Patents

Literature

33results about How to "Excellent repeatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-repairing solid-state hybrid dynamic polymer and application thereof

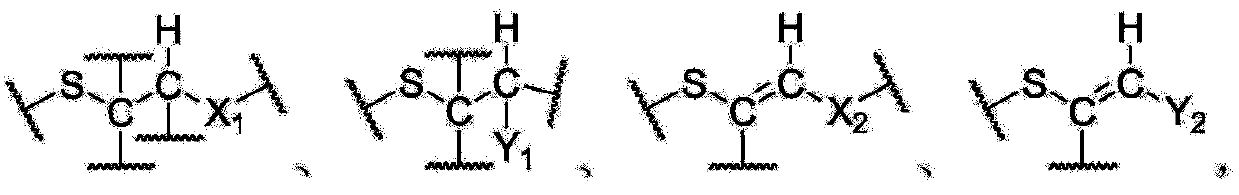

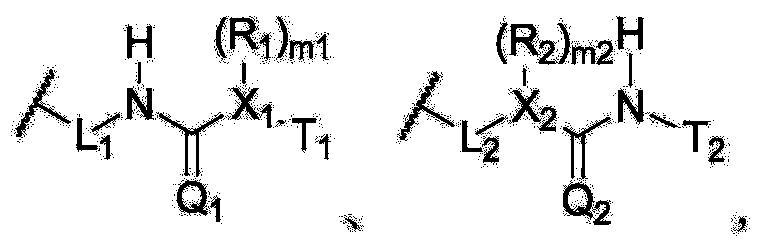

PendingCN109666168ARich dynamic reversible characteristicsVarious forms of activationDevice materialBackbone chain

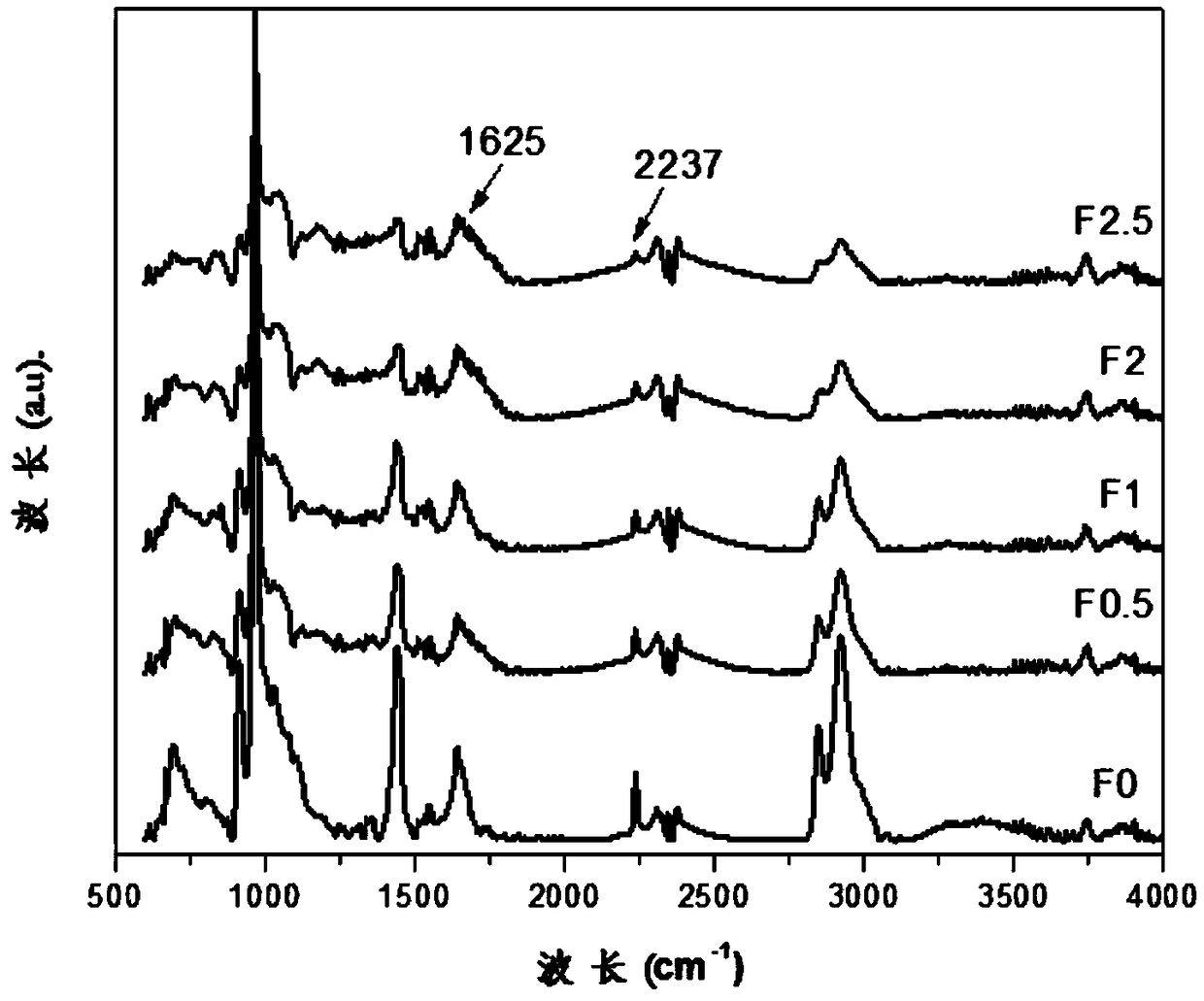

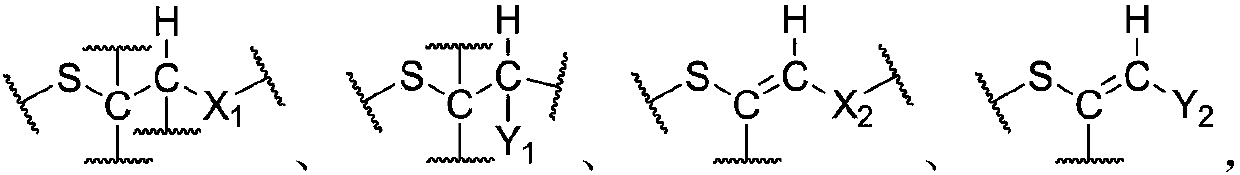

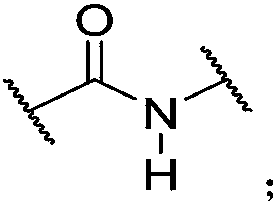

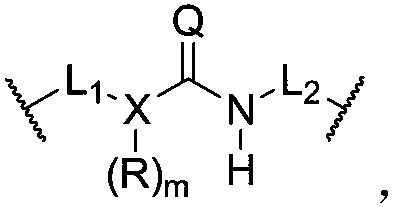

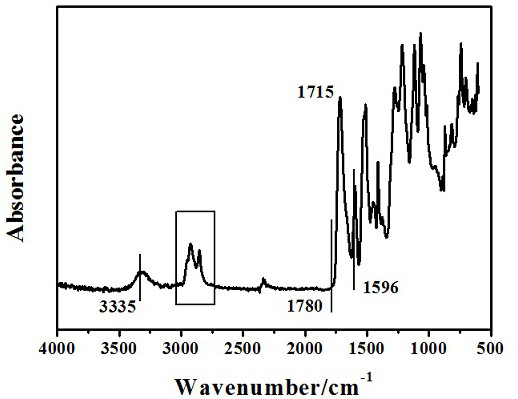

The invention discloses a self-repairing solid-state hybrid dynamic polymer. The self-repairing solid-state hybrid dynamic polymer contains sulfydryl-Michael addition bond dynamic covalent crosslinking and supermolecular hydrogen bond interaction, wherein the sulfydryl-Michael addition bond dynamic covalent crosslinking reaches above a gel point in at least one crosslinking network; sulfydryl-Michael addition bonds are obtained through sulfydryl-Michael addition reaction between sulfydryl groups and electron-deficient conjugate alkenes / enynes; the supermolecular hydrogen bond interaction contains hydrogen bond interaction involving at least one from side hydrogen bond groups, backbone hydrogen bond groups and other end hydrogen bond groups; with dynamic reversibility, the sulfydryl-Michaeladdition bonds and the supermolecular hydrogen bonds endow the self-repairing solid-state hybrid dynamic polymer with good plasticity, self-repairability, repeatability, reusability and recoverability and ensure that the self-repairing solid-state hybrid dynamic polymer can be widely applied to self-repairing materials, flexible materials, shape memory materials, energy storage device materials and the like.

Owner:厦门天策材料科技有限公司

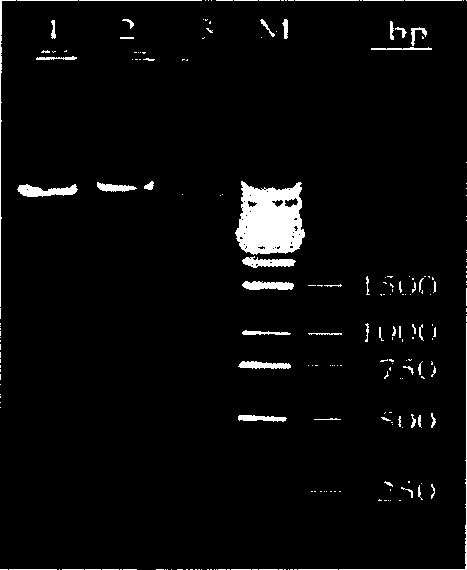

Toxophasma gondii detecting kit based on recombined antigen

InactiveCN1861633AImprove immune activityExcellent repeatabilityBiological testingAnimals/human peptidesSephadexEscherichia coli

A reagent kit based on recombinant antigen for detecting Toxoplasma is prepared through taking 542-1218 fragment (t SAG1) from the primary surface antigen gene SAG1 of Toxoplasma, subcloning it to soluble expression carrier pET32a(+), transferring it to colibacillus, configuring engineering bacterium pET32a-tSAG1 / BL21, IPTG induced efficient expression, ultrasonic splitting to obtain supernatant, purifying by Ni-NTA and Sephadex-G75, and coating the microholes on ELISA plate. Its test paper can also be prepared by same way.

Owner:深圳市绿诗源生物技术有限公司

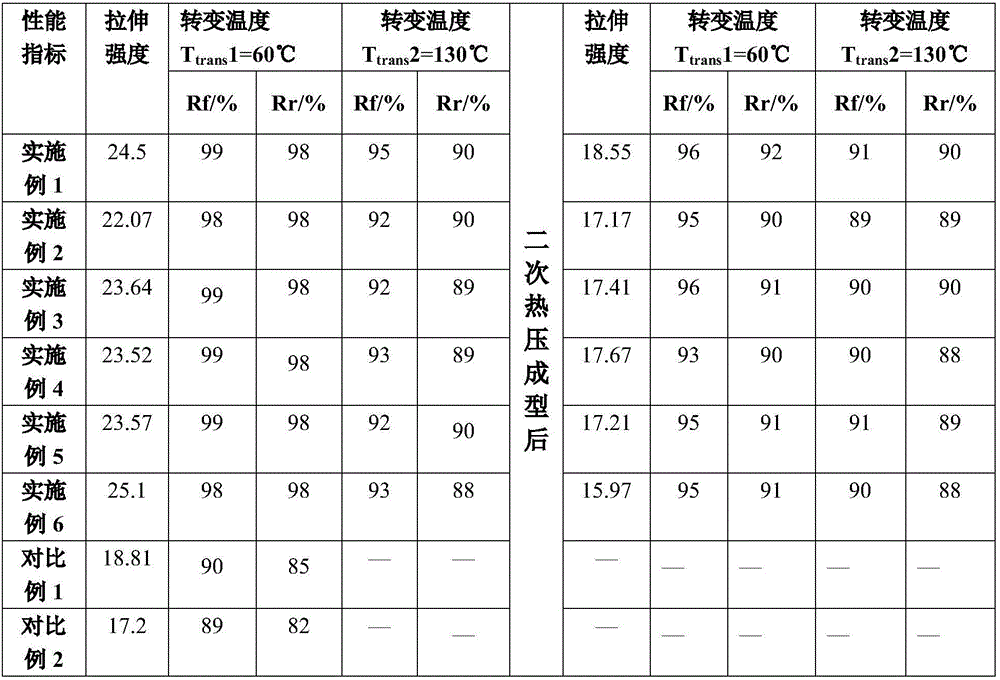

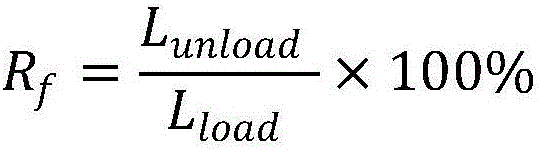

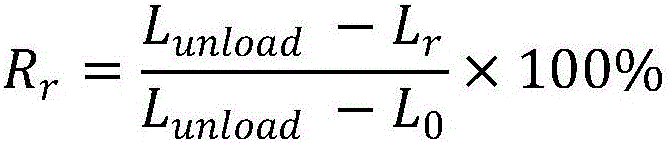

Thermally reversible crosslinking gutta-percha double-shape memory elastomer and preparation method thereof

The invention relates to a thermally reversible crosslinking gutta-percha double-shape memory elastomer and a preparation method thereof. The preparation method comprises the following steps: performing grafting reaction on gutta-percha, a diene body and a photoinitiator in a solution; and performing thermally reversible crosslinking of the graft product and a dienophile crosslinking agent to obtain a shape memory elastomer. According to the elastomer, grafting and then hot pressing are performed in the solution, and the technology is simple. The prepared elastomer has double-shape memory performance as well as good fixed rate and recovery rate and can be repeatedly utilized to save energy and resource.

Owner:BEIJING UNIV OF CHEM TECH

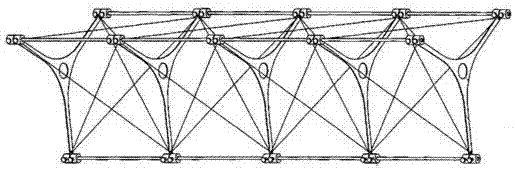

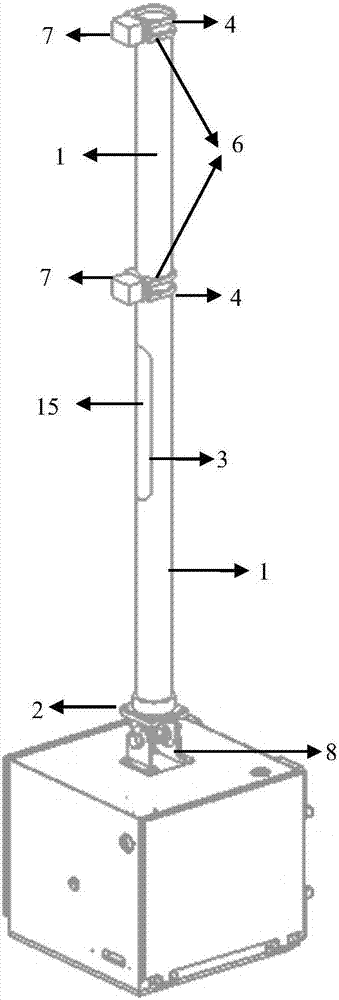

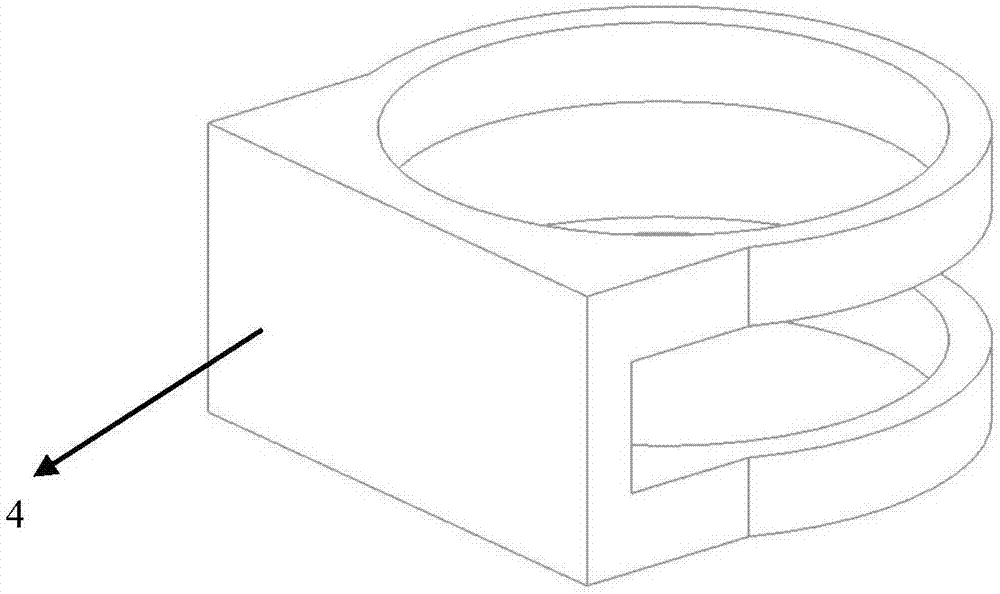

Satellite-borne flexible ultra-light folding carbon fiber extending rod

ActiveCN107323687AHigh Structural Support RigidityHigh folding and unfolding reusabilityCosmonautic vehiclesCosmonautic partsFiberCarbon fibers

The invention discloses a satellite-borne flexible ultra-light folding carbon fiber extending rod. The carbon fiber extending rod comprises a flexible extending rod body (1). The flexible extending rod body (1) is provided with a plurality of long circular through holes (3) which are used as flexible bent joints (15) in the axial direction of the rod. The satellite-borne flexible ultra-light folding carbon fiber extending rod adopts the integrated carbon fiber material configuration design, the carbon fiber extending rod has the characteristic of ultra-low mass, and is suitable for being used for mounting of satellites, such as the large satellites and small satellites, of different scales, and the weight per unit length of the carbon fiber extending rod is smaller than 200 g; due to the fact that the carbon fiber extending rod adopts the design of the flexible bent joints capable of automatically storing and releasing elastic potential energy, the carbon fiber extending rod has the function that the rod can automatically extend without external-demand energy and automatically extends to be fixed in shape, so that consumption of resources on a satellite is saved.

