A thermally reversible crosslinked Eucommia gum double shape memory elastomer and its preparation method

A dual-shape and eucommia glue technology, applied in the field of shape memory elastomers, can solve the problems of low recovery rate of shape memory, eucommia glue cannot be reused many times, and large consumption, so as to achieve flexible shape changes and good repeatable processing performance , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

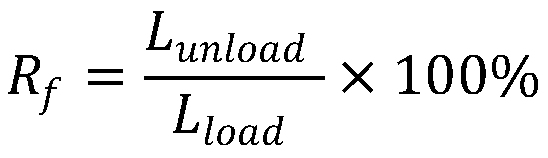

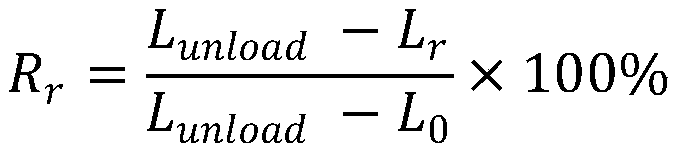

Method used

Image

Examples

Embodiment 1

[0019] 100g of eucommia gum (commercially available) with a crystallinity of 40% is dissolved in 1000ml of toluene solvent, stirred until fully dissolved to form a uniform, transparent solution; then 30g of furfuryl mercaptan, 1g of 2-methyl-1-( -4-methylthiophenyl)-2-morpholino-1-propanone, added to the dissolved solution, and irradiated with ultraviolet light (spectronics SB-100P / FC, the same below) at 30°C for 30min, grafting occurred reaction, washed with methanol, and suction filtered to remove unreacted dienes; the grafted product and 50 g of diphenylmethane bismaleimide were added to 1000 ml of tetrahydrofuran solution, stirred at 30 ° C until fully dissolved, 40 Vacuum dry at ℃ for 24 hours to remove the solvent; use a flat vulcanizing machine (manufactured by Zhejiang Huzhou Dongfang Machinery Co., Ltd., model XLB-D350X350, the same below) to heat press at a pressure of 15Mpa and a temperature of 120℃ for 30 minutes, and thermal reversibility occurs. Cross-linking to ...

Embodiment 2

[0025] 100g of eucommia peptiformis with a crystallinity of 50% was dissolved in 1000ml of tetrahydrofuran solvent, stirred until fully dissolved to form a uniform and transparent solution; 40g of furfurylamine, 2g of 2,2-dimethoxy-2-phenylbenzene Add ethyl ketone to the dissolved solution, and irradiate with ultraviolet light for 60 minutes at 20°C to cause grafting reaction, wash with methanol and filter with suction to remove unreacted dienes; mix the grafted product with 70g of diphenylmethane bismale The imide was added to 1000ml tetrahydrofuran solution, stirred at 30°C until fully dissolved, then vacuum-dried at 40°C for 24 hours, and the solvent was removed; the product was hot-pressed at 110°C for 30 minutes under a pressure of 15Mpa, and a thermally reversible crosslinking reaction occurred to obtain Shape memory elastomers crosslinked by thermoreversible bonds. The properties are shown in Table 1.

Embodiment 3

[0027] 100g of eucommia gum with a crystallinity of 40% was dissolved in 1000ml of toluene and tetrahydrofuran mixed solvent, stirred until fully dissolved to form a uniform and transparent solution; 50g of methoxythiophene, 3g of 2,4,6-trimethyl Add benzoyl-diphenylphosphine oxide to the dissolved solution, irradiate with ultraviolet light at 35°C for 2 hours, and a grafting reaction occurs, wash with methanol and filter with suction to remove unreacted dienes; mix the grafted product with 90g The bismaleimide hexane was added to 1000ml tetrahydrofuran, stirred at 30°C until fully dissolved, then vacuum-dried at 40°C for 24 hours, and the solvent was removed; Reversible cross-linking to obtain a shape-memory elastomer cross-linked by thermoreversible bonds. The properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com