Patents

Literature

32results about How to "Excellent uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

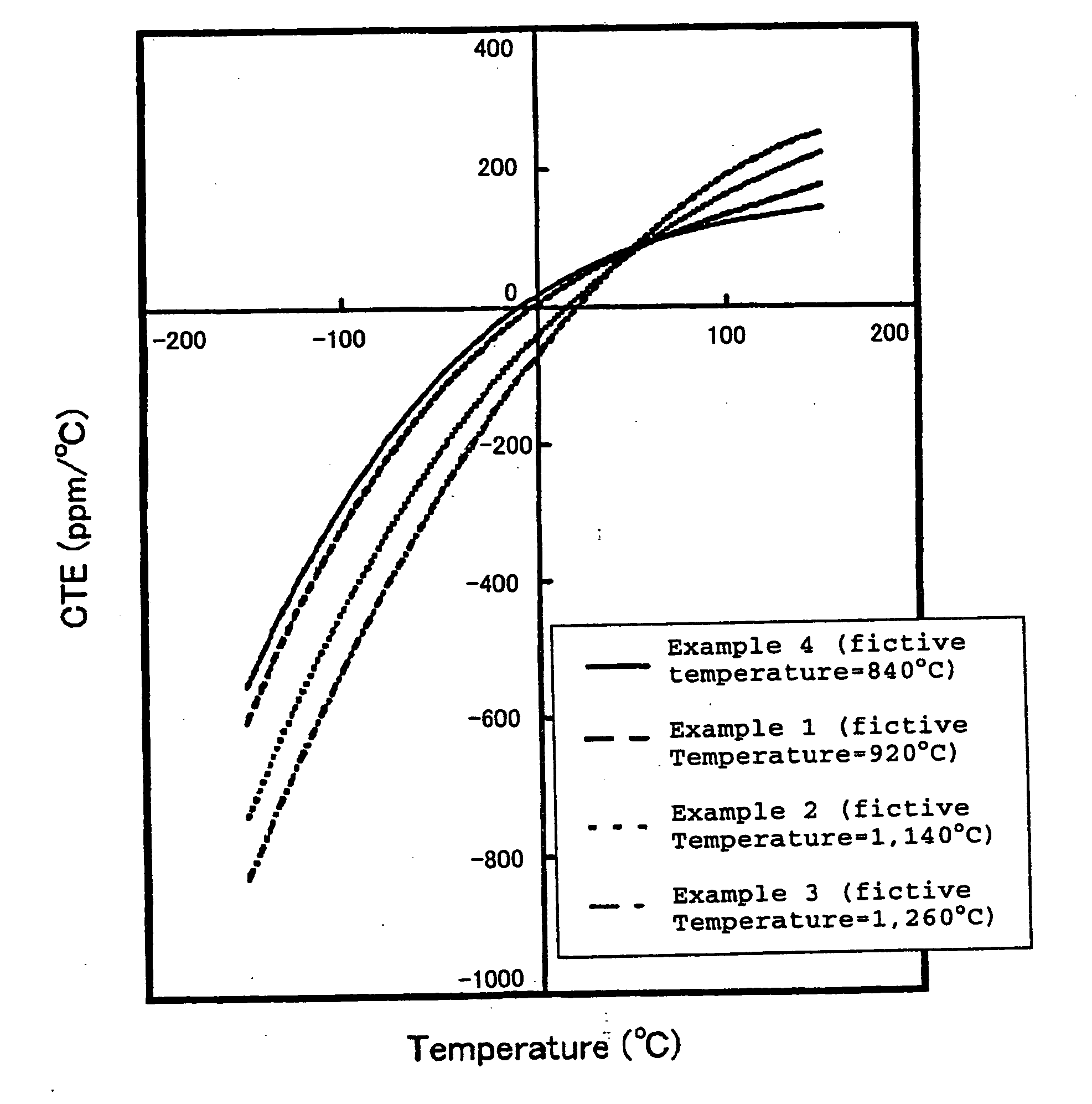

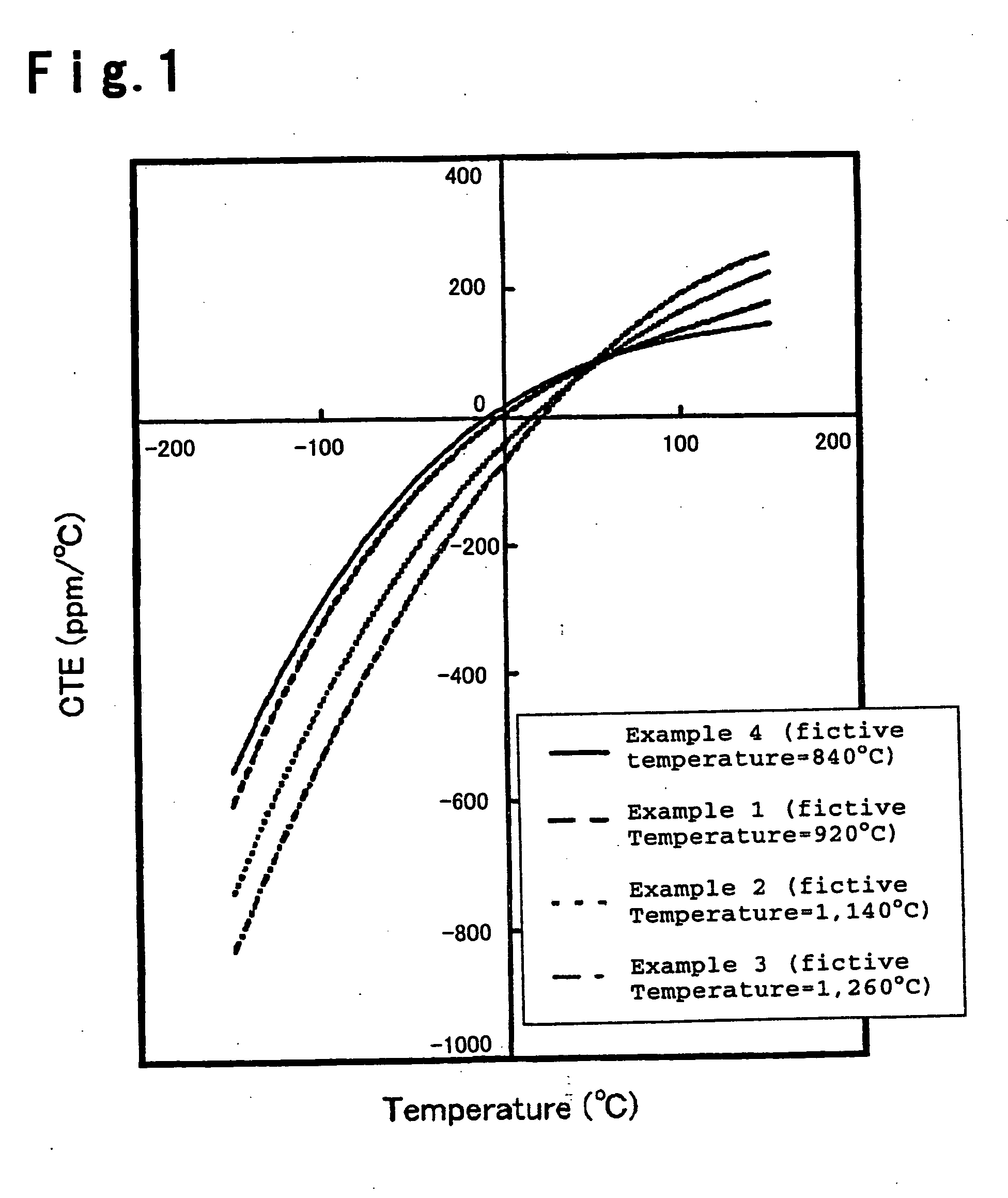

Silica glass containing TiO2 and process for its production

ActiveUS20050245382A1Excellent uniformitySmall thermal expansionSemiconductor/solid-state device manufacturingGlass shaping apparatusTitanium dioxideSilica glass

A silica glass containing TiO2, which has a fictive temperature of at most 1,200° C., an OH group concentration of at most 600 ppm and a coefficient of thermal expansion of 0±200 ppb / ° C. from 0 to 100° C.

Owner:ASAHI GLASS CO LTD

Method of fabricating oxide thin film transistor

ActiveUS20100304528A1Excellent uniformityEnhance characteristicSolid-state devicesSemiconductor/solid-state device manufacturingOxide semiconductorSputter deposition

According to a method of fabricating an oxide thin-film transistor, when a thin-film transistor is fabricated by using an amorphous zinc oxide (ZnO)-based semiconductor as an active layer, it may be possible to reduce a tact time as well as attain an enhanced element characteristic by depositing an insulation layer having an oxide characteristic in-situ through controlling oxygen (O2) flow subsequent to depositing an oxide semiconductor using a sputter, and the method may include the steps of forming a gate electrode on a substrate; forming a gate insulation layer on the substrate; depositing an amorphous zinc oxide-based semiconductor layer made of an amorphous zinc oxide-based semiconductor and an amorphous zinc oxide-based insulation layer having an oxide characteristic in-situ on the gate insulation layer; forming an active layer made of the amorphous zinc oxide-based semiconductor over the gate electrode while at the same time forming a channel protection layer made of the amorphous zinc oxide-based insulation layer on a channel region of the active layer; and forming a source electrode and a drain electrode electrically connected to a source region and a drain region of the active layer over the active layer.

Owner:LG DISPLAY CO LTD

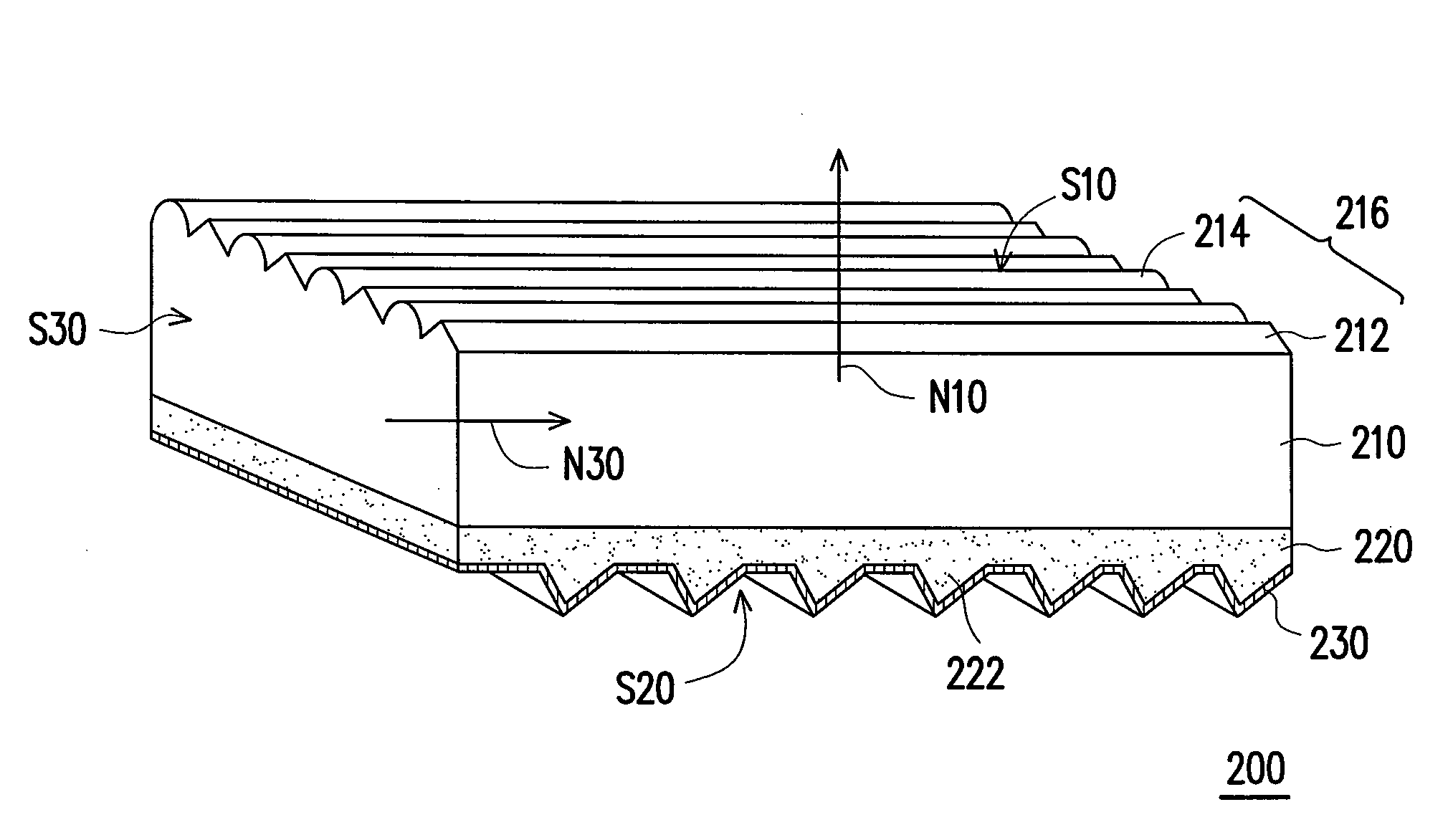

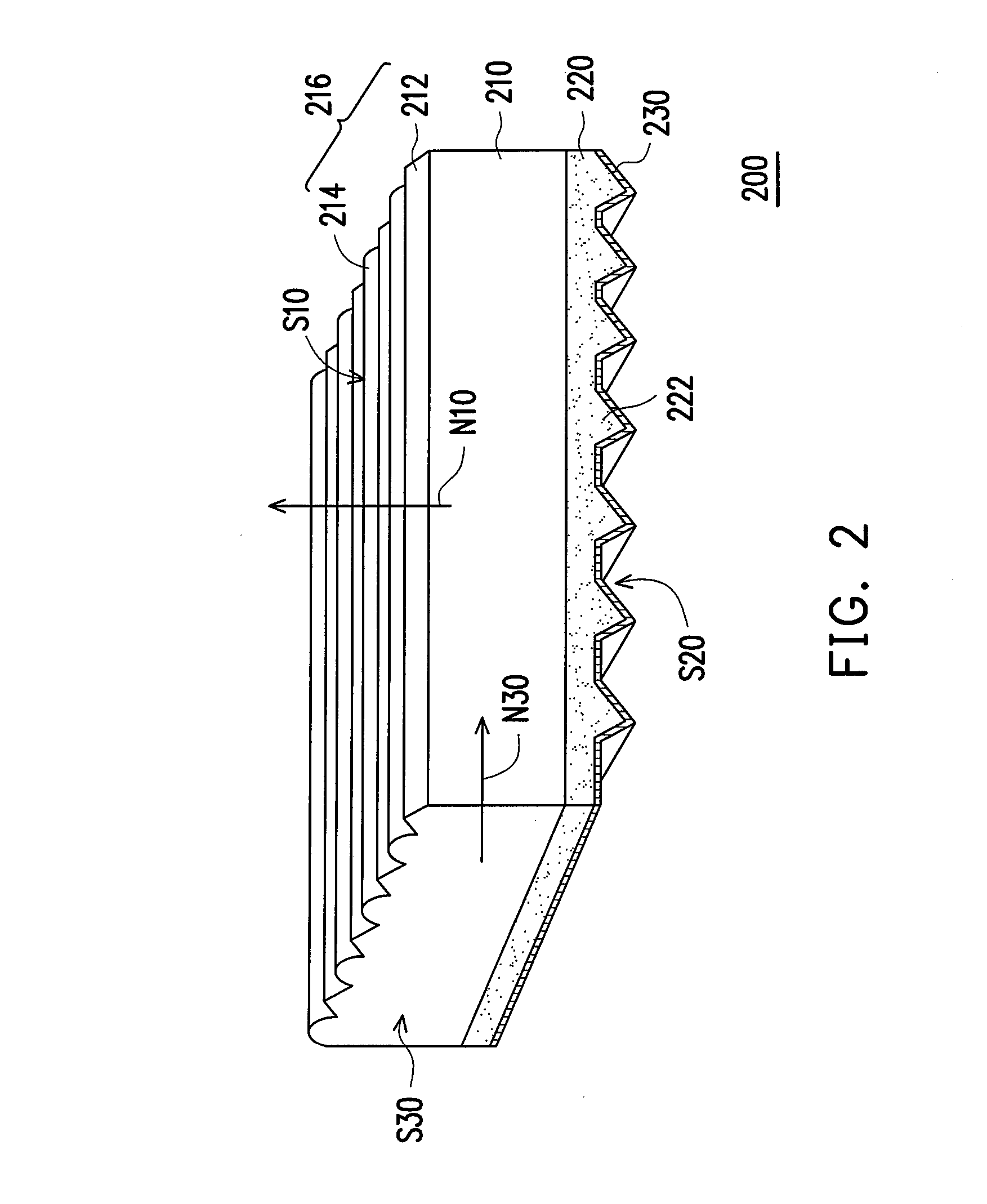

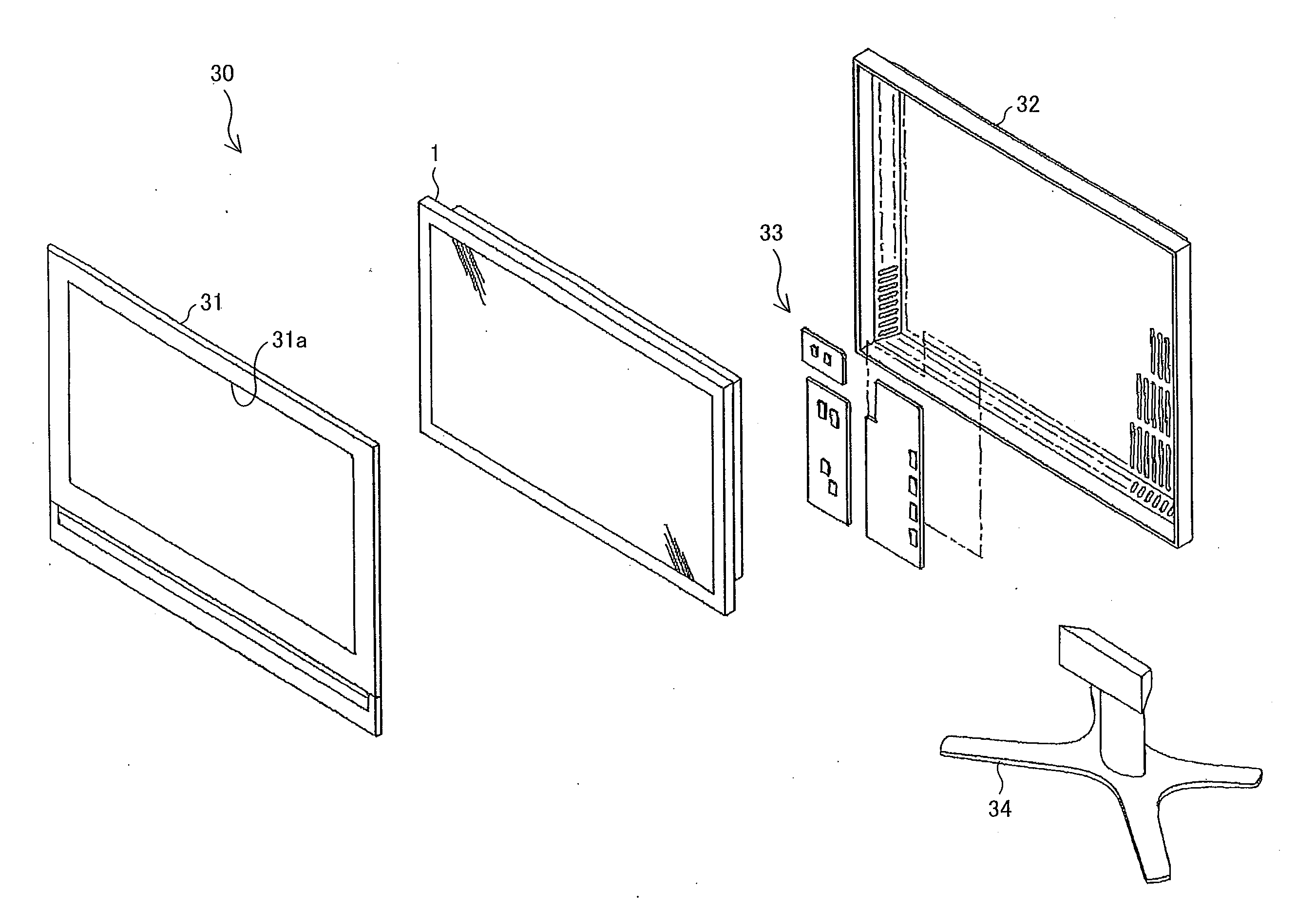

Light guide plate

InactiveUS20080158912A1Excellent light convergencyExcellent uniformityOptical light guidesReflectorsOptoelectronicsLight guide

A light guide plate with a light emitting surface, a bottom surface and at least one light incident surface being connected with the light emitting surface and the bottom surface is provided. The light guide plate is a superposition of a plurality of layers substantially parallel to the light emitting surface. A plurality of stripe-shaped light-controlling structures are formed on the light emitting surface and a plurality of light-reflecting structures are formed on the bottom surface. The light guide plate provides a surface light source with high brightness and excellent uniformity in a direction perpendicular to the light emitting surface.

