Hybrid dynamic crosslinking polymer and application thereof

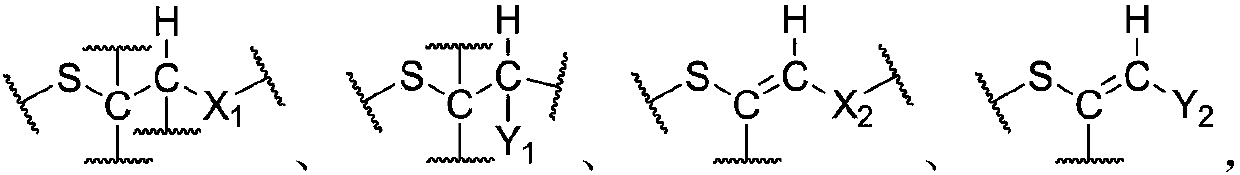

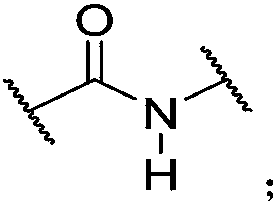

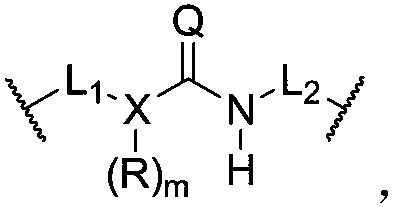

A dynamic cross-linking, polymer technology, applied in the field of smart polymers, can solve the problems of difficult reprocessing, inability to recycle, and the lack of structural dynamic reversibility of ordinary covalent structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0283] In the preparation process of hybrid dynamic cross-linked polymers, three methods of foaming are mainly used: mechanical foaming method, physical foaming method and chemical foaming method.

[0284] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0285] Wherein, the physical foaming method is to utilize physical principles to realize the foaming of the polymer in the preparation process of the hybrid dynamic crosslinked polymer, which includes but not limited to the following methods: (1) inert gas foaming method , that is, under pressure, the inert gas is pressed into t...

Embodiment 1

[0305] With THF as solvent, AIBN as initiator, hydroxyethyl acrylate and 3-(dimethyl(2-prop-2-enoyloxyethyl)dimethyl)propane-1-sulfonate as monomers , controlling the molar ratio of the initiator to each monomer to be 1:15:15, and obtaining a polyacrylate copolymer through free radical polymerization. Dissolve the above acrylate copolymer and 6-acrylamido caproic acid in THF according to the equimolar ratio of hydroxyl and carboxyl groups, and after the materials are mixed evenly, add DCC and DMAP, and obtain the acrylamide graft modified by esterification. It is a kind of polyacrylate; using stannous octoate as a catalyst, the dihydric mercaptan containing urea group is prepared by reacting 2-hydroxyethanethiol and hexamethylene diisocyanate; take a certain amount of the above-mentioned modified acrylate and two thiol, keep the molar ratio of side group acrylamide group and mercapto group at 1:1, add the above material to 80mL 1-butyl-3-methylimidazolium hexafluorophosphate, ...

Embodiment 2

[0307] Using DBU as a catalyst, 3-hexyn-2-one and 6-aminohexane-1-mercaptan are used as raw materials to prepare diamines through mercapto-Michael addition reaction; using DBU as a catalyst, the molar ratio is 3:1 2-mercaptoethanol reacts with tris (2-(acryloyloxy) ethyl) isocyanurate to obtain a polyol; in No. 1 container, weigh 40.0 g of hydroxyl-terminated polyoxypropylene Diol, heated to 110°C, dehydrated and dried under reduced pressure for 2 hours, then cooled to below 60°C, added 1.9g toluene diisocyanate, 0.6g stannous octoate, controlled temperature at 80°C, stirred and reacted for 2h, cooled to room temperature, NCO can be obtained The mass fraction is about 3.6% of the prepolymer, and then add an appropriate amount of MDI and toluene to obtain the NCO mass fraction of 10% prepolymer (component A); in No. 2 container, take 40 parts of diamine expanded Chain agent, 10 parts of polyol curing agent, 0.4 parts of stannous octoate, 5 parts of diisononyl phthalate, 10 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com