer is uniformly coated with an epoxy permeation primer layer, a glass fiber layer, a rough epoxy putty layer, a fine epoxy putty layer and an epoxy flooring finish paint layer sequentially; a moisture-proof coating I is applied between the epoxy permeation primer layer and the glass fiber layer, a moisture-proof coating II is applied between the rough epoxy putty layer and the fine epoxy putty layer, a nano porous ceramic granular layer is applied between the glass fiber layer and the rough epoxy putty layer, and an infrared coating is applied between the fine epoxy putty layer and the epoxy flooring finish paint layer. By means of the arranged moisture-proof coatings and the porous characteristic of porous ceramic, the water evaporation area can be greatly increased, heat can be converted into infrared rays through the design of the infrared coating, the infrared rays can easily permeate below the flooring structure, water evaporation is accelerated in an infrared heating manner, and a better moisture-proof effect can be realized.

Owner:龚郑春

Repairing process for aircraft skin surface defects

InactiveCN110877006AGood restorativeSimple construction processPretreated surfacesSpecial surfacesGlass fiberMechanical engineering

The invention provides a repairing process for aircraft skin surface defects. The process comprises the following steps: (1) surface treatment of parts; (2) epoxy putty preparation; (3) putty coating:the prepared epoxy putty is evenly brushed or scraped to the cleaned to-be-repaired part of metal parts through a banister brush or a scraper; (4) curing: the metal parts coated with the epoxy puttyis cured at room temperature or by heating; and (5) shape modification: after the putty is cured, the repaired part of the parts is polished. The repairing process for aircraft skin surface defects can well solve the surface defect problem of aluminum alloy, glass fiber reinforced plastic and other substrates, is simple and convenient to operate, can effectively avoid the problems of reworking, scrapping and the like of parts, reduces the production cost, shortens the delivery period, improves the product quality, and is suitable for popularization and application.

Owner:AVIC GUIZHOU AIRPLANE

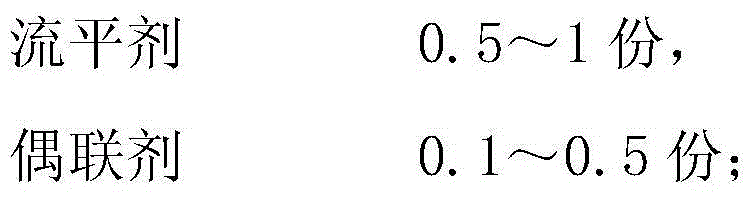

Water-based epoxy putty coating specially used for floors, and preparation method thereof

The invention discloses a water-based epoxy putty coating specially used for floors, and a preparation method thereof, and belongs to the field of functional environmentally-friendly coatings. The water-based epoxy putty coating specially used for floors comprises: a component A comprising, by mass, 30-50 parts of an epoxy curing agent, 30-40 parts of deionized water, 0.1-0.3 part of an antifoaming agent, 0.1-0.4 part of a dispersant, 0.2-0.6 part of a substrate wetting agent and 0.1-0.5 part of a leveling agent; a component B comprising, by mass, 85-95 parts of an epoxy resin and 5-15 parts of aliphatic glycidyl ether; and a component C comprising, by mass, 80-100 parts of 200 mesh quartz powder, 0.5-1.5 parts of wood fibers and 1-3 parts of PP fibers. The product of the invention has theadvantages of low VOC content, good slip resistance, strong adhesion of the formed film, good interlayer adhesion, excellent water and solvent resistance, and solving of the cracking problem during thick application of existing water-based epoxy resin intermediate coats.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