Owner:NAT SPACE SCI CENT CAS

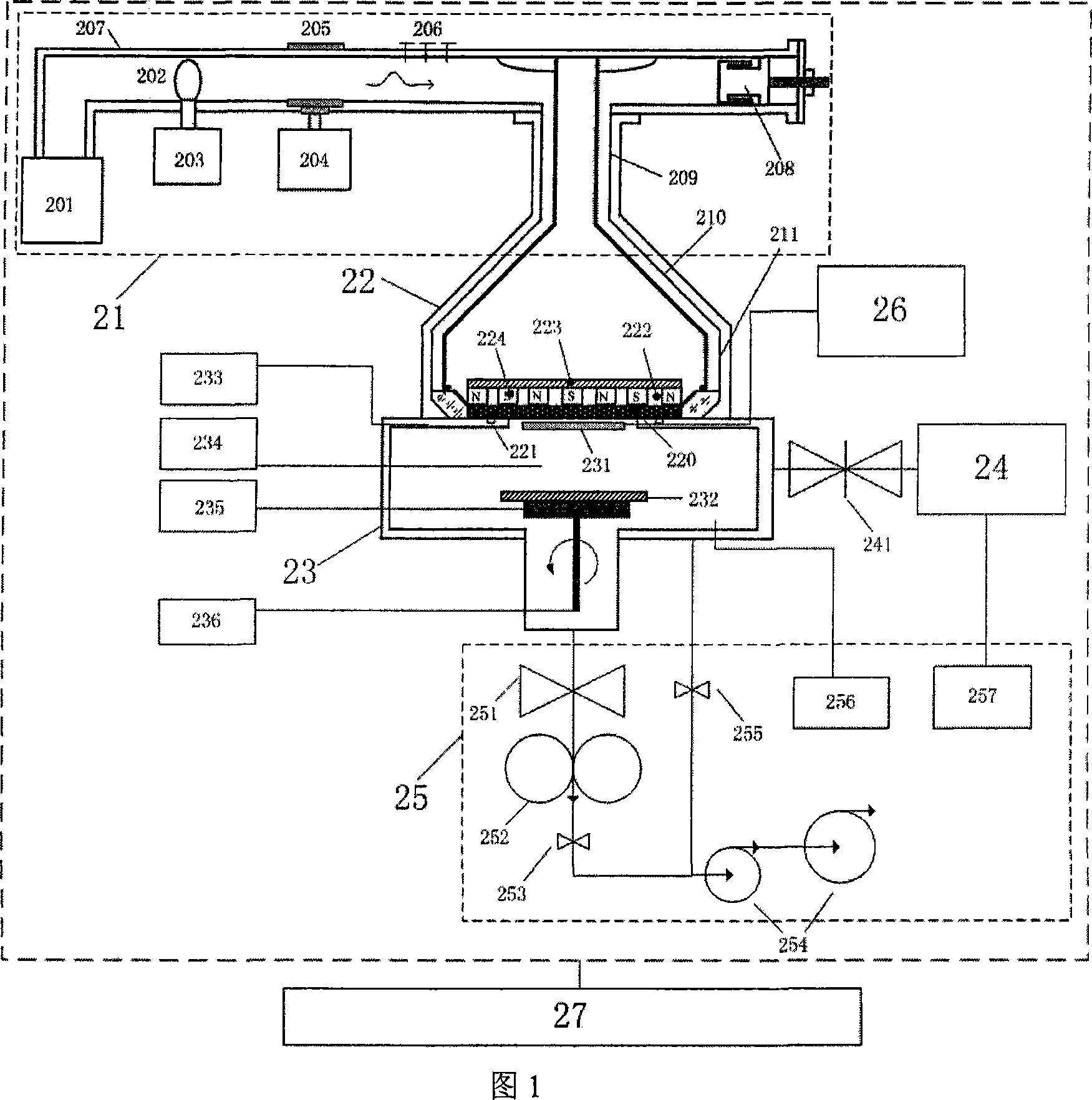

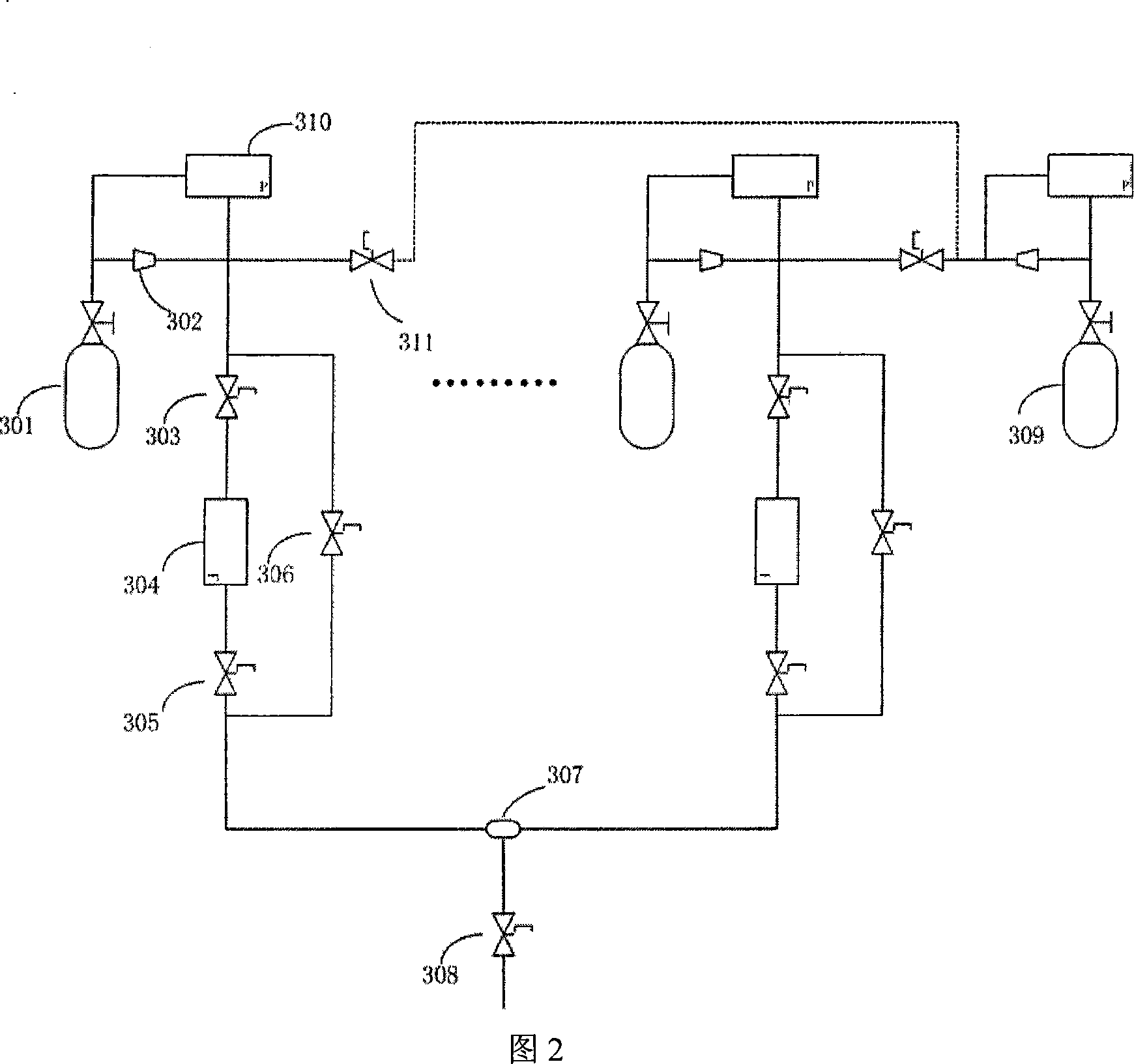

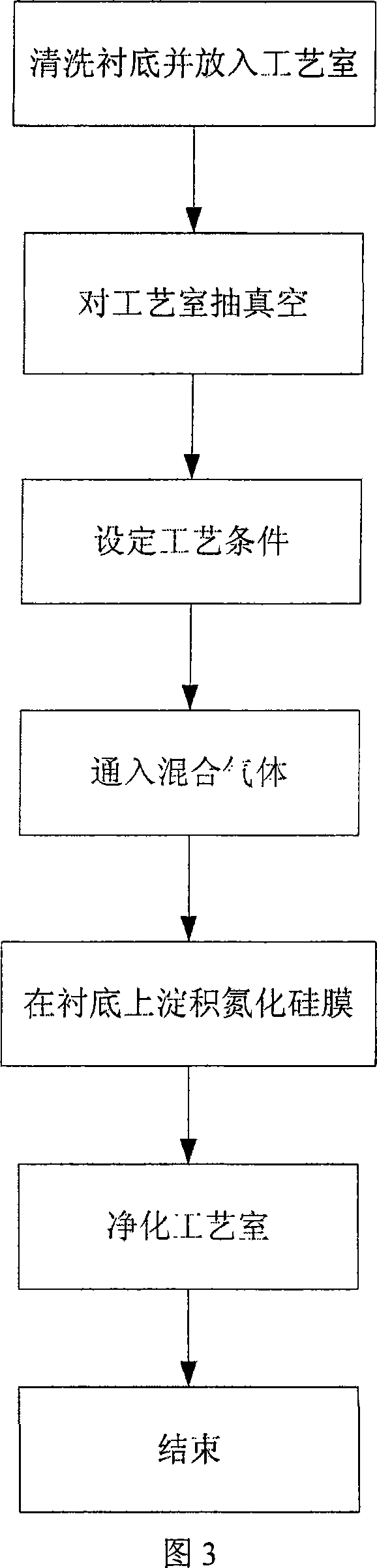

Method for chemical gaseous phase deposition of silicon nitride film by electron cyclotron resonance plasma

InactiveCN101104925ALow deposition temperatureExcellent uniformityChemical vapor deposition coatingDecompositionFlow ratio

The invention discloses a low-temperature manufacturing method of silicon nitride film used in passivation layer of an integrated circuit. The silicon nitride film grows on a substrate positioned inside a deposition chamber. The method comprises cleaning the substrate and placing inside the working chamber, vacuumizing the working chamber and presetting working conditions, introducing a mixed gas composed of silicon source gas and nitride source gas into the working chamber, performing ionization and decomposition of the mixed gas with the action of energy absorbed from a microwave source upon electron cyclotron resonance effect, transferring active charged particles produced by the ionization and decomposition to the surface of the substrate with the action of permanent magnetic field, and depositing silicon nitride film on the substrate. The working conditions are as follows: working chamber pressure: 0.1-5Pa, microwave power: 600-2000W, deposition temperature: room temperature to 300 DEG C, total gas flow: 50-300sccm, flow ratio of silicon source gas to nitride source gas: 1:6 to 1:12, and substrate rotation speed: 60 r / min. The inventive method can rapidly and uniformly deposit the low-hydrogen silicon nitride film (6 inch thickness) at low temperature (below 300 DEG C), which is used as a material for passivation layer of integrated circuit or optical devices.

Owner:XIDIAN UNIV

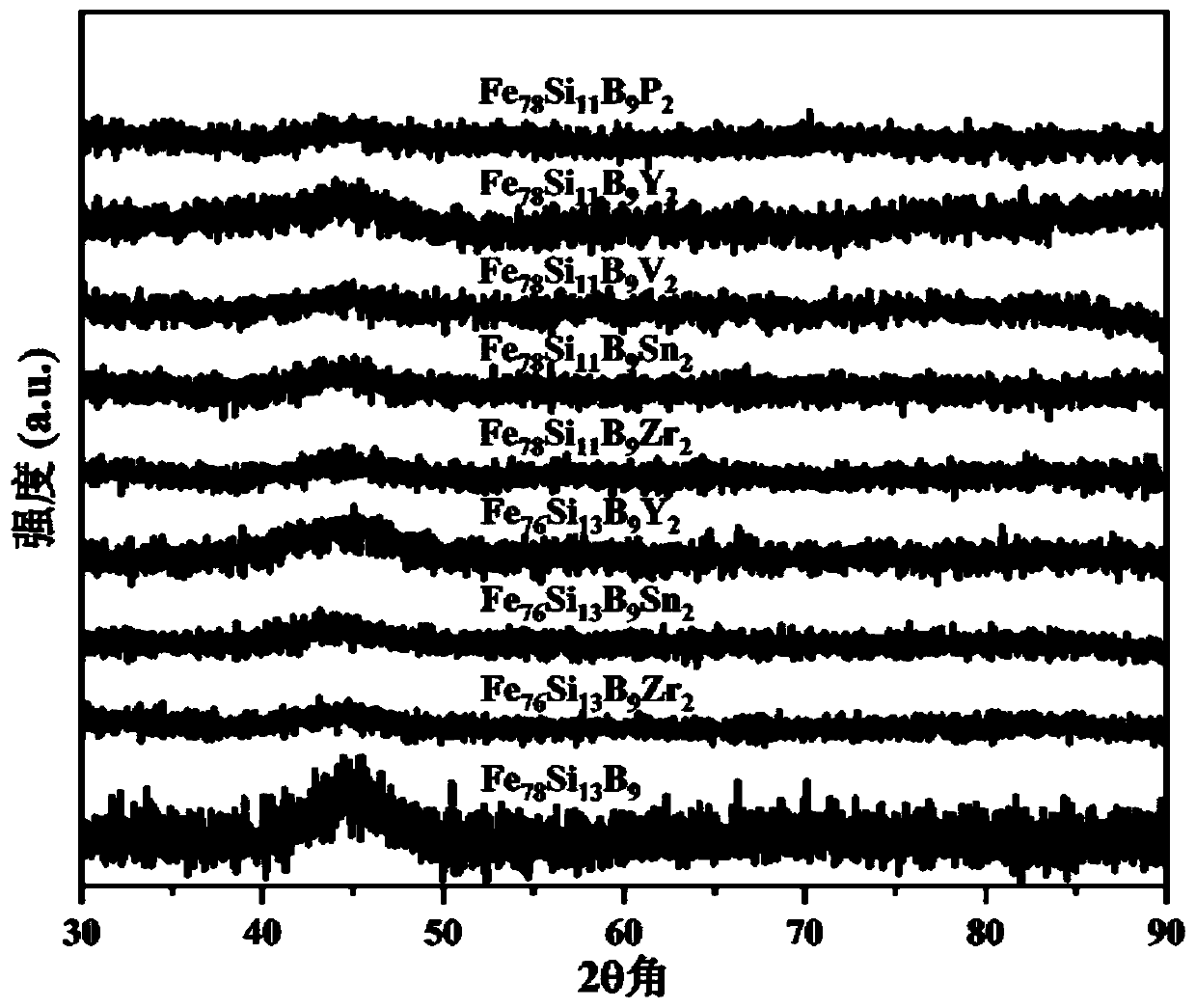

Iron-based series amorphous alloy strip and preparation method thereof and application in degradation of azo dye wastewater

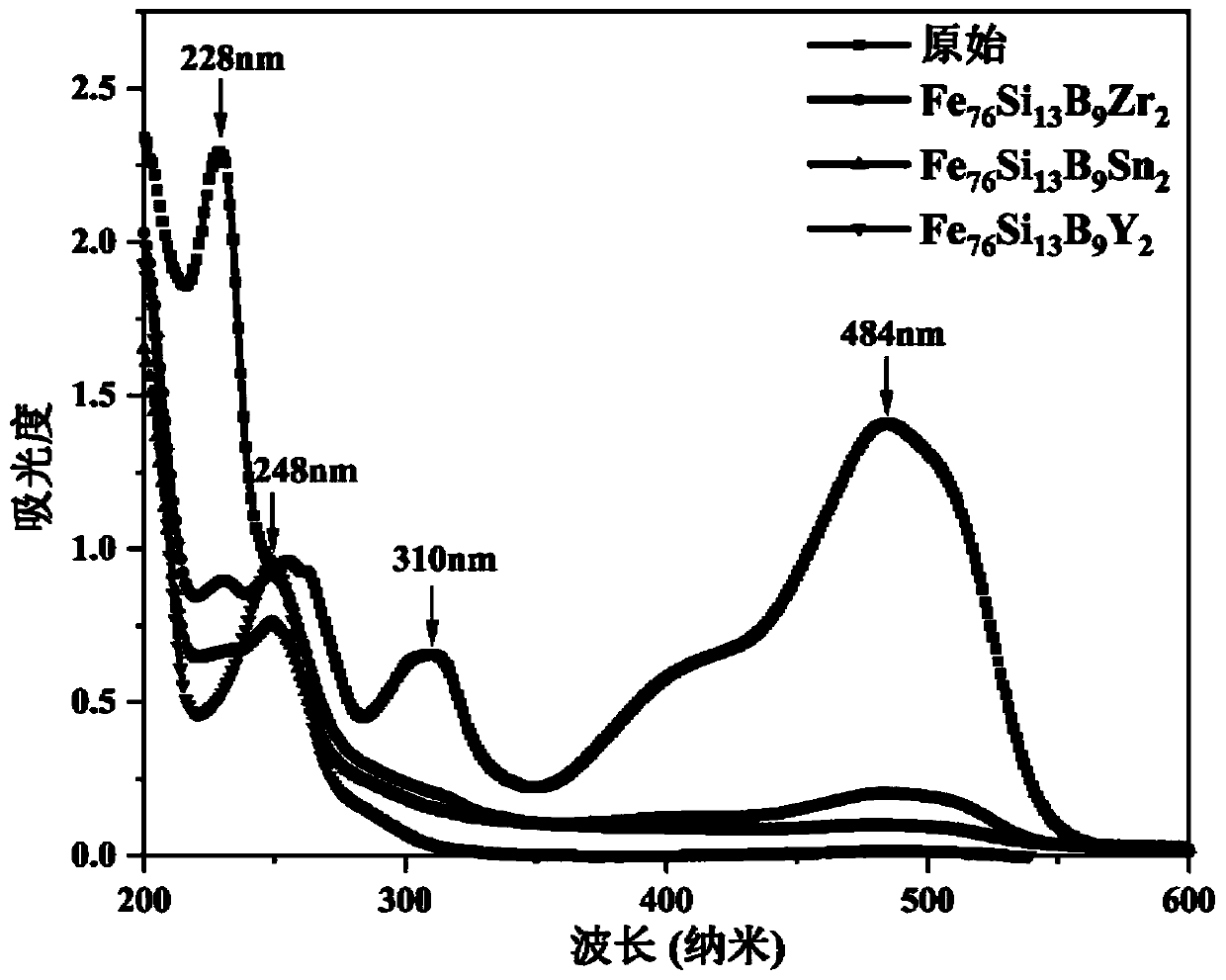

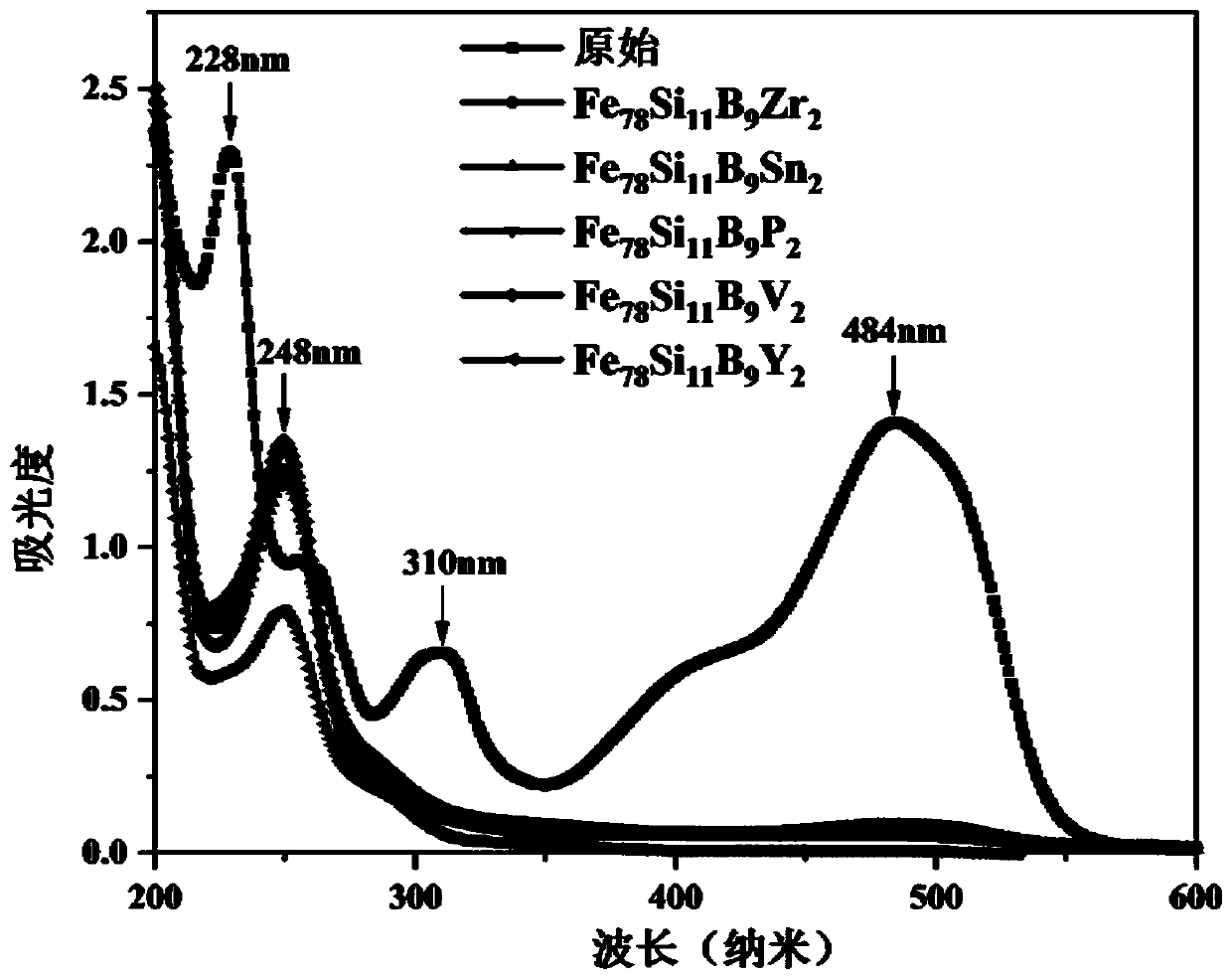

ActiveCN110918911APromote degradationExcellent repeatabilityWater contaminantsWater/sewage treatmentAlloyDyeing wastewater

The invention discloses an iron-based series amorphous alloy strip and a preparation method thereof and application in degradation of azo dye wastewater, and belongs to the technical field of azo dye-containing wastewater treatment. The iron-based series amorphous alloy strip is Fe(78-x)Si13B9Mx or Fe78Si(13-x)B9Mx, wherein M is Zr or Sn or P or V or Y, and x is larger than 0 and smaller than or equal to 3. The iron-based series amorphous strip has better corrosion resistance, higher catalytic activity, higher degradation efficiency and rate for azo dyes, and shows good comprehensive performance.

