A kind of repairing environment-friendly armor oil and preparation method thereof

A nail polish and environment-friendly technology, applied in the field of environment-friendly nail polish and its preparation, can solve the problem of nails not being repairable, and achieve the effects of improving skin aging phenomenon, strong anti-oxidation, and ensuring repairing efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

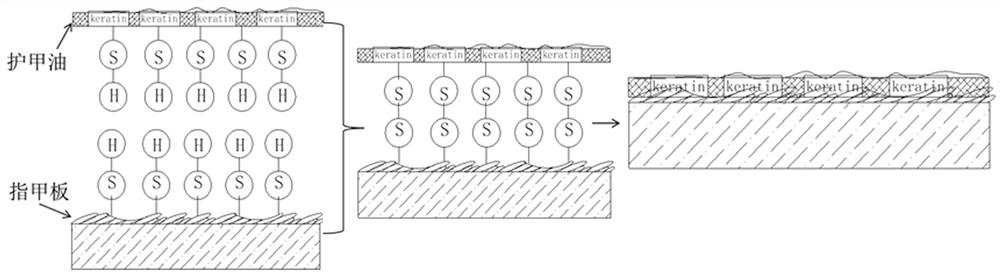

Method used

Image

Examples

Embodiment 1

[0031] A restorative, environment-friendly armor oil, the armor oil is composed of the following products in parts by weight: 22 parts of seabuckthorn oil, 5 parts of hydrolyzed keratin, 4 parts of thyme essential oil, 15 parts of bergamot essential oil, happy mouse 5 parts of tailgrass essential oil, 13 parts of rose essential oil, 16 parts of hyaluronic acid, 2 parts of EDTA, 10 parts of dipotassium glycyrrhizinate, 3 parts of germ milk, 2 parts of mica powder, and 3 parts of curcumin.

[0032] Wherein the preparation method of hydrolyzed keratin is: first prepare the solution that pH is 10 that the final concentration is 7mol / L denaturing agent urea, 1%wt surfactant SDS, sodium hydroxide and solvent water preparation, and then wool After being placed in the solution, treated at 85°C for 3 hours, filtered, dialyzed, and titrated with acetic acid until the pH of the solution was 6, the obtained titration solution was spray-dried to prepare hydrolyzed keratin.

[0033] The pre...

Embodiment 2

[0038] A repairing environment-friendly nail oil, the nail oil is composed of the following components in percentages by weight: 22 parts of seabuckthorn oil, 7 parts of hydrolyzed keratin, 4 parts of thyme essential oil, and 15 parts of bergamot essential oil , 5 parts of clary sage essential oil, 13 parts of rose essential oil, 16 parts of honey, 2 parts of SDS for acid protease, 8 parts of dipotassium glycyrrhizinate, 3 parts of endosperm, 2 parts of mica powder, and 3 parts of catechin.

[0039] Wherein the preparation method of hydrolyzed keratin is: first prepare the solution that pH is 12 that the final concentration is 7mol / L denaturing agent urea, 1%wt surfactant SDS, sodium hydroxide and solvent water preparation, and then wool After being placed in the solution, treated at 100°C for 3 hours, filtered, dialyzed, and titrated with acetic acid until the pH of the solution was 7.5, the obtained titration solution was spray-dried to prepare hydrolyzed keratin.

[0040] A...

Embodiment 3

[0045] A repairing environment-friendly nail oil, the nail oil is composed of the following components in percentages by weight: 21 parts of seabuckthorn oil, 8 parts of hydrolyzed keratin, 4 parts of thyme essential oil, and 15 parts of bergamot essential oil , clary sage essential oil 5 parts, lavender essential oil 13 parts, aloe vera 9 parts, N-bromosuccinimide 3 parts, dipotassium glycyrrhizinate 8 parts, germ milk 3 parts, mica powder 2 parts, gallic acid 3 parts.

[0046] Wherein the preparation method of hydrolyzed keratin is: first prepare the solution that pH is 11 that the final concentration is 7mol / L denaturant urea, 1%wt surfactant SDS, sodium hydroxide and solvent water preparation, and then wool After being placed in the solution, treated at 95°C for 3 hours, filtered, dialyzed, and titrated with acetic acid until the pH of the solution was 7, the obtained titration solution was spray-dried to prepare hydrolyzed keratin.

[0047] A preparation method of a nail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com