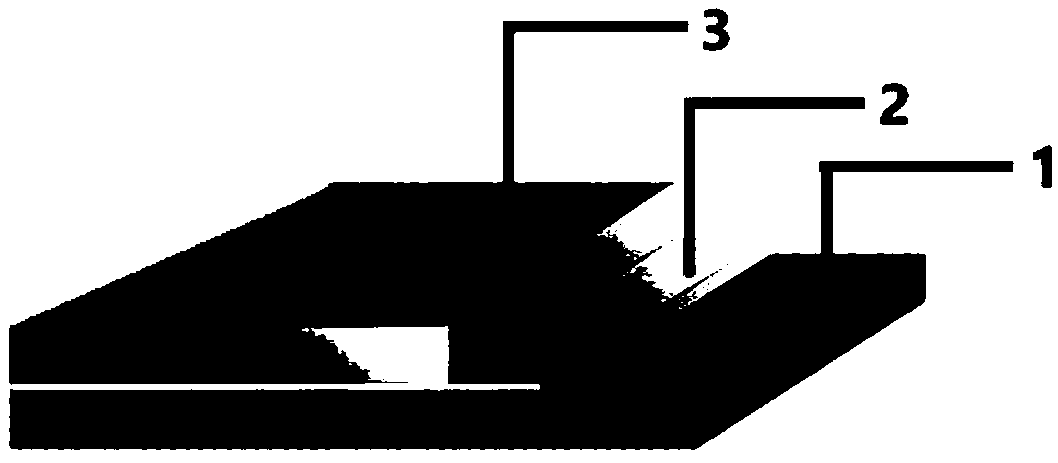

Isolating type coating and method for concrete repair and protection

A concrete base, concrete technology, applied in the direction of coating, anti-corrosion coating, filling slurry, etc., can solve the problem of reducing the safety and service life of concrete structures, freezing and thawing, external force, rain erosion or cold and heat changes, paint The coating is prone to foaming and other problems, achieving high body strength and bonding strength, solving repair and protection problems, and a simple coating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

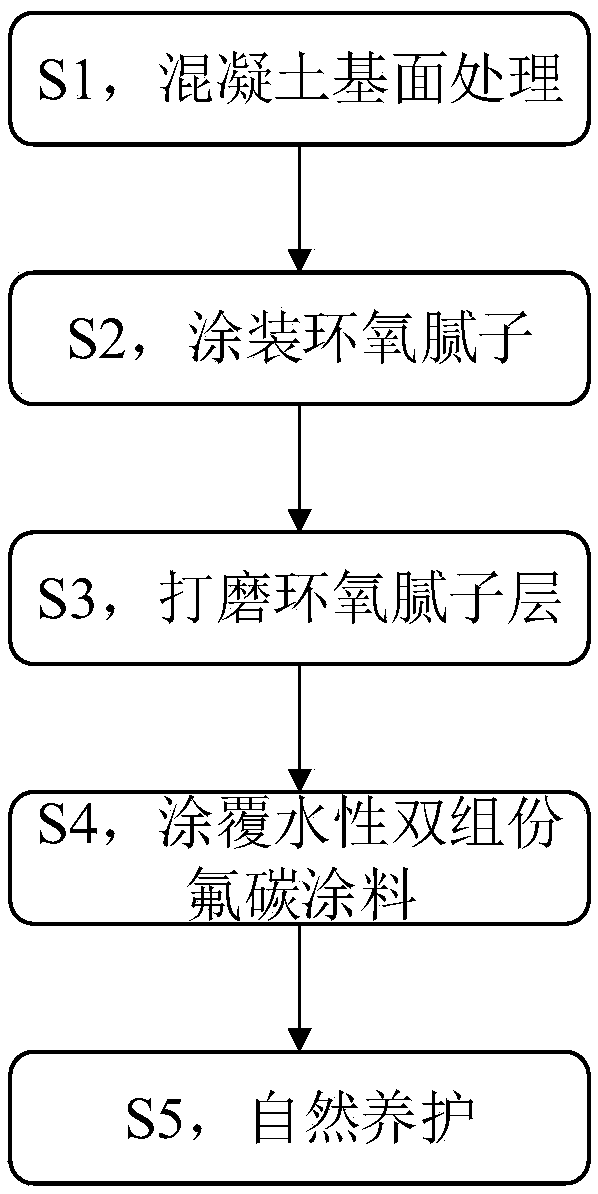

Method used

Image

Examples

Embodiment 1

[0031] The epoxy putty of this embodiment adopts a solvent-free epoxy putty with high adhesion and high bonding strength, which includes component A and component B, wherein component A is the main agent and component B is the curing agent.

[0032] Based on the total mass percentage as 100%, the mass percentages of each component in the formula of component A are as follows: bisphenol A epoxy resin 50%; titanium dioxide 10%; silicon micropowder 15%; ceramic powder 12%; nitrile rubber 8%; Phenyl glycidyl ether reactive diluent 5%. The ceramic powder adopts 400 mesh powder.

[0033] Based on the total mass percentage as 100%, the mass percentages of the components in the B component formula are as follows: fatty amine 45%; silicon micropowder 47%; fumed silicon dioxide 8%.

[0034] The water-based two-component fluorocarbon coating in this embodiment adopts a water-based two-component fluorocarbon coating with good weather resistance and high hardness, which includes component...

Embodiment 2

[0045]The epoxy putty of this embodiment adopts a solvent-free epoxy putty with high adhesion and high bonding strength, which includes component A and component B, wherein component A is the main agent and component B is the curing agent.

[0046] Based on the total mass percentage as 100%, the mass percentages of each component in the epoxy putty A component formula are as follows: bisphenol A epoxy resin 35%; titanium dioxide 5%; silicon micropowder 30%; ceramic powder 20%; Nitrile rubber 7%; Phenyl glycidyl ether reactive diluent 3%. Specifically, the ceramic powder is 400-mesh powder.

[0047] Based on the total mass percentage as 100%, the mass percentages of the components in the epoxy putty B component formula are as follows: fatty amine 35%; silicon micropowder 60%; fumed silica 5%.

[0048] The water-based two-component fluorocarbon coating in this embodiment adopts a water-based two-component fluorocarbon coating with good weather resistance and high hardness, whic...

Embodiment 3

[0059] The epoxy putty of this embodiment adopts a solvent-free epoxy putty with high adhesion and high bonding strength, which includes component A and component B, wherein component A is the main agent and component B is the curing agent.

[0060] Based on the total mass percentage as 100%, the mass percentage of each component in the epoxy putty A component formula is as follows: bisphenol A epoxy resin 30%; titanium dioxide 10%; silicon micropowder 30%; ceramic powder 20%; Nitrile rubber 8%; phenyl glycidyl ether reactive diluent 2%. Specifically, the ceramic powder is 400-mesh powder.

[0061] Based on the total mass percentage as 100%, the mass percentages of the components in the epoxy putty B component formula are as follows: fatty amine 32%; silicon micropowder 60%; fumed silicon dioxide 8%.

[0062] The water-based two-component fluorocarbon coating in this embodiment adopts a water-based two-component fluorocarbon coating with good weather resistance and high hardn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com