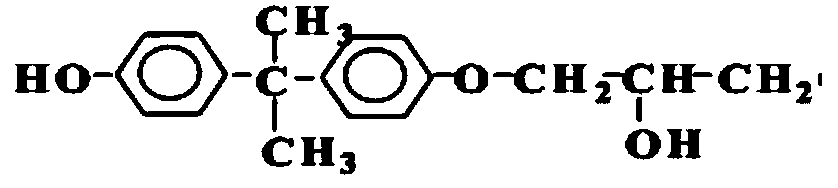

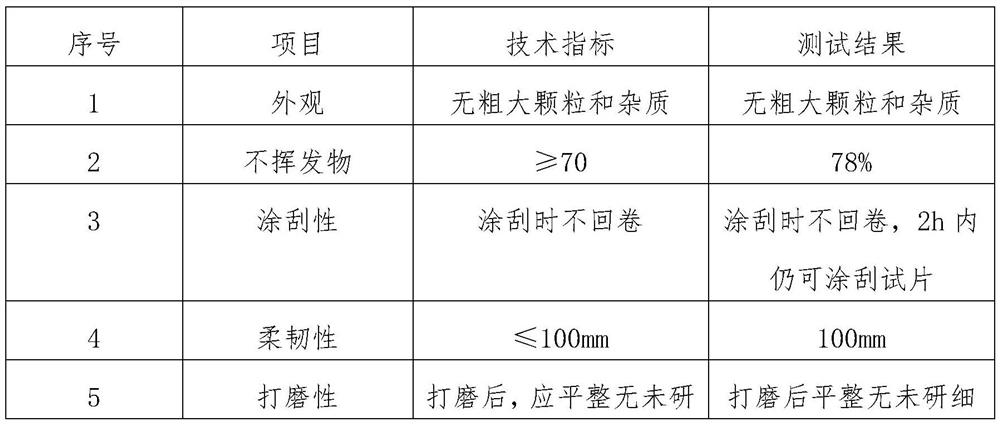

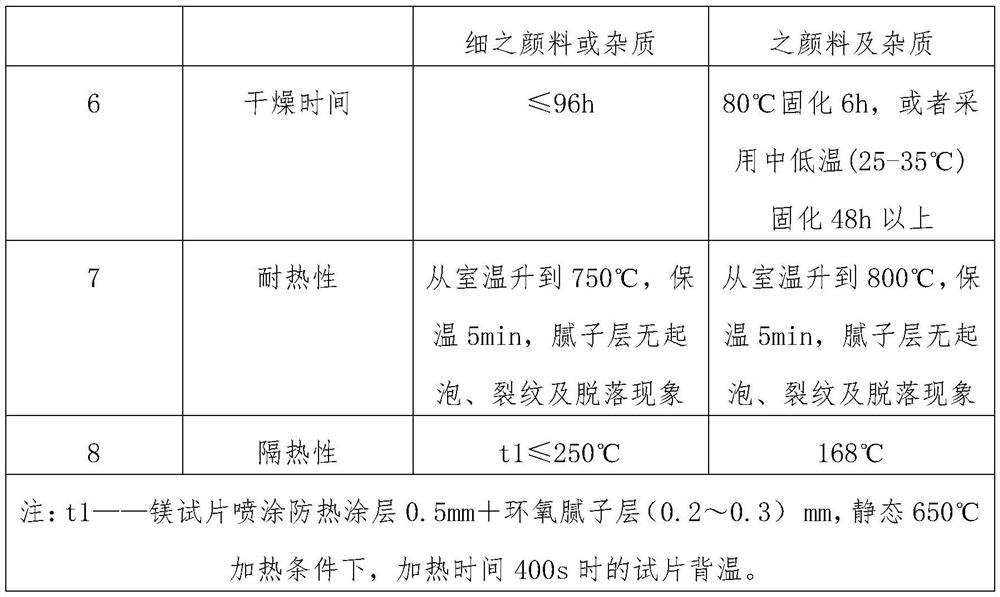

High-temperature-resistant epoxy putty and preparation method thereof

InactiveCN112159603AGuaranteed scratchabilityGuaranteed grinding effectFireproof paintsFilling pastesPolymer sciencePutty

The invention belongs to the technical field of aerospace heat-proof coating repairing, and particularly relates to a high-temperature-resistant epoxy putty and a preparation method thereof. Organic silicon resin and epoxy resin are used for modification treatment, and nitrided nano ceramic micro powder is used as a filler, so that the comprehensive properties such as scrape resistance, sanding property, heat resistance, heat insulation property, environment adaptability, and the like of the putty are guaranteed, the density of a cabin heat-proof coating is effectively improved, and the problem of repairing of a certain type of bomb heat-proof coating is solved.