Owner:IND TECH RES INST

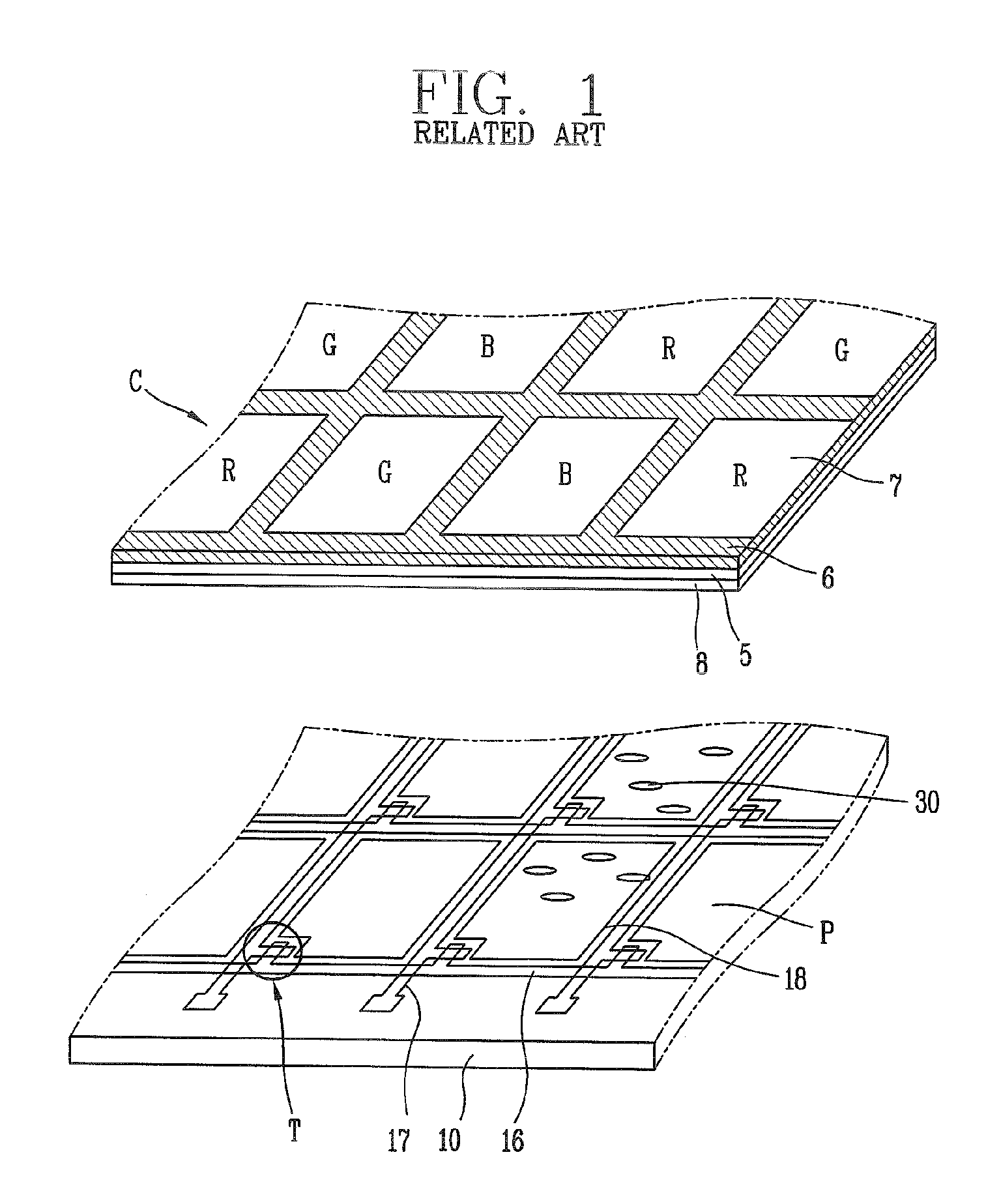

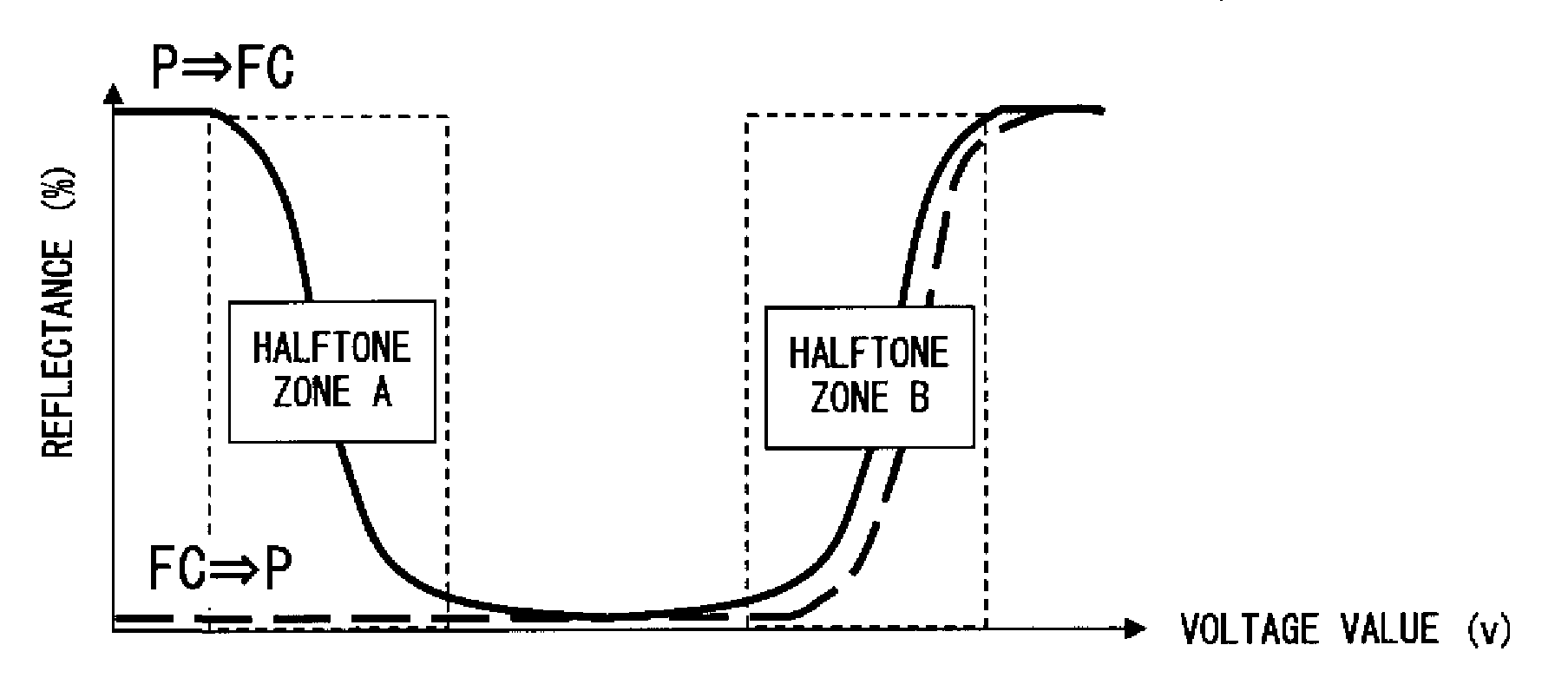

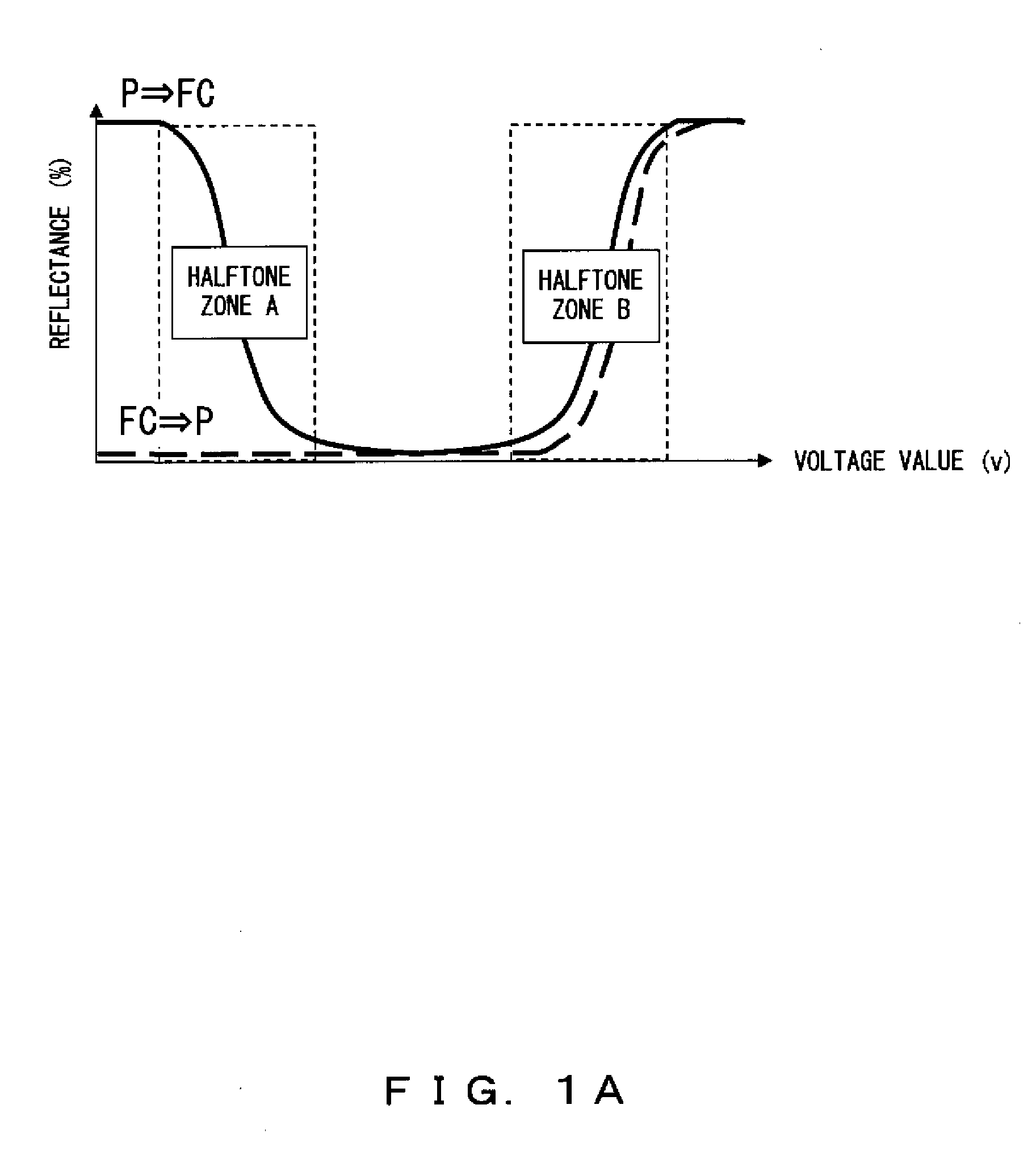

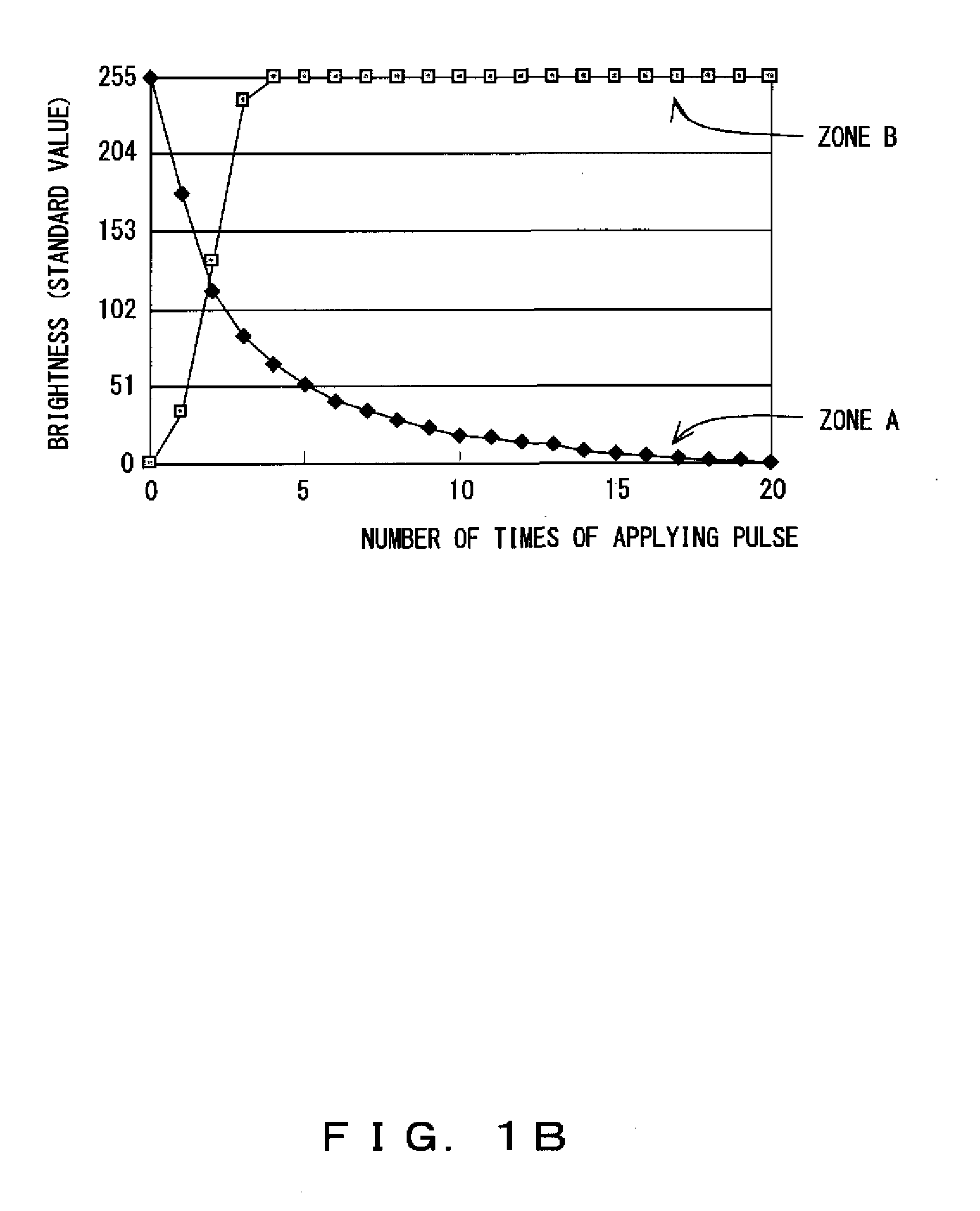

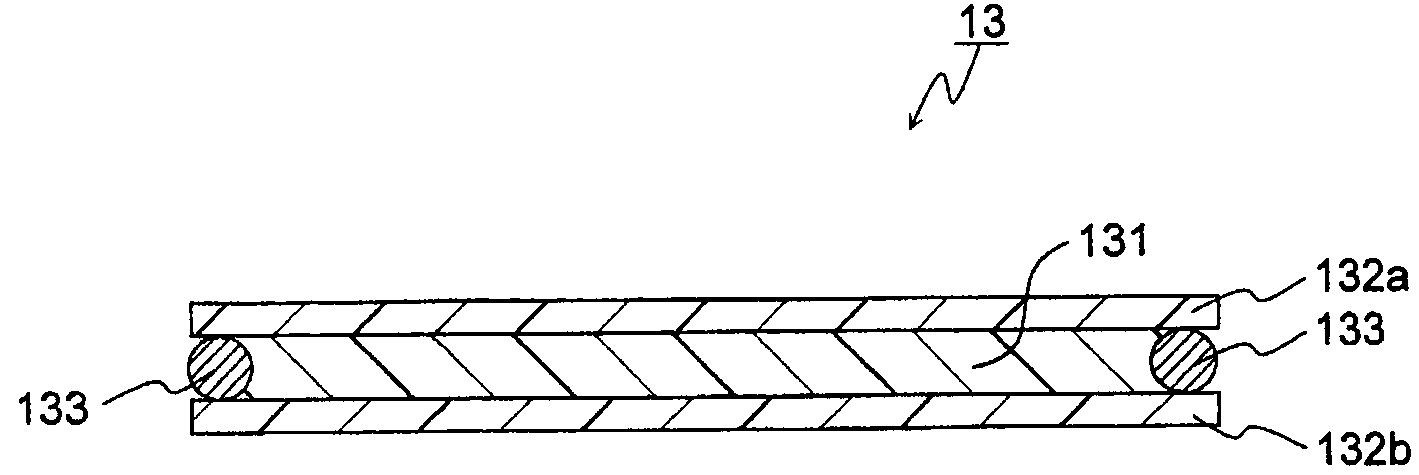

Method of driving liquid crystal display element

InactiveUS20080024412A1Low voltage enduranceExcellent uniformityStatic indicating devicesLiquid-crystal displayGray level

In order to realize a display with a multilevel halftone that is excellent in uniformity by using a liquid crystal display element employing an inexpensive and general purpose driver having a low voltage endurance, a pulse application employing a cumulative response (overwriting) of liquid crystals is performed a plurality of times, the driving voltage and the pulse width are set to be variable for each step, and the liquid crystals are controlled to be in a prescribed halftone state by using a region having a large margin from a reflection state as the initial state. Since an increase in drive voltage is prevented, an inexpensive binary output general purpose driver having a low voltage endurance can be used. Furthermore, a display with a multilevel halftone that is excellent in uniformity is realized because of a gray level conversion that uses a region having a large margin.

