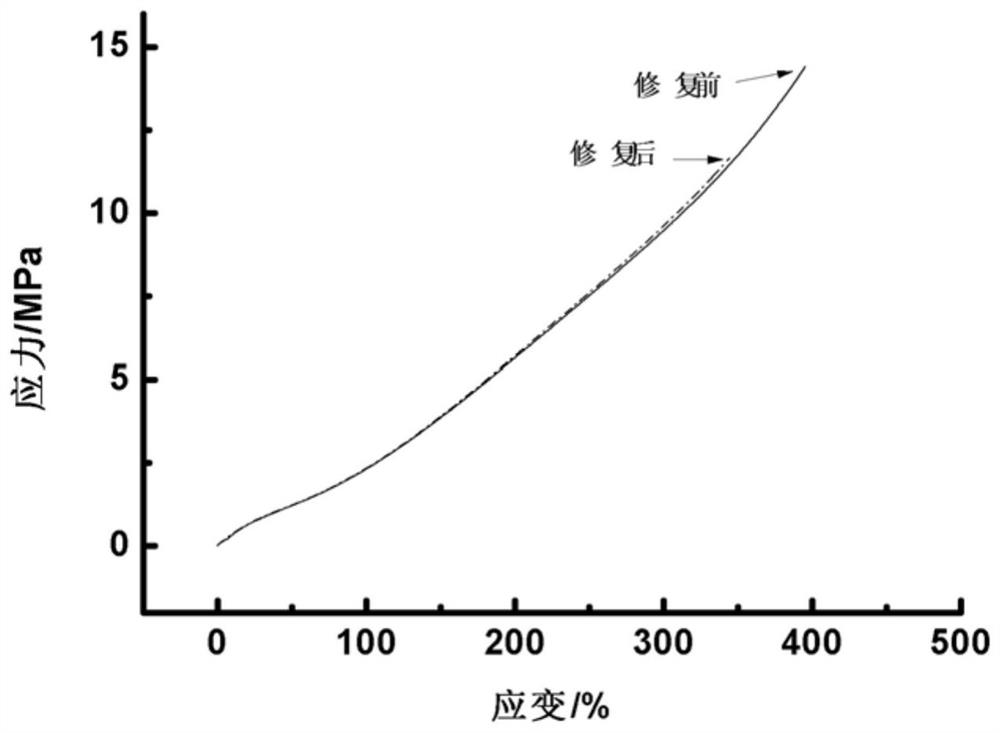

A kind of nitrile rubber system with repairability and preparation method and repair method thereof

A nitrile rubber and repairing technology, applied in the field of nitrile rubber, can solve problems such as environmental pollution, and achieve the effects of high repairing efficiency, good repeatability and improving self-healing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention also provides a kind of preparation method of the repairable nitrile rubber system, comprising the following steps:

[0039] (1) Take the raw materials by weighing the following parts by weight:

[0040]100 parts of rubber, 5-40 parts of coordination salt, 0.5-10 parts of filler, 1-5 parts of polysulfide bond vulcanizing agent, 1-3 parts of anti-aging agent and 5-10 parts of polyhydroxy compound, wherein the rubber includes The mass ratio is 2:8-8:2 mixed nitrile rubber and halogenated butyl rubber, and the polyhydroxy compound is polyhydric alcohol or phenol.

[0041] (2) Disperse the weighed coordination salt and the polyhydroxy compound into a uniform solution at normal temperature;

[0042] (3) mixing the rubber and filler weighed in step (1) to obtain the rubber mix;

[0043] (4) Add the homogeneous solution into the rubber compound by dropping, continue to add the anti-aging agent and polysulfide bond vulcanizing agent wei...

Embodiment 1

[0050] Present embodiment provides a kind of repairable nitrile rubber system, and its preparation method comprises the steps:

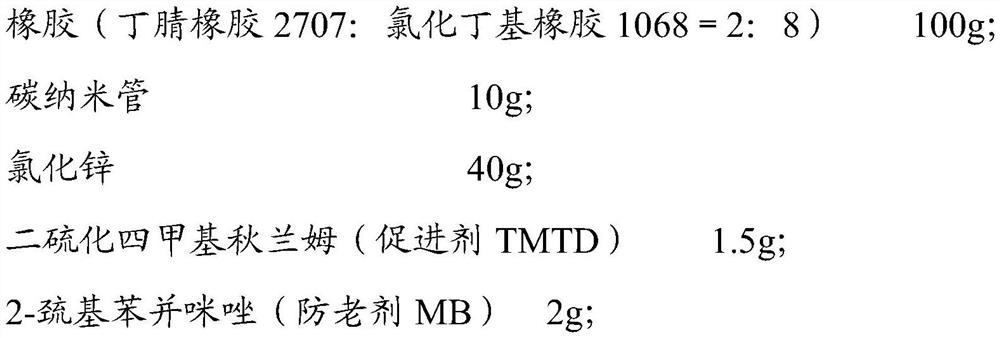

[0051] (1) Take the following raw materials:

[0052]

[0053]

[0054] (2) Add the zinc chloride and tea polyphenols weighed in step (1) into 200 mL of acetone at room temperature, and ultrasonically dissolve to form a homogeneous solution.

[0055] (3) Mix other raw materials taken in step (1) on the open mill:

[0056] Carry out mastication of nitrile rubber 2707, blend with chlorinated butyl rubber 1068 after mastication, add weighed carbon nanotubes to obtain the compounded rubber;

[0057] The temperature of the roller is raised to 80°C, and when the temperature of the rubber mix is 90°C, the homogeneous solution prepared in step (2) is added dropwise to the rubber mix. After that, lower the roll temperature to normal temperature, continue to add the weighed anti-aging agent MB and accelerator TMTD, make a triangle bag, and thin the f...

Embodiment 2

[0062] The present embodiment provides a kind of repairable nitrile rubber system, and its preparation method comprises the following steps

[0063]

[0064] (2) At normal temperature, the stannous chloride and dipropylene glycol weighed in step (1) are formulated into a solution, and ultrasonically dissolved to form a homogeneous solution.

[0065] (3) Mix other raw materials taken in step (1) on the open mill:

[0066] The raw rubber of hydrogenated nitrile rubber Zepel 2010 is masticated, after mastication, it is blended with brominated butyl rubber Lanxess 2030, and the weighed superconducting carbon black is added to obtain the mixed rubber;

[0067] The temperature of the roller is raised to 80°C, and when the temperature of the rubber mix is 95°C, the solution prepared in step (2) is added dropwise to the rubber mix. After that, lower the temperature of the roll to normal temperature, continue to add the weighed anti-aging agent RD and accelerator DM, make a trian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com