Owner:SOUTH CHINA UNIV OF TECH

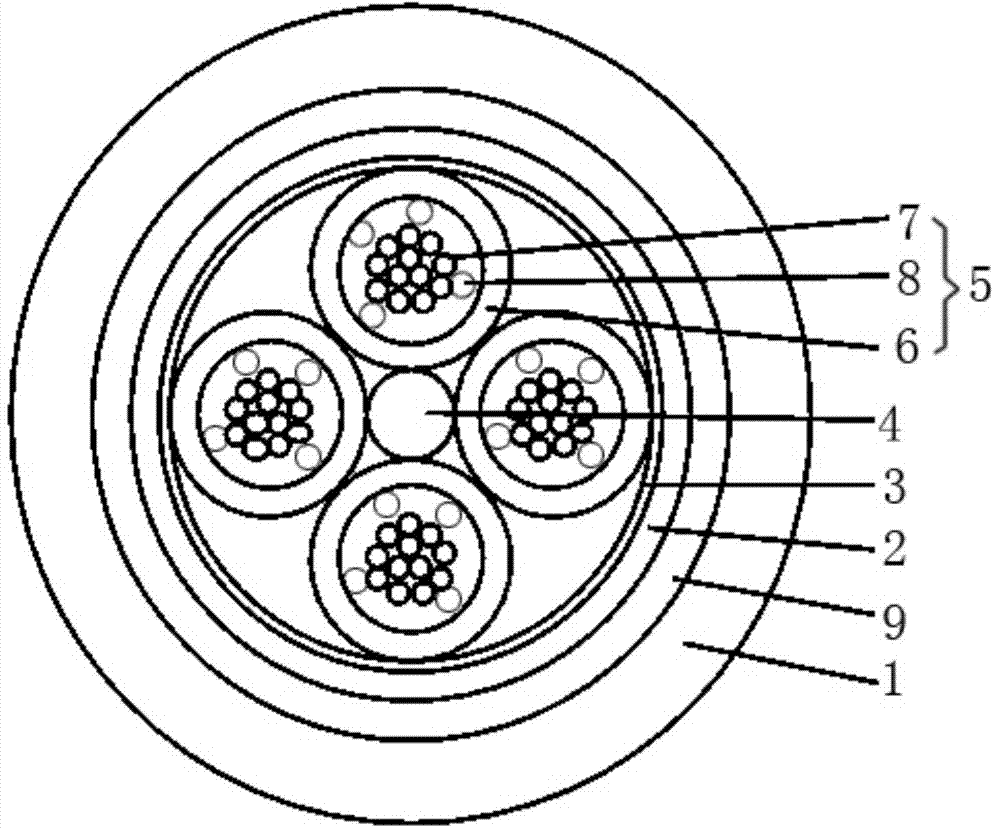

Super-strength large core number multi-purpose optical fiber cable

The invention provides a super-strength large core number multi-purpose optical fiber cable which is light in weight, small in external diameter, more in inner core, and capable of meeting different laying environments. A brand novel optical fiber cable is provided for FTTx establishment in our country. The sequentially arranged cross section structure of the super-strength large core number multi-purpose optical fiber cable comprises an outer sheath, a metal hose and a water-blocking tape from outside to inside. An inner cavity of the water-blocking tape is a cabling cable core. The outer side of the cabling cable core is covered with the water-blocking tape. The center of the cabling cable core is provided with a centre reinforcer. The outer ring surface of the centre reinforcer is evenly provided with three or more optical cable units. Each optical cable unit comprises a micro beam tube arranged outside, fiber optical bundles arranged in the center and water-blocking yarns arranged between the inner wall of the micro beam tube and the outer walls of the fiber optical bundles.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

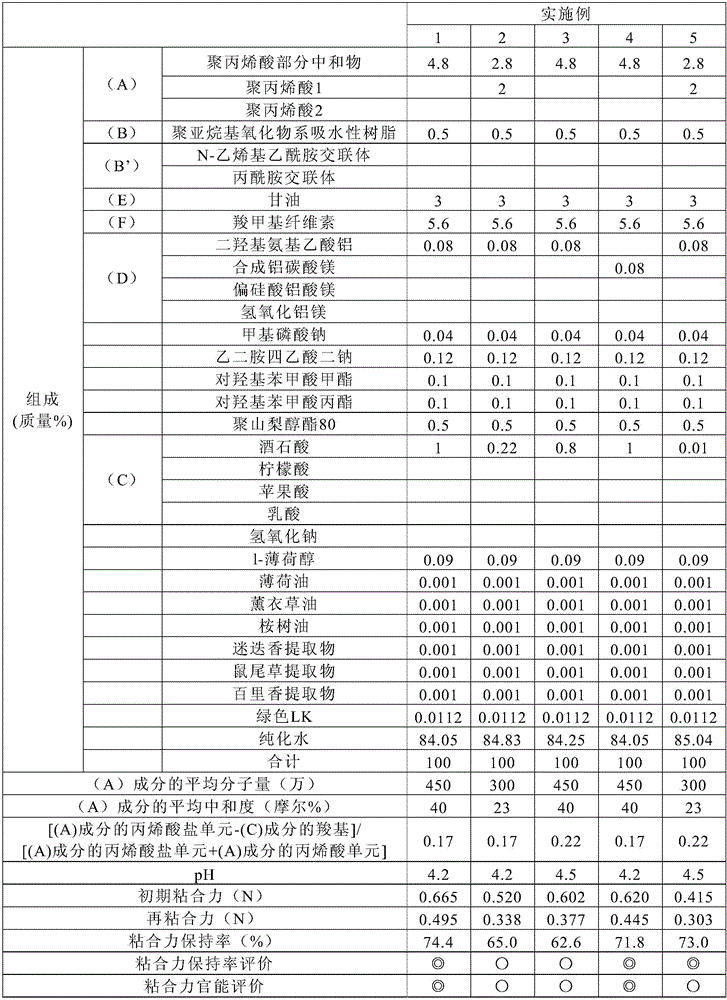

Patch

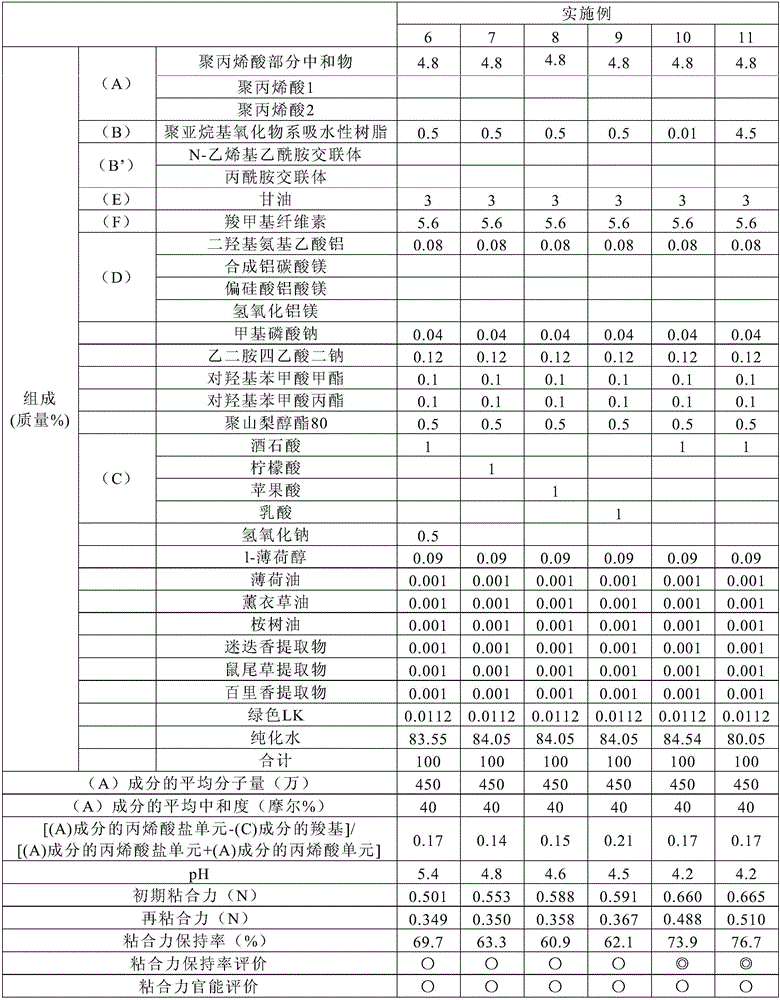

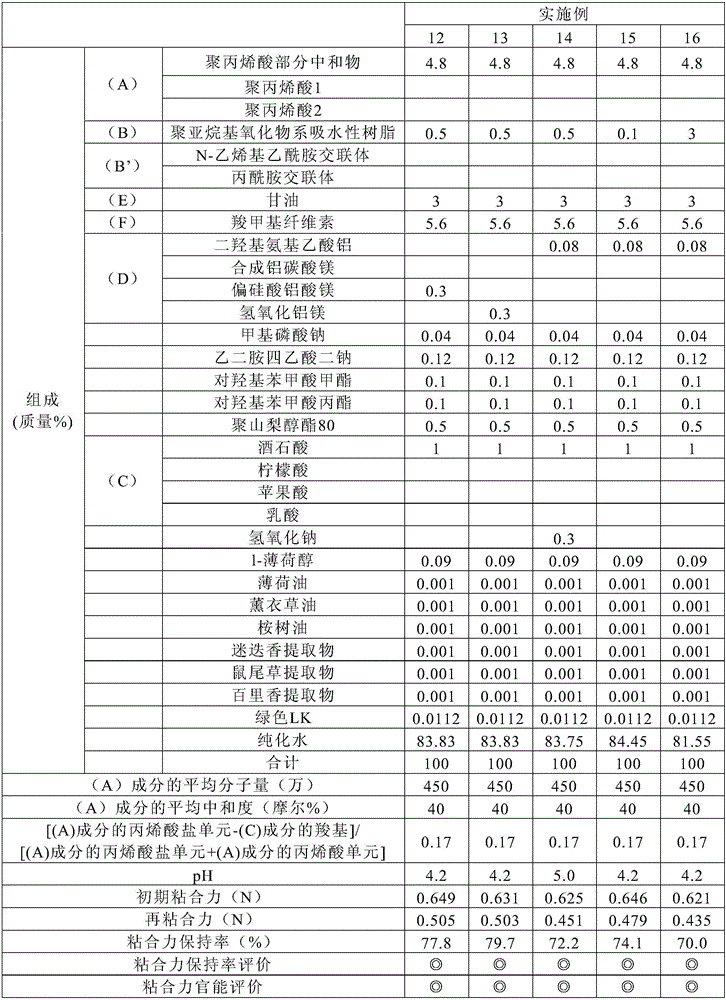

ActiveCN106256866AHigh re-adhesionExcellent repeatabilityNon-macromolecular adhesive additivesAcid polymer adhesivesWater contentHydroxycitric acid

The invention provides a patch having excellent repeated adhesive ability. The patch includes a support body and an adhesive layer. The adhesive layer includes (A) polyacrylic acid and / or salt thereof, (B) poly alkylene oxide series water-absorbent resin, (C) an adhesive composition of organic acid selected from more than one of tartaric acid, malic acid, lactic acid and citric acid; the average mean molecular weight of the (A) is more than 3 millions, the hybrid-mass of the (A) and the (C) meets a relation that [acrylate units of the (A)-carboxyl of the (C)] / [ the acrylate units of the (A)+ acrylic acid units of the (A)] <=0.22; and the pH of the adhesive composition is 4-5.5, and the water content is more than 80 mass%.