Owner:贵州航天风华精密设备有限公司

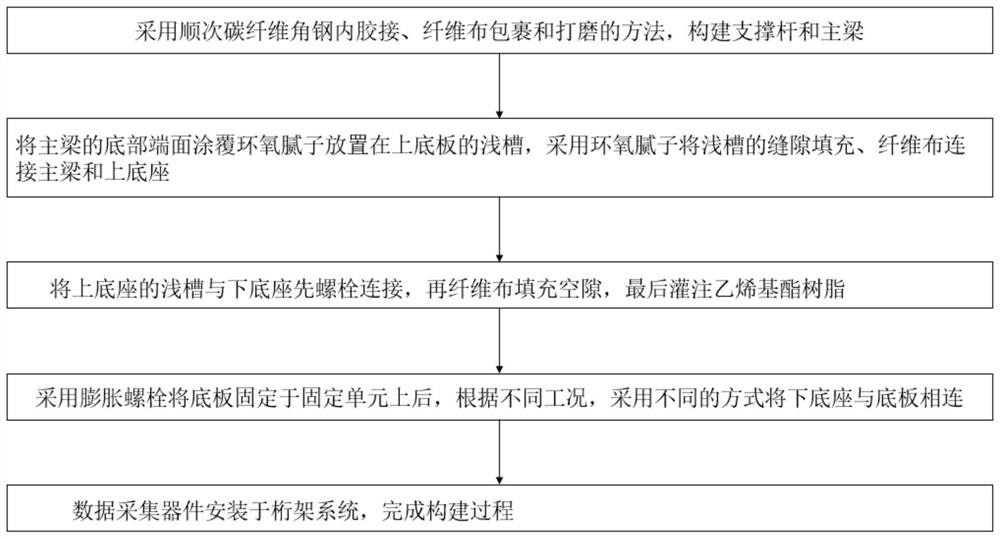

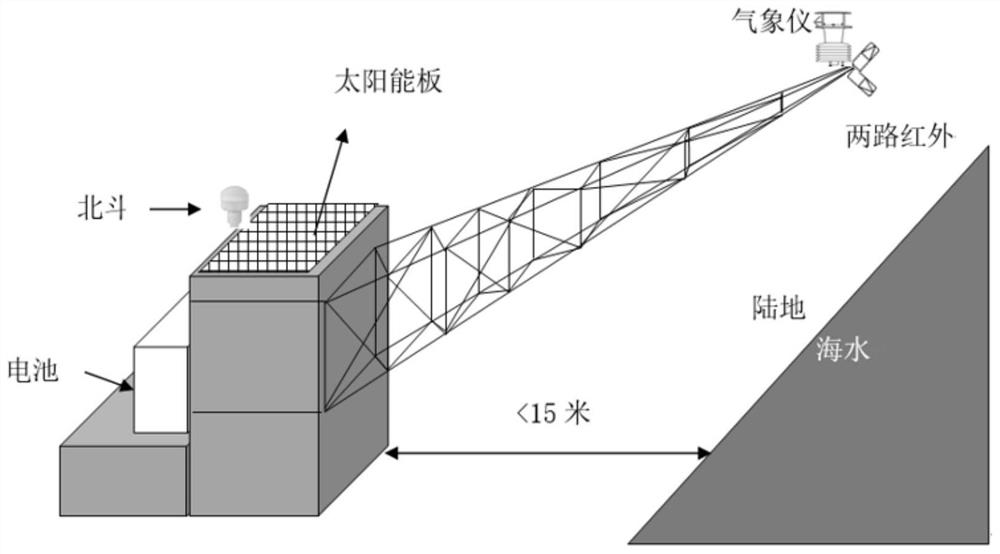

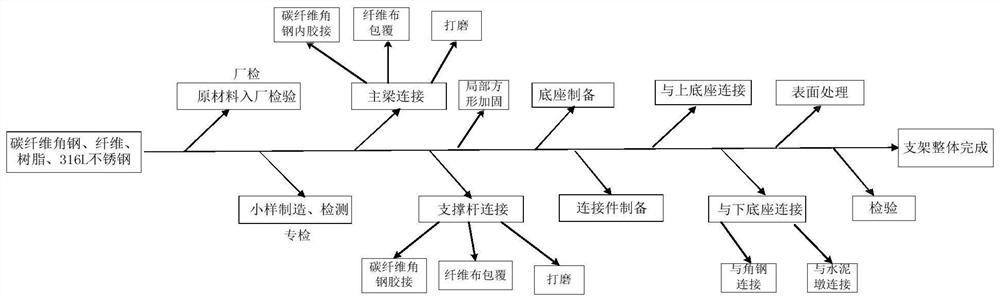

Construction method of truss type island marine meteorological environment data acquisition device

The invention discloses a construction method of a truss type island marine meteorological environment data acquisition device, and belongs to the field of marine meteorological data acquisition, and the method specifically comprises the following steps: completing the construction of a supporting rod and a main beam by adopting a method of sequentially carrying out carbon fiber angle steel inner cementing, fiber cloth wrapping and polishing; after the bottom end face of the main beam is coated with epoxy putty and placed in the shallow groove of the upper bottom plate, gaps of the shallow groove are filled with the epoxy putty in sequence, and the main beam and the upper base are connected through fiber cloth; after the shallow grooves of the upper base are connected with the lower base through bolts, gaps are filled with fiber cloth, and vinyl ester resin is poured; after the bottom plate is fixed on the fixing unit through expansion bolts, the lower base is connected with the bottom plate in different modes according to different working conditions of the island marine meteorological environment data acquisition device; and installing the data acquisition device on the truss system to complete the construction process. The problem that existing marine hydrological detection equipment is inconvenient to install, replace and maintain can be solved.

Owner:NAVAL UNIV OF ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com