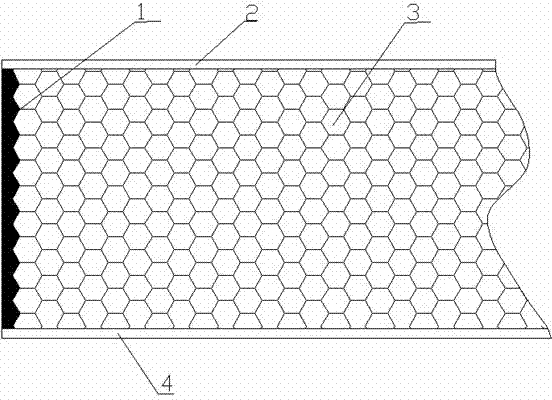

Edge sealing structure of honeycomb sandwich shelter wallboard, and edge sealing method thereof

A technology of honeycomb core and bulkhead panels, which is applied in the field of shelters, can solve problems such as unsuitable edge sealing and performance impact of shelters, and achieve the effects of improving lateral pressure resistance and overall rigidity, low cost, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An edge-sealing structure of a honeycomb core square bulkhead is low-density epoxy putty, which is composed of epoxy resin and hollow glass microspheres, and the epoxy resin accounts for 35% of the total volume of the low-density epoxy putty.

Embodiment 2

[0027] An edge-sealing structure of a honeycomb core square bulkhead is low-density epoxy putty, which is composed of epoxy resin and hollow glass microspheres, and the epoxy resin accounts for 45% of the total volume of the low-density epoxy putty.

Embodiment 3

[0029] An edge-sealing structure of a honeycomb core square bulkhead is a low-density epoxy putty, which is composed of epoxy resin and hollow glass microspheres, and the epoxy resin accounts for 40% of the total volume of the low-density epoxy putty.

[0030] Embodiment of an edge sealing method for a honeycomb sandwich square bulkhead panel

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com