Owner:LION CORP

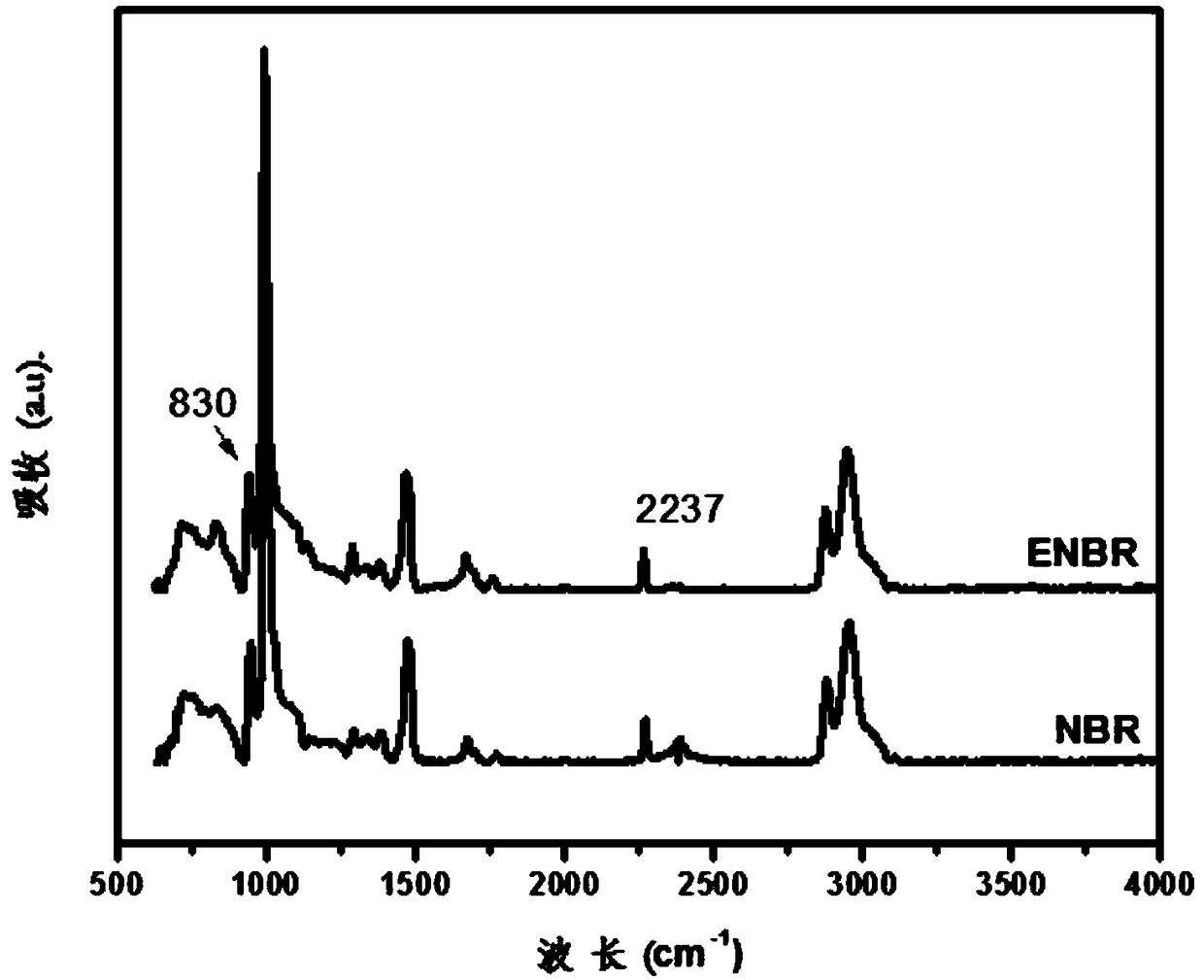

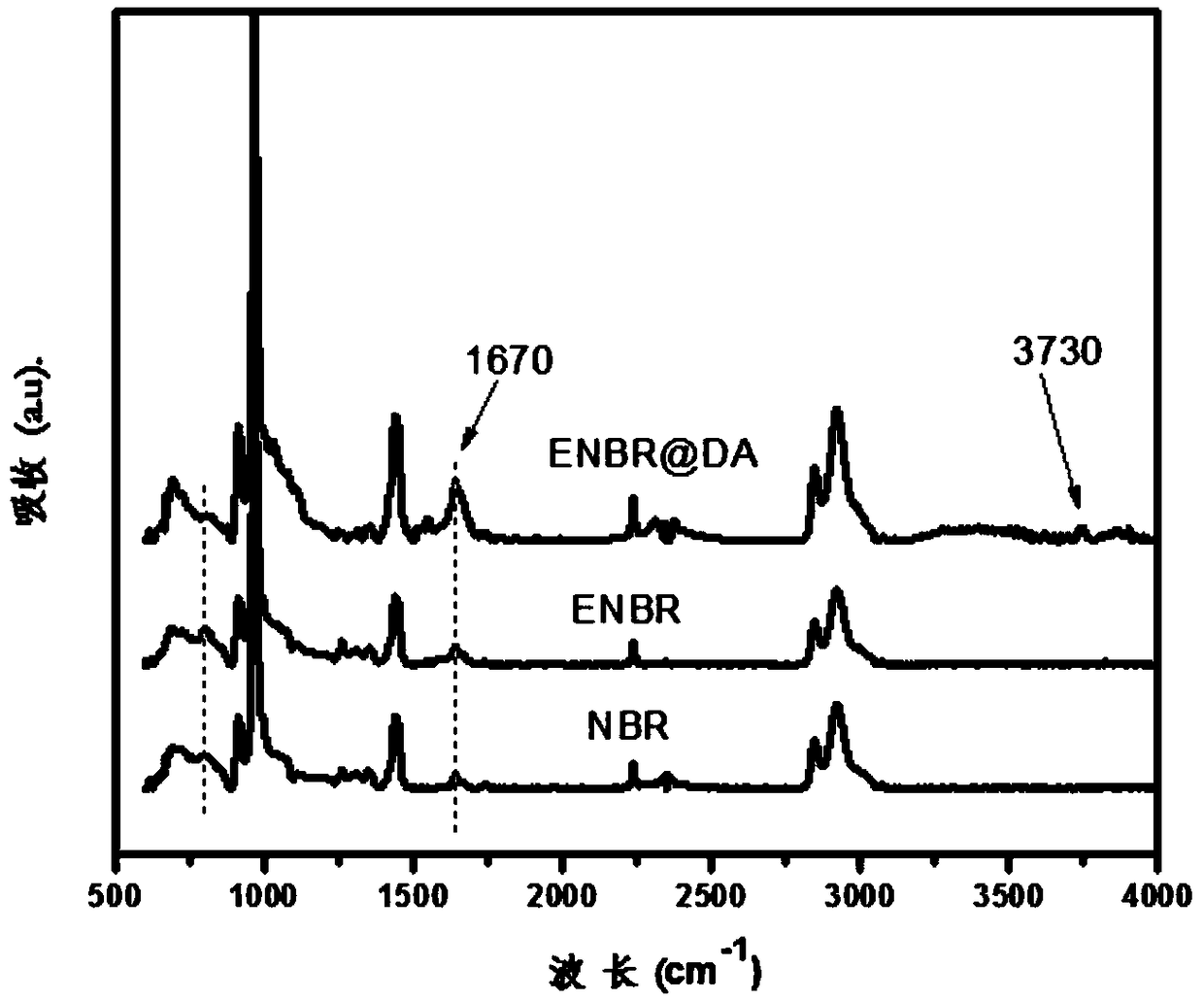

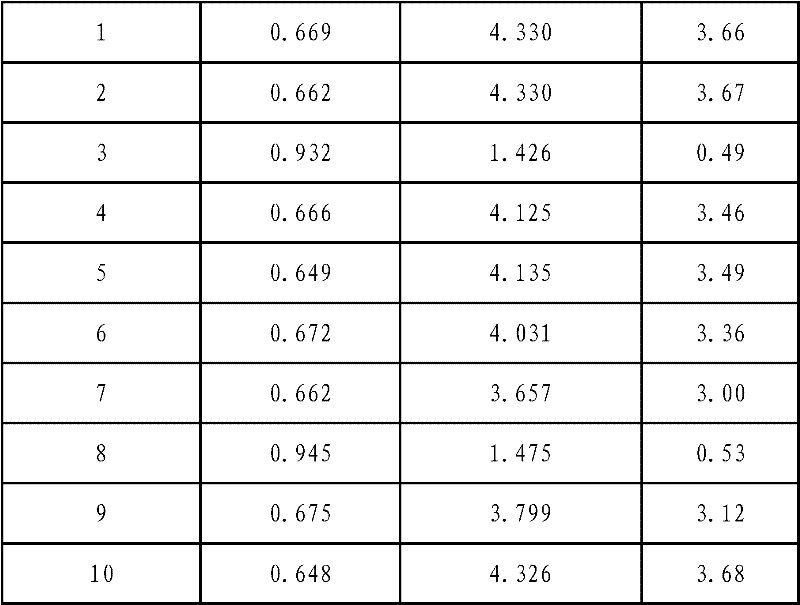

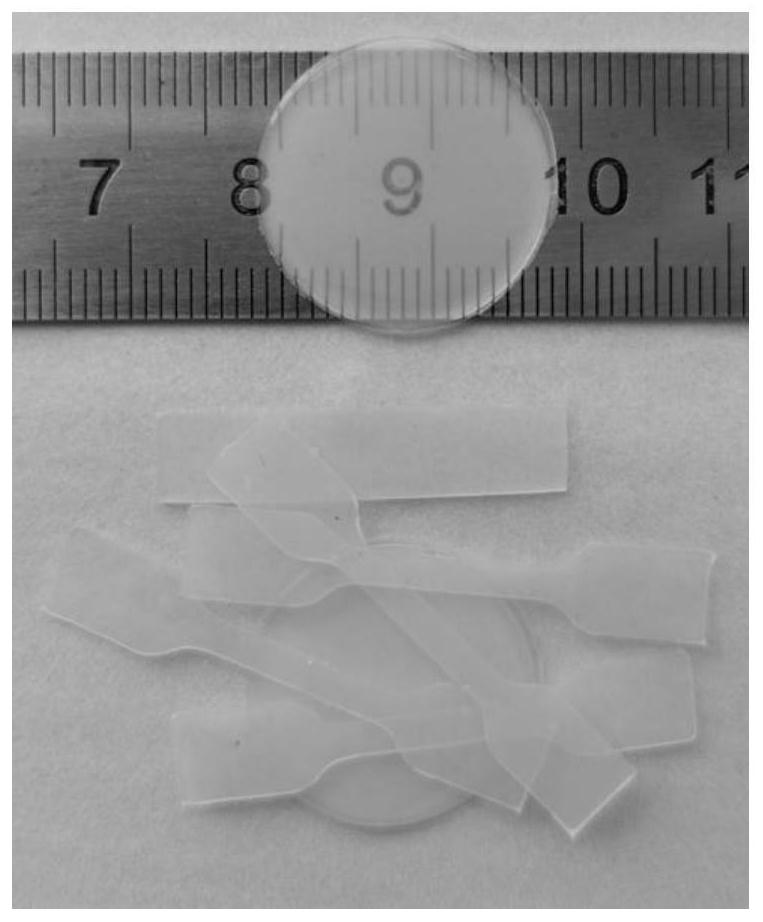

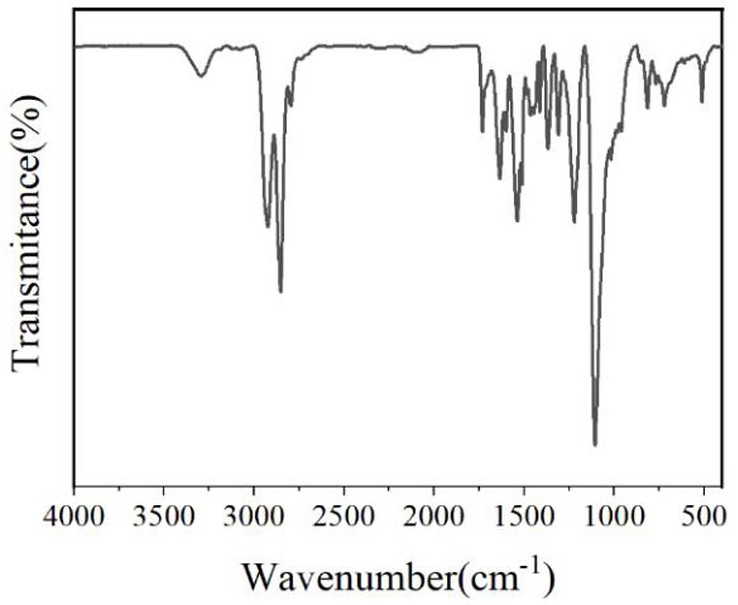

Modified butadiene-acrylonitrile rubber with high strength and good repeatable processability and preparation method thereof

The invention discloses dopamine grafted epoxidized butadiene-acrylonitrile rubber with high strength and good repeatable processability and a preparation method thereof. A formula of the dopamine grafted epoxidized butadiene-acrylonitrile rubber comprises the raw material components in parts by mass: 100 parts of butadiene-acrylonitrile latex, 3-500 parts of an epoxidizer, 1-25 parts of dopamine,and 0.1-5 parts of anhydrous ferric trichloride; the epoxidizer is hydrogen peroxide or molybdenum trioxide. The preparation method comprises the steps: during preparation, carrying out epoxidation of nitrile-butadiene rubber firstly to obtain epoxidized butadiene-acrylonitrile rubber; adding dopamine, and carrying out grafting reaction; and after the reaction is completed, adding anhydrous ferric trichloride, drying, mixing, and carrying out hot pressing to obtain the dopamine grafted epoxidized butadiene-acrylonitrile rubber. The prepared modified butadiene-acrylonitrile rubber has high strength and good repeatable processability without filler reinforcement.

Owner:SOUTH CHINA UNIV OF TECH

Hybrid dynamic crosslinking polymer and application thereof

PendingCN109666121ARich dynamic reversible characteristicsVarious forms of activationPolyurea/polyurethane coatingsDevice materialAlkyne

The invention discloses a hybrid dynamic crosslinking polymer. The hybrid dynamic crosslinking polymer contains sulfydryl-Michael addition bond dynamic covalent crosslinking and supermolecular hydrogen bond interaction, wherein the sulfydryl-Michael addition bond dynamic covalent crosslinking reaches above a gel point in at least one crosslinking network; sulfydryl-Michael addition bonds are obtained through sulfydryl-Michael addition reaction between sulfydryl groups and electron-deficient conjugate alkenes / enynes; the supermolecular hydrogen bond interaction involves backbone hydrogen bond groups; with dynamic reversibility, the sulfydryl-Michael addition bonds and the supermolecular hydrogen bonds endow the hybrid dynamic crosslinking polymer with good plasticity, self-repairability, repeatability, reusability and recoverability and ensure that the hybrid dynamic crosslinking polymer can be widely applied to self-repairing materials, flexible materials, shape memory materials, energy storage device materials and the like.

Owner:厦门逍扬运动科技有限公司

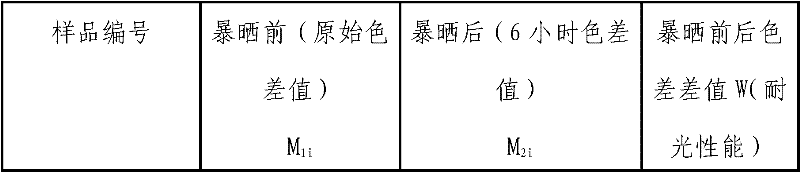

Determination method of light resistance of cigarette wrapping paper

InactiveCN102288535ASmall environmentHuman factors have little influenceWeather/light/corrosion resistanceWithdrawing sample devicesHueRepeatability

The invention discloses a method for measuring the light resistance performance of cigarette wrapping paper. First use a spectrophotometer to measure the original color difference of the main color block of the cigarette wrapping paper to be tested, then place the sample in a preheated exposure box for 6 hours and then measure the color difference value after exposure, and finally use the cigarette wrapping paper The hue change (color difference value) before and after exposure to the sun is used to characterize the lightfastness of cigarette wrapping paper. This method is less affected by environmental and human factors, and the data is more objective and fair and can be quantified. The measurement time is short, which is beneficial to guide production. The repeatability and consistency of the determination results are superior to other test methods.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Method for Determination of Chemical Composition in Blast Furnace Hot Metal by X-ray Fluorescence Spectrometry

InactiveCN102279202AEasy to operateFast analysisMaterial analysis using wave/particle radiationChemical compositionPhysical chemistry

Owner:TANGSHAN JIANLONG IND CO LTD

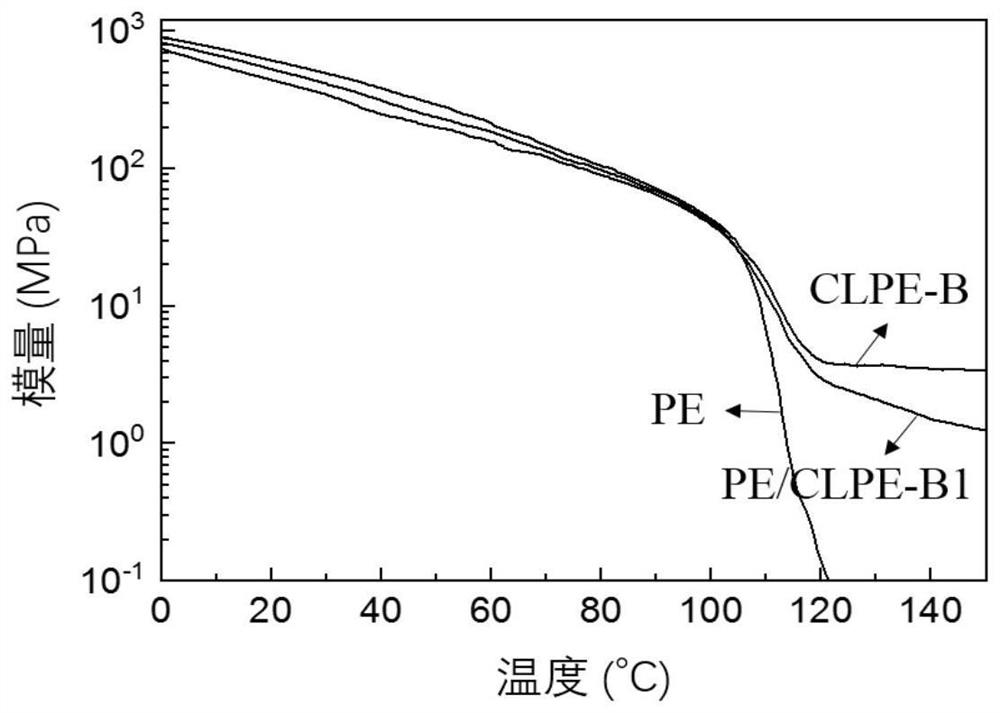

Dynamic covalent cross-linking material for enhancing polyethylene performance and preparation method and application thereof

ActiveCN112358631AImprove mechanical propertiesImprove creep resistancePolymer sciencePolymer network

The invention belongs to the technical field of high polymer materials, and particularly relates to a dynamic covalent cross-linking material for enhancing polyethylene performance and a preparation method and application thereof. The dynamic covalent cross-linking material is prepared from linear polyethylene with a borate group and a borate cross-linking agent through a borate exchange reaction,wherein the borate cross-linking agent is prepared from polybasic boric acid molecules and 1, 2-diol molecules or 1, 3-diol molecules through a dehydration condensation reaction; according to the dynamic covalent cross-linking polyethylene material, conversion and recombination of a polymer network can be realized through reversible exchange reaction among different borate groups. The dynamic covalent cross-linking polyethylene is added into commercial thermoplastic polyethylene to synthesize a polyethylene / dynamic cross-linked polyethylene composite polymer material; the mechanical properties (such as tensile strength and Young's modulus), creep resistance, solvent resistance, heat resistance and the like of the composite polymer material are remarkably enhanced, and the composite polymer material can be used for repeated processing, repeated shaping and 3D printing.

Owner:FUDAN UNIV

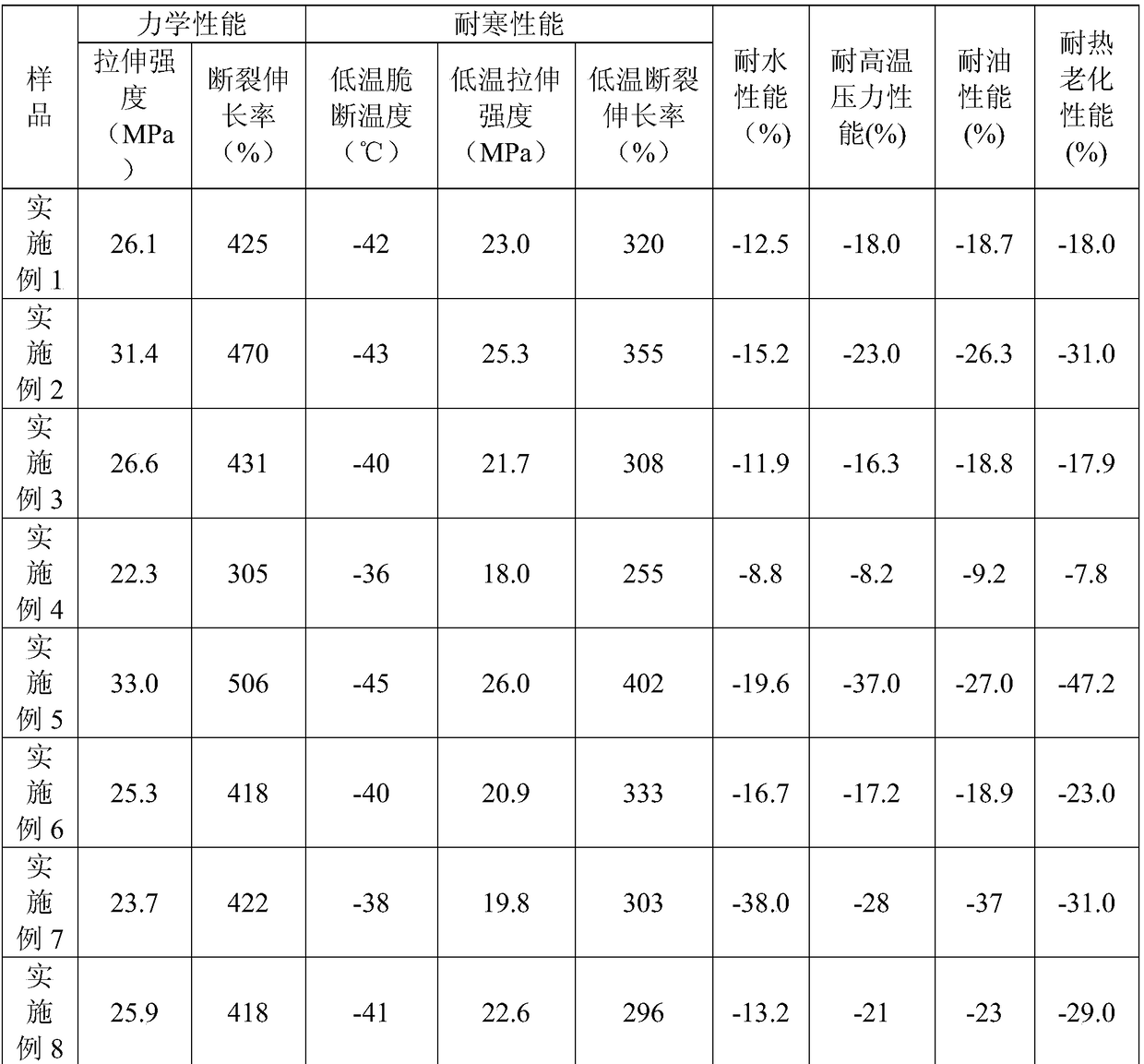

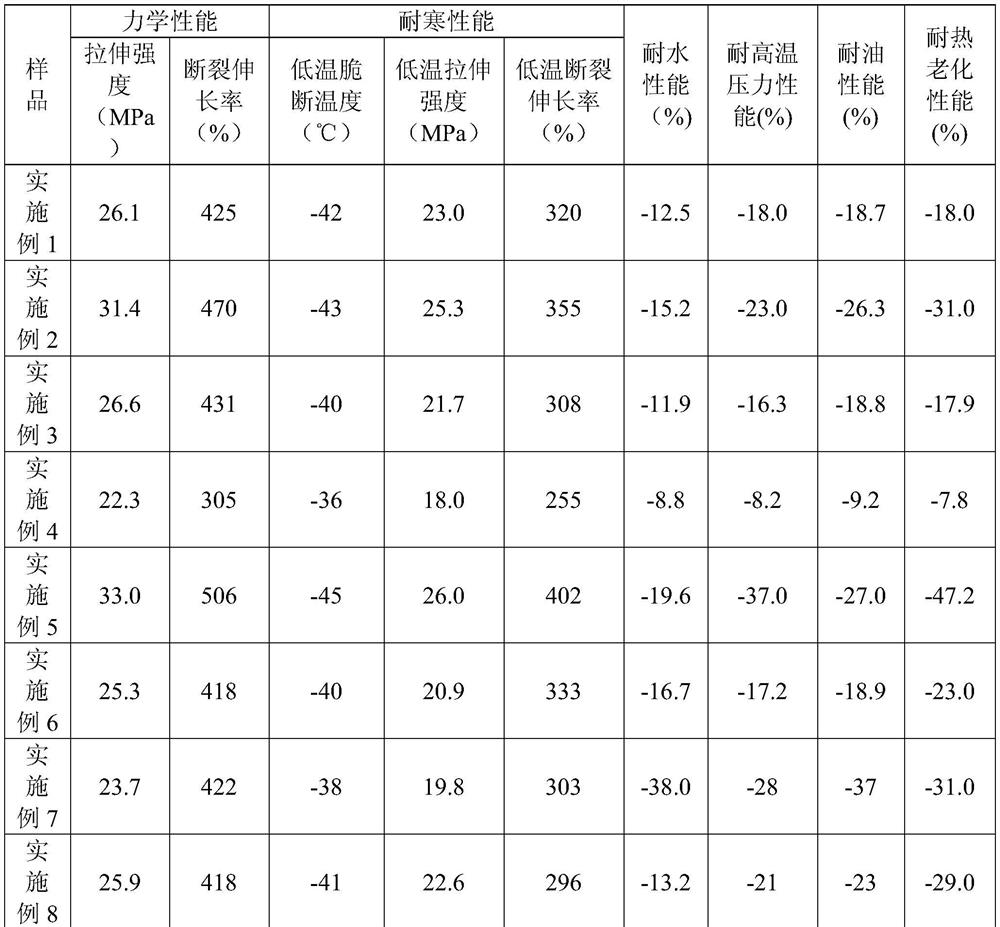

Thermoplastic composite elastomer material and preparation method thereof

The invention provides a thermoplastic composite elastomer material and a preparation method thereof. The thermoplastic composite elastomer material is prepared by mixing polyamide / acrylate rubber dynamic vulcanized rubber with thermoplastic polyurethane elastomer according to weight ratio of (3-9) to (1-7); compared with the polyamide / acrylate rubber dynamic vulcanized rubber and the thermoplastic polyurethane elastomer which are not mixed together, the thermoplastic composite elastomer material provided by the invention has significantly improved comprehensive performance, especially low temperature elastic property, low temperature tensile strength and low temperature brittleness property; at a low temperature of -35 DEG C, the low temperature tensile strength can reach 26MPa, the elongation can reach 402%, and the low temperature brittleness temperature is as low as 45 DEG C; the material also has excellent water resistance, long-term high temperature service performance, high temperature oil resistance, high elasticity and good reworkability; the materials such as wires and cables, sealing elements and hoses can make up for the technical gap in the application of the materialin the field of high-end technologies.

