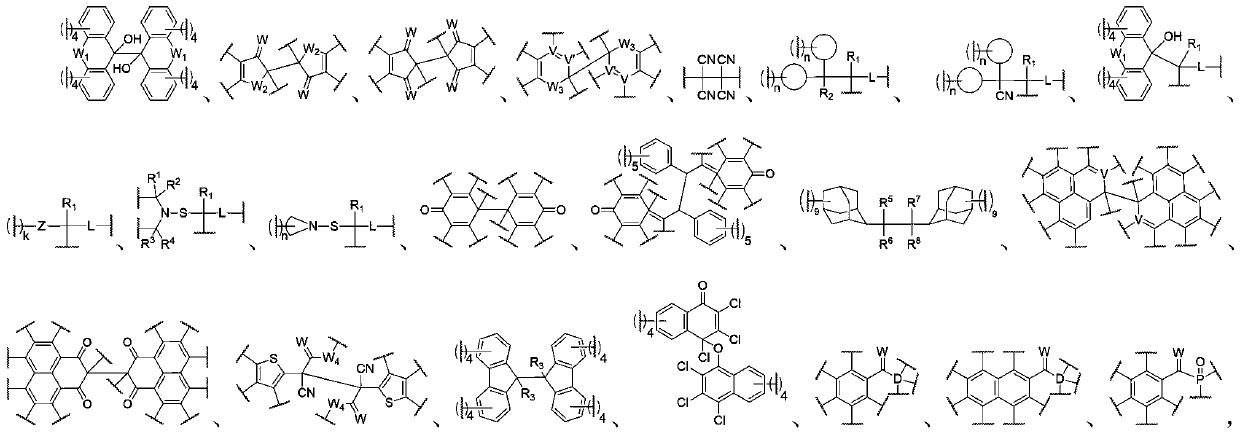

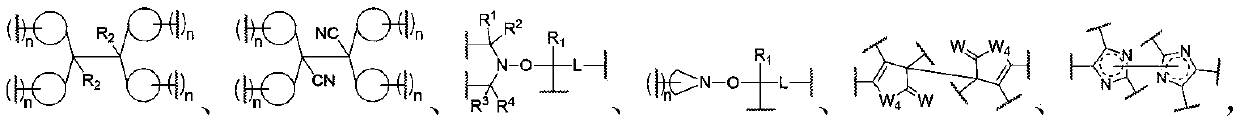

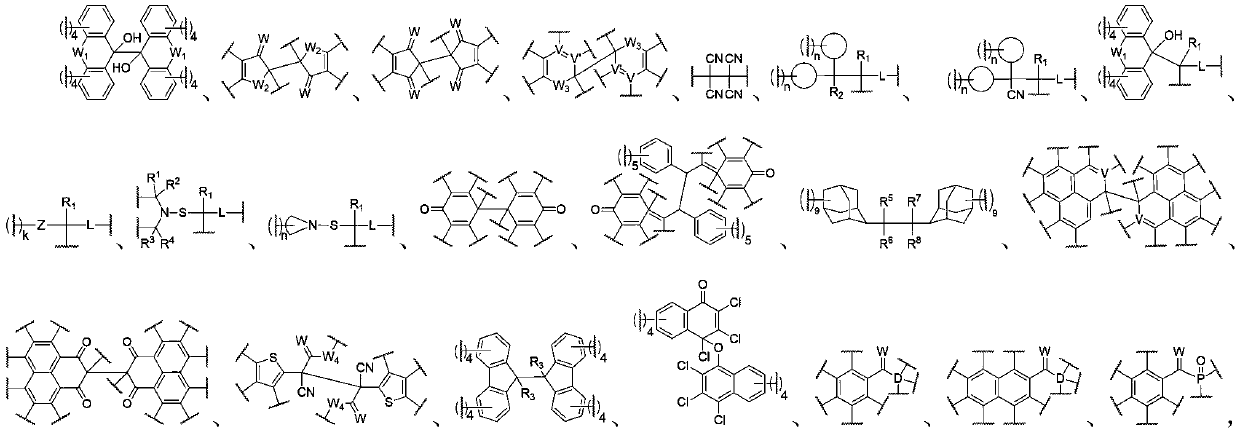

Hybrid dynamic polymer containing reversible free radical type dynamic covalent bonds and application thereof

A dynamic covalent bond and free radical technology, applied in the field of intelligent polymers, can solve problems such as poor dynamic reversibility, difficult recycling and regeneration, and harsh dynamic transformation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0514] In the preparation process of dynamic polymer, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam it.

[0515] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0516] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under pressure, and then increase the te...

Embodiment 1

[0527]

[0528] Using azobisisobutyronitrile as an initiator and N-(2-amino-2-oxoethyl)acrylamide as a monomer, under a nitrogen atmosphere, stir and react at 70°C for 24 hours to prepare an acrylamide homopolymer (a), it is dried and ground to obtain hydrogen-bonded cross-linked polymer particles. Take 5 molar equivalents of hydroxyl double-terminated polybutadiene (b), 2.5 molar equivalents of compound (c), and 5 molar equivalents of compound (d), put them in a reaction vessel, dissolve them with an appropriate amount of tetrahydrofuran, and add 30 molar equivalents of dicyclohexyl Carbodiimide, 5 moles of single-quantity 4-dimethylaminopyridine, then stirred at room temperature for 24 hours, then added 30wt% hydrogen-bonded cross-linked polymer particles, 0.8wt% nano-palladium, 0.5wt% carbon nanotubes, 0.3wt% Composite antibacterial agent KHFS-ZN, 0.3wt% dispersant N, mixed evenly, poured the product into a mold, first dried naturally for 24 hours, and then dried in a va...

Embodiment 2

[0530]

[0531] Take 3.5 molar equivalents of hydroxyl-terminated four-armed polyethylene glycol (molecular weight: 5000) and 7 molar equivalents of compound (a), place them in a reaction vessel, dissolve them with an appropriate amount of tetrahydrofuran, then add an appropriate amount of stannous octoate catalyst, and then After reacting for 6 hours, hydrogen-bonded cross-linked polyethylene glycol was obtained. Get 10 molar equivalents of polyoxypropylene diamine (b) (molecular weight is 2000), 5 molar equivalents of compound (c), 20 molar equivalents of 1-ethyl-3-(3-dimethylaminopropyl)-carbodiethylene Amine, 4 molar equivalents of 4-dimethylaminopyridine, placed in a reaction vessel, dissolved with an appropriate amount of tetrahydrofuran, then stirred at room temperature for 8 hours, added 50wt% hydrogen-bonded cross-linked polyethylene glycol, 180wt% polyethylene glycol oligomerized substance, 5wt% nano-silver antibacterial solution, 5wt% liquid metal gallium, after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com