Graphene oxide-Cu-Co/foam titanium substrate composite electrode as well as preparation method and application thereof

A composite electrode and titanium foam technology, which is applied in chemical instruments and methods, water/sewage treatment, water treatment parameter control, etc., can solve the problems of poor treatment effect, achieve low cost, strengthen adhesion, reduce shedding and precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

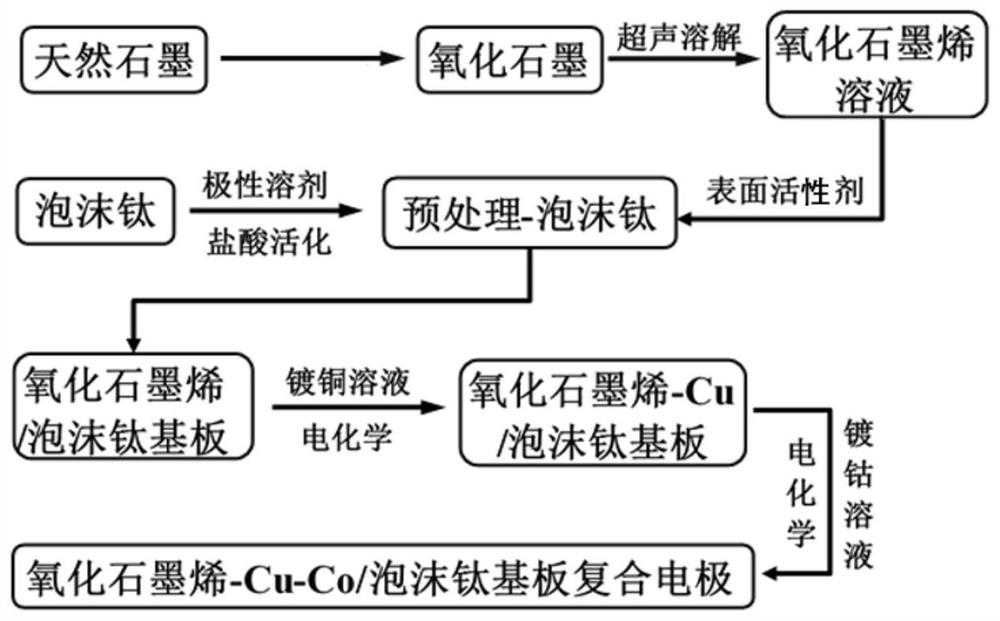

Method used

Image

Examples

Embodiment 1

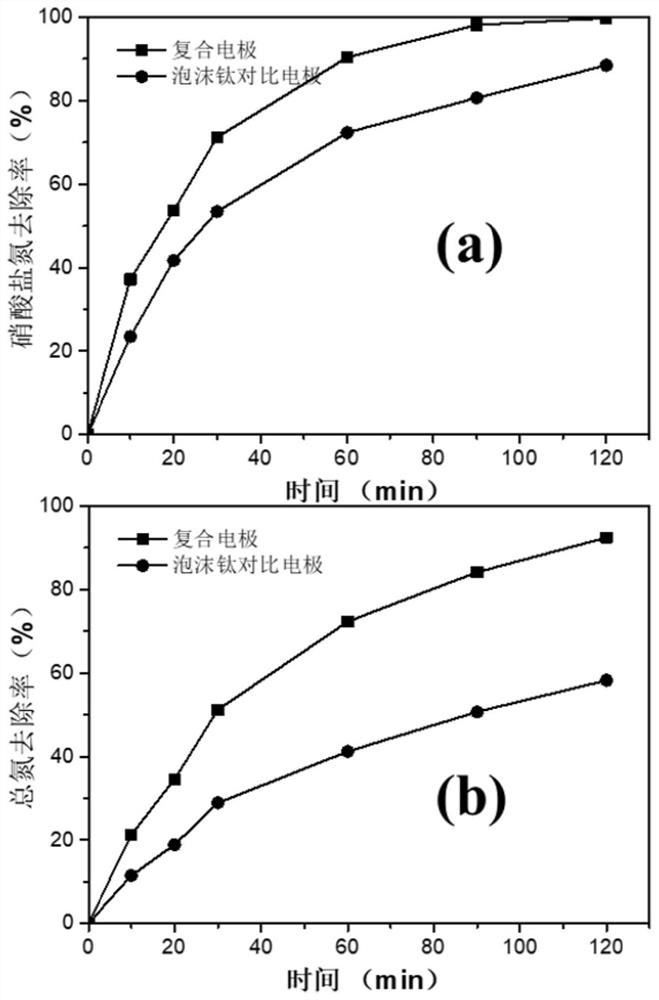

[0037] A graphene oxide-Co-Cu / titanium foam substrate composite electrode of the present invention comprises a titanium substrate, a graphene oxide layer, a Cu layer and a Co layer arranged sequentially from inside to outside, and the titanium substrate is a titanium foam substrate. The titanium foam substrate used in the present invention has a porous structure with a porosity of 80%-95%. The invention combines graphene oxide-Cu-Co, and strengthens the removal effect of nitrate nitrogen and total nitrogen through the coupling effect of multiple elements. At the same time, the addition of Cu and Co coatings reduces the shedding and precipitation of graphene oxide, and improves the reusability and reaction stability of the composite electrode. In the present invention, Cu is first plated and then Co is plated to avoid passivation of Cu on the outer surface of the electrode, and the use of non-precious metals Cu and Co also reduces the cost.

[0038] The present invention also ...