Owner:SUZHOU HENGLI COMM MATERIAL +1

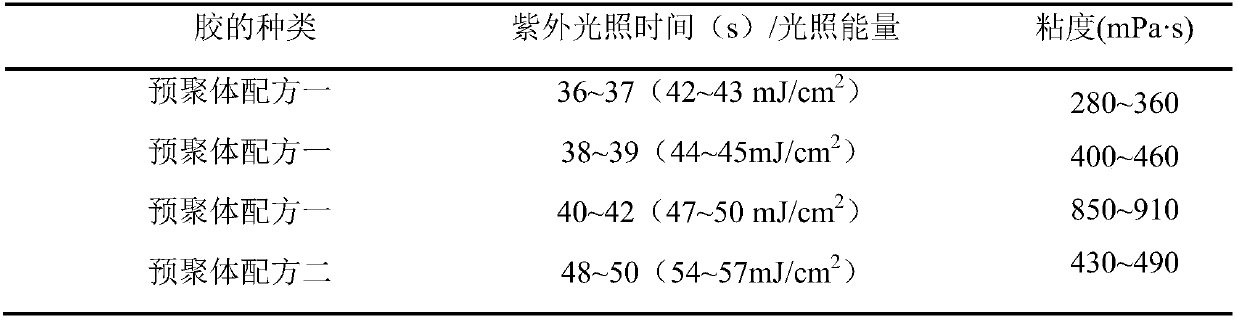

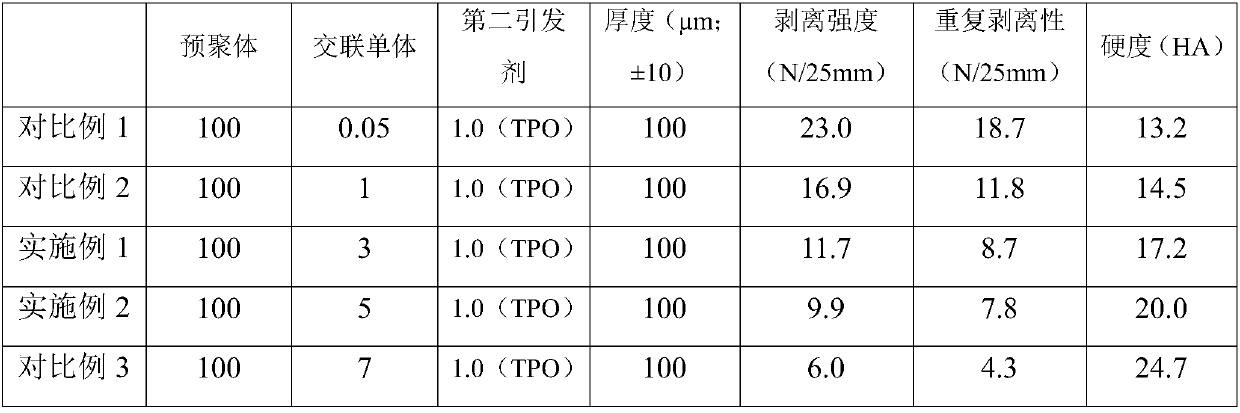

UV curing pressure-sensitive adhesive with medium peel strength, and preparation method thereof

ActiveCN109536076AImprove cohesive strengthGood adhesionPressure sensitive film/foil adhesivesIsooctyl acrylateUV curing

The invention discloses an UV curing pressure-sensitive adhesive with a medium peel strength, and a preparation method thereof. The UV curing pressure-sensitive adhesive comprises, by weight, 100 parts of an acrylate prepolymer, 0.05-10 parts of a crosslinking monomer, and a second photoinitiator; the acrylate prepolymer is formed by ultraviolet light irradiation polymerization of prepolymer monomers under the action of a first photoinitiator, the prepolymer monomers comprise, by mass, 85-90% of isooctyl acrylate and 10-15% of acrylic acid or hydroxyethyl acrylate, and the addition amount of the first photoinitiator is 0.01-0.5% of the mass of the prepolymer monomers; and the addition amount of the second photoinitiator is 0.5-5% of the mass of the acrylate prepolymer. The UV curing pressure-sensitive adhesive has the advantages of moderate peel strength, moderate flexibility and good reusability.

Owner:湖南省和祥润新材料有限公司

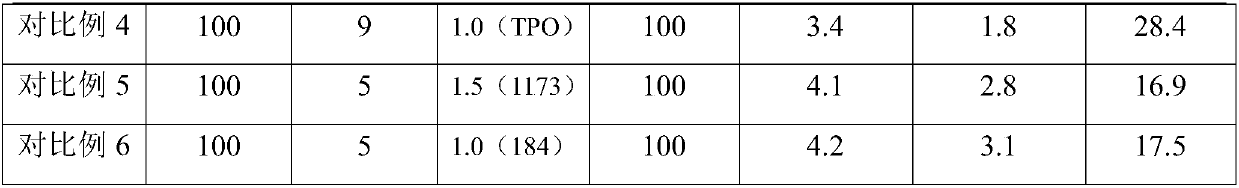

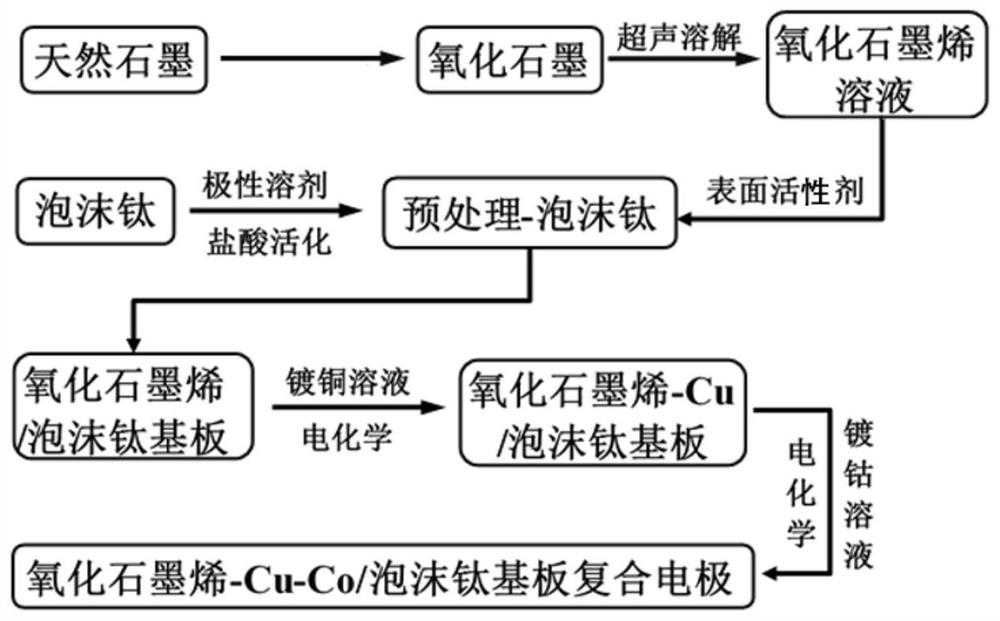

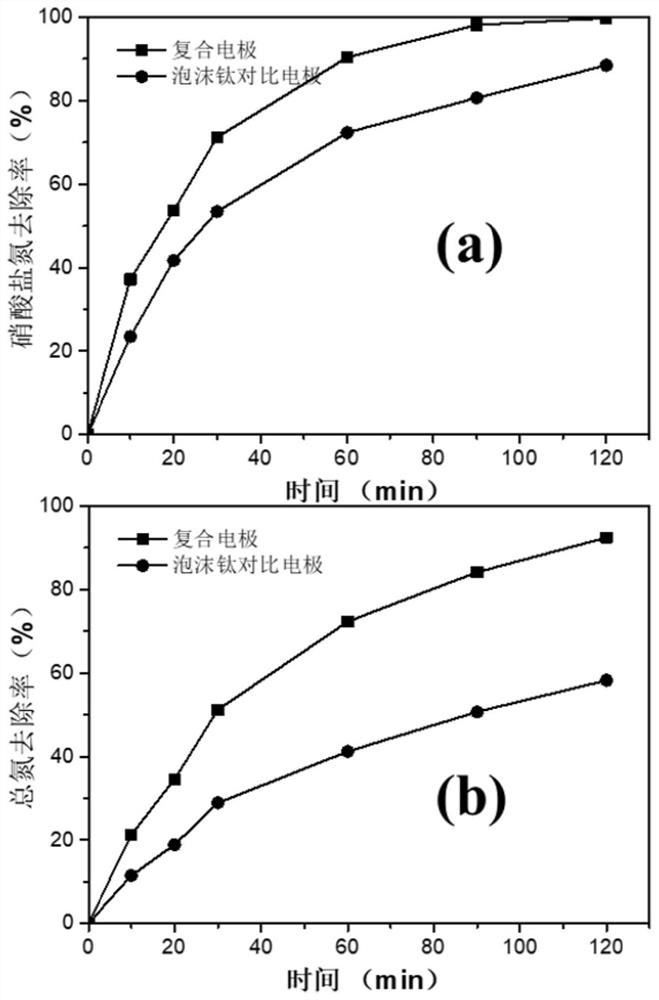

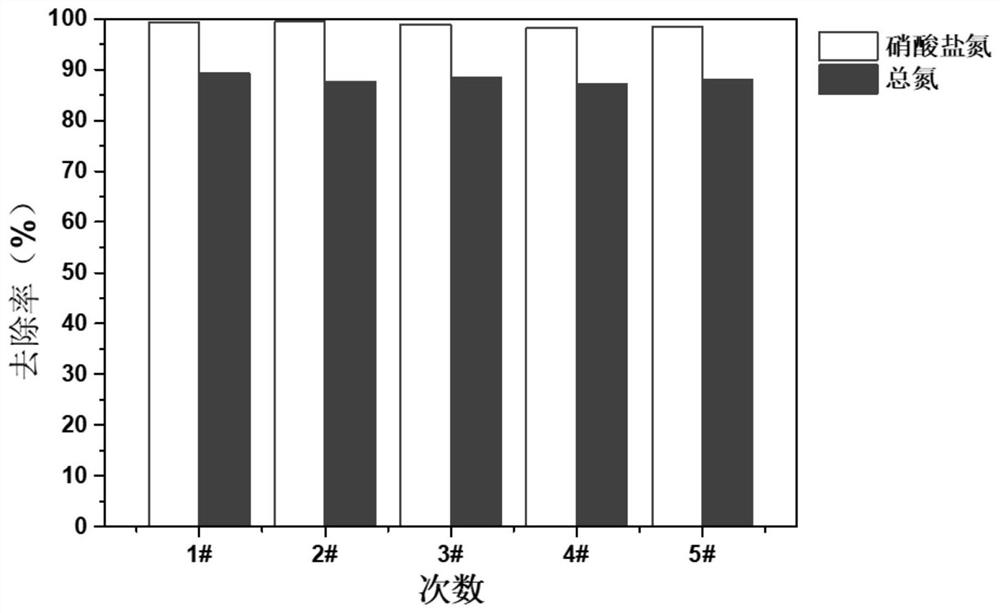

Graphene oxide-Cu-Co/foam titanium substrate composite electrode as well as preparation method and application thereof

PendingCN112723495AImprove adhesionReduce sheddingWater treatment parameter controlWater contaminantsComposite electrodeNitrate nitrogen

The invention discloses a graphene oxide-Cu-Co / foam titanium substrate composite electrode as well as a preparation method and application thereof, and belongs to the technical field of nitrate treatment in water. The composite electrode comprises a foam titanium substrate, a graphene oxide layer, a Cu layer and a Co layer which are arranged from inside to outside. The preparation method mainly comprises the following steps: 1) pretreating foamed titanium; 2) preparing a graphene oxide solution, and attaching graphene oxide to the surface of the foamed titanium; and 3) sequentially electroplating Cu and Co on the graphene oxide / foam titanium substrate by an electrochemical method. The composite electrode is large in specific surface area and high in catalytic efficiency, 90% or above of nitrate nitrogen and 70% or above of total nitrogen can be removed within 60 min through the coupling synergistic effect of graphene, Cu and Co, and the composite electrode is high in stability and repeatability and has good application prospects.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

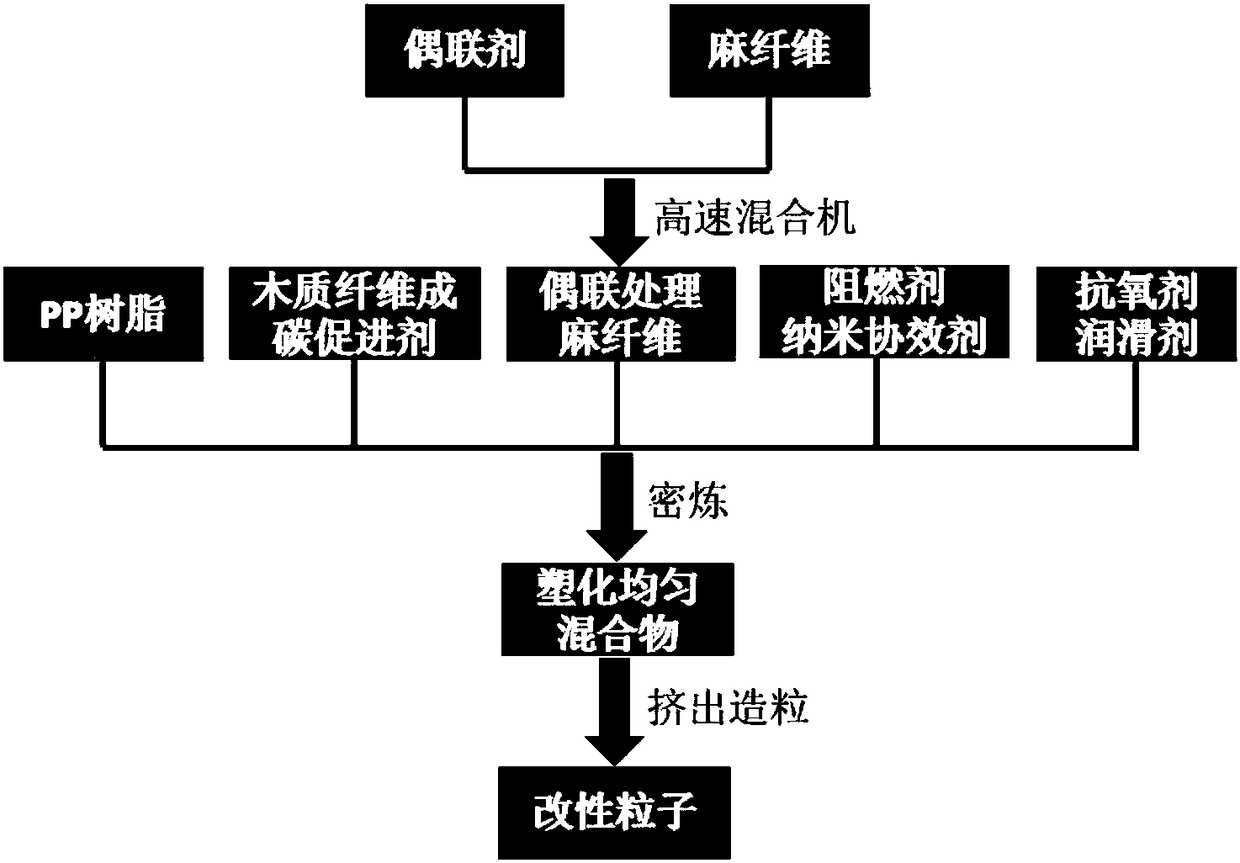

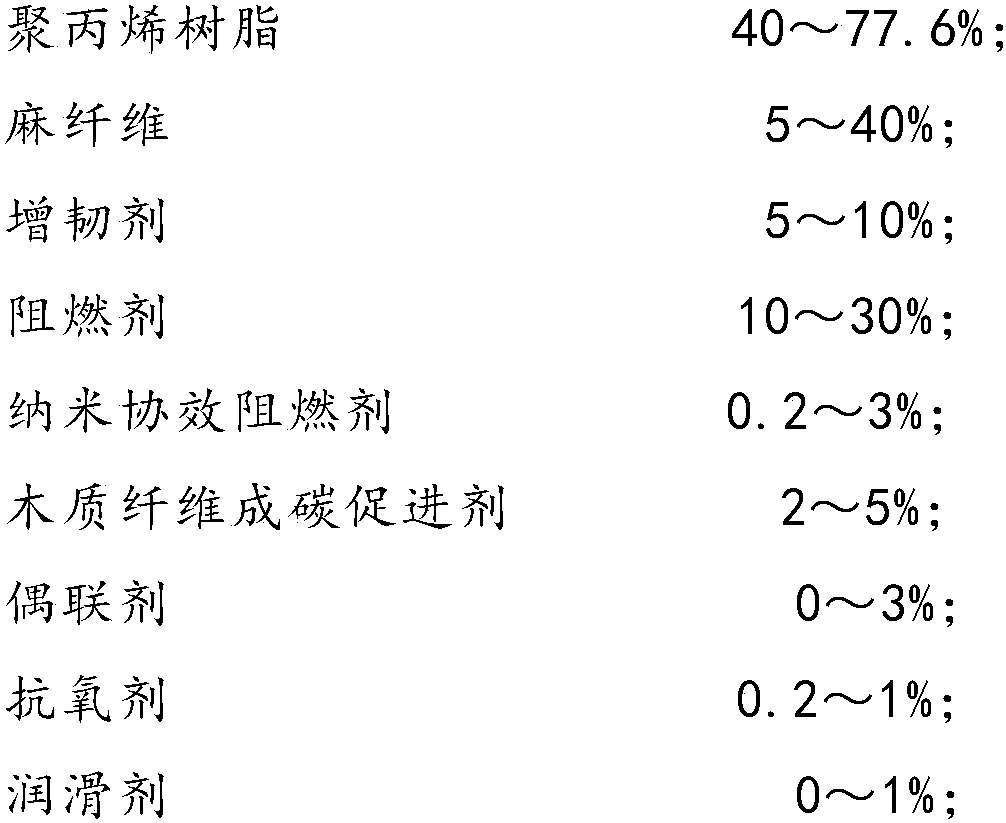

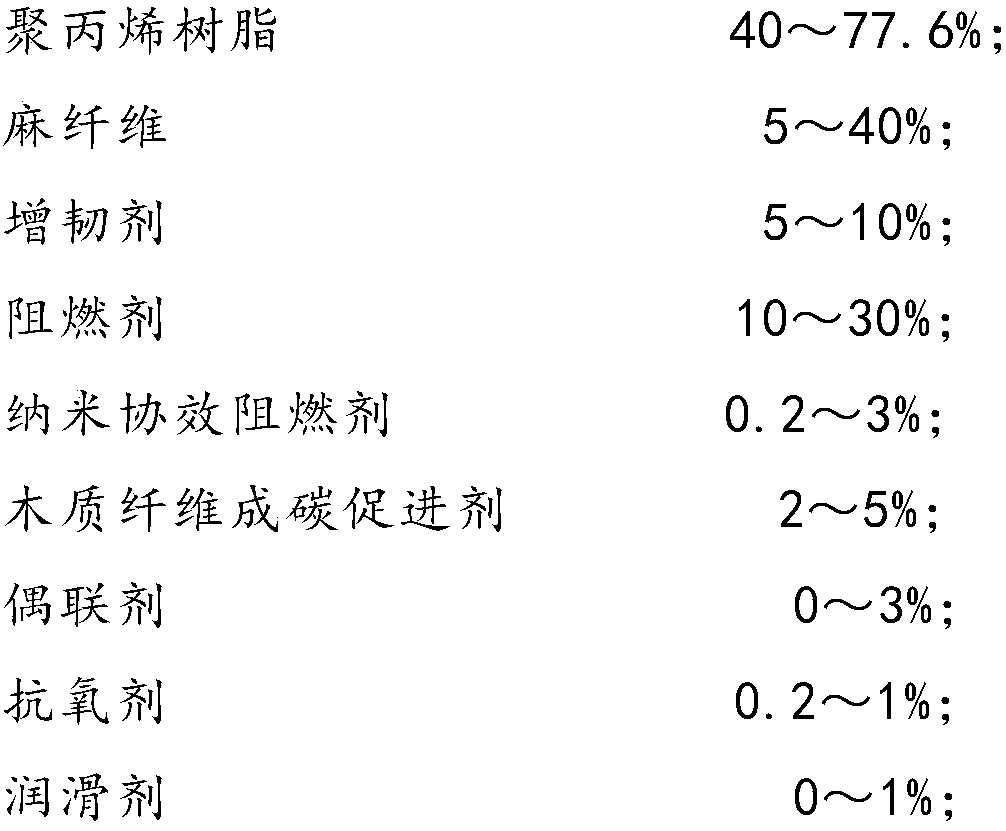

Lightweight, environment-friendly and flame-retardant bast fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a lightweight, environment-friendly and flame-retardant bast fiber reinforced polypropylene composite material and a preparation method thereof. The polypropylene composite material comprises 40-77.6% of polypropylene resin, 5-40% of bast fibers, 10-30% of flame retardant, 5-10% of toughening agent, 0.2-3% of nano synergistic flame retardant, 2-5% of wood fiber carbon-forming accelerant, 0-3% of coupling agent, 0.2-1% of antioxidant and 0-1% of lubricating agent. The lightweight, environment-friendly and flame-retardant bast fiber reinforced polypropylene composite material and the preparation method thereof have the advantages that polypropylene is used as the base material, the bast fibers are used as the reinforcement, the synergistic effects of halogen-free intumescent flame retardant, the nano synergistic flame retardant and the wood fiber carbon-forming accelerant are utilized, a banburying-extrusion two-stage continuous processing method is used, and accordingly the prepared composite material is excellent in flame retardance, and the bast fibers are evenly dispersed in the matrix.