Owner:FUJITSU LTD

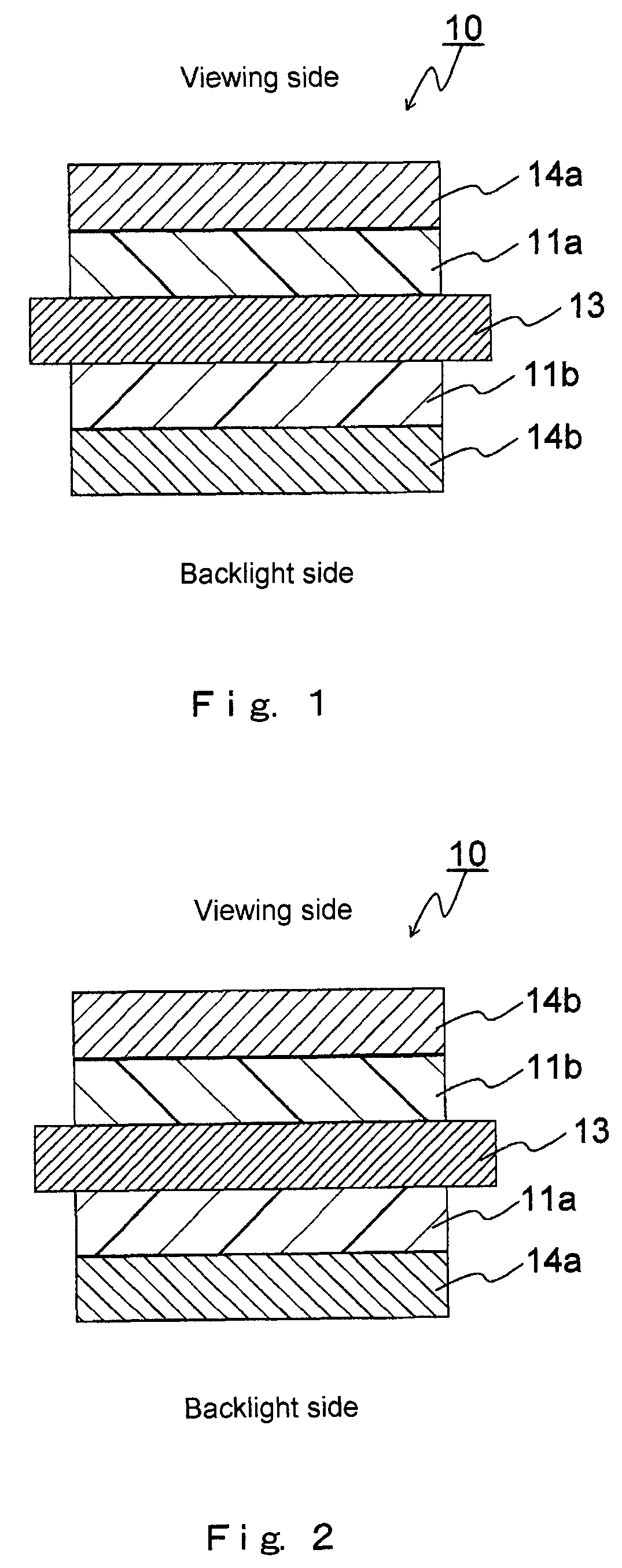

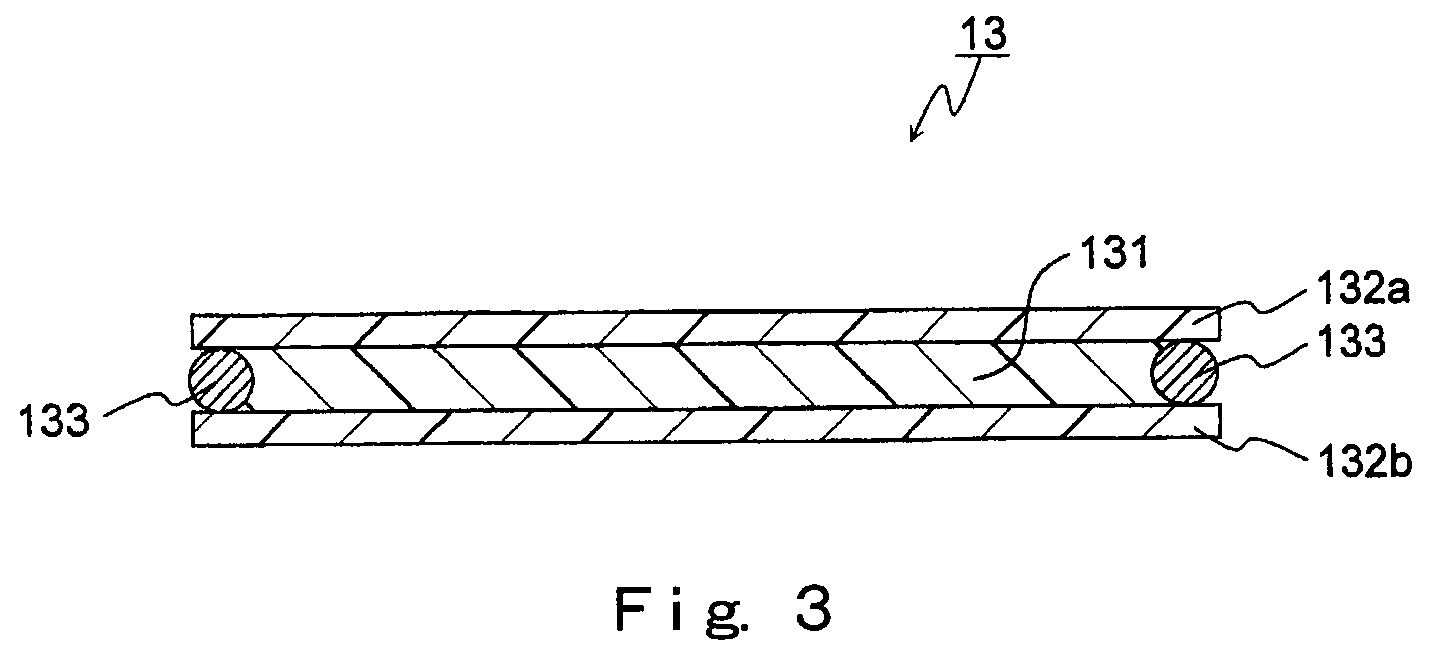

Liquid crystal panel, and liquid crystal display

ActiveUS20090128759A1Excellent uniformityHigh display qualityNon-linear opticsPolarizerIndex ellipsoid

A liquid crystal panel or the present invention comprising a liquid crystal cell, a first polarizer and a second polarizer provided on both sides of the liquid crystal cell, a first optical compensation layer provided between the liquid crystal cell and the first polarizer, and a second optical compensation layer provided between the liquid crystal cell and the second polarizer, wherein a wavelength dispersion of the liquid crystal cell satisfies Re40(450)>Re40(550)>Re40(650), an index ellipsoid of the first optical compensation layer satisfies a relationship of nx>nz>ny, and a wavelength dispersion of the second optical compensation layer satisfies Re40(450)≧Re40(550)≧Re40(650).

Owner:NITTO DENKO CORP

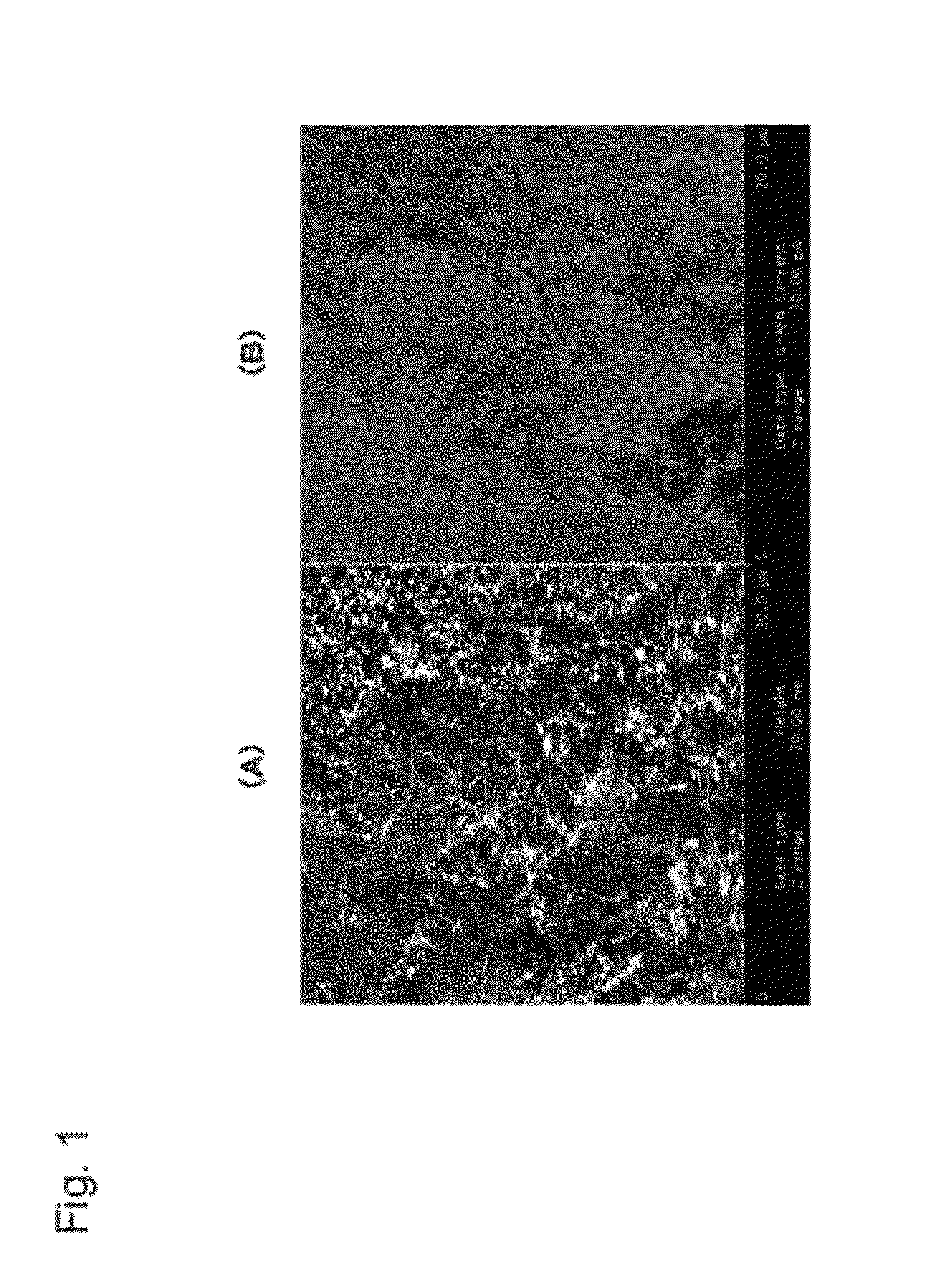

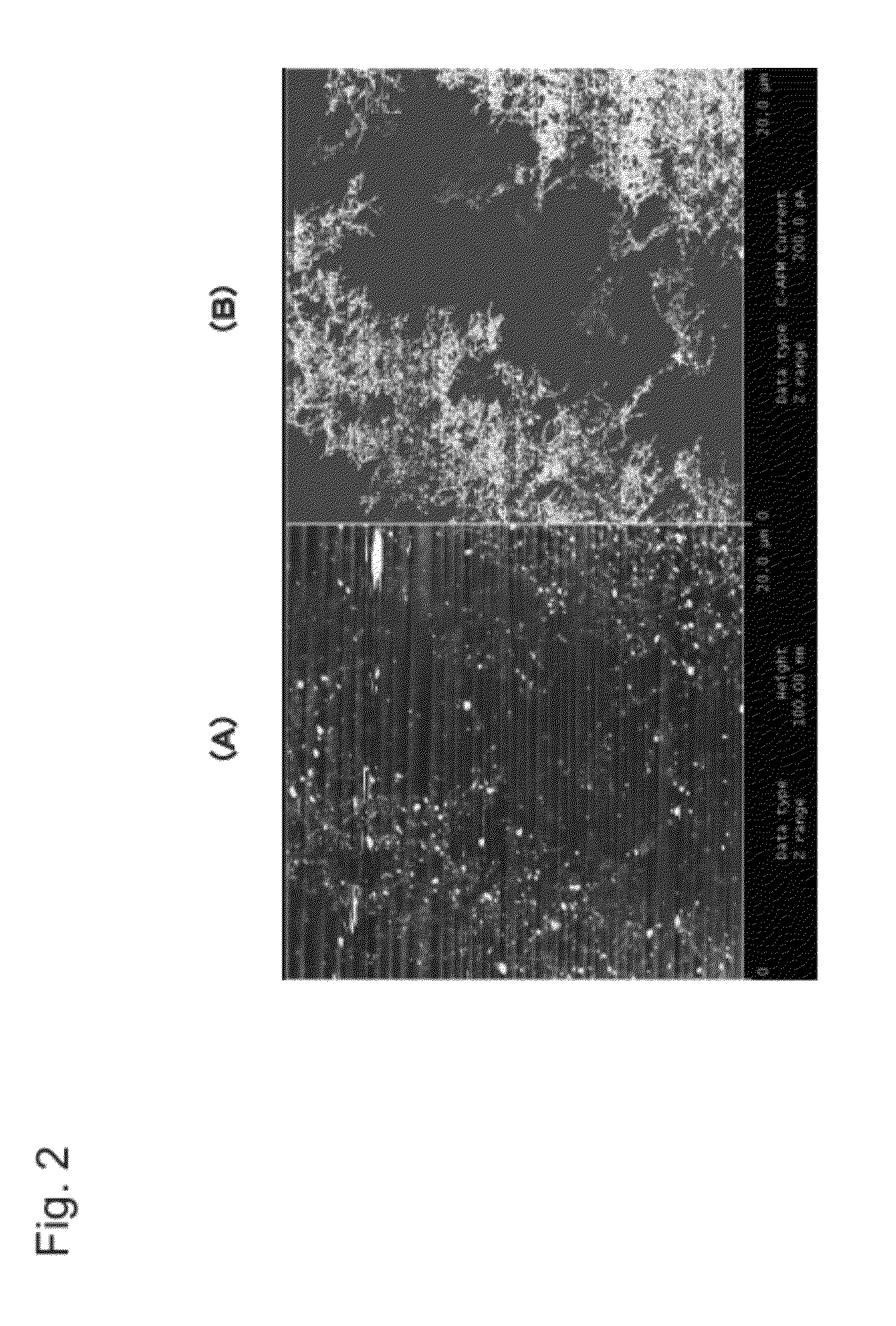

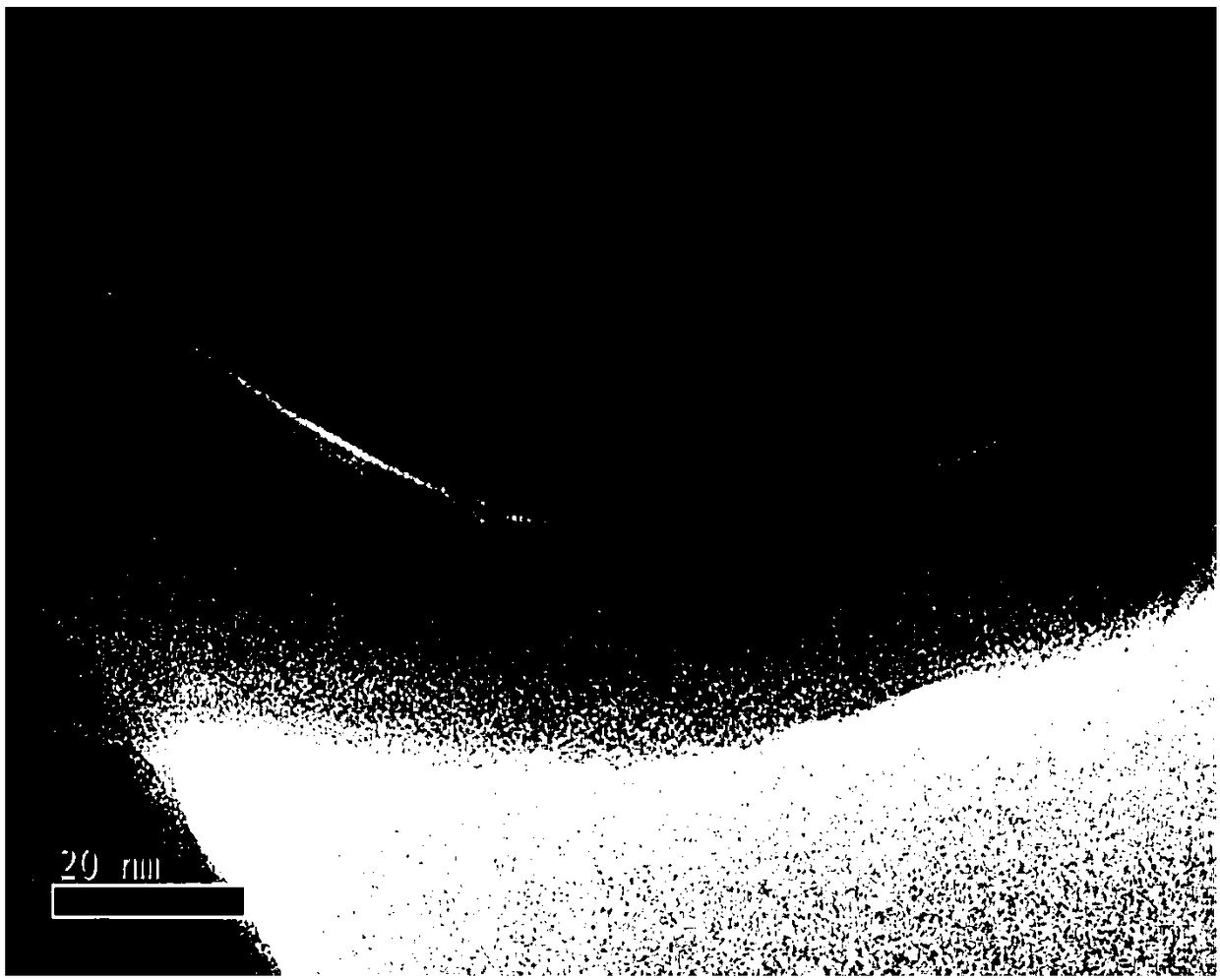

Carbon nanotube dispersion liquid and method for manufacturing semiconductor device

InactiveUS20120295406A1Stably disperseExcellent uniformityMaterial nanotechnologyNon-metal conductorsSolventCarbon nanotube

A carbon nanotube dispersion liquid obtained by mixing carbon nanotubes, a first organic solvent that is a nonpolar solvent, and a second organic solvent that has a polarity higher than that of this first organic solvent and is compatible with this first organic solvent.

