Solvent-free spraying type epoxy putty

An epoxy putty, solvent-free technology, applied in filling slurry and other directions, can solve problems such as affecting the appearance of concrete structures, not seeing sprayed epoxy putty, affecting structural durability, etc., to protect workers' health and avoid the risk of filler settlement. , the effect of increasing the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

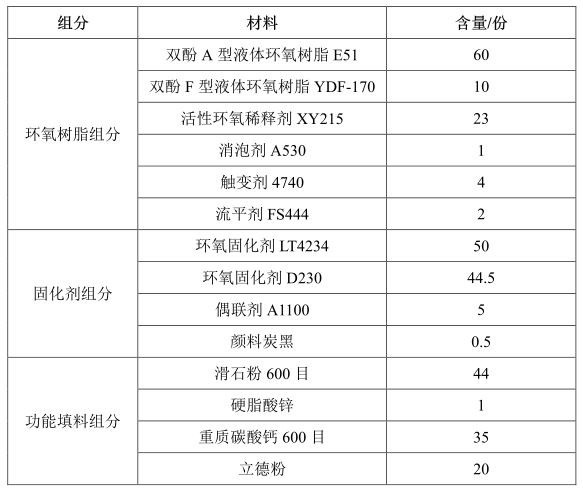

[0030] Embodiment 1: 100 parts of each component formula of solvent-free spraying epoxy putty are measured as follows.

[0031] Table 1 Example 1 material formula

[0032]

[0033] Among the above: bisphenol A liquid epoxy resin E51, produced by Baling Petrochemical Co., Ltd.

[0034] Bisphenol F type liquid epoxy resin YDF-170, produced by Kunshan Guodu Chemical Industry.

[0035] Reactive epoxy diluent XY215, produced by Anhui Xinyuan Technology Co., Ltd.

[0036] Defoamer A530, produced by BYK.

[0037] Thixotropic agent 4740, produced by Cabot Corporation.

[0038] Leveling agent FS444, produced by Hemings Company.

[0039] Epoxy curing agent LT4234, produced by Changzhou Shanfeng Chemical Industry.

[0040] Epoxy curing agent D230, produced by Huntsman.

[0041] Coupling agent A1100, produced by Momentive High-tech Materials Group.

[0042] Pigment carbon black, produced by Xinxiang Huamei Chengde Pigment Company.

Embodiment 2

[0050] Embodiment 2: 100 parts of each component formula of solvent-free spraying epoxy putty are measured as follows.

[0051] Table 2 Example 2 material formula

[0052]

[0053] Among the above: bisphenol A liquid epoxy resin E44, produced by Baling Petrochemical Co., Ltd.

[0054] Bisphenol A liquid epoxy resin E51, produced by Baling Petrochemical Co., Ltd.

[0055] Bisphenol F type liquid epoxy resin DER351, produced by Dow Chemical.

[0056] Reactive epoxy diluent XY215, produced by Anhui Xinyuan Technology Co., Ltd.

[0057] Reactive epoxy diluent XY748, produced by Anhui Xinyuan Technology Co., Ltd.

[0058] Defoamer BYK 141, produced by BYK Chemie.

[0059] THIXATROL PLUS, manufactured by Hemings Chemical Company.

[0060] Leveling agent FS444, produced by Hemings Chemical Company.

[0061] Epoxy curing agent R3318, produced by Guangzhou Rich Chemical.

[0062] Epoxy curing agent D230, produced by Huntsman.

[0063] Coupling agent A1110, produced by Moment...

Embodiment 3

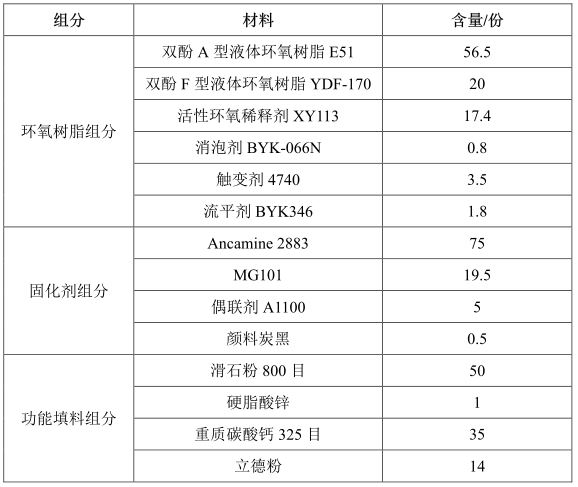

[0071] Embodiment 3: 100 parts of each component formula of solvent-free spraying epoxy putty are measured as follows.

[0072] Table 3 Example 3 material formula

[0073]

[0074] Among the above: bisphenol A liquid epoxy resin E51, produced by Baling Petrochemical Co., Ltd.

[0075] Bisphenol F type liquid epoxy resin YDF-170, produced by Kunshan Guodu Chemical Industry.

[0076] Reactive epoxy diluent XY113, produced by Anhui Xinyuan Technology Co., Ltd.

[0077] Defoamer BYK-066N, produced by BYK Chemicals.

[0078] Thixotropic agent 4740, produced by Cabot Corporation.

[0079] Leveling agent BYK346, produced by Hemings Company.

[0080] Ancamine 2883, produced by Evonik Chemical Company.

[0081] Epoxy curing agent D230, produced by Huntsman.

[0082] Coupling agent A1100, produced by Momentive High-tech Materials Group.

[0083] Pigment carbon black, produced by Xinxiang Huamei Chengde Pigment Company.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com