Owner:SHANGHAI KINGFA SCI & TECH +1

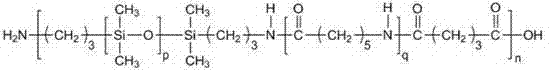

Modified polyester hot melt adhesive and preparation method thereof

InactiveCN105441005AHigh tensile strength and low temperature impact strengthGood tear resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryPolyamide

The invention relates to a modified polyester hot melt adhesive and a preparation method thereof. The modified polyester hot melt adhesive is prepared from components in parts by weight as follows: 40-70 parts of a polyester hot melt adhesive, 30-50 parts of a polyamide based organic silicon thermoplastic elastomer, 0.5-1 part of an antioxidant 164 and 1-3 parts of an auxiliary. The polyamide based organic silicon thermoplastic elastomer and organic bentonite are jointly adopted to modify the polyester hot melt adhesive, and the polyamide based organic silicon thermoplastic elastomer has high tensile strength and low-temperature impact strength, good tear resistance and good chemical resistance; the organic bentonite has good thixotropy and chemical stability, proper quantities of the polyamide based organic silicon thermoplastic elastomer and the organic bentonite are added, promote each other and have a synergistic effect, efficient modification of the polyester hot melt adhesive is realized, the low-temperature toughness, the aging resistance and the anti-stripping performance of the polyester hot melt adhesive can be remarkably improved, the processing performance is excellent, the bonding strength to metal-epoxy resin is high, and repeated processing performance for residual leftover materials is good.

Owner:林初煌

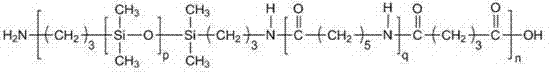

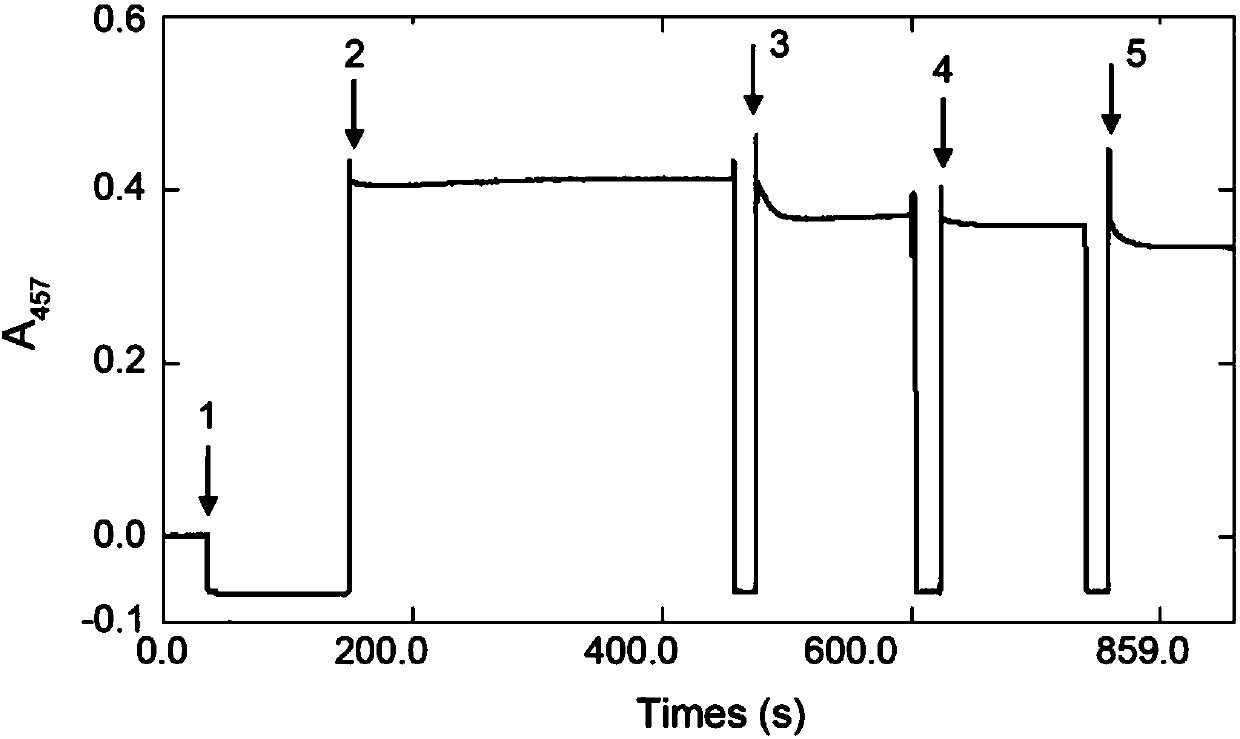

A novel method for measuring hydrogen pumping capability of mitochondria

ActiveCN108037082AHigh purityImprove qualityColor/spectral properties measurementsPhotochemistryBenzoquinone

The invention discloses a novel method for measuring hydrogen pumping capability of mitochondria, and belongs to the field of scientific research and experiments. The method includes S1) putting a magnetic stirrer below an absorption cell rack of a spectrophotometer; S2) setting the spectrophotometer into a time scanning state; S3) adding an absorption cell into the spectrophotometer, adding KCl into the absorption cell, starting the magnetic stirrer and starting scanning; S4) adding 8-hydroxy-1,3,6-pyrenetrisulfonic acid; S5) adding ferrocytochrome c, valinomycin, 2,3-dimethoxy-5-methyl-6-(10-bromo)-1,4-benzoquinone and a mitochondrion solution; S6) recording an absorption value A1 after an absorption line is flat; S7) adding 1 [mu]L of sodium ferricyanide having a concentration of 5 mM,and recording an absorption value A2; S8) adding a proton carrier that is [(3-chlorophenyl)hydrazono]malononitrile, and recording an absorption value A3; and S9) adding sodium ferricyanide, and recording an absorption value A4; and S10) calculating the hydrogen pumping capability according to an equation that is (H<+> / e)=x / y=(A1-A2) / (A3-A4). The method is reasonable in design, simple to operate and low in interference by the environment, and a measurement result is good in precision and repeatability. The method is suitable for use in common laboratories.

Owner:LINYI UNIVERSITY

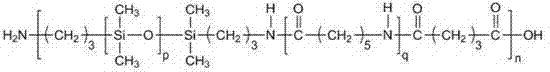

Preparation of a silicone rubber thermoplastic elastomer

ActiveCN103788656BImprove mechanical propertiesSimple processing technologyThermoplastic elastomerCarvacryl acetate

The invention discloses a thermoplastic elastomer, and a preparation method and application thereof. The thermoplastic elastomer comprises the following components in parts by weight: 13.63 to 95.41 parts of silicon rubber, 90 to 30 parts of ethylene-vinyl acetate copolymer, and 0.4425 to 4.125 parts of crosslinking system. The thermoplastic elastomer shows outstanding mechanical property, is simple in process, low in production cost, and excellent in processing reproducibility, and completely meets the recycling requirements.

Owner:SICHUAN UNIV

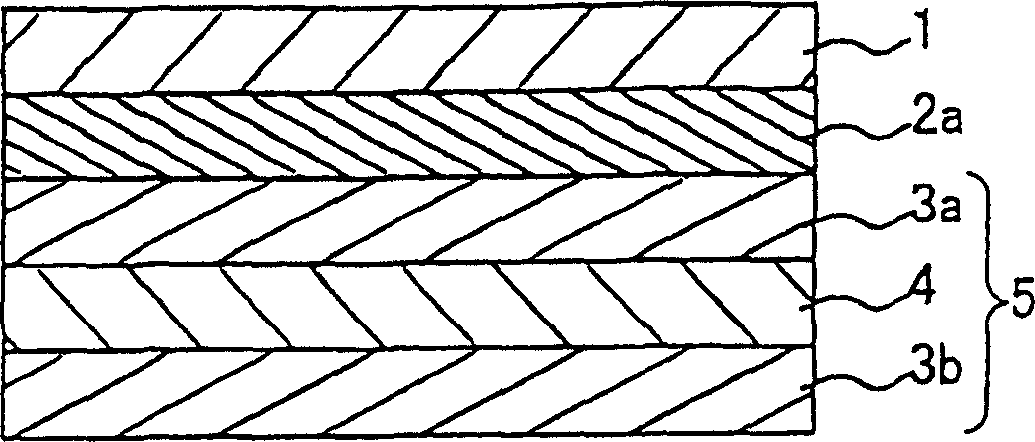

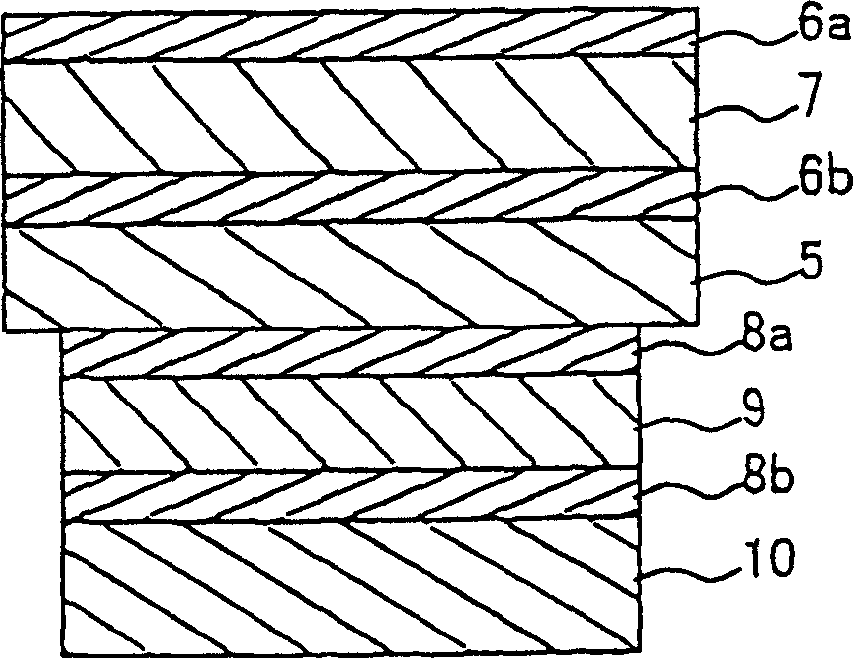

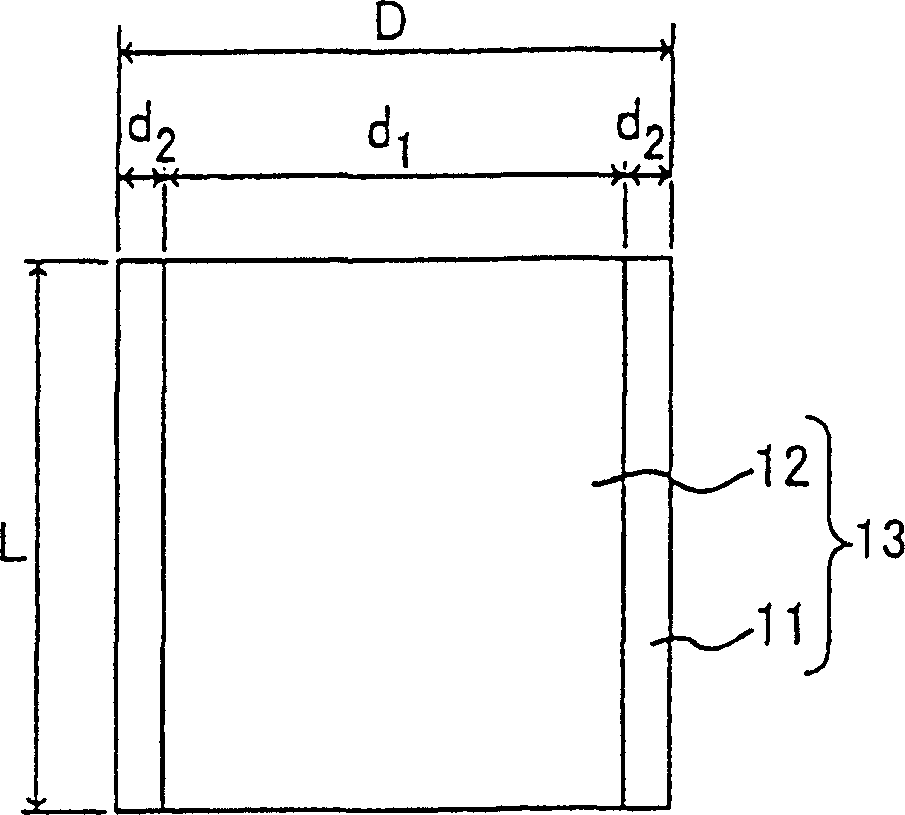

Laminated optical film, manufacture and use thereof

InactiveCN1220103CExcellent repeatabilityImprove mechanical propertiesPolarising elementsNon-linear opticsLiquid-crystal displayEngineering

A method of producing a laminated optical film constituted by a laminate of a plurality of optical films different in area, the method including the steps of: laminating an optical film (B) having a plurality of rectangular holes parallel to one another, on at least one surface of an optical film (A) to thereby form a laminate; and cutting the laminate into a plurality of chips to thereby obtain laminated optical films.

Owner:NITTO DENKO CORP +1

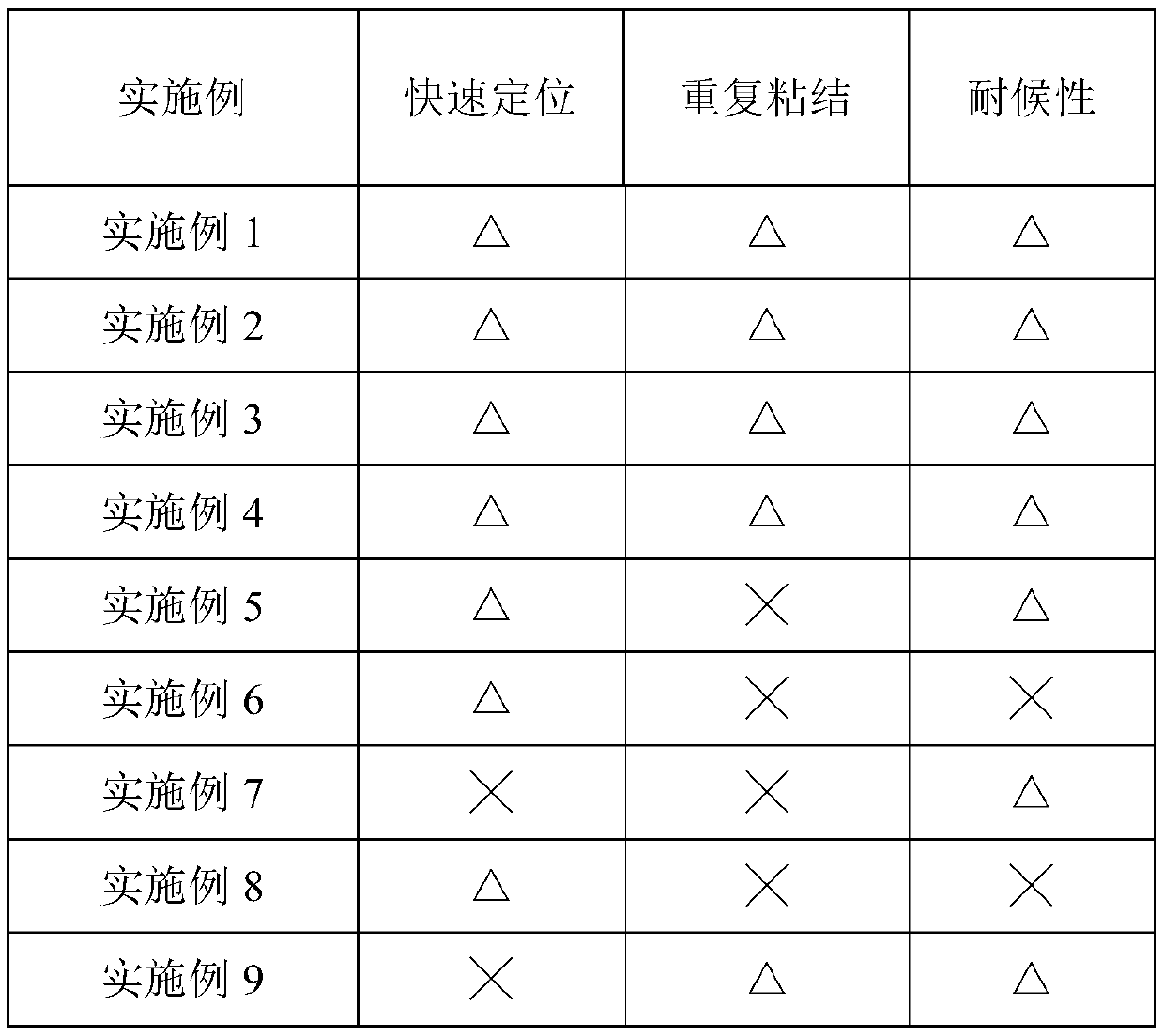

Adhesive special for quick positioning and preparation method thereof

ActiveCN110423583AExcellent repeatabilitySolve large area construction problemsMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAdhesive cementChemistry

Belonging to the technical field of adhesives, the invention in particular relates to an adhesive special for quick positioning and a preparation method thereof. The adhesive special for quick positioning comprises the following components by weight: 30-50 parts of petroleum resin, 15-25 parts of SBS rubber, 0.5-3 parts of silica, 15-25 parts of n-heptane and 8-12 parts of haloalkane. The adhesivespecial for quick positioning prepared according to the invention has superstrong binding force and viscosity of over 100000, is lasting and firm after curing, has quick positioning effect, can position the vast majority of base material within 10 seconds, can bear load, and also has no need for support and no need for fixation by adhesive tape. With excellent repeated cohesiveness, and for skewbonding, wrong bonding and other errors occurring in the construction process, the adhesive can be subjected to secondary repeated bonding with affecting the final adhesive force. With a long open time up to 40-60min, the adhesive can better solve the large-area construction problem and saves manpower.