Owner:NEC CORP

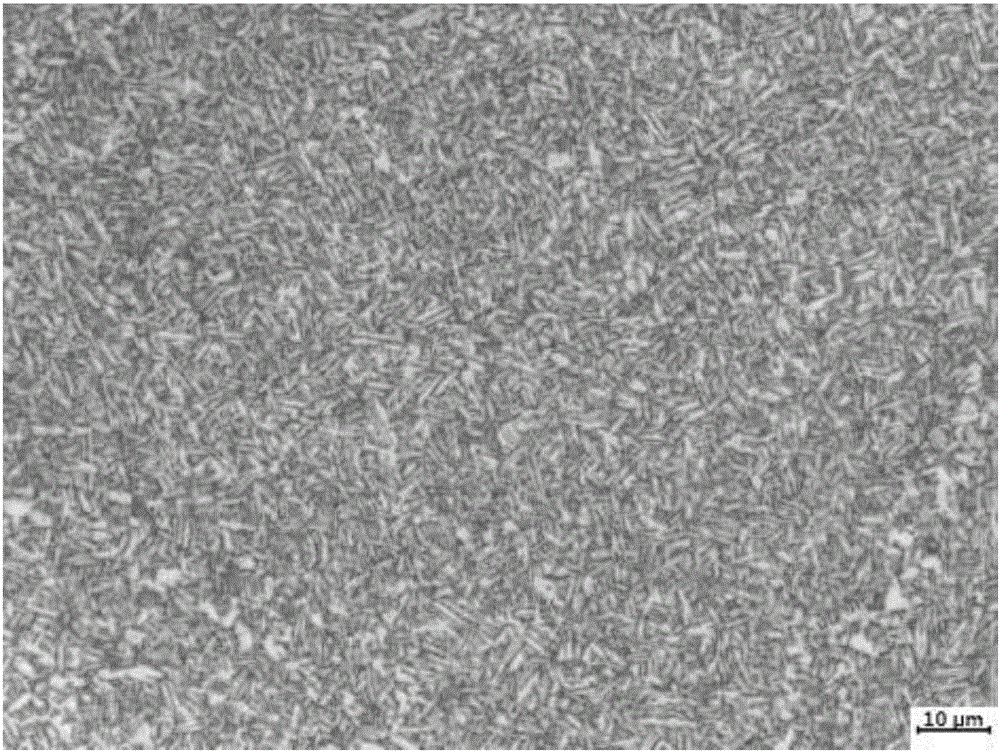

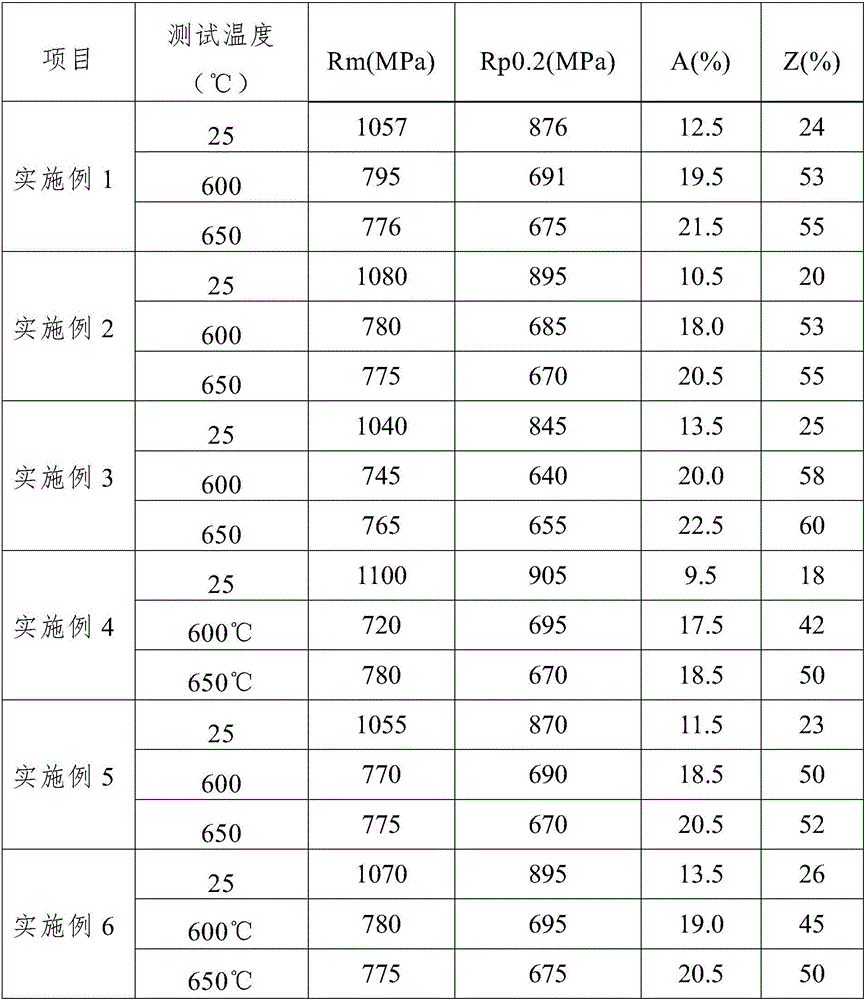

Preparation method of Ti2AlNb alloy material

ActiveCN106319236AImproves ingredient uniformityGood chemical uniformitySelf consumptionHeating time

The invention discloses a preparation method of a Ti2AlNb alloy material. The method comprises the steps of 1, preparing a Ti2AlNb alloy ingot through vacuum self-consumption electric arc melting, kish furnace smelting and vacuum self-consumption electric arc melting; 2, conducting primary homogenization treatment on the Ti2AlNb alloy ingot; and 3, wrapping the Ti2AlNb alloy ingot with asbestos cloth, then conducting heat-preservation heat treatment, and then sequentially conducting cogging forging, improved forging and finished product forging, so that the Ti2AlNb alloy material is finally obtained. The preparation method of the Ti2AlNb alloy material is simple in preparation process and reasonable in process design; an alloy is uniform in structure and stable in performance; the alloy ingot can be effectively refined, purified and homogenized through a smelting method; through the high-quality ingot, smooth implementation of subsequent hot working is guaranteed; by means of homogenization treatment, uniformity of alloy elements can be further improved through element diffusion; and wrapping treatment is conducted with the asbestos cloth, the temperature of the material can be effectively prevented from being lowered in the whole forging process, and large-deformation-amount forging for one heating time is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

