Epoxy ash for high performance megawatt wind turbine blades and preparation method thereof

A wind power blade and megawatt-level technology, which is applied in the field of epoxy ash for wind power blades and its preparation, can solve problems such as poor light resistance, and achieve the effects of excellent alkali resistance, low shrinkage, and small internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

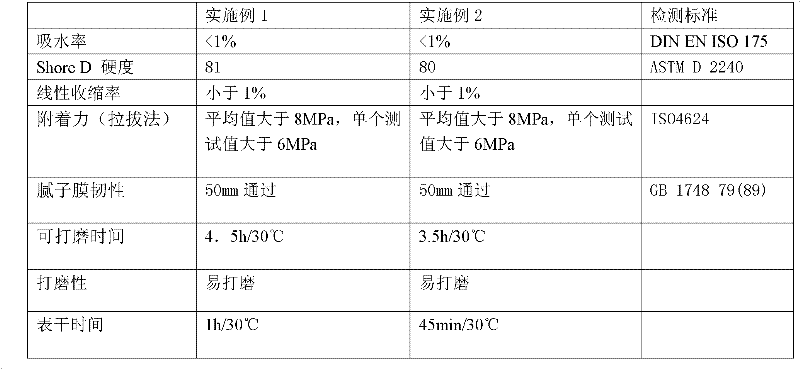

Examples

Embodiment 1

[0035] Component A: Add 33 parts (parts by weight, the same below) of epoxy resin (polyurethane modified E-52D epoxy resin, the epoxy value of which is 0.5 and the solid content is greater than or equal to 98) in a 1.5L stainless steel tank %), and 1 part of thixotropic agent (hydrogenated castor oil thixotropic agent), 1.5 parts of wetting and dispersing agent additives (EFKA4010 and EFKA4009), 6 parts of reactive diluent (propylene oxide butyl ether), heated to Stir evenly after 85℃~100℃, add 55 parts of pigments and fillers (calcium carbonate) under the high-speed disperser, and add 2 parts of silicone defoamer (AFCONA-2020), 1.5 parts of polyacrylate leveling agent, At the same time, stir at a high speed until the powder is basically opened without agglomerates, and the A component of the high-performance megawatt-level wind power blade epoxy putty is prepared.

[0036] Component B: Add 85 parts of amines into a 1.5L stainless steel tank (cardanol modified phenalkamine, th...

Embodiment 2

[0039] Component A: Add 38 parts of epoxy resin (SM-828, the epoxy resin has an epoxy value of 0.5 and a solid content greater than or equal to 98%) in a 1.5L stainless steel tank, and 1.2 parts of a thixotropic agent (oxidized castor oil Thixotropic agent), 1.3 parts of wetting and dispersing agent additive (EFKA4009), 6 parts of reactive diluent (tetradecyl glycidyl ether), after being heated to 85 ℃ ~ 100 ℃, disperse evenly at high speed, and put it in a high-speed disperser Next, add 51 parts of pigments and fillers (kaolin), and add 2 parts of silicone defoamer (AFCONA-3239), 1.5 parts of polyacrylate leveling agent, and stir at high speed until the powder basically opens without agglomerates, that is, Component A of epoxy putty for high-performance megawatt wind turbine blades.

[0040] Component B: Add 95 parts of amine substances (fatty amine, amine value of 220mgKOH / g, solid content of 80%), 5 parts of thixotropic agent (fumed silica) into a 1.5L stainless steel tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com