Owner:中山市力得化工有限公司

A kind of thermoplastic composite elastomer material and preparation method thereof

The invention provides a thermoplastic composite elastomer material and a preparation method thereof. The thermoplastic composite elastomer material comprises polyamide / acrylate rubber dynamic vulcanizate and thermoplastic polyurethane elastomer in a weight ratio of (3-9):( 1~7) the composite elastomer material obtained by blending in the ratio; the overall performance of the thermoplastic composite elastomer material obtained by the present invention has significantly improved compared with the two materials before blending, especially low temperature elastic performance, low temperature Tensile strength and low-temperature brittleness, the low-temperature tensile strength can reach 26MPa at ‑35°C, the elongation can reach 402%, and the low-temperature brittleness temperature can be as low as ‑45°C. The material also has excellent water resistance, Long-term high-temperature service performance, high-temperature oil resistance, high elasticity and good repeated processing performance, the use of it to prepare materials such as wires and cables, seals, rubber hoses can fill the technical gap in the application of the above materials in high-end technical fields in my country.

Owner:SUZHOU HENGLI COMM MATERIAL +1

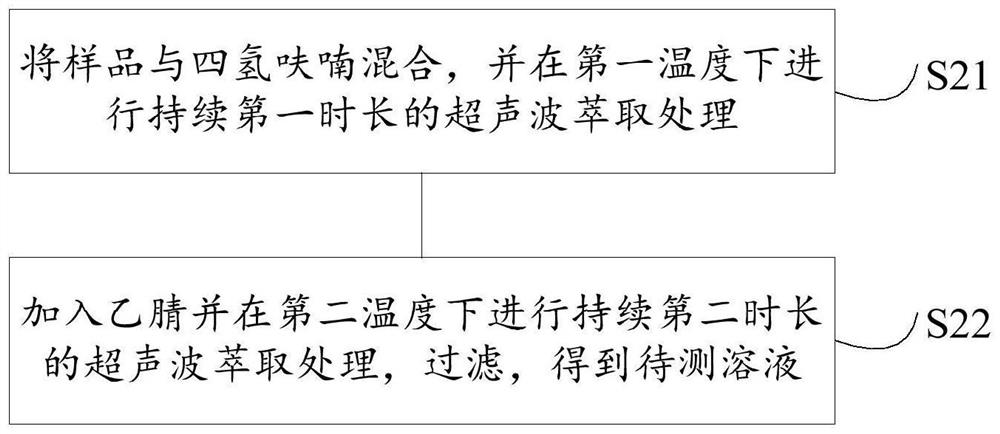

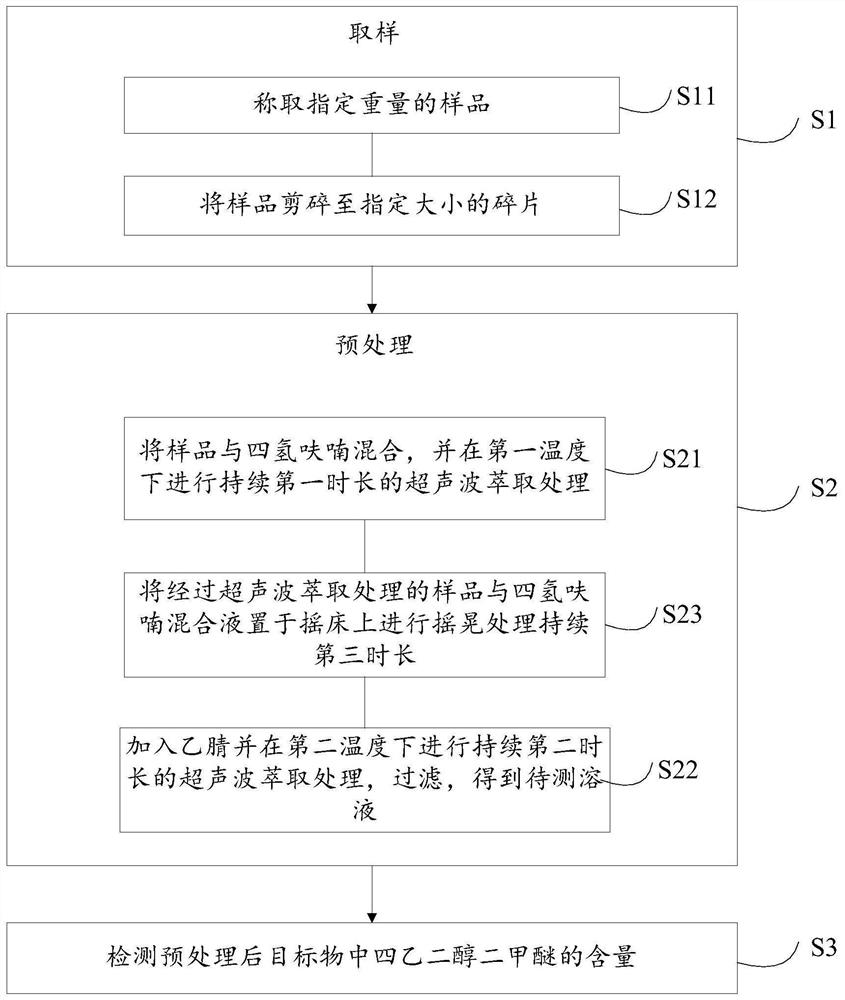

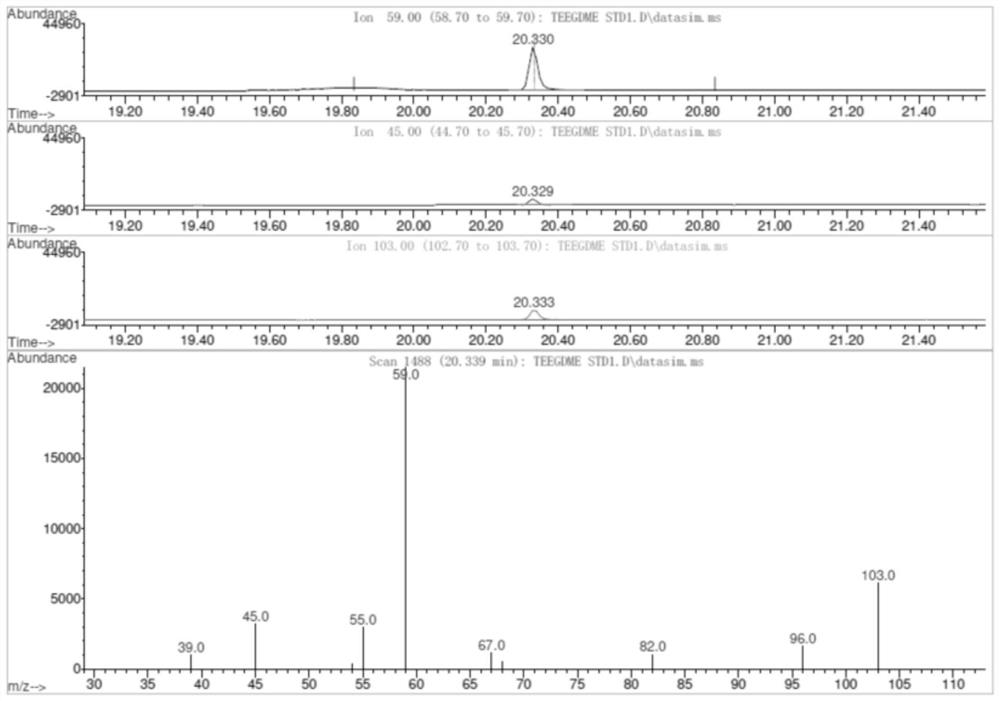

Method for detecting tetraethylene glycol dimethyl ether

PendingCN114414708AFulfil requirementsEasy to separateComponent separationPhysical chemistryTetraethylene glycol dimethyl ether

The invention provides a method for detecting tetraethylene glycol dimethyl ether, which is used for detecting tetraethylene glycol dimethyl ether in consumer goods, and comprises the following steps: sampling; pre-treating and detecting the content of tetraethylene glycol dimethyl ether in the pre-treated target object; wherein the pretreatment step comprises the following steps: mixing a sample with tetrahydrofuran, and carrying out ultrasonic extraction treatment at a first temperature for a first duration; adding acetonitrile, carrying out ultrasonic extraction treatment for a second duration at a second temperature, and filtering to obtain a solution to be detected. According to the method for detecting tetraethylene glycol dimethyl ether, the blank of national standard methods is filled, the requirements of customers with the detection requirements are met, the operation is simple, the recovery rate is high, the used equipment is easy to obtain, the method has high generalizability, and the detection lower limit can reach 50mg / kg.

Owner:深圳天祥质量技术服务有限公司

A thermally reversible crosslinked Eucommia gum double shape memory elastomer and its preparation method

The invention relates to a thermally reversible crosslinking gutta-percha double-shape memory elastomer and a preparation method thereof. The preparation method comprises the following steps: performing grafting reaction on gutta-percha, a diene body and a photoinitiator in a solution; and performing thermally reversible crosslinking of the graft product and a dienophile crosslinking agent to obtain a shape memory elastomer. According to the elastomer, grafting and then hot pressing are performed in the solution, and the technology is simple. The prepared elastomer has double-shape memory performance as well as good fixed rate and recovery rate and can be repeatedly utilized to save energy and resource.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of poly(urethane-urea-amide) elastomer powder for selective laser sintering, and product

PendingCN113667295ALow densityLow water absorptionAdditive manufacturing apparatusPolyamidePolyester

The invention belongs to the technical field of additive manufacturing, and discloses a poly(urethane-urea-amide) elastomer powder for selective laser sintering, and a preparation method thereof. The elastomer powder is a segmented block copolymer composed of polyamide and polyurethane, and the polyurethane is composed of diisocyanate and polyether and / or polyester. The preparation method comprises the following steps: 1) pre-cooling poly(urethane-urea-amide) elastomer granules by liquid nitrogen, and then crushing the pre-cooled poly(urethane-urea-amide) elastomer granules; 2) screening the powder, wherein the selection range of the particle size of the powder is 0-300 [mu]m; and 3) uniformly mixing the screened poly(urethane-urea-amide) elastomer powder with the flow aid and the antioxidant according to a certain mass ratio to obtain the poly(urethane-urea-amide) elastomer powder for selective laser sintering printing. The product is good in fluidity, wide in printing window, antistatic and excellent in product mechanical property and water resistance. The material can be applied to the fields of aerospace, medical orthopedics, sports equipment and the like.

Owner:ZHENGZHOU UNIV

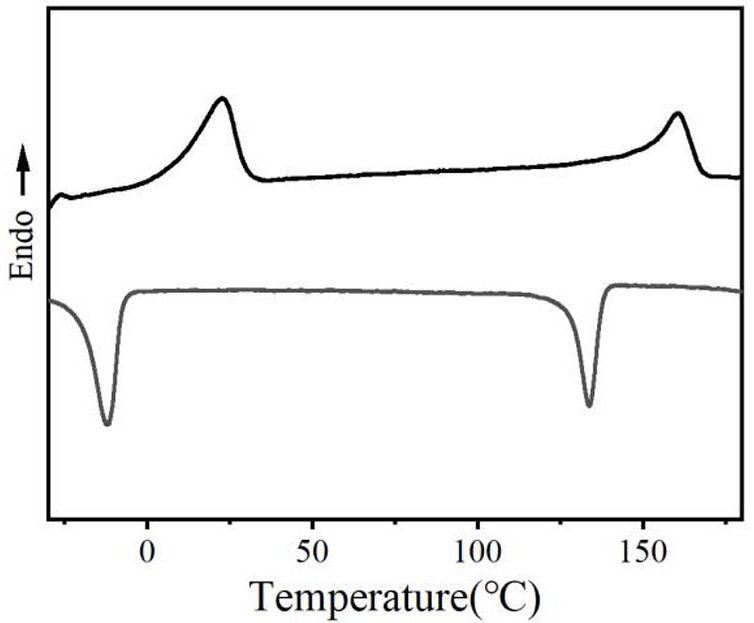

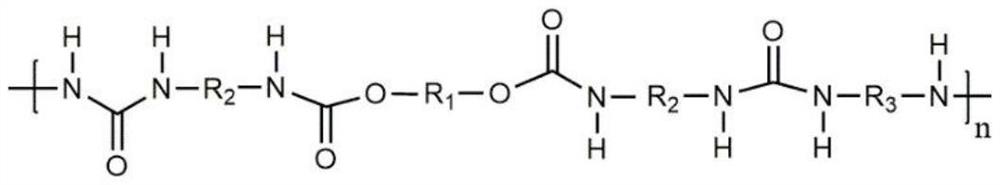

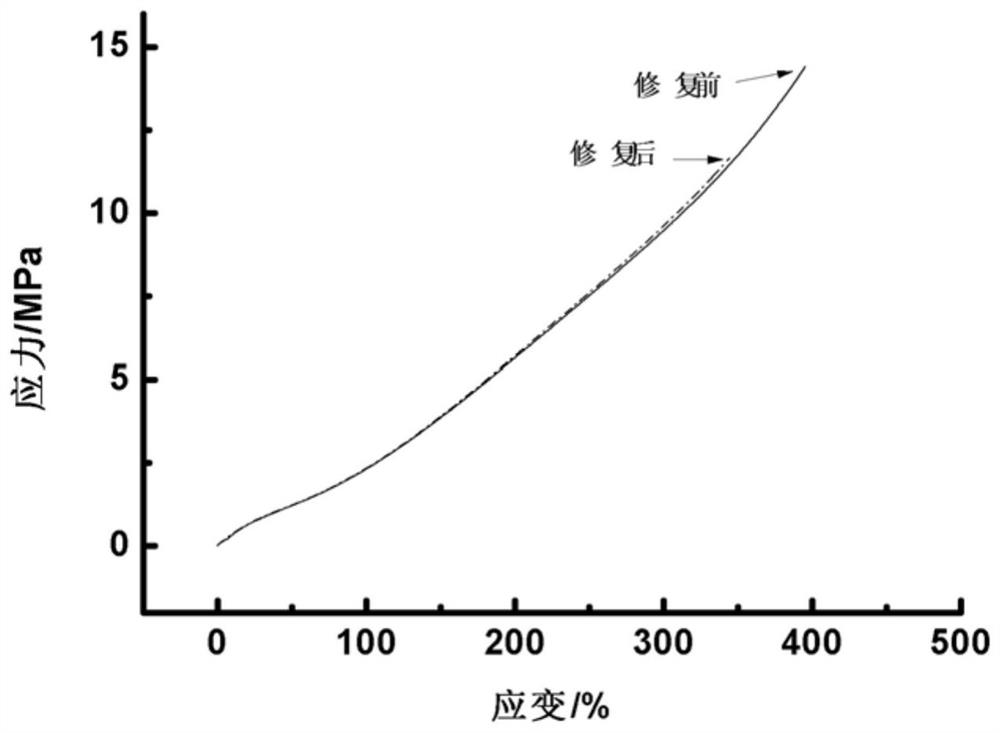

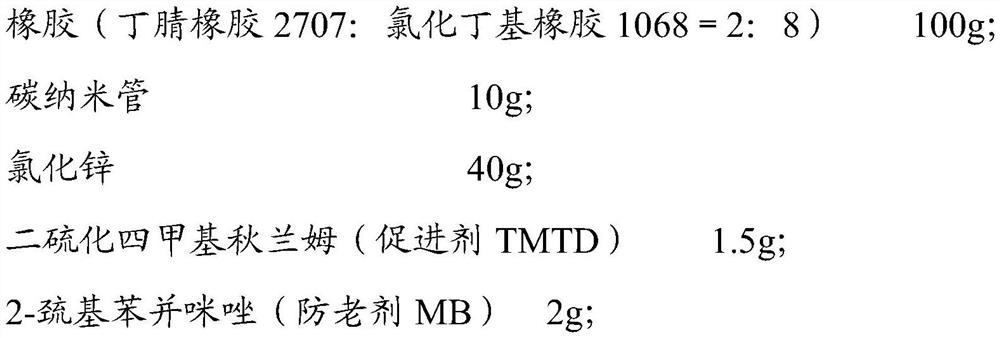

A kind of nitrile rubber system with repairability and preparation method and repair method thereof

The invention discloses a repairable nitrile rubber system, a preparation method and a repair method thereof, and belongs to the technical field of nitrile rubber. The raw materials of the rubber system include the following components in parts by weight: 100 parts of rubber, 5-40 parts of coordination salt, 0.5-10 parts of filler, 1-5 parts of polysulfide bond curing agent, 1-3 parts of anti-aging agent and more 5-10 parts of hydroxyl compound, wherein the rubber includes nitrile rubber and halogenated butyl rubber mixed in a mass ratio of 2:8-8:2, and the polyhydroxy compound is polyhydric alcohol or polyhydric phenol. The restorative nitrile rubber system provided by the embodiments of the present invention forms a cross-linked structure with covalent bonds and non-covalent bonds by constructing coordination bonds, hydrogen bonds and polysulfide exchange bonds inside the nitrile rubber , comprehensively improve the self-repair ability of rubber, and the repair process is simple, economical and environmentally friendly, and the repair efficiency is high.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

