Deformation joint processing structure of top plate

A deformation joint and roof technology, which is applied in building components, building structures, building insulation materials, etc., to reduce adverse effects, prevent rainwater from infiltrating into deformation joints, and achieve good structural performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

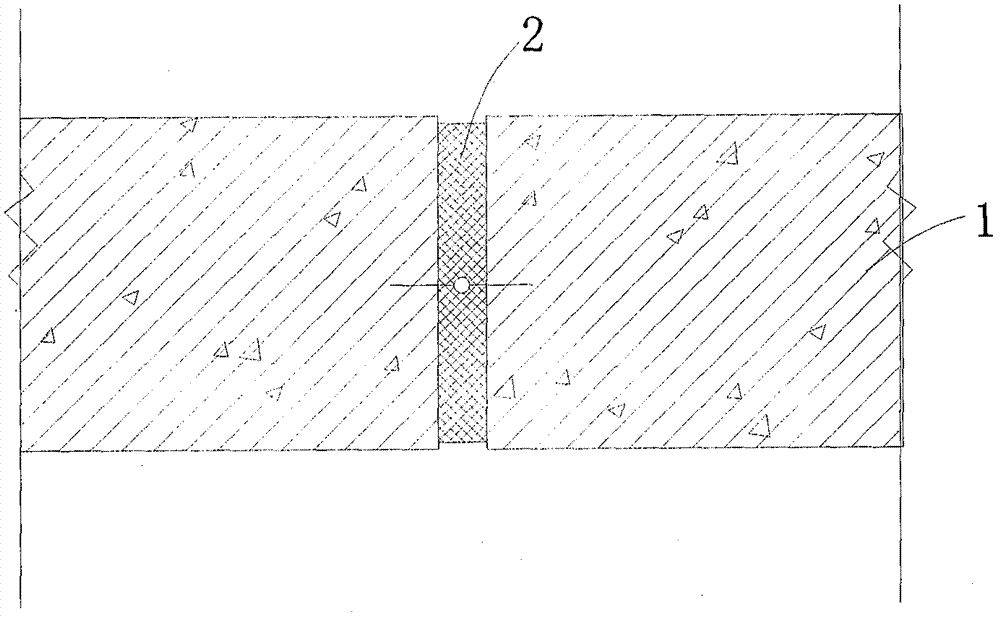

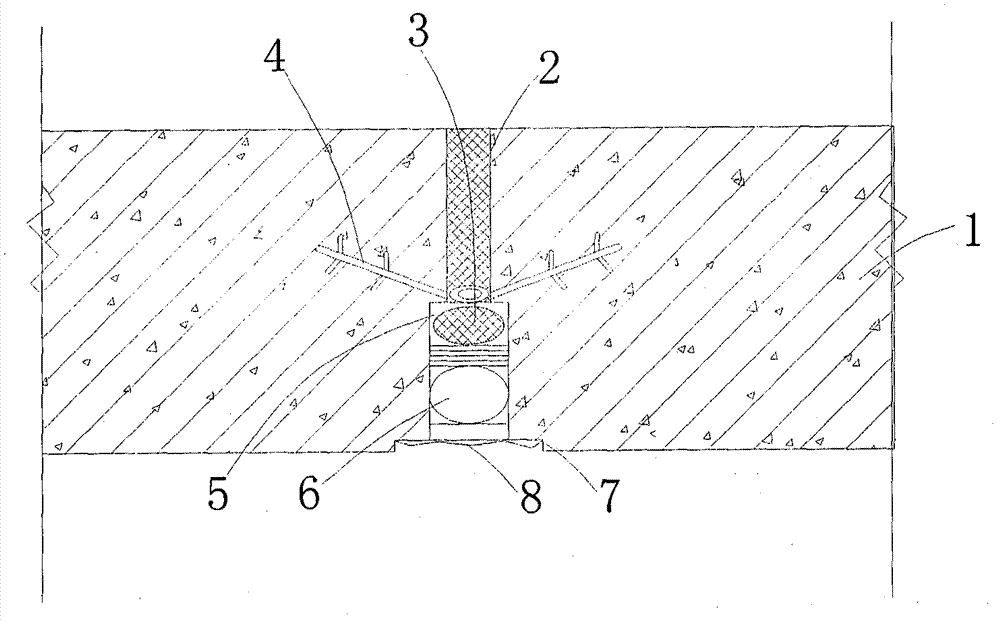

[0012] Such as figure 1 , figure 2 As shown, a concrete structure deformation joint treatment includes a concrete structure layer 1, a deformation joint 2 is arranged on the concrete structure layer 1, a gap grouting cavity 4 that is chiseled wide is provided at one end of the deformation joint 2, two ends of the deformation joint 2 The side connection grouting tank pumping pipe cavity 5, the gap grouting cavity 5 is sealed by leaking treasure and epoxy putty, and the non-curing liquid rubber glue waterstop 3 is poured into the gap grouting cavity 5.

[0013] Further, in the concrete structure layer 1, the pre-embedded grouting pipe 6 is located in the middle of the deformation joint 2, and the two sides of the deformation joint 2 have a made concrete shoulder shape 7, and the deformation joint 2 is located at the concrete shoulder shape 7. A W-shaped The stainless steel plate 8 and the W-shaped stainless steel plate 8 are sealed by polyurethane or thixotropic polysulfide se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com