Embodiment 2

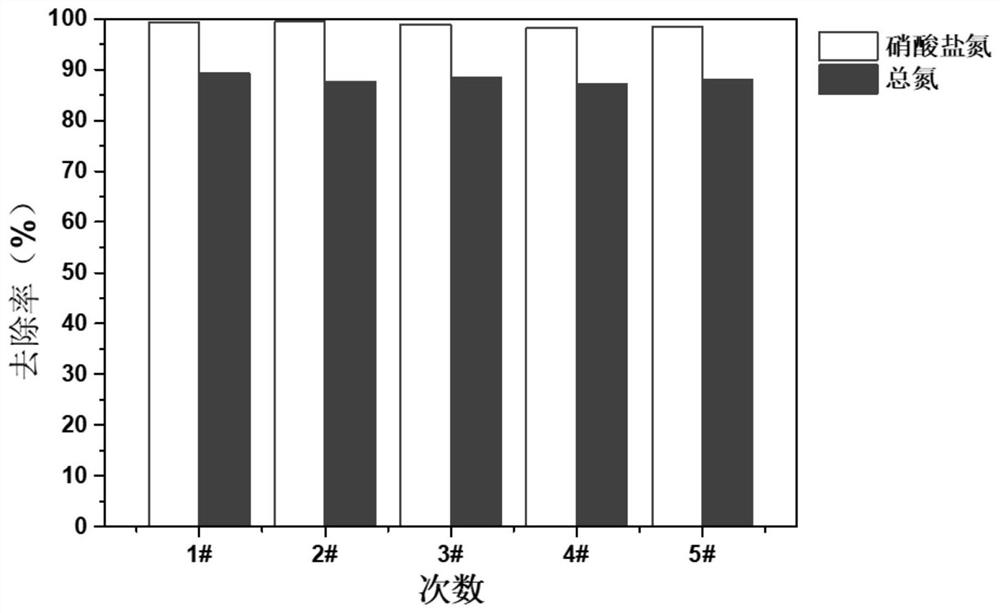

[0065] The basic content of the present embodiment is the same as that of embodiment 1, and its difference is: the degradation test is repeated 5 times, and the results are as follows: image 3 As shown, it can be seen that the removal of nitrate nitrogen and total nitrogen by the composite electrode fluctuates only slightly with the number of times, indicating that the composite electrode has good stability and repeatability.

Embodiment 3

[0067] The basic content of this embodiment is the same as that of Example 1, and the difference is that in this embodiment, the concentration of graphene oxide used in the preparation of graphene oxide / titanium foam substrate electrode is 5g / L, and the titanium foam after pretreatment The substrate was soaked in the solution for 10 minutes, then taken out lightly and dried naturally to obtain a graphene oxide / titanium foam substrate electrode.

[0068] In this embodiment, the Cu plating solution is a mixed solution of copper sulfate solution, fatty alcohol polyoxyethylene ether sodium sulfate and sodium alkylbenzene sulfonate. The current density during Cu plating is 10mA / cm 2 , The reaction time is 10min. During the Cu plating process, the solution was stirred at a stirring speed of 500 rpm, and the distance between the anode and the cathode was adjusted to 1 cm.

[0069] In this embodiment, the Co plating solution is a mixed solution of cobalt chloride hexahydrate, boric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com