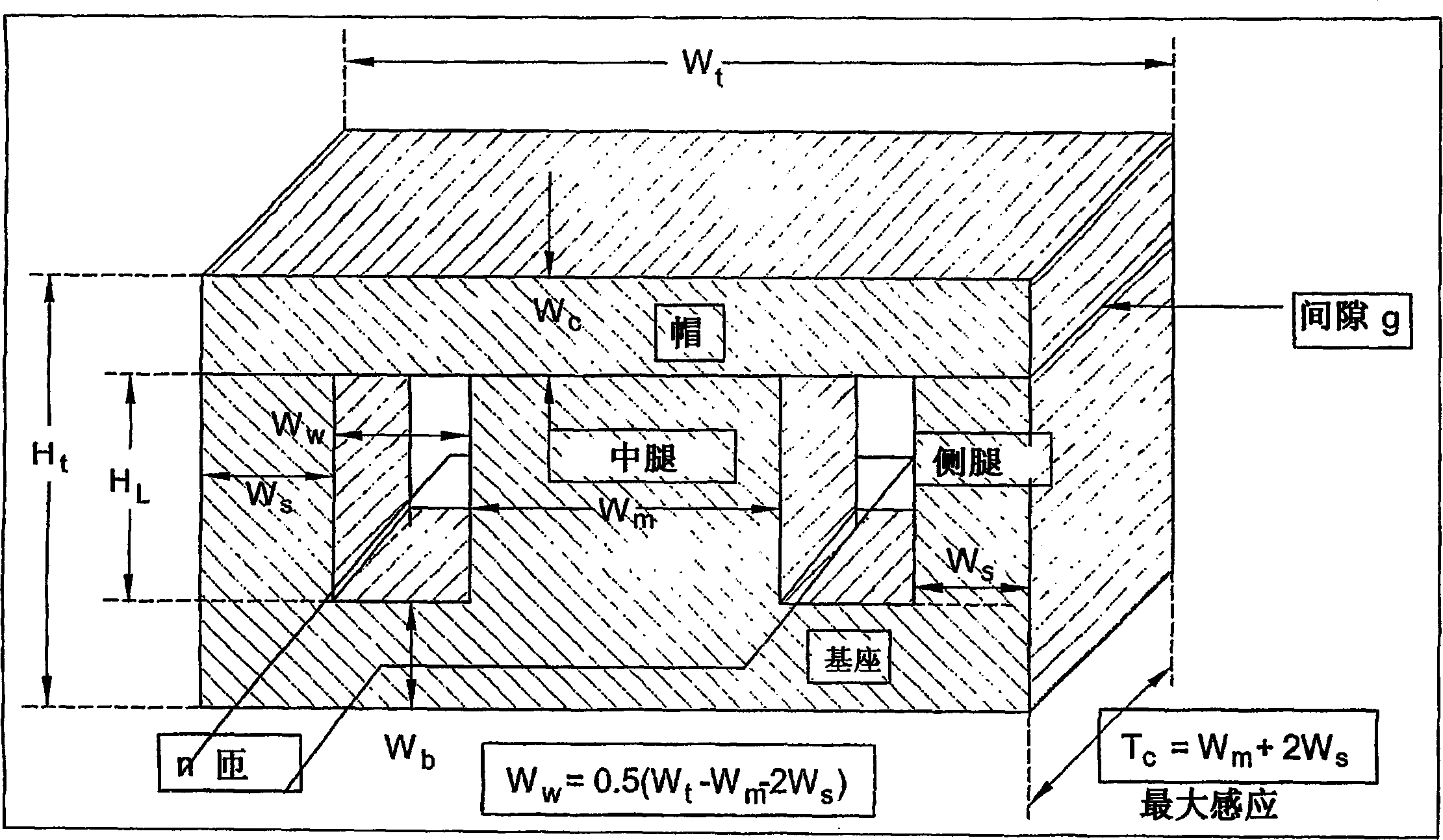

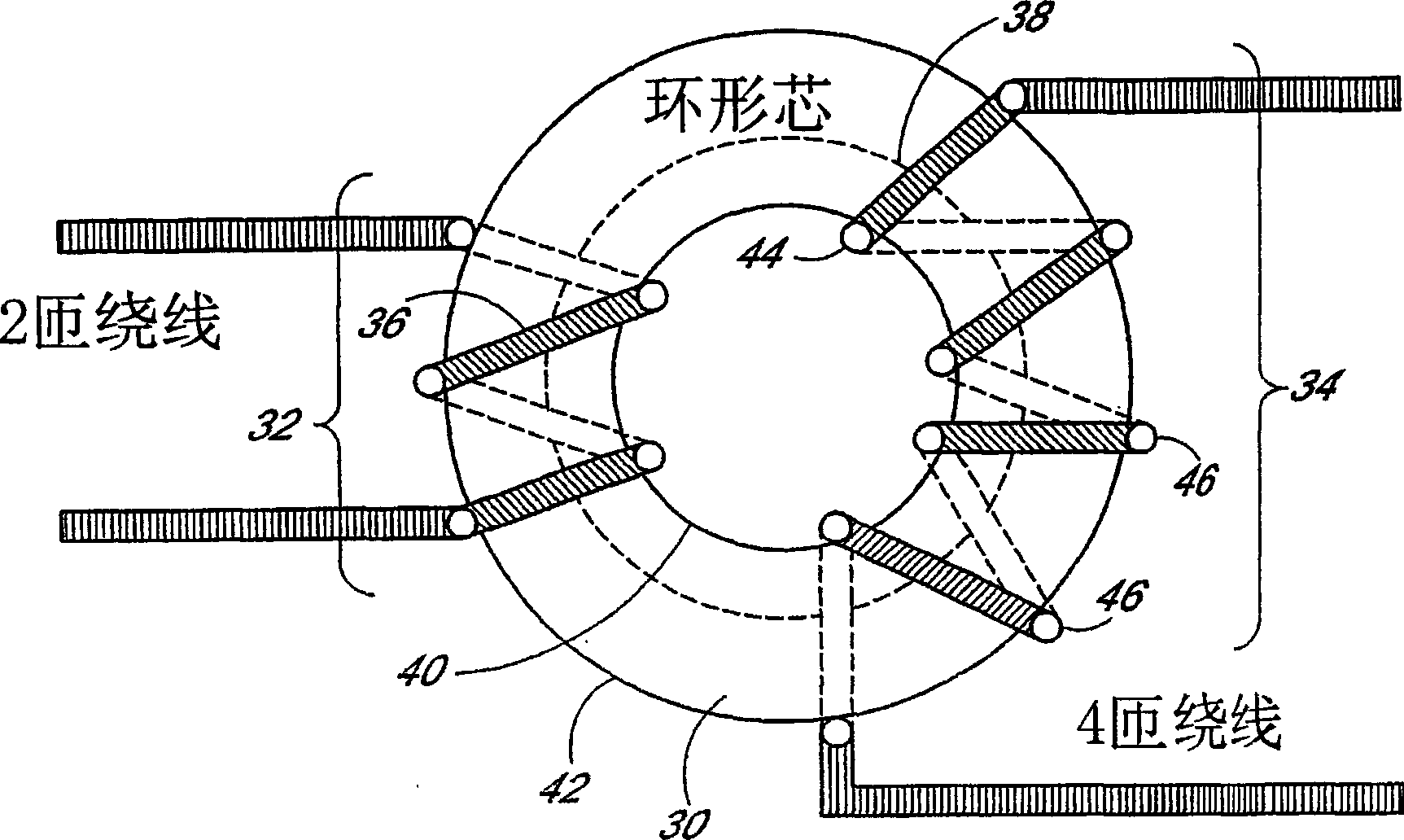

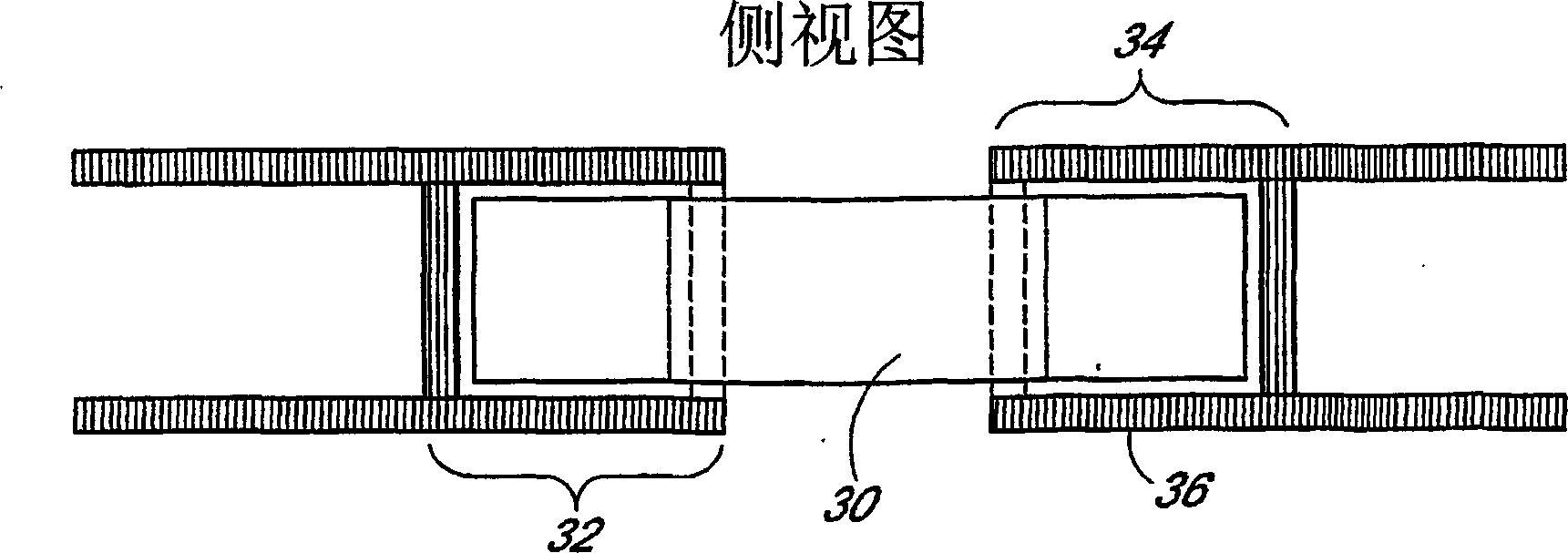

Electronic transformer/inductor devices and methods for making same

InactiveCN1783367AImprove cooling effectImprove performanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresHigh volume manufacturingTransformer

The present invention relates to a method of forming inductive elements, such as inductors, chokes and transformers used as an integral part of the manufacture of PCBs or FLEXs, preferably from ferromagnetic materials. In a preferred embodiment, holes (56, 58) are formed through the ferromagnetic substrate (50) and plated with a conductive material. The placement of these holes and subsequent design will form the inductive element in the plane of the medium in which the device is formed; the substrate (50) for the magnetic core (90). By employing this approach, the inductive element can be minimized to a physical size compatible with the demands of modern surface mount technology (SMT) for integrated circuits (ICs). This process also allows these components to be fabricated using mass production techniques, thereby avoiding the need to manipulate individual devices during the fabrication process. In another preferred embodiment, a series of thin, concentric high permeability rings (315) are etched on the substrate (330) to provide high permeability transformers and inductors with minimal eddy current effects.

Owner:MULTI FINELINE ELECTRONIX INC

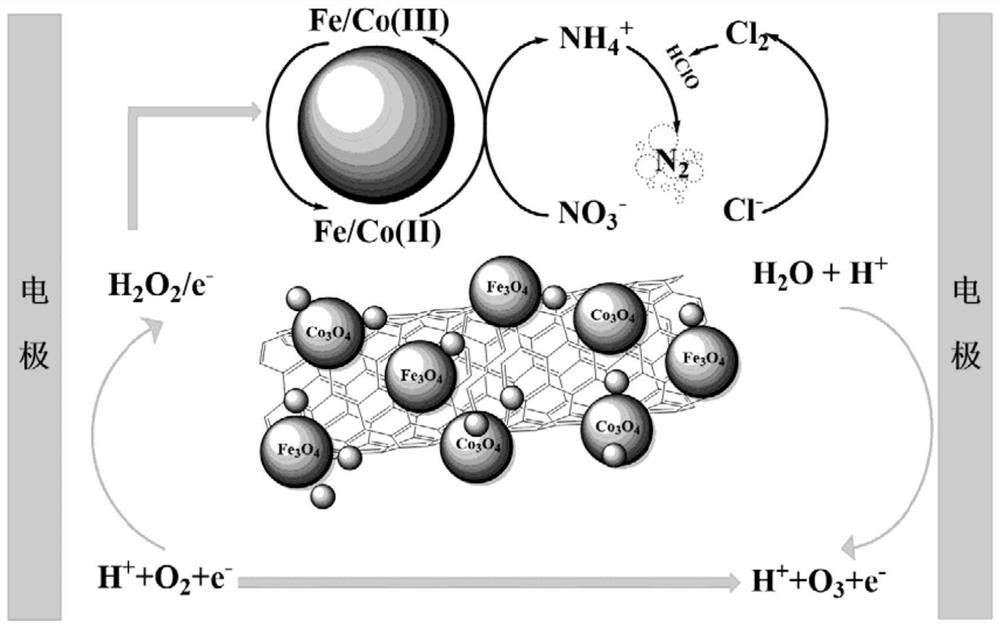

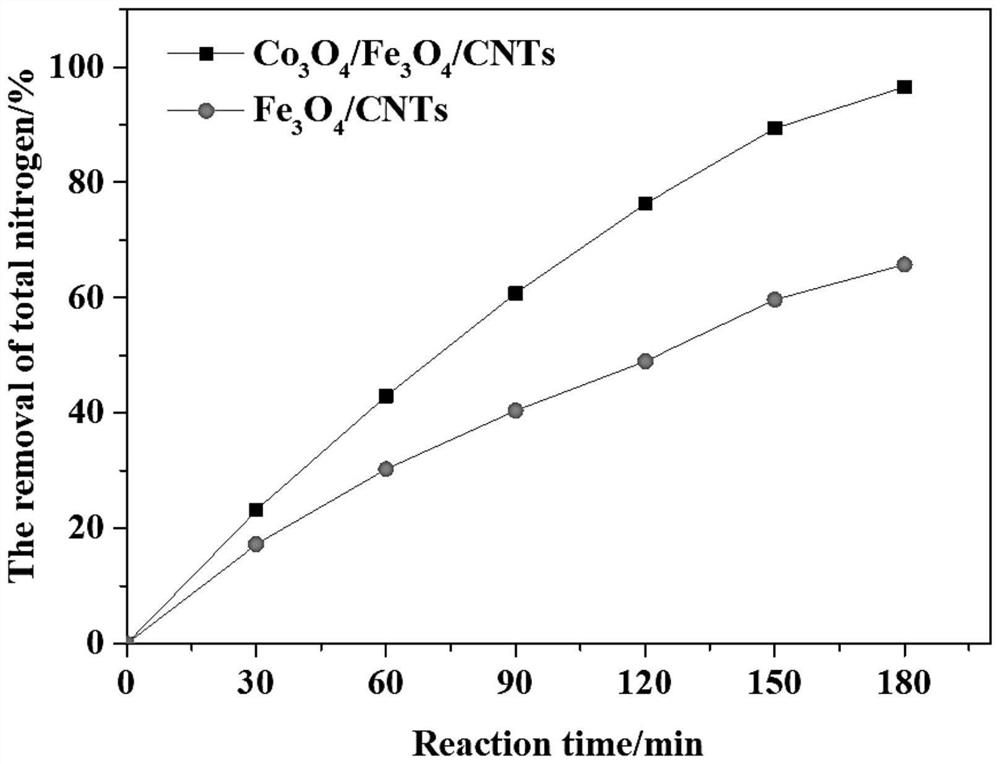

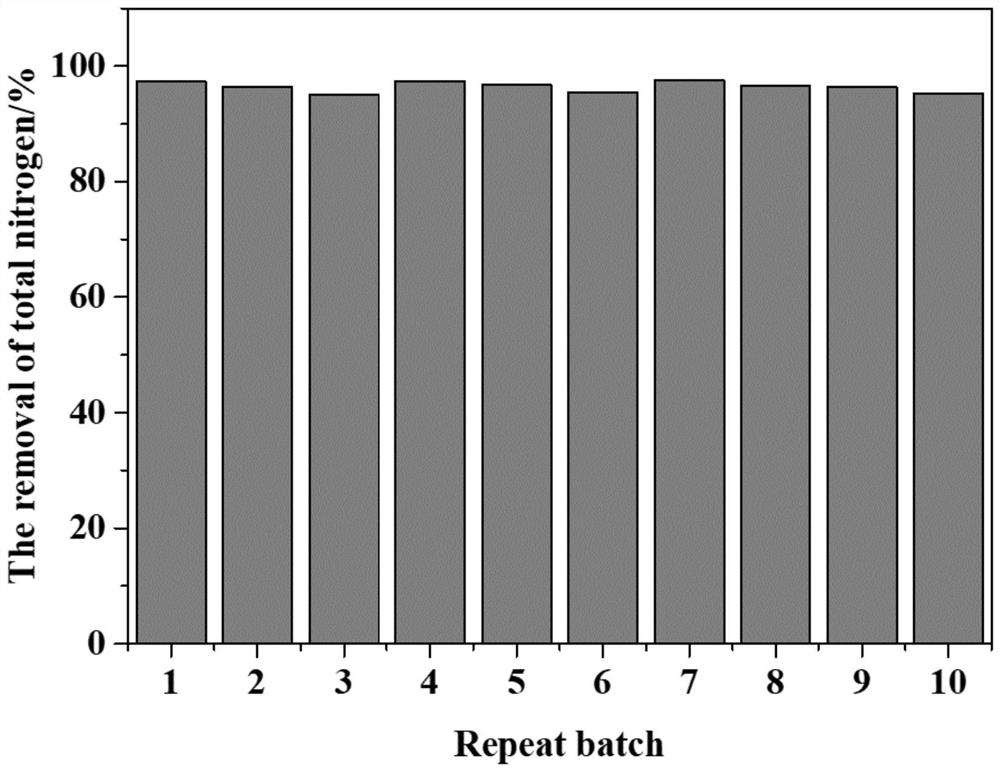

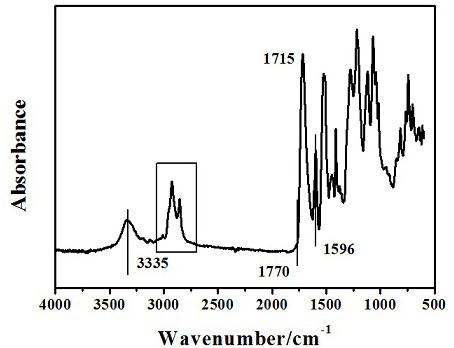

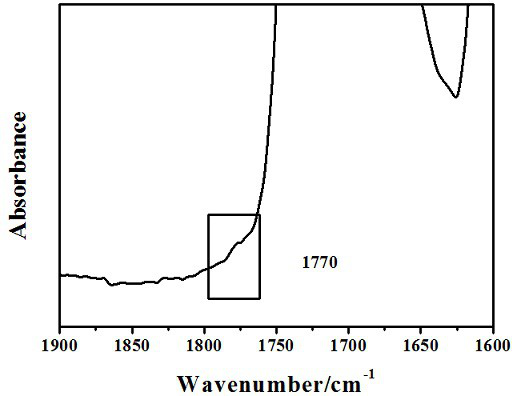

Method for treating nitrate nitrogen-containing wastewater based on Co3O4/Fe3O4/CNTs composite dispersed electrode

ActiveCN113880198AAchieve removalImprove catalytic performanceWater contaminantsWater/sewage treatment using germicide/oligodynamic-processNitrate saltsNitrate nitrogen

The invention discloses a method for treating nitrate nitrogen-containing wastewater based on Co3O4 / Fe3O4 / CNTs composite dispersed electrode, belonging to the field of sewage treatment. According to the method, a Co3O4 / Fe3O4 / CNTs composite material is used as the dispersed electrode, and nitrate in water is treated via a three-dimensional electrode electrolytic bath and by adding chlorine salt electrolyte into wastewater in the electrolytic bath. According to the invention, the magnetism and catalytic performance of Fe3O4 are cooperated with the good catalytic performance of Co3O4 on nitrate nitrogen, and the chlorine-containing electrolyte is combined, so a high mass transfer rate can be realized, relatively high current intensity can be provided at relatively low current density, and the method has the advantages of high current efficiency, good treatment effect, large treatment capacity and low energy consumption.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

Thermally reversible crosslinked polyurethane containing dicyclopentadiene crosslinked bridge, preparation method and application thereof

ActiveCN110128618BEnables repeated reprocessingEnables thermoplastic processingPolymer scienceCross linker

The invention provides thermally reversible crosslinked polyurethane containing dicyclopentadiene crosslinking bridged bonds, and a preparation method and applications thereof. Dicyclopentadiene dicarboxylic acid and polyisocyanate (I) carry out reactions to generate a terminal isocyanate component, which contains a dicyclopentadiene structure and is taken as a crosslinking agent, and the terminalisocyanate component and a terminal hydroxyl component carry out reactions to form a crosslinked polyurethane network. By introducing dicyclopentadiene bridged bonds into polyurethane, at a high temperature, bridged bonds are broken; at a low temperature, bridged bonds are formed again; and repeated processing of chemical crosslinking type polyurethane is realized. The primary reverse Diels-Alderreaction temperature of dicyclopentadiene bridged bonds is 170 DEG C; and dicyclopentadiene bridged bonds are introduced into polyurethane to realized thermoplastic processing of crosslinking type polyurethane in a temperature range of 170 to 210 DEG C. The prepared thermally reversible polyurethane has an excellent repeated processing property, and still has good mechanical properties after manytimes of processing and moulding.

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com