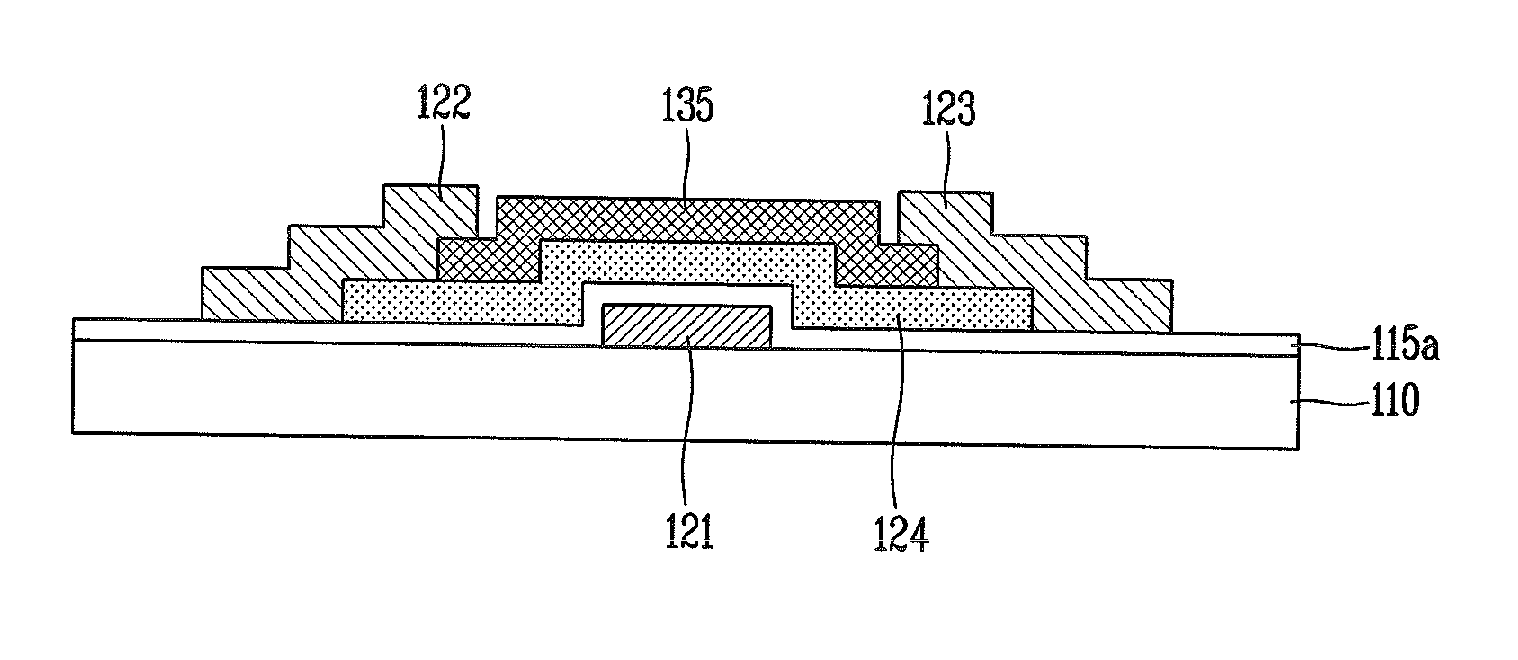

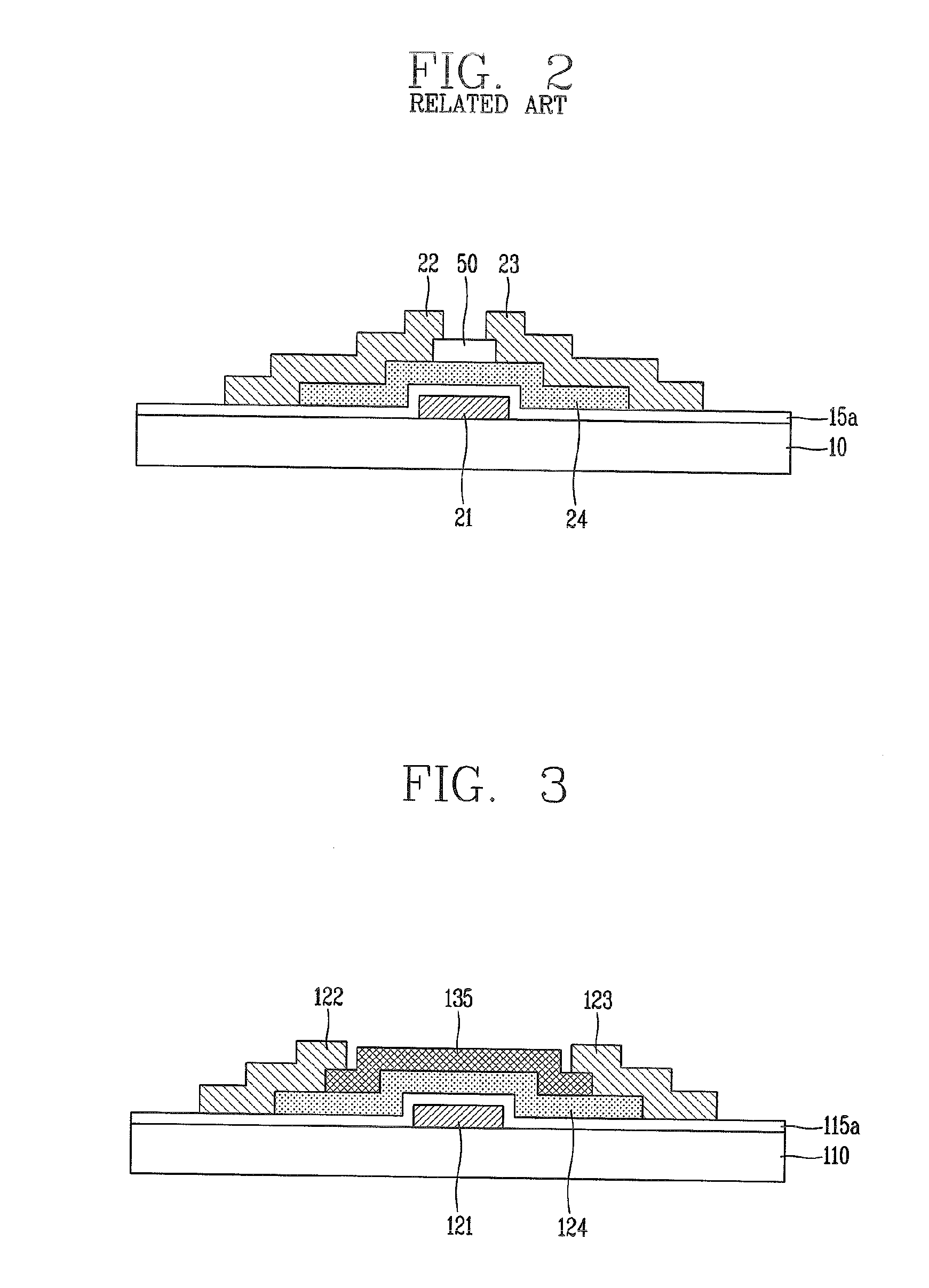

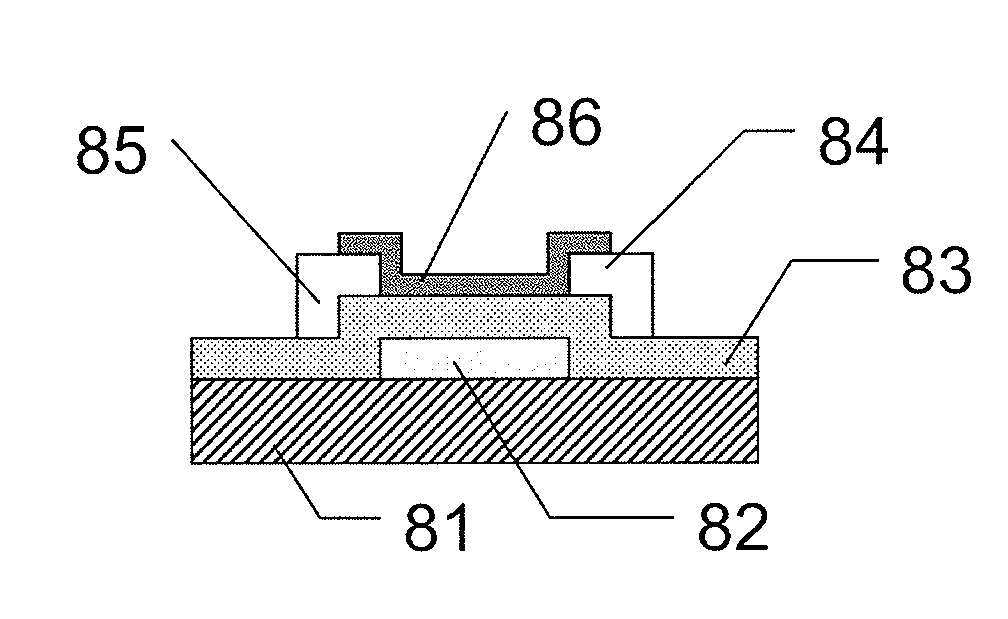

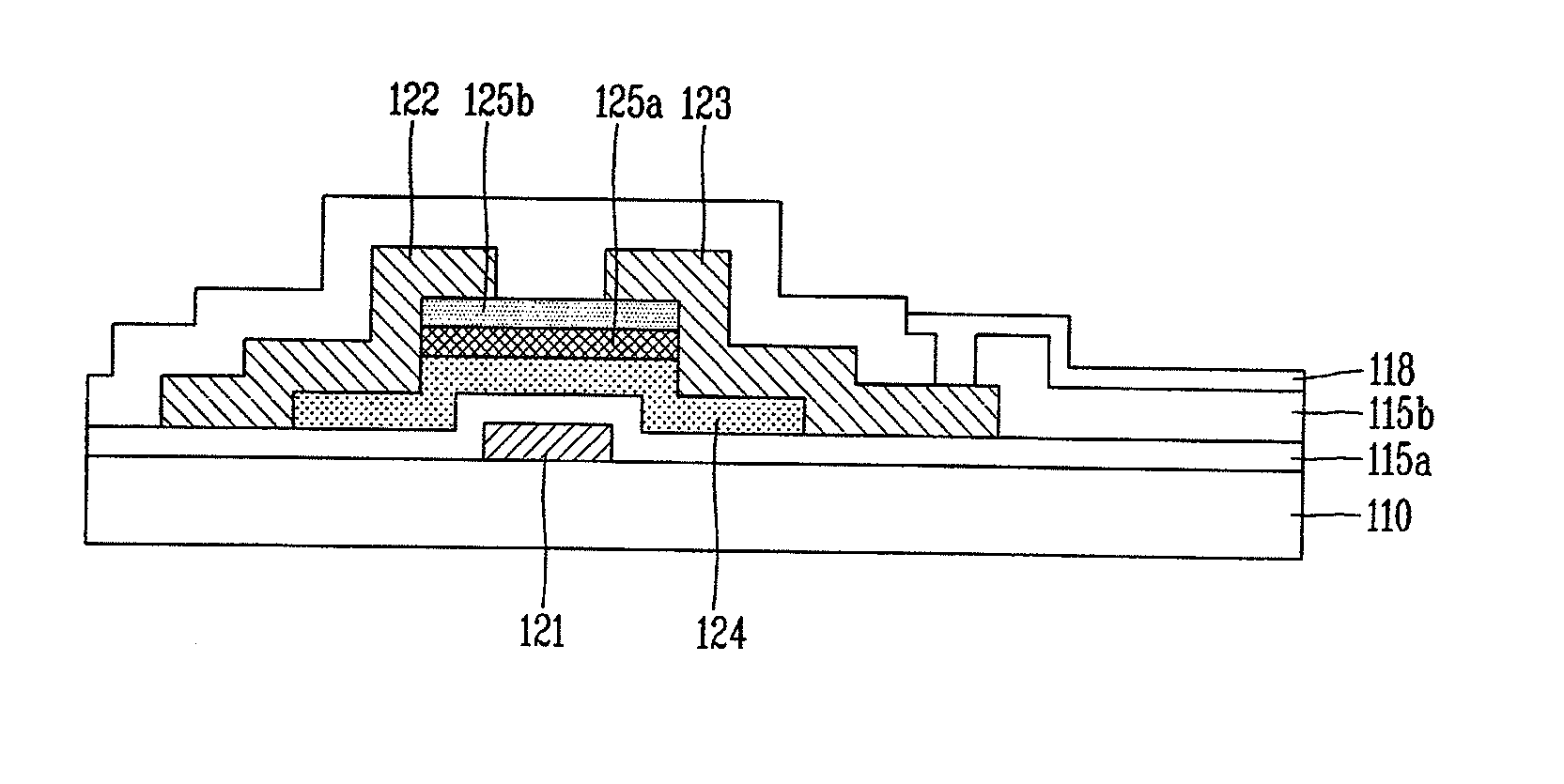

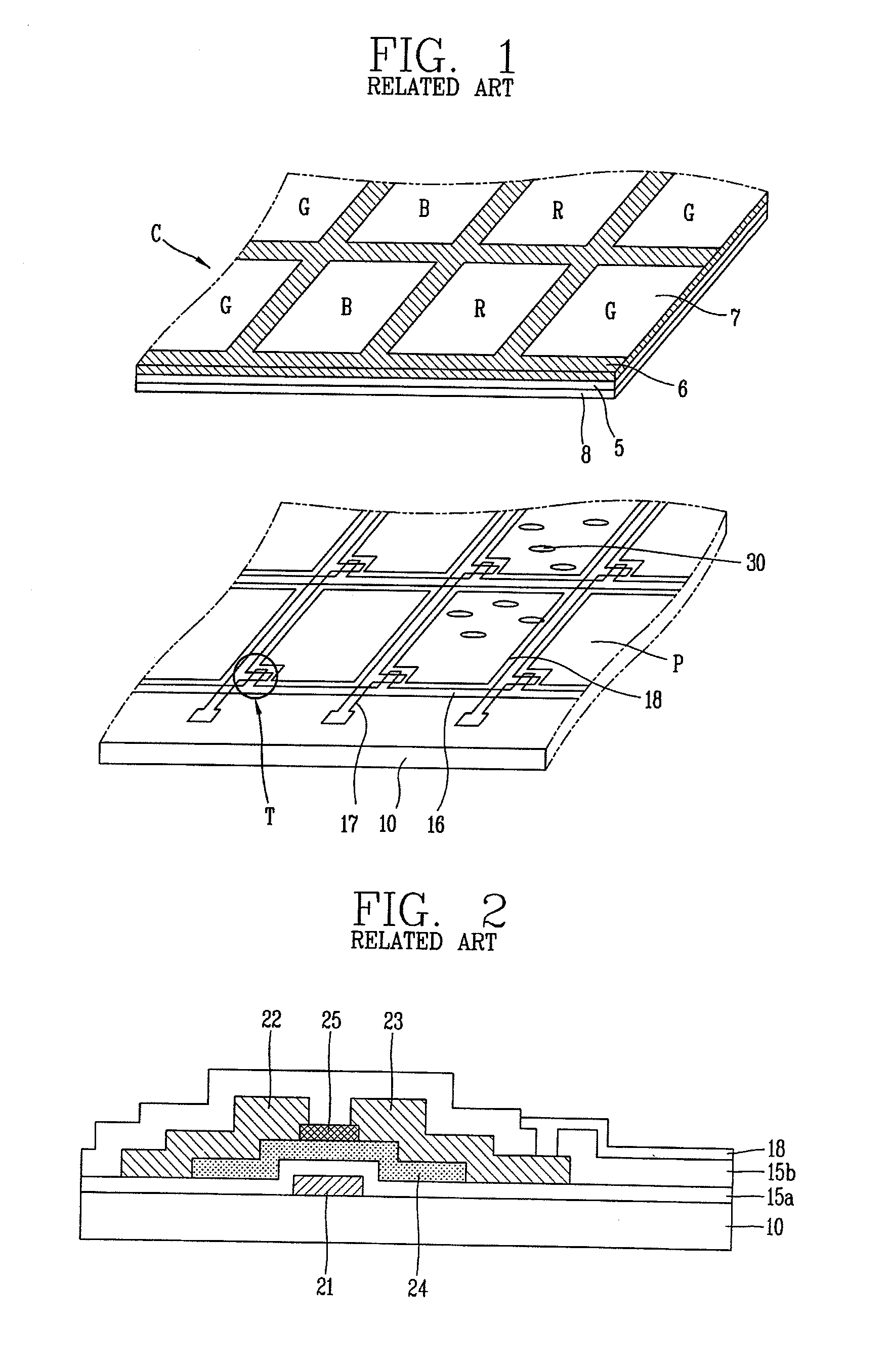

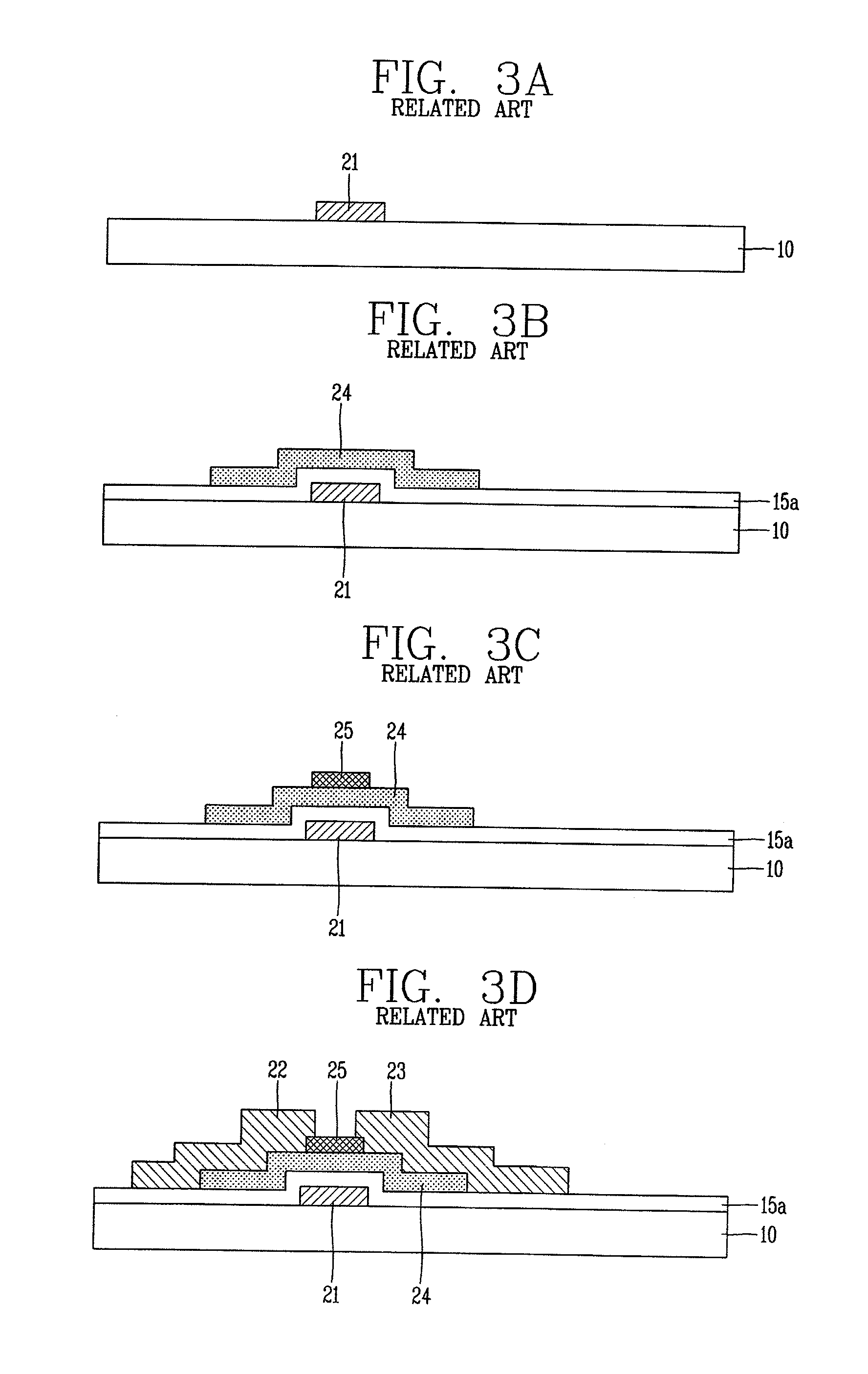

Oxide thin film transistor and method of fabricating the same

ActiveUS20120146017A1Excellent uniformityPrevent degradationSolid-state devicesSemiconductor/solid-state device manufacturingOxide semiconductorOxide

A method for fabricating an oxide thin film transistor includes sequentially forming a gate insulating film, an oxide semiconductor layer, and a first insulating layer; selectively patterning the oxide semiconductor layer and the first insulating layer to form an active layer and an insulating layer pattern on the gate electrode; forming a second insulating layer on the substrate having the active layer and the insulating layer pattern formed thereon; and selectively patterning the insulating layer pattern and the second insulating layer to form first and second etch stoppers on the active layer. The oxide semiconductor layer may be a ternary system or quaternary system oxide semiconductor comprising a combination of AxByCzO (A, B, C═Zn, Cd, Ga, In, Sn, Hf, Zr; x, y, z≧0).

Owner:LG DISPLAY CO LTD

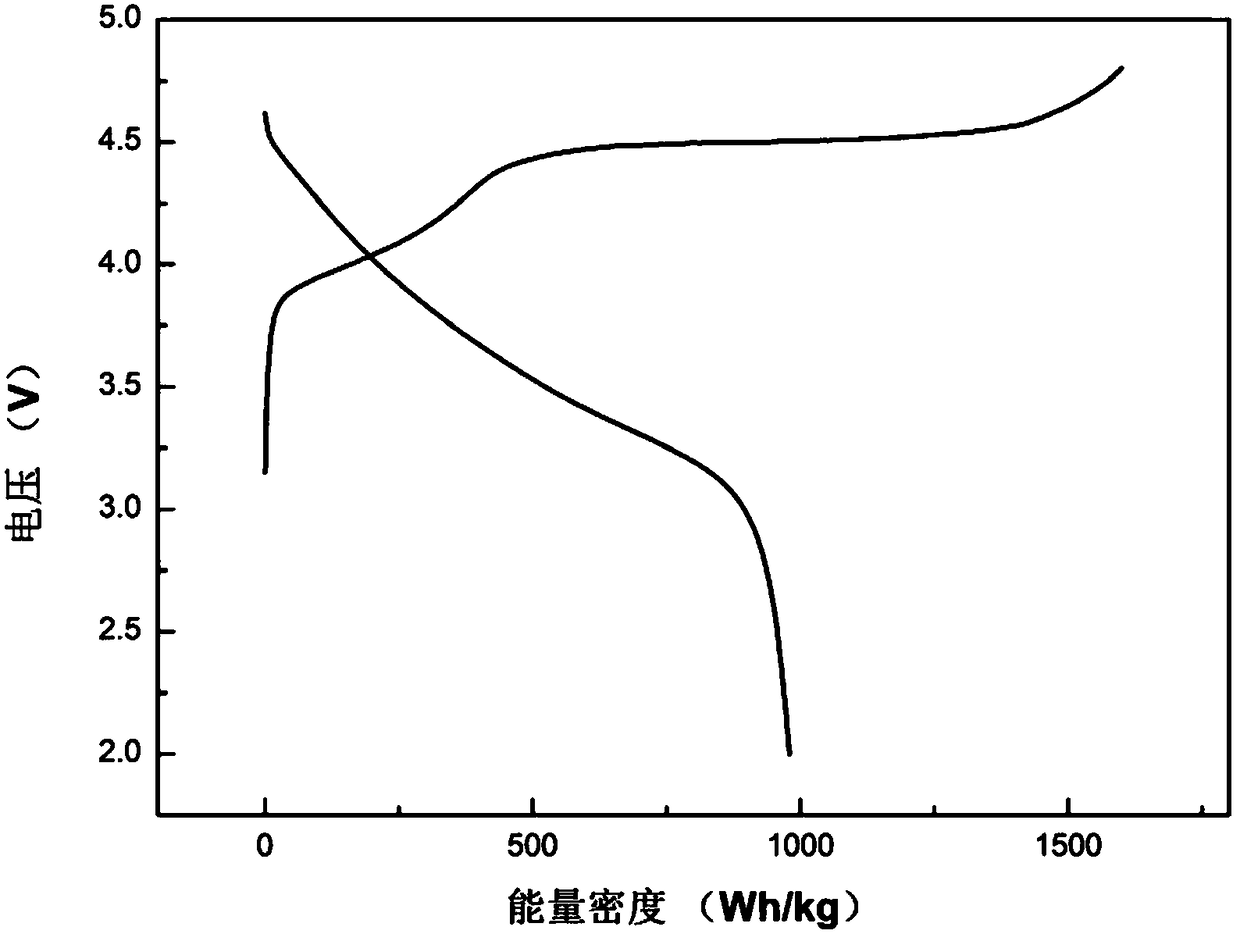

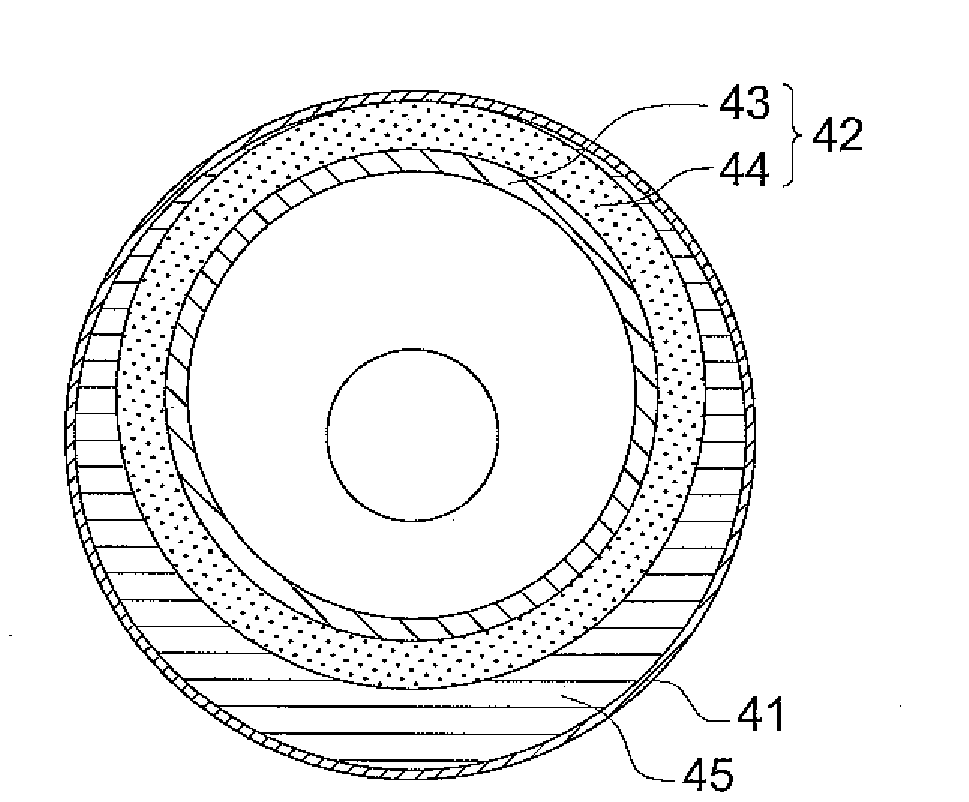

Spinel-coated layered positive electrode material and preparation method and application thereof

ActiveCN108550791AImprove securitySimple and fast operationCell electrodesHeterojunctionElectrical battery

The invention discloses a spinel-coated layered positive electrode material with a heterostructure and a preparation method thereof, a positive electrode of a lithium-ion battery of using the positiveelectrode material and the lithium-ion battery of using the positive electrode. According to the spinel-coated layered positive electrode material, a precursor is prepared by using an existing coprecipitation preparation technology, and the precursor is subjected to surface oxidation treatment through an extremely simple mixing method and then subjected to high-temperature heat treatment, therebyobtaining a heterogeneous positive electrode material of employing a lithium-rich layered material as a core and a spinel material as a protective shell. The modification method is easy to operate, high in security, low in cost and suitable for large-scale production; the obtained spinel coating layer is relatively high in integrity and uniformity and adjustable in thickness; the spinel-coated layered positive electrode material is much higher than a commercial positive electrode material in rate capability and cycling stability; and the demand for the lithium-ion battery with high energy density, a long cycle and high stability in the market can be met.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

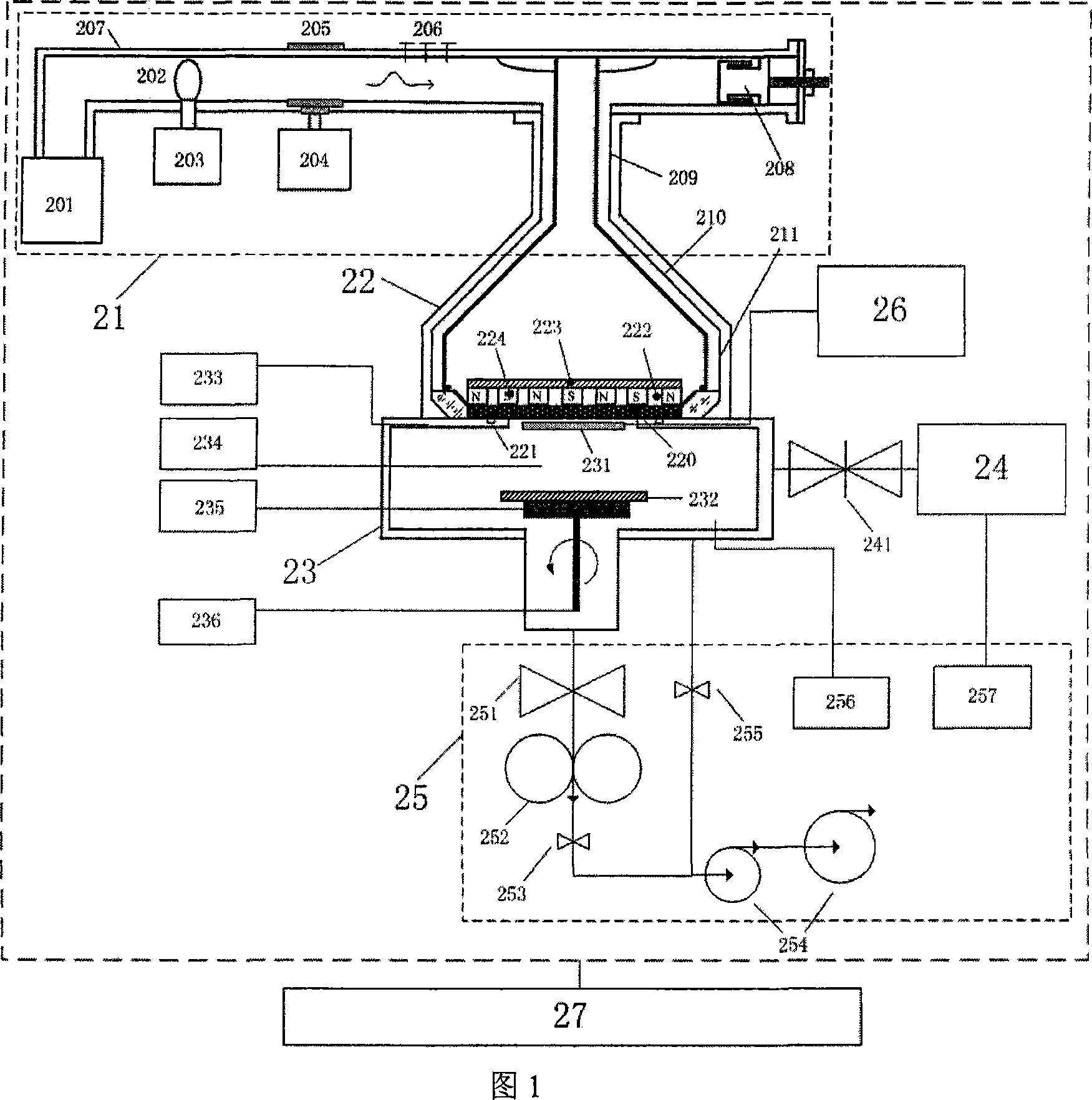

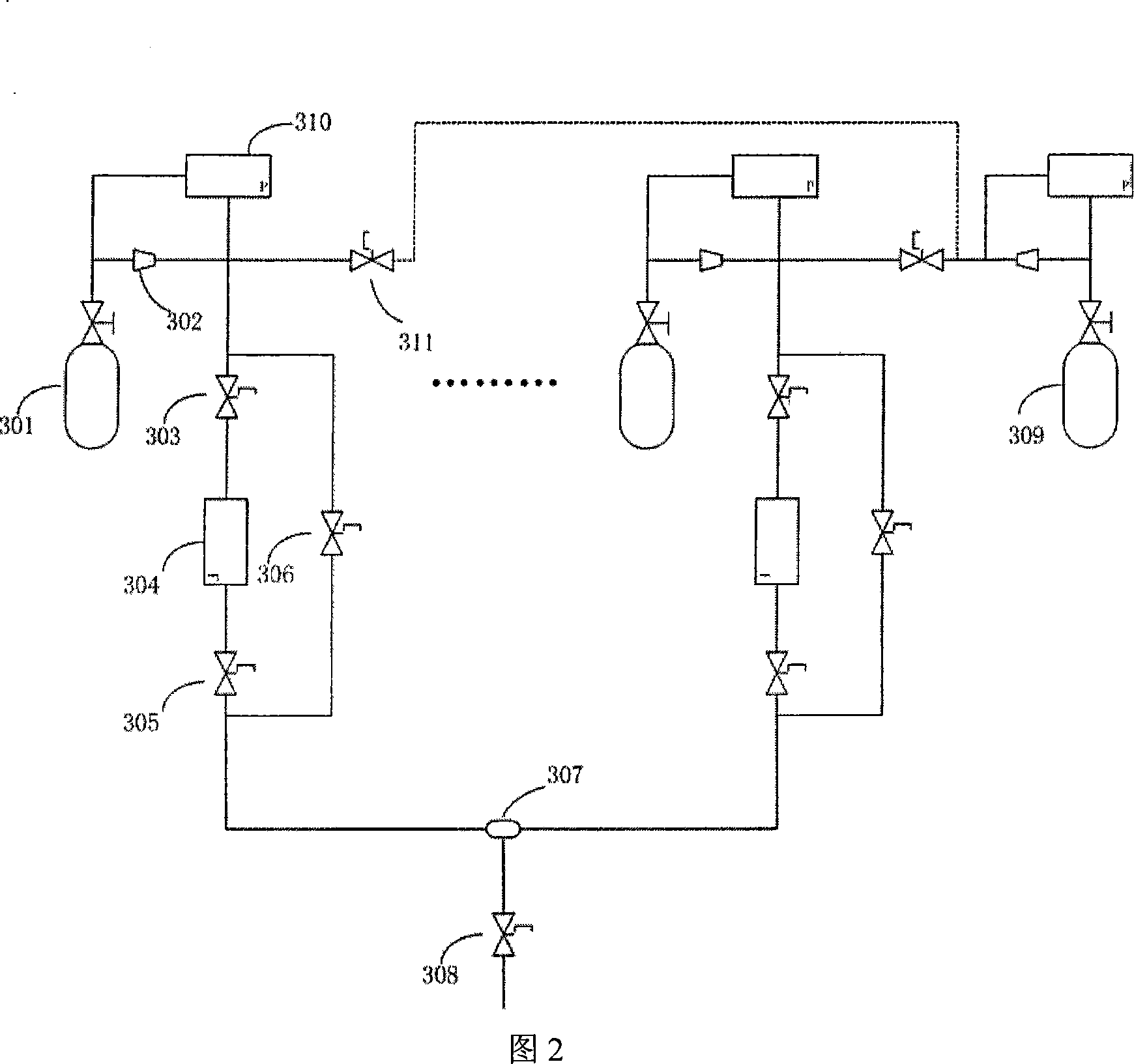

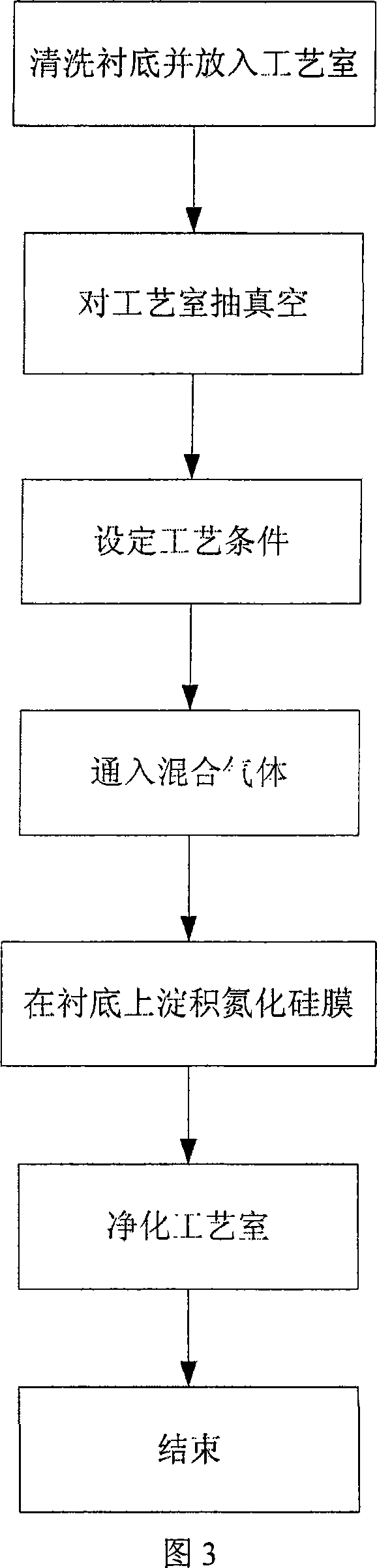

Method for chemical gaseous phase deposition of silicon nitride film by electron cyclotron resonance plasma

InactiveCN101104925ALow deposition temperatureExcellent uniformityChemical vapor deposition coatingDecompositionFlow ratio

The invention discloses a low-temperature manufacturing method of silicon nitride film used in passivation layer of an integrated circuit. The silicon nitride film grows on a substrate positioned inside a deposition chamber. The method comprises cleaning the substrate and placing inside the working chamber, vacuumizing the working chamber and presetting working conditions, introducing a mixed gas composed of silicon source gas and nitride source gas into the working chamber, performing ionization and decomposition of the mixed gas with the action of energy absorbed from a microwave source upon electron cyclotron resonance effect, transferring active charged particles produced by the ionization and decomposition to the surface of the substrate with the action of permanent magnetic field, and depositing silicon nitride film on the substrate. The working conditions are as follows: working chamber pressure: 0.1-5Pa, microwave power: 600-2000W, deposition temperature: room temperature to 300 DEG C, total gas flow: 50-300sccm, flow ratio of silicon source gas to nitride source gas: 1:6 to 1:12, and substrate rotation speed: 60 r / min. The inventive method can rapidly and uniformly deposit the low-hydrogen silicon nitride film (6 inch thickness) at low temperature (below 300 DEG C), which is used as a material for passivation layer of integrated circuit or optical devices.

Owner:XIDIAN UNIV

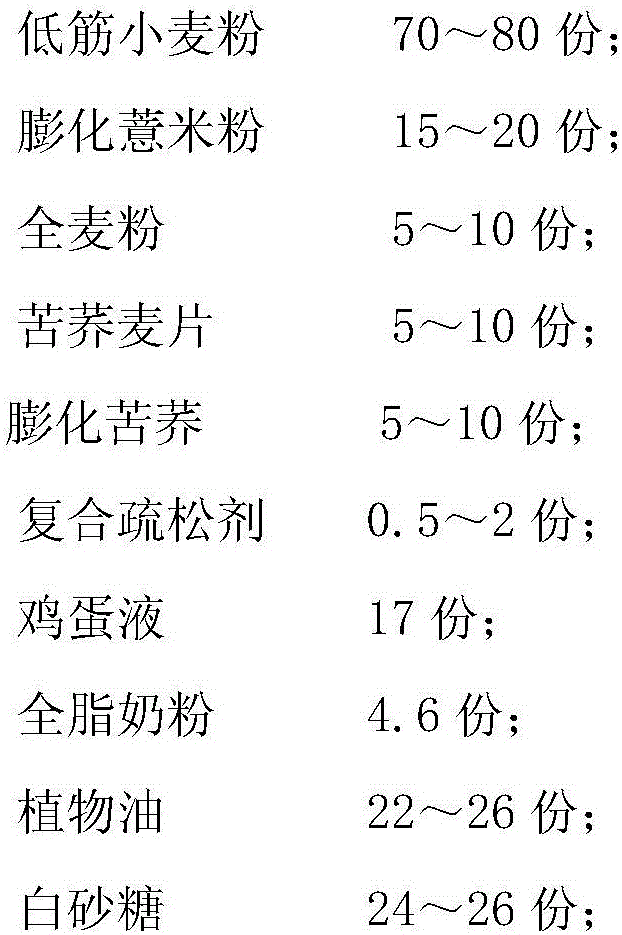

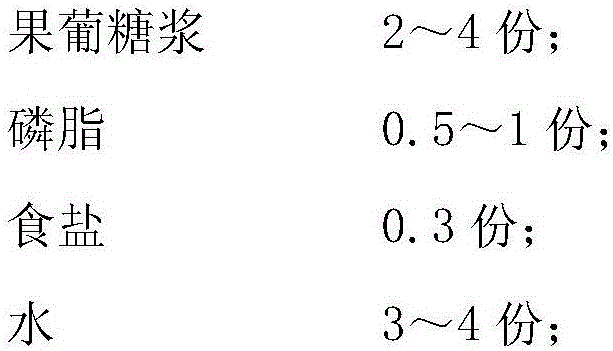

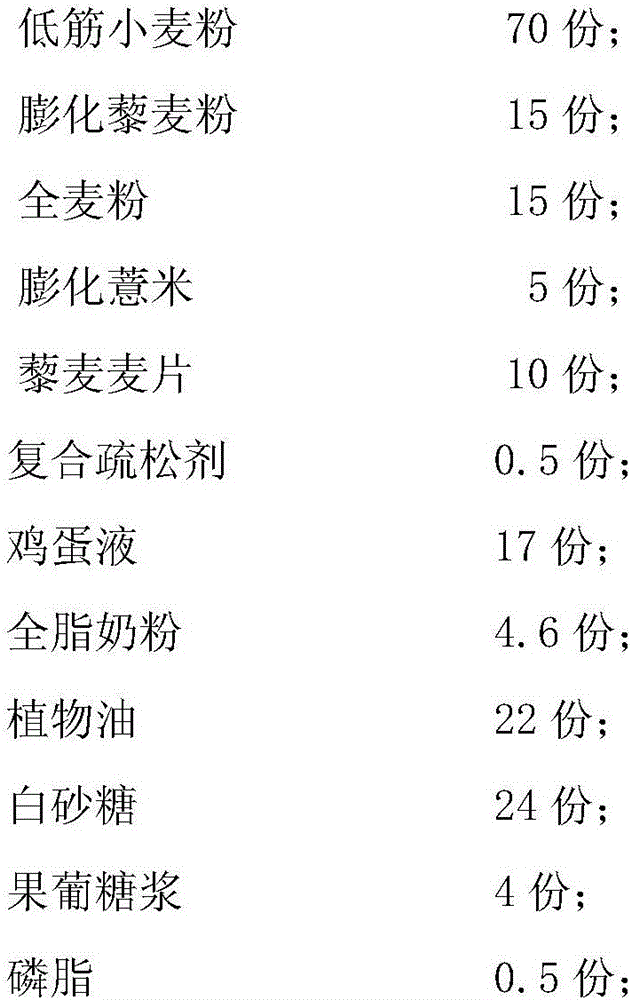

Crispy cereal biscuits and making method thereof

InactiveCN105660796AImprove sensory qualityLow sensory qualityDough treatmentBakery productsDigestible starchPolygonum fagopyrum

The invention provides crispy cereal biscuits.The crispy cereal biscuits are prepared from, by weight of dry powder, 70-80 parts of low-gluten wheat flour, 15-20 parts of puffed coix seed flour, 5-10 parts of whole wheat flour, 5-10 parts of puffed tartary buckwheat, 5-10 parts of bitter tartary buckwheat pieces, 0.5-2 parts of a composite bulking agent, 17 parts of egg liquid, 0.3 part of salt, 4.6 parts of whole milk powder, 22-26 parts of vegetable oil, 24-26 parts of white granulated sugar, 2-4 parts of high fructose syrup, 0.5-1 part of phospholipid and 3-4 parts of water.The invention further provides a making method of the crispy cereal biscuits.According to the prepared crispy cereal biscuits, the content of flavonoid compounds like rutin, the content of 18 kinds of amino acid needed by the human body and the content of mineral are higher than those of common crispy biscuits sold in the market, the content of slow digestible starch is no smaller than 35 g / 100 g, and when being eaten frequently, the prepared crispy cereal biscuits have a nutrition function of balancing food and have nutrition effects of softening blood vessels and resisting oxidation.

Owner:SHANGHAI INST OF TECH

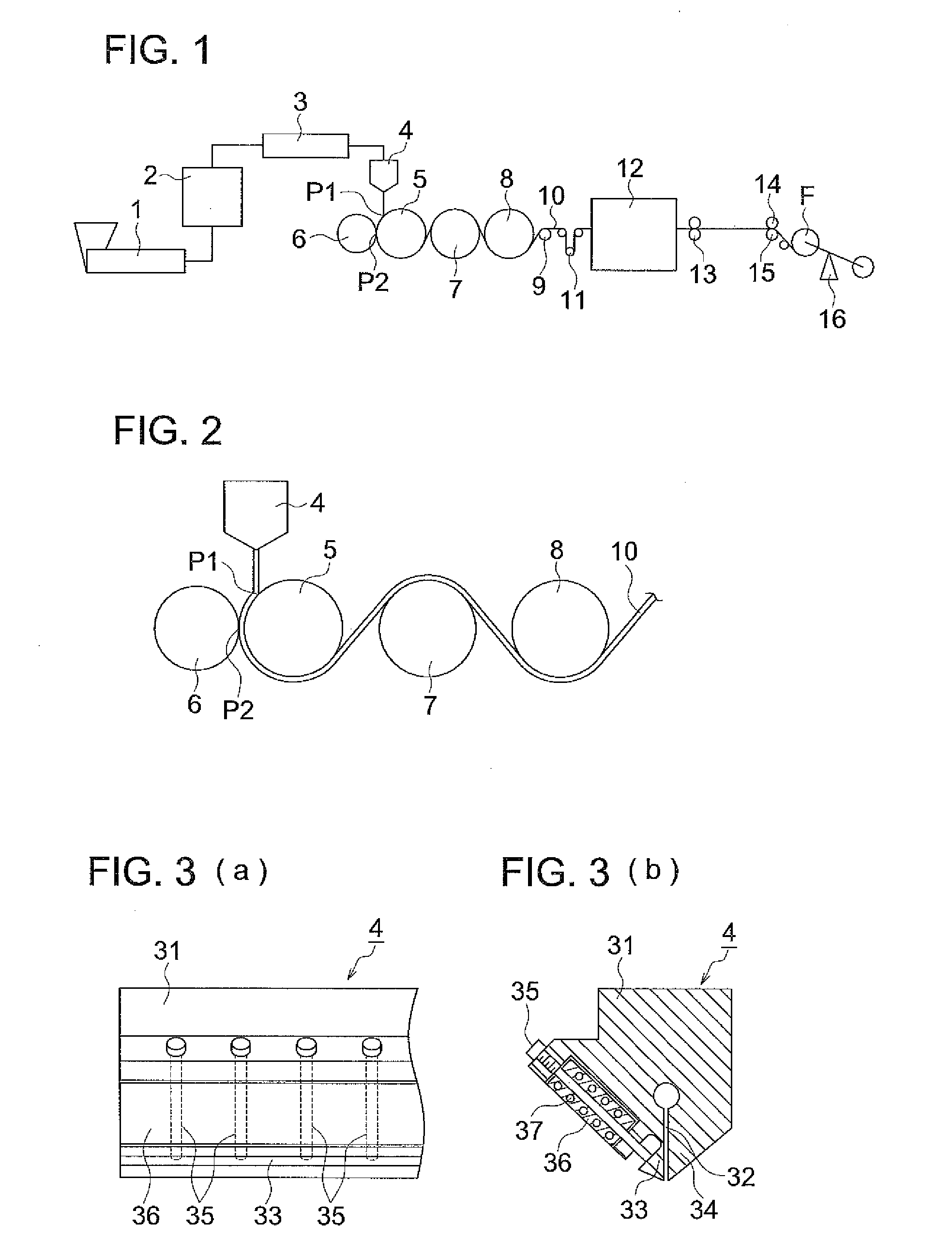

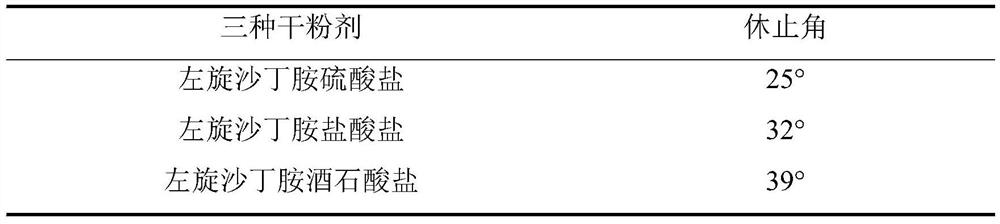

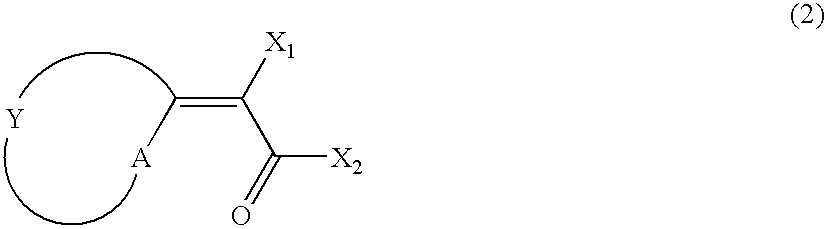

Process for producing cellulose acylate film, cellulose acylate film, polarizer, and liquid-crystal display

InactiveUS20090155495A1Excellent flatnessExcellent uniformityLiquid crystal compositionsOther chemical processesPolarizerChemistry

A process for cellulose acylate film production which is sufficiently effective in reducing viscosity and in reducing moisture permeability. The cellulose acylate film does not suffer bleeding, i.e., the phenomenon in which a component separates out or volatilizes from the cellulose acylate film, has high flatness, is inhibited from having streak unevenness, and has high evenness. Even through long-term storage, the film does not suffer film deformation failures such as ridge failures or protrusion failures. This process for cellulose acylate film production comprises forming a cellulose acylate film by the melt casting method, and is characterized in that the cellulose acylate film contains at least one compound represented by the following general formula (1) and that the cellulose acylate film extruded from a casting dye in the film formation by melt casting is pressed between a touch roll having an elastically deformable surface and a cooling roll to produce the target film.

Owner:KONICA MINOLTA OPTO

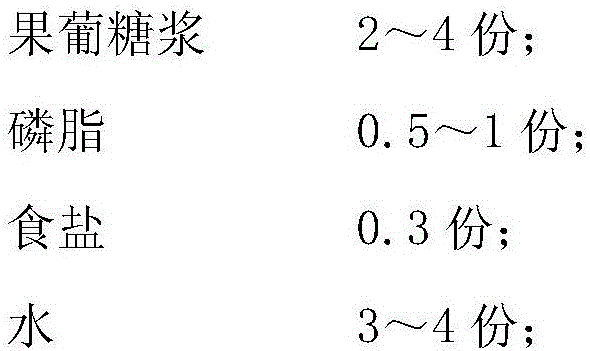

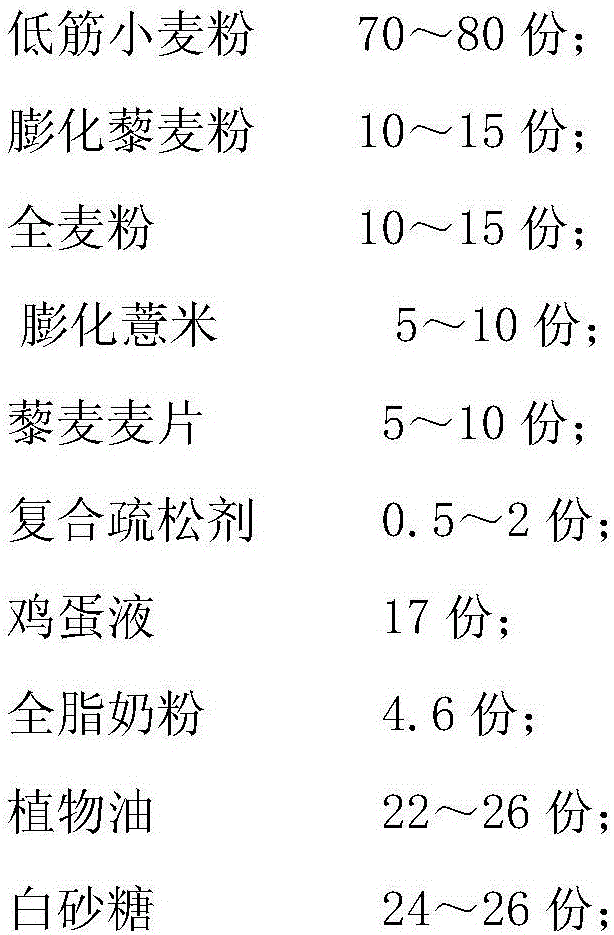

Improved cereal short biscuit and preparing method thereof

ActiveCN105685182AImprove sensory qualityHigh in total phenolsDough treatmentBakery productsPearl barleyVegetable oil

The invention discloses an improved cereal short biscuit. Dry materials of the improved cereal short biscuit comprise, by weight, 70-80 parts of low-gluten wheat flour, 10-15 parts of puffed quinoa flour, 10-15 parts of whole wheat flour, 5-10 parts of puffed pearl barley, 5-10 parts of quinoa oatmeal, 0.5-2 parts of composite bulking agent, 17 parts of egg liquid, 0.3 part of salt, 4.6 parts of whole milk powder, 22-26 parts of vegetable oil, 24-26 parts of white granulated sugar, 2-4 parts of high fructose corn syrup, 0.5-1 part of phospholipid amd 3-4 parts of water. The invention further provides a preparing method of the improved cereal short biscuit. According to the cereal short biscuit prepared with the method, the contents of polyphenol, 18 kinds of amino acid required by the human body, vitamins and mineral substances are higher that the contents in a common market short biscuit; if the cereal short biscuit prepared with the method is frequently eaten, the important effects of adjusting the blood glucose level and protecting the heart are achieved, and after the improved cereal short biscuit is eaten, satiety exists and contributes to weight losing.

Owner:科丝美特生物科技(白山)有限公司

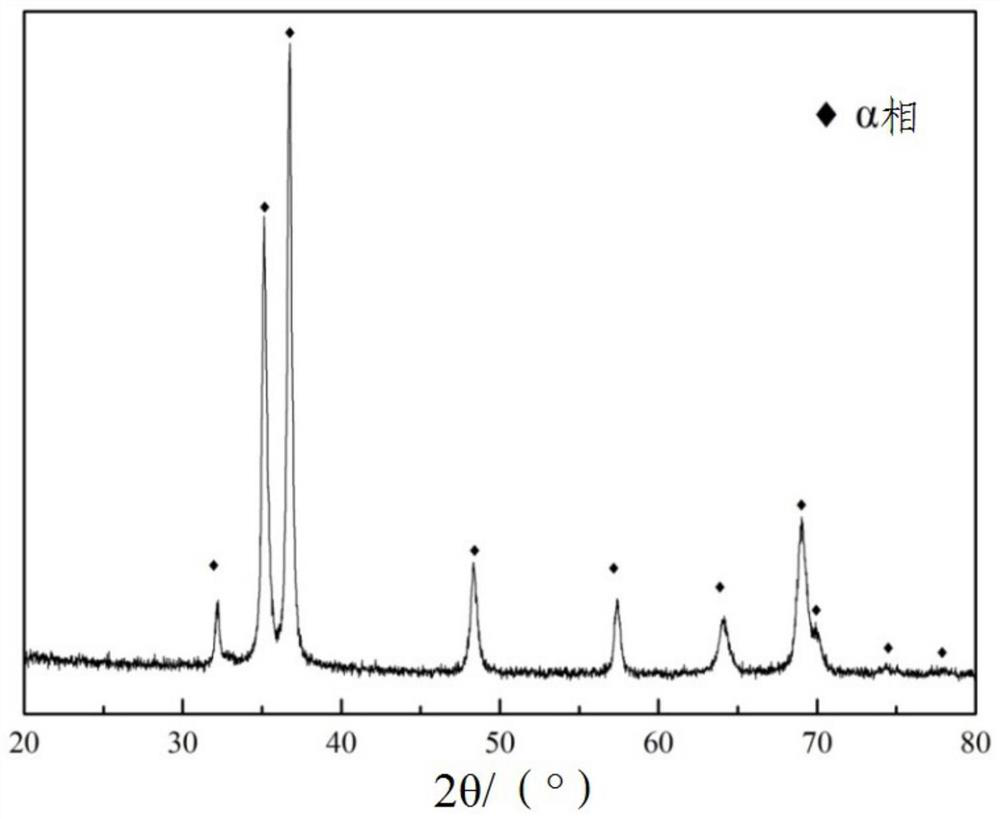

Corrosion-resistant high-strength neutron shielding alloy material and preparation method thereof

The invention discloses a corrosion-resistant high-strength neutron shielding alloy material which is composed of the following elements including, by mass, 49%-51% of Hf and the balance Zr and inevitable impurities. The invention also provides a preparation method of the corrosion-resistant high-strength neutron shielding alloy material. The method comprises the following steps of mixing sponge zirconium and sponge hafnium, conducting pressing and vacuum consumable electrode smelting to obtain an alloy cast ingot, sequentially machining and chamfering the alloy cast ingot, carrying out three-heating-number forging to obtain a forged alloy ingot, carrying out heat treatment on the forged alloy ingot, and cooling to obtain the alloy material. According to the corrosion-resistant high-strength neutron shielding alloy material and the preparation method, the Zr serves as a matrix, the Hf serves as a main alloy element, the alloy material is prepared through vacuum consumable electrode smelting and three-heating-number forging, and the prepared alloy material is single in phase and uniform in structure, has excellent neutron shielding performance and strength and meanwhile has extremely high corrosion resistance and machinable performance.

Owner:西安稀有金属材料研究院有限公司

Single cell whole genome amplification method

InactiveCN105296466AGood repeatabilityExcellent uniformityMicrobiological testing/measurementDNA preparationGenomic sequencingNucleotide

The invention discloses a single cell whole genome amplification method, comprising following steps: (1), performing separating to obtain single cell samples; (2), subjecting the single cell samples to whole genome DNA amplification; (3), subjecting an amplification product to quantitative and qualitative analysis; (4), establishing a genome sequencing library, performing sequencing, and performing genome bioinformatic analysis. The single cell genome DNA amplification method is built and can be used to detect the single, tertiary, multiple and sex chromosome deficiency of a whole chromosome, the insertion and deficiency of few bases, DNA copy number variation, and the genetic variation information of single cell genomes such as single nucleotide polymorphisms.

Owner:SUZHOU BASECARE MEDICAL DEVICE CO LTD

Method for producing surface-treated glass fiber film and flexible fiber substrate

ActiveUS20150315073A1Excellent uniformityExcellent dimensional stabilitySynthetic resin layered productsPretreated surfacesFlexible fiberHigh intensity

The present invention provides a method for producing a surface-treated glass fiber film comprising steps of: preparing a treatment solution consisting of a mixture of a hydrolysable silane compound and a partially hydrolyzed condensate thereof; coating a glass fiber film with the treatment solution so that the attached amount of the mixture is 2% by mass or more and 90% by mass or less, relative to 100% by mass of the surface-treated glass fiber film and drying the same; and heat-treating the glass fiber film coated.There can be provided a method for producing a surface-treated glass fiber film having high strength, a low average coefficient of linear expansion, a high storage rigidity at high temperature and excellent in heat resistance, flexibility, electric insulation, dimensional stability, and surface homogeneity, with less environmental impact.

Owner:SHIN ETSU CHEM IND CO LTD

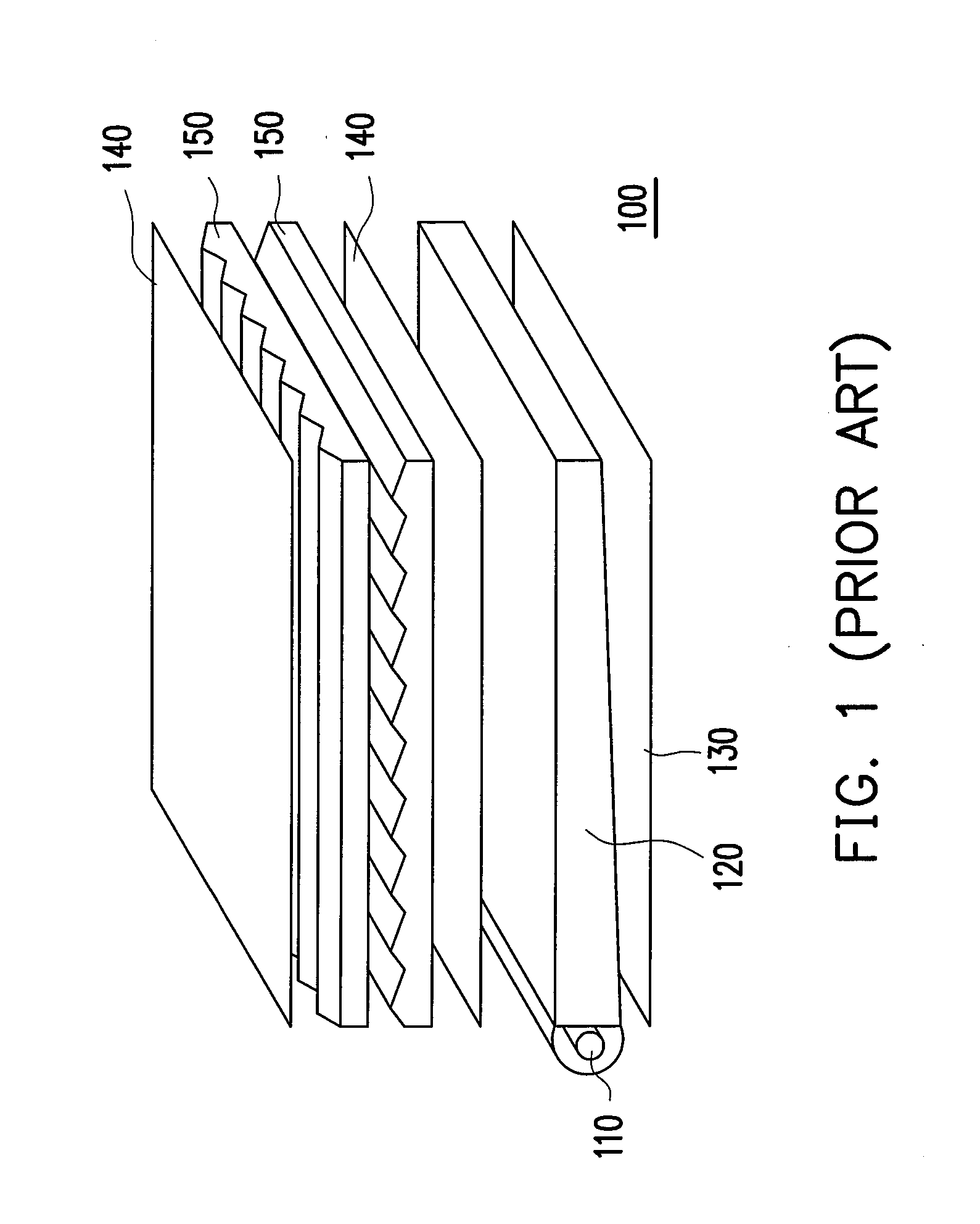

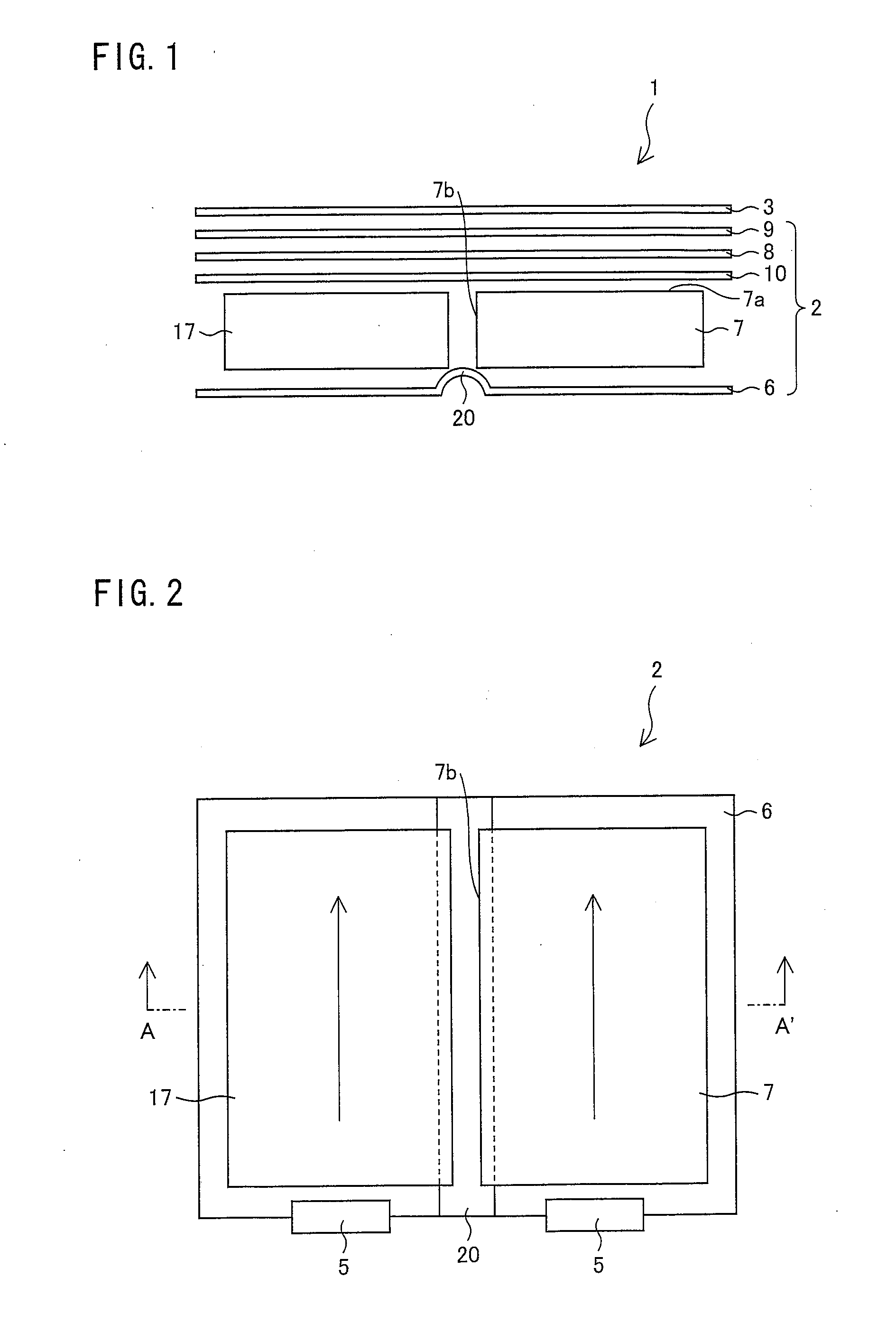

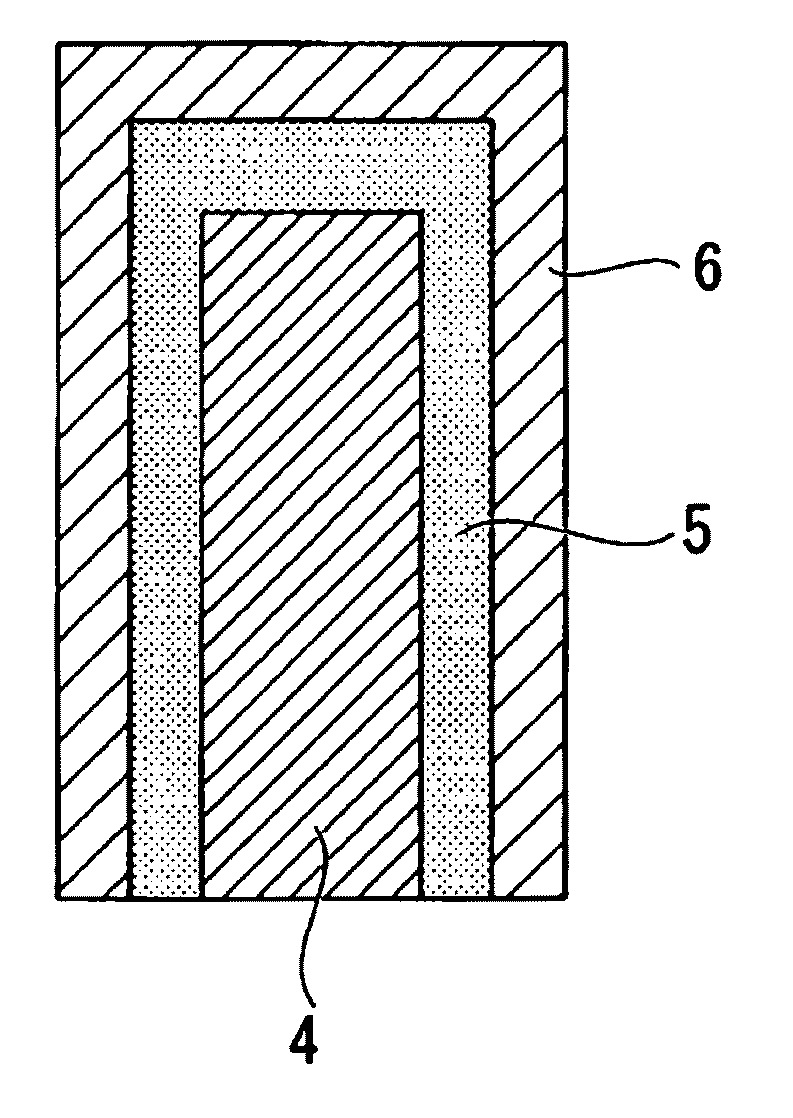

Illumination device and liquid crystal display device

InactiveUS20110170022A1Excellent uniformityImprove brightness uniformityMechanical apparatusTelevision system scanning detailsPhysicsLiquid-crystal display

A backlight (2) of the present invention includes a light source (5), a plurality of light guides (7) and (17) for emitting light emitted from the light source (5), and a reflecting material (6), which is disposed so as to face surfaces of the plurality of light guides (7) and (17) which surfaces are opposite to light emission surfaces (7a) of the plurality of light guides (7) and (17). The light guide (7) and the light guide (17) are adjacent to each other. The reflecting material (6) includes a protruding section (20) having a curved surface in a region on that surface of the reflecting material (6) which faces the light guides (7) and (17), which region corresponds to a region between the light guide (7) and the light guide (17). The arrangement makes it possible to realize an illumination device having further improved uniformity of luminance.

Owner:SHARP KK

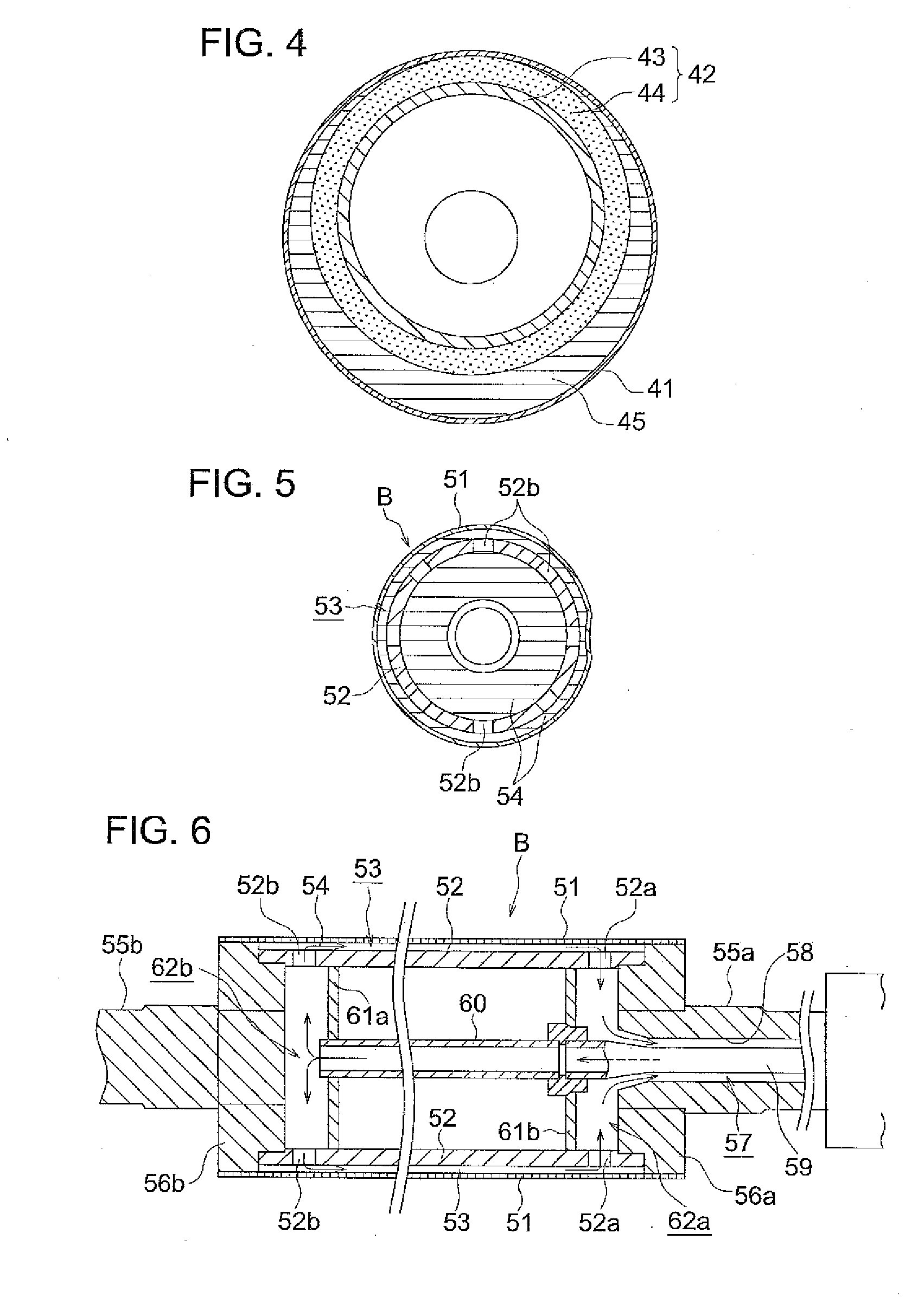

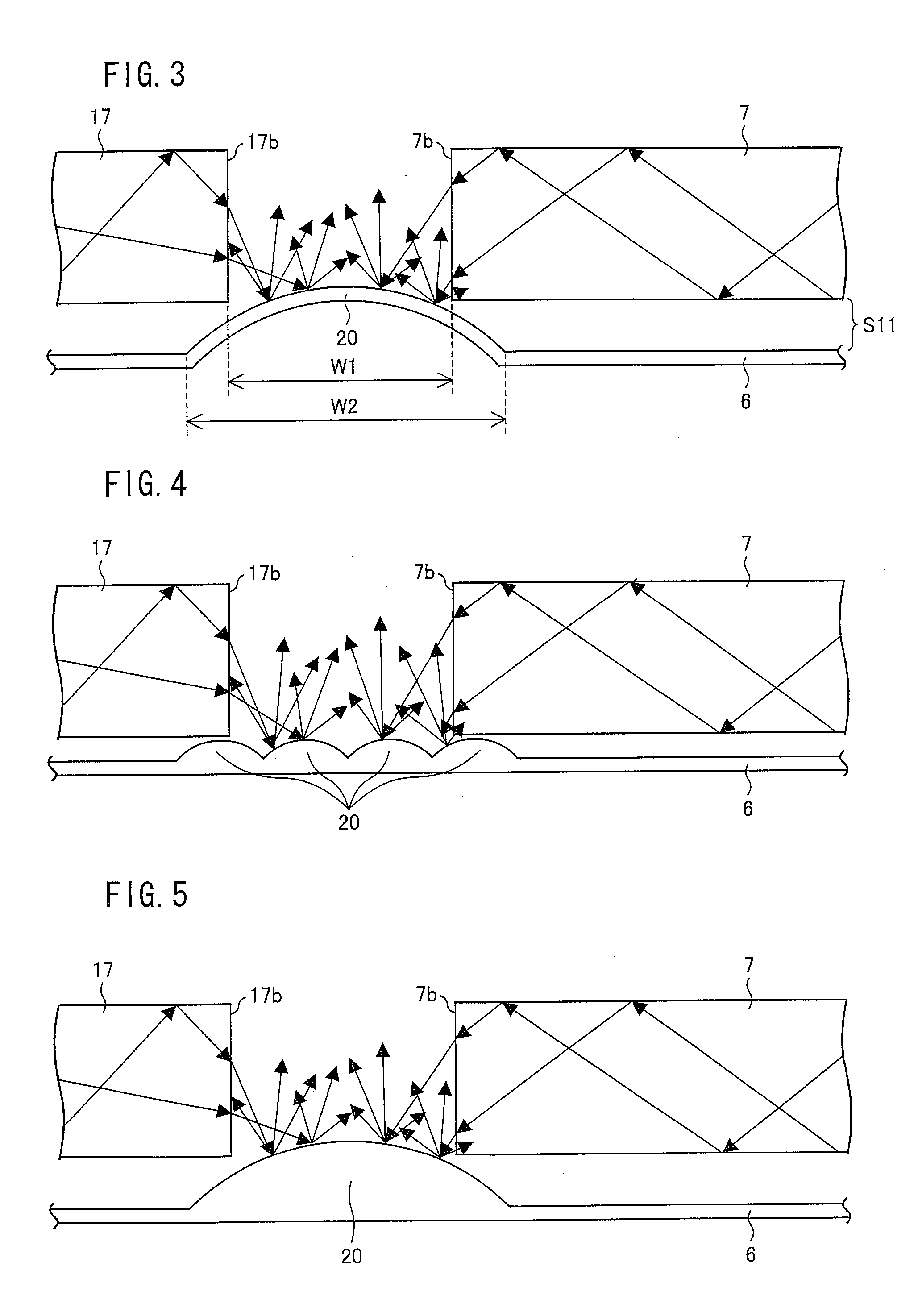

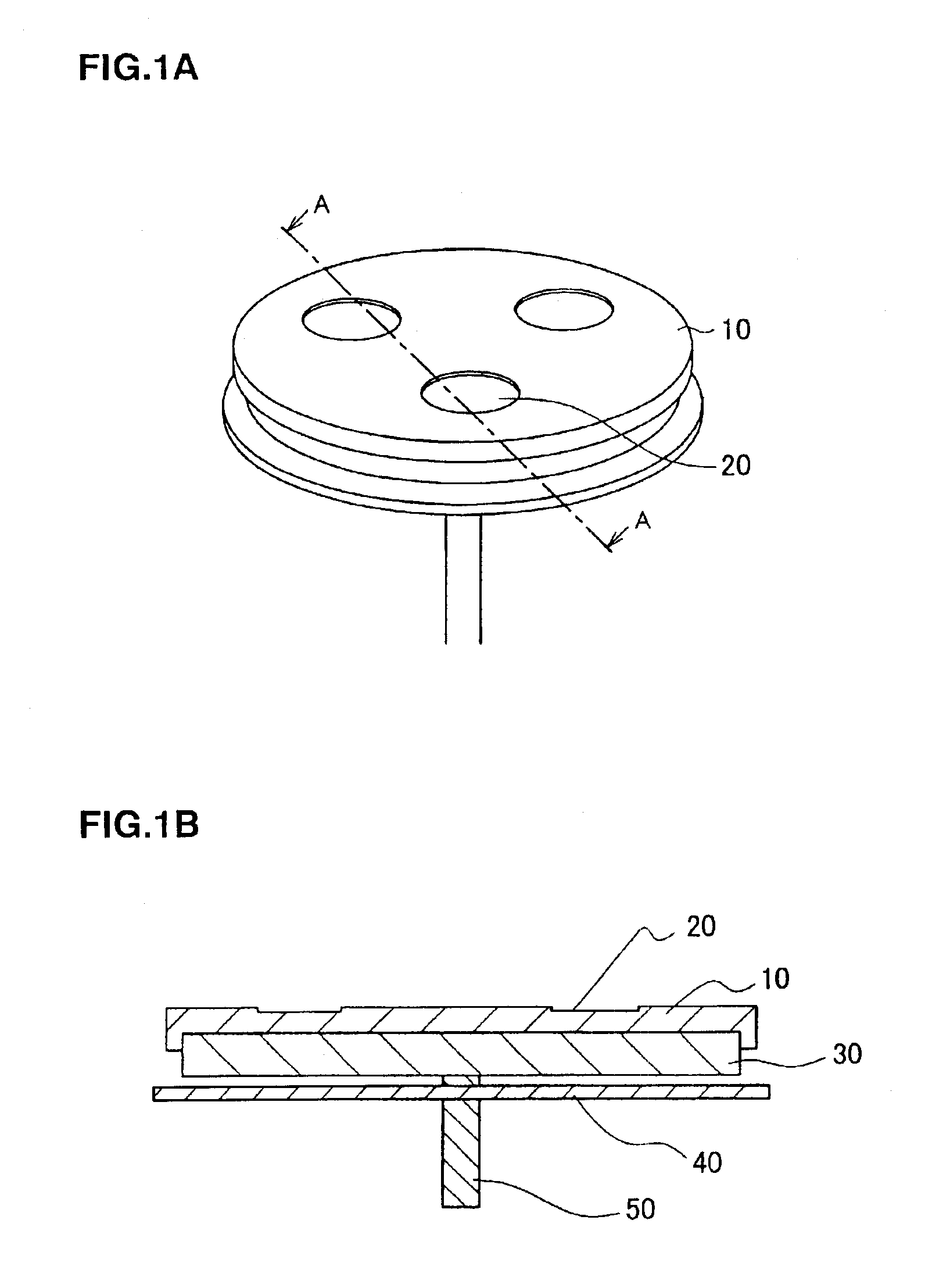

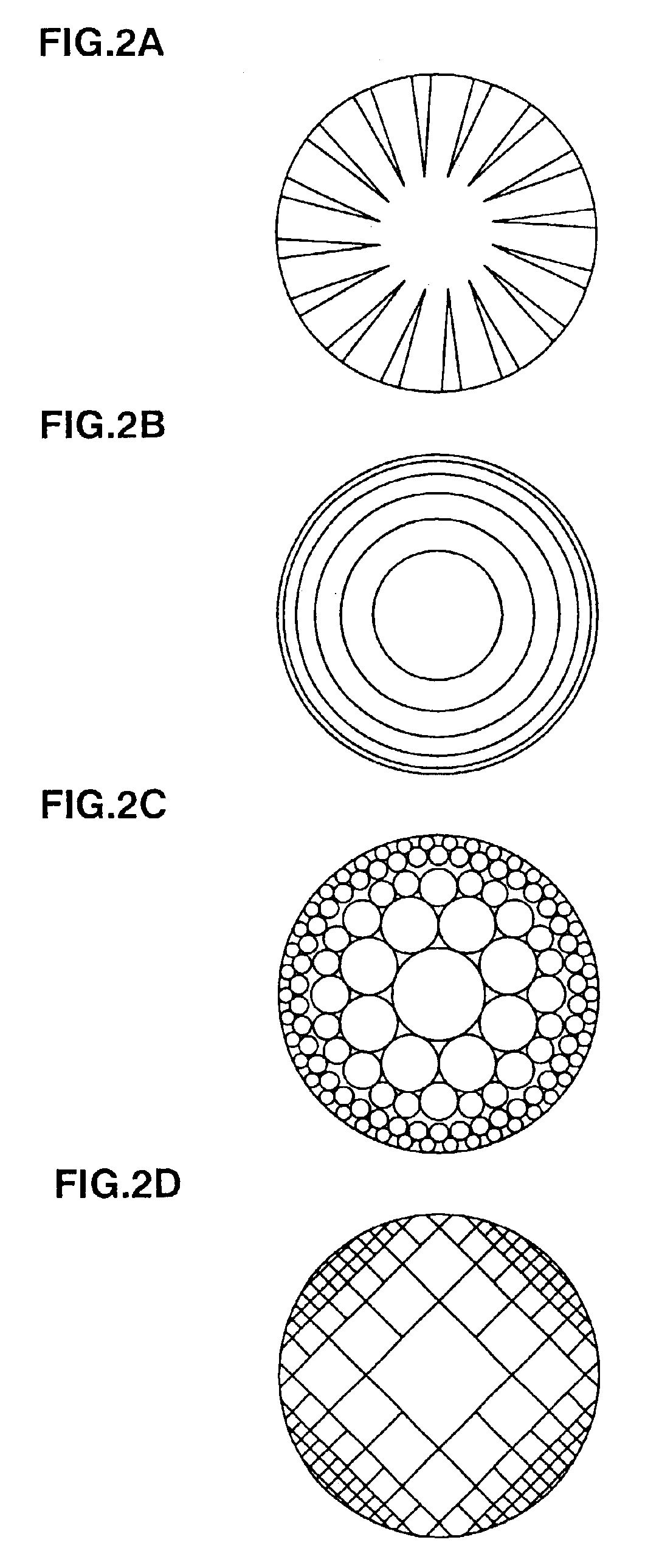

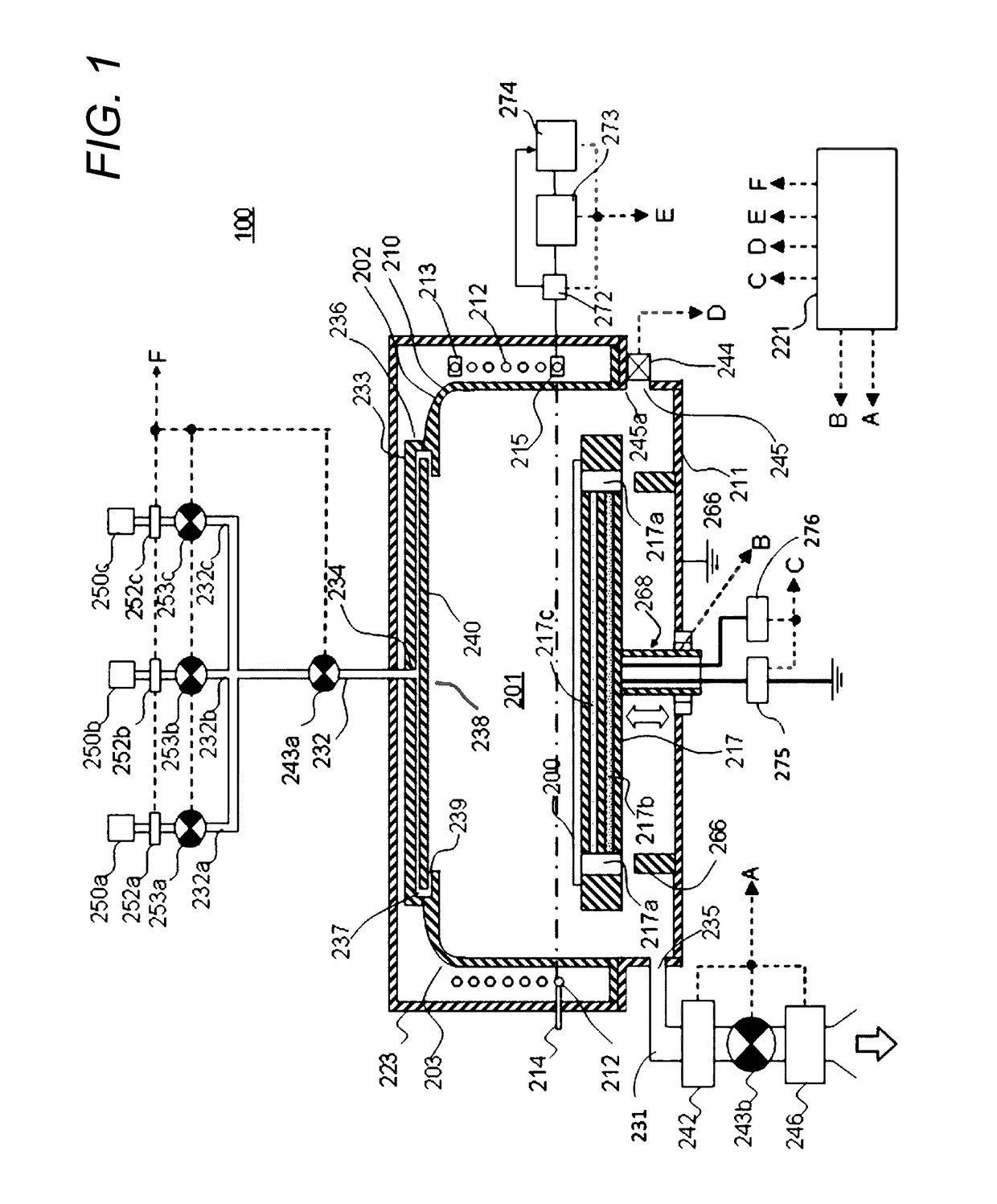

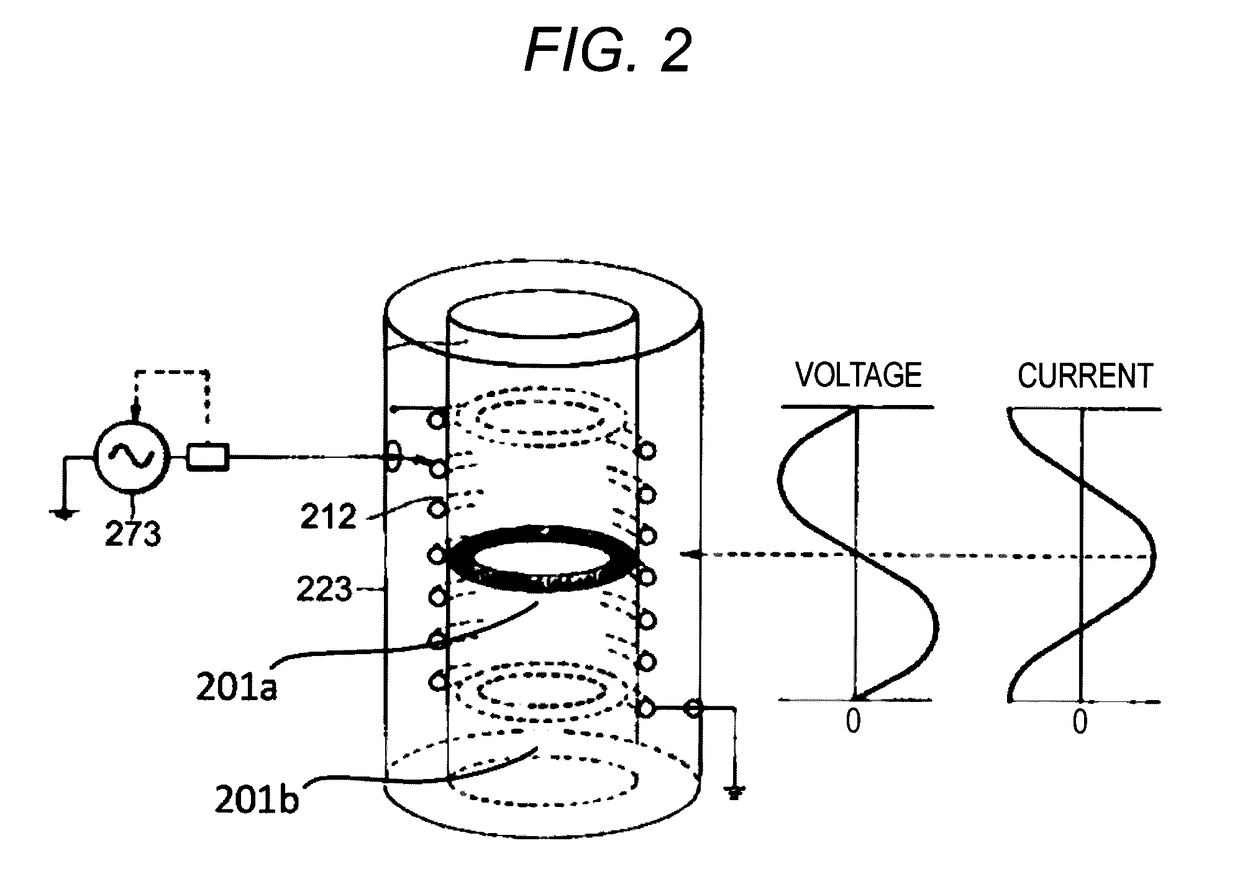

