Insulating mould coating, laminated glass intermediate film, heat-protecting glass and laminated glass thereof

A heat-insulating coating and laminated glass technology, applied in the field of coatings, can solve the problems of XIR film instrument wrinkles, low visible light transmittance, limited life cycle, etc., achieve good dispersion and stability, high visible light transmittance, Good for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

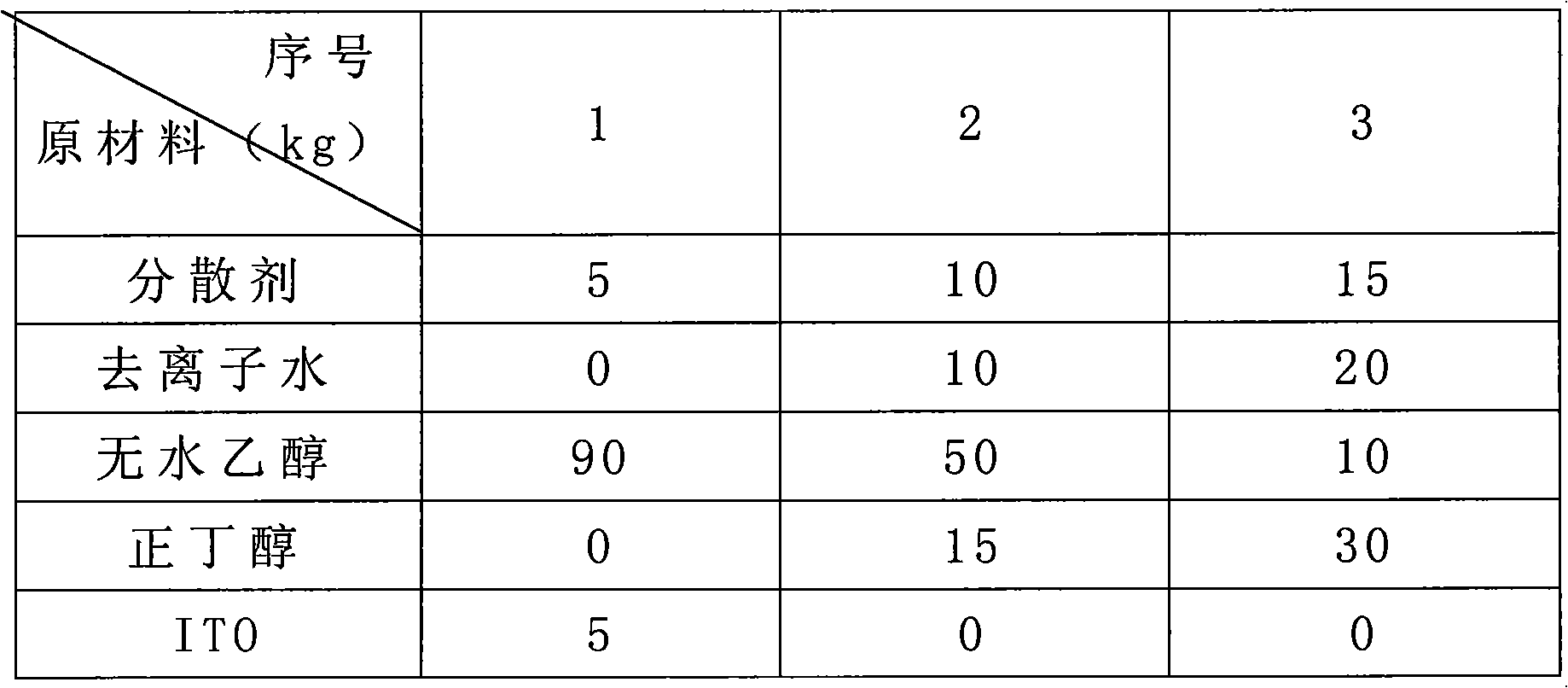

[0020] Preparation ratio table of nano powder slurry:

[0021]

[0022] ATO

Embodiment 1

[0023] Embodiment 1: get 20kg polyethylene type resin and be dissolved in the mixed solvent of the ethanol of 43.2kg and n-butanol, add the nano material body slurry 30kg that makes by above-mentioned proportion 1 again, and leveling agent 1.0kg, defoaming agent Add 0.8kg of solvent, 2.0kg of dispersant, and 3.0kg of adhesion promoter, and stir evenly to prepare a transparent heat-insulating coating. Coat the prepared transparent heat-insulating coating on the surface of the glass substrate to make heat-insulating glass, and heat it to dry and cure. The drying temperature is 60°C, and the coating film is dry for 5 minutes, and the coating film is dry after drying at 100°C for 3 minutes. The dry film thickness is 30um. Then laminated glass is made from this heat-insulating glass, the visible light transmittance is 85%, the infrared shielding rate is 75%, and the heat insulation lowers the temperature by 7°C.

Embodiment 2

[0024] Embodiment 2: Get 44kg acrylic resin and dissolve in the mixed solvent of 32kg of acetone and butanol, then add 20kg of nano material body slurry made by the above proportion 2, and 0.7kg of leveling agent, 0.6kg of defoamer kg, 1.1kg of dispersant, and 1.6kg of adhesion promoter, and stirred at a high speed to obtain a transparent heat-insulating coating. Apply the prepared transparent heat-insulating coating on the surface of PET film to prepare a laminated glass interlayer film, and dry it with heat at 60°C for 12 minutes to dry the film, with a dry film thickness of 35um. Then laminated glass is made from this laminated glass interlayer film, the visible light transmittance is 82%, the infrared shielding rate is 70%, and the heat insulation and temperature reduction are 6°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com