Super-strength large core number multi-purpose optical fiber cable

A fiber optic cable, ultra-high-strength technology, applied in the field of ultra-high-strength, large-core multi-purpose fiber optic cable, can solve the problems of cumbersome construction, single use place, difficult maintenance, etc., and achieve light weight, small outer diameter, and excellent flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

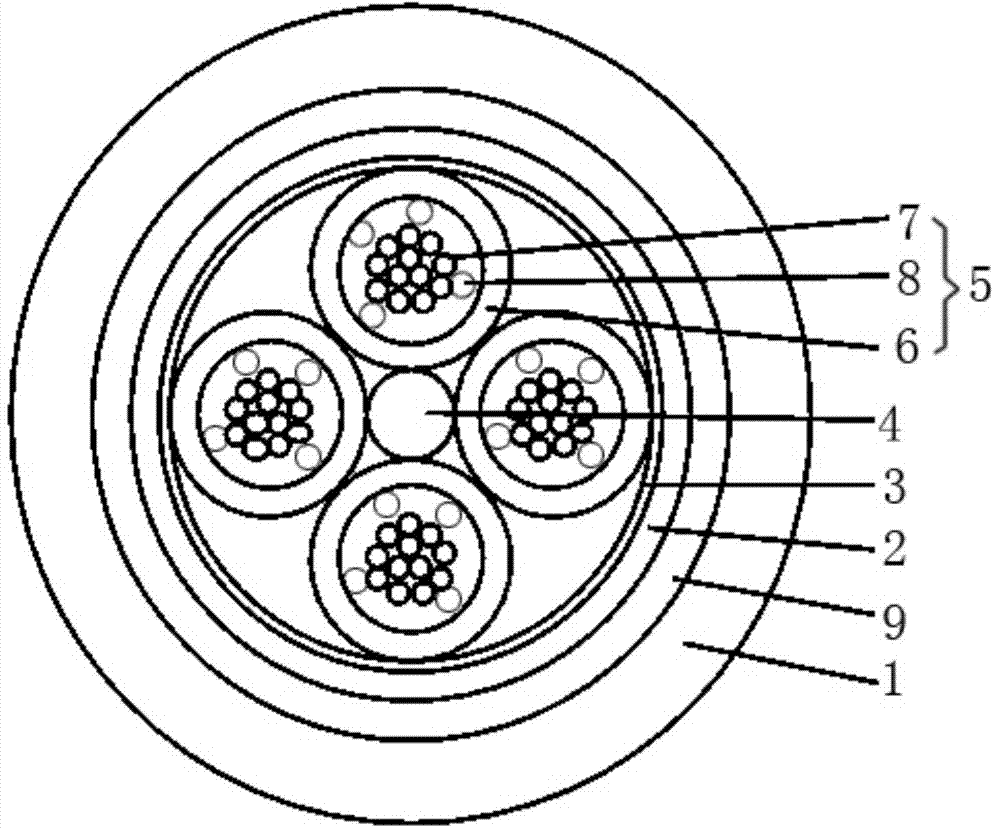

[0015] A multi-purpose optical fiber cable with ultra-high strength and large core count, see figure 1 : Its cross-sectional structure arranged in sequence from outside to inside is outer sheath 1, metal hose 2, water blocking tape 3, the inner cavity of water blocking tape 3 is a cable core, and water blocking tape 3 is wrapped around the formation Outside the cable core, the center of the cable core is a central strengthening member 4, and the outer ring surface of the central strengthening member 4 is evenly distributed with at least three optical cable subunits 5, and each optical cable subunit 5 includes an external micro-bundle tube 6, The optical fiber bundle 7 at the center, and the water-blocking yarn 8 between the inner wall of the micro-bundle tube 6 and the outer wall of the optical fiber bundle 7, the size of the water-blocking yarn 8 250dtex occupies a very small space, so that the optical cable can be small in size and light in weight And the water blocking effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com