Enzyme stock solution and environmental-protection enzyme, and preparation methods thereof

A technology of enzyme stock solution and environmental protection enzyme, which is applied in the field of detergents, can solve the problems of difficult handling of straw, and achieve the effects of good cleaning effect, good cleaning effect and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

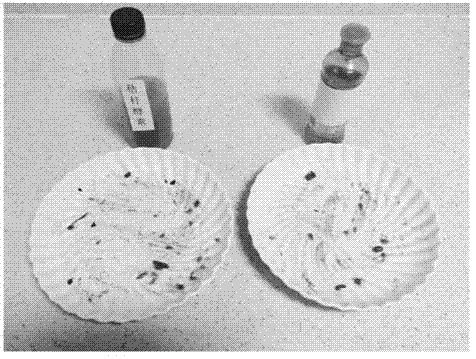

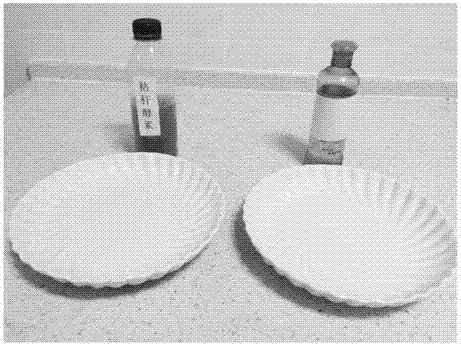

Image

Examples

Embodiment 1

[0038] A preparation method for an enzyme stock solution, comprising the following steps:

[0039] (1) Raw material processing: pick the cyan corn stalks in the mature period of corn, wash with water, dry, chop, and set aside;

[0040] (2) Mixing: by weight, it is 1 part of brown sugar, 4 parts of straw, and 11 parts of water. Weigh the raw materials, put the weighed brown sugar and water into an airtight container with a cover, stir to make them mix evenly, Then put the weighed corn stalks into the mixture of brown sugar and water to obtain a mixed solution;

[0041] (3) adjust the pH value of the mixture to 5 with citric acid;

[0042] (4) Anaerobically fermenting the mixed solution with adjusted pH value in an airtight container, the fermentation temperature is 20°C, and the fermentation time is 6 months;

[0043] (5) Filtrating the fermented mixed solution to obtain an enzyme stock solution.

[0044] A method for preparing an environmentally friendly enzyme from the enz...

Embodiment 2

[0046] A preparation method for an enzyme stock solution, comprising the following steps:

[0047] (1) Raw material processing: pick the cyan corn stalks in the mature period of corn, wash with water, dry, chop, and set aside;

[0048] (2) Mixing: by weight, it is 1.5 parts of brown sugar, 4 parts of straw, and 8 parts of water. Weigh the raw materials, put the weighed brown sugar and water into an airtight container with a cover, stir to make them mix evenly, Then put the weighed corn stalks into the mixture of brown sugar and water to obtain a mixed solution;

[0049] (3) adjust the pH value of the mixture to 6 with citric acid;

[0050] (4) Anaerobically fermenting the mixed solution with adjusted pH value in a closed container, the fermentation temperature is 25°C, and the fermentation time is 3 months;

[0051] (5) Filtrating the fermented mixed solution to obtain an enzyme stock solution.

[0052]A method for preparing an environmentally friendly enzyme from the enzym...

Embodiment 3

[0054] A preparation method for an enzyme stock solution, comprising the following steps:

[0055] (1) Raw material processing: pick the cyan corn stalks in the mature period of corn, wash with water, dry, chop, and set aside;

[0056] (2) Mixing: by weight, it is 1.2 parts of brown sugar, 3 parts of straw, and 9.6 parts of water. Weigh the raw materials, put the weighed brown sugar and water into a closed container with a cover, stir to make them mix evenly, Then put the weighed corn stalks into the mixture of brown sugar and water to obtain a mixed solution;

[0057] (3) adjust the pH value of the mixture to 4 with citric acid;

[0058] (4) Anaerobic fermentation is performed on the mixed liquor with adjusted pH value in an airtight container, the fermentation temperature is 23° C., and the fermentation time is 5 months;

[0059] (5) Filtrating the fermented mixed solution to obtain an enzyme stock solution.

[0060] A method for preparing an environmentally friendly enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com