Modified butadiene-acrylonitrile rubber with high strength and good repeatable processability and preparation method thereof

A technology of nitrile-butadiene rubber and repeated processing is applied in the field of modification research of nitrile-butadiene rubber, which can solve the problems of high density of composite materials, achieve high tensile strength, high tensile strength, and promote resource saving and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

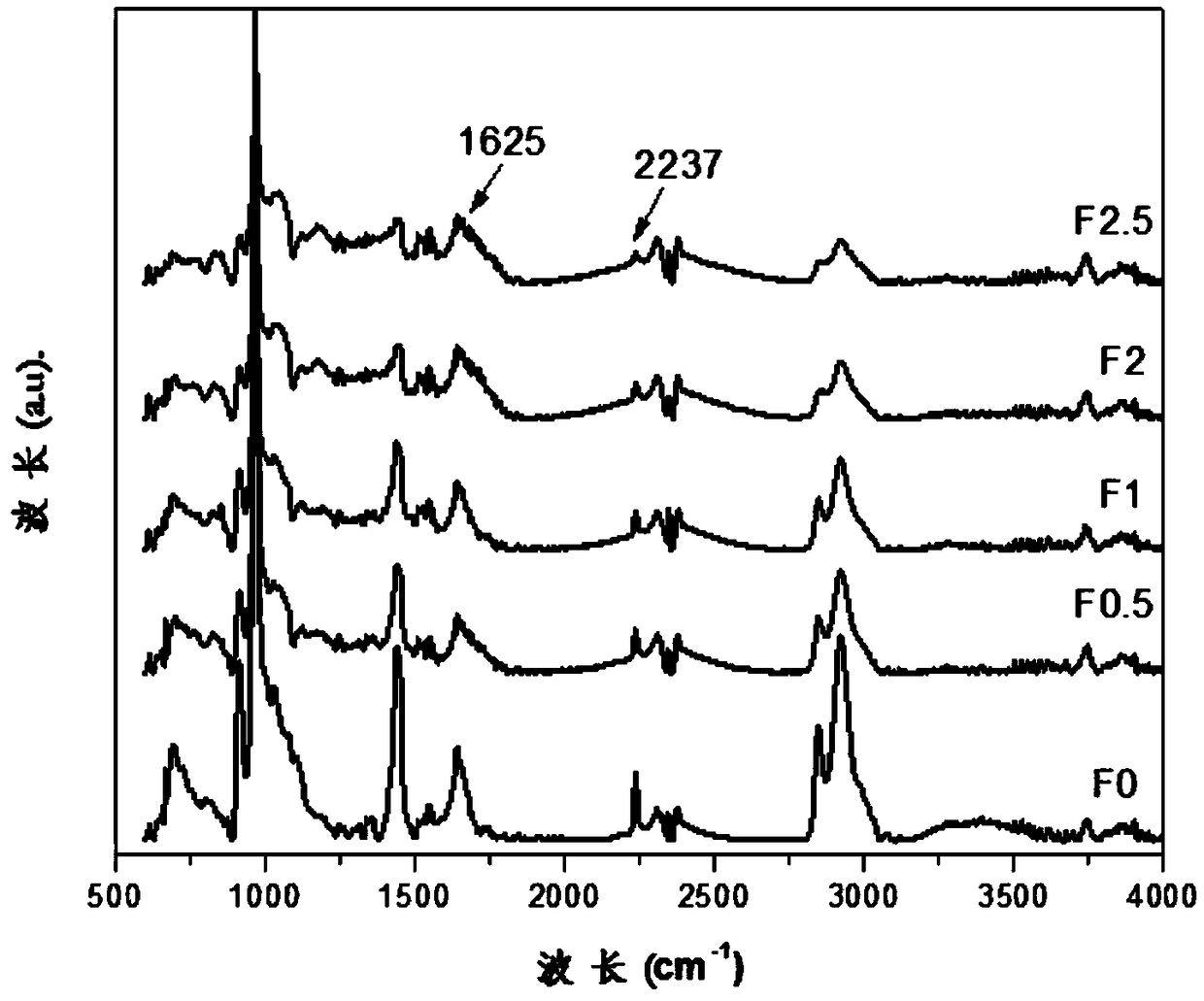

[0037] Embodiment 1 (embodiment 1-4 difference is respectively 0.5%, 1%, 2%, 2.5% in the consumption of ferric chloride respectively)

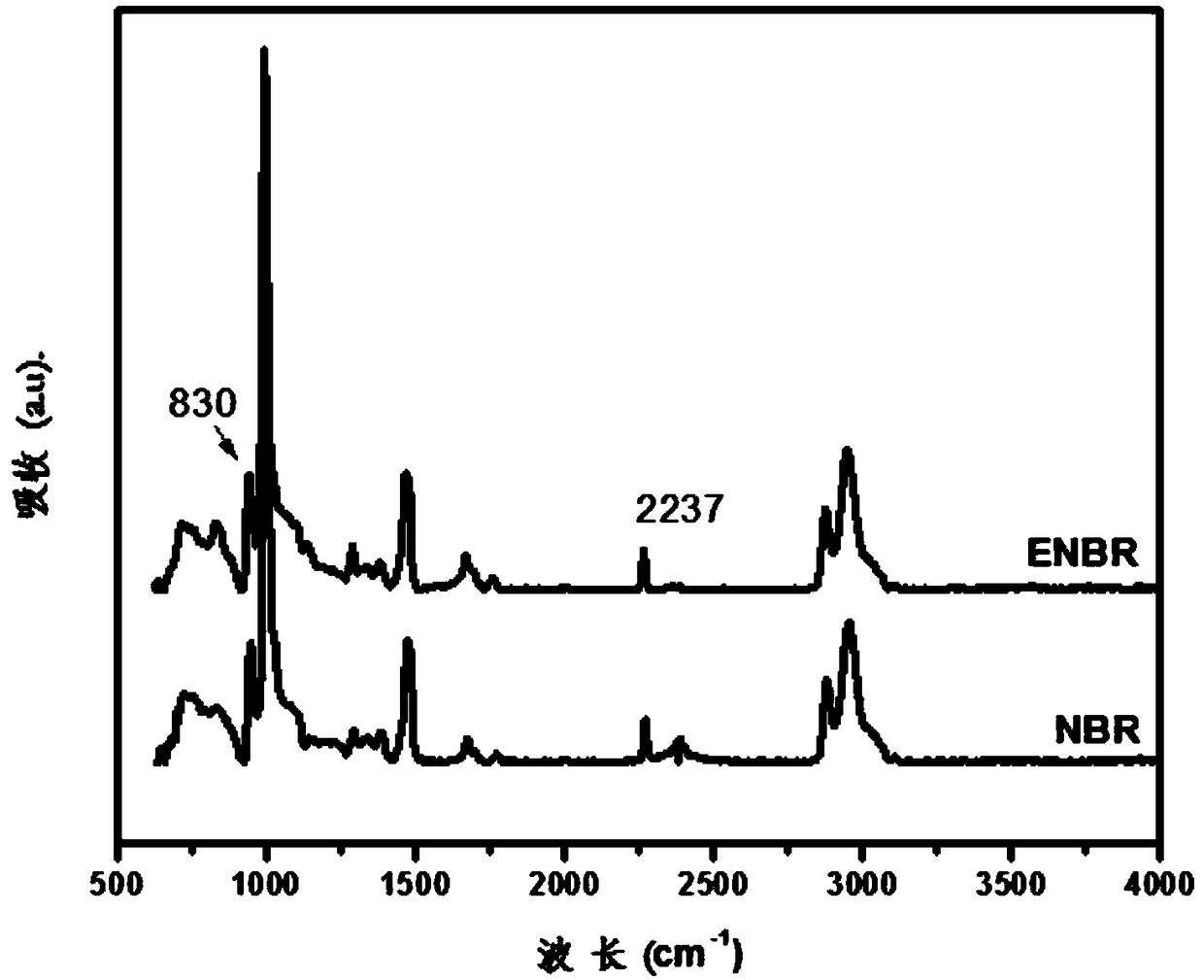

[0038] The nitrile latex (butyronitrile content 33%) that will contain 100g dry glue is placed in the flask, adjust the solid content of nitrile latex with deionized water to be 20%, drop formic acid to adjust the latex pH to be equal to 3, slowly add mass concentration of Put 155 g of 30% hydrogen peroxide into the flask, and then react for 8 hours under magnetic stirring in a water bath at 40° C. to obtain epoxidized nitrile latex. figure 1 Infrared absorption spectra before and after epoxidation of nitrile latex, from figure 1 It can be seen that after the epoxidation modification of nitrile latex, epoxidized nitrile rubber (abbreviated as ENBR) is obtained;

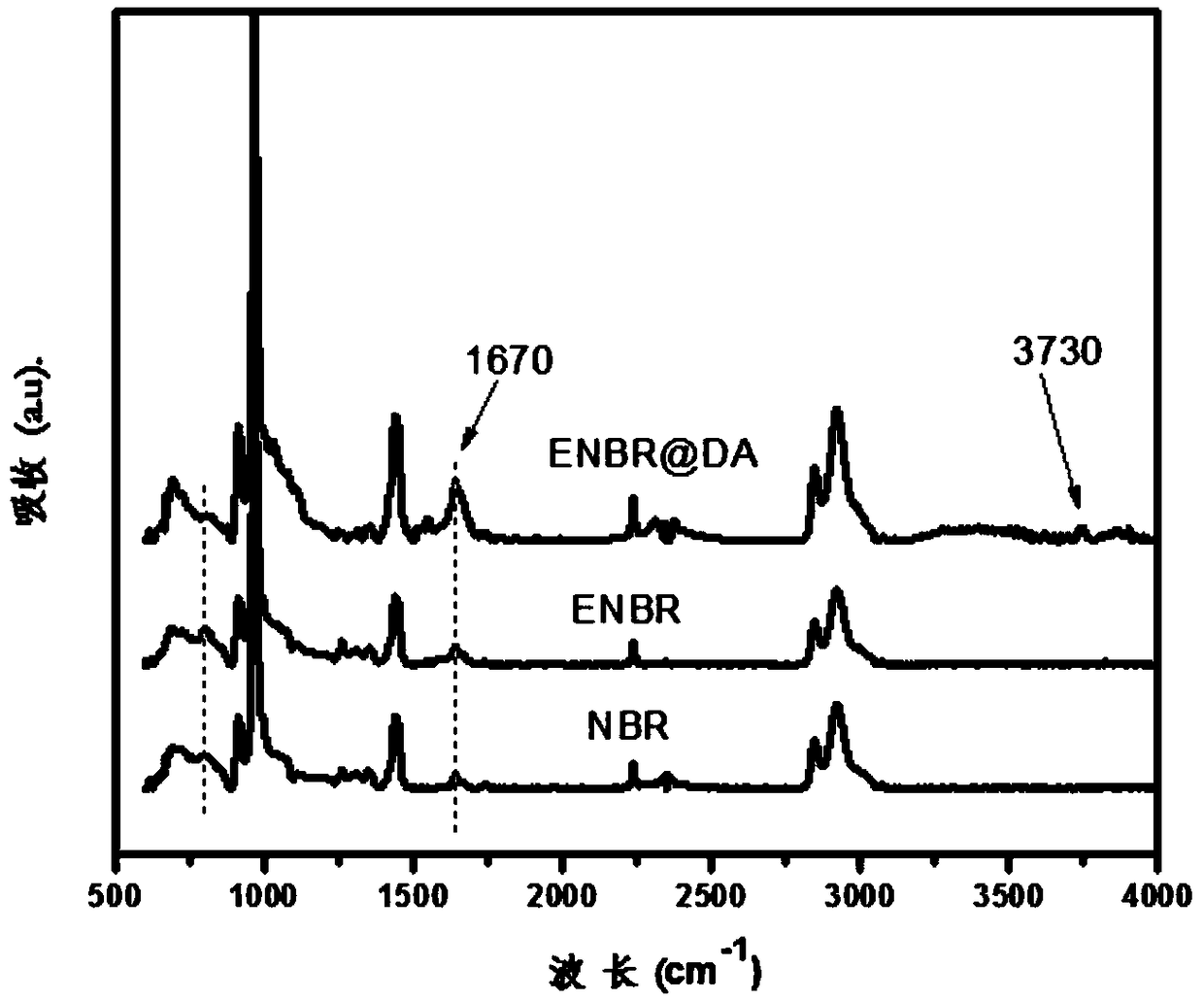

[0039] Dilute epoxidized nitrile latex with deionized water to a solid content of 5%, then dropwise add ammonia water to adjust the latex pH to 7, then add Tris to make the latex pH ...

Embodiment 2

[0044] The nitrile latex (butyronitrile content 33%) that will contain 100g dry glue is placed in the flask, adjust the solid content of nitrile latex with deionized water to be 20%, drop formic acid to adjust the latex pH to be equal to 3, slowly add mass concentration of Put 155 g of 30% hydrogen peroxide into the flask, and then react for 8 hours under magnetic stirring in a water bath at 40° C. to obtain epoxidized nitrile latex.

[0045] Dilute the epoxidized nitrile latex (butyronitrile content 26%) to a solid content of 5% with deionized water, then add dropwise ammonia water to adjust the pH of the latex to 7, then add Tris to make the pH of the latex reach 8.5, then slowly add dopamine powder 10g, reacted at room temperature for 24h to obtain ENBR@DA latex.

[0046] Slowly add 1 g of anhydrous ferric chloride aqueous solution to ENBR@DA latex, react for 0.5 h under magnetic stirring at room temperature, and then filter with suction to obtain a solid product, and dry i...

Embodiment 3

[0049] The nitrile latex (butyronitrile content 33%) that will contain 100g dry glue is placed in the flask, adjust the solid content of nitrile latex with deionized water to be 20%, drop formic acid to adjust the latex pH to be equal to 3, slowly add mass concentration of Put 155 g of 30% hydrogen peroxide into the flask, and then react for 8 hours under magnetic stirring in a water bath at 40° C. to obtain epoxidized nitrile latex.

[0050] Dilute epoxidized nitrile latex with deionized water to a solid content of 5%, then dropwise add ammonia water to adjust the latex pH to 7, then add Tris to make the latex pH to 8.5, then slowly add 10 g of dopamine powder, and react at room temperature for 24 hours Get ENBR@DA latex.

[0051] Slowly add 2g of anhydrous ferric chloride aqueous solution to ENBR@DA latex, react for 0.5h under magnetic stirring at room temperature, and then filter with suction to obtain a solid product, and dry it in a 60°C blast drying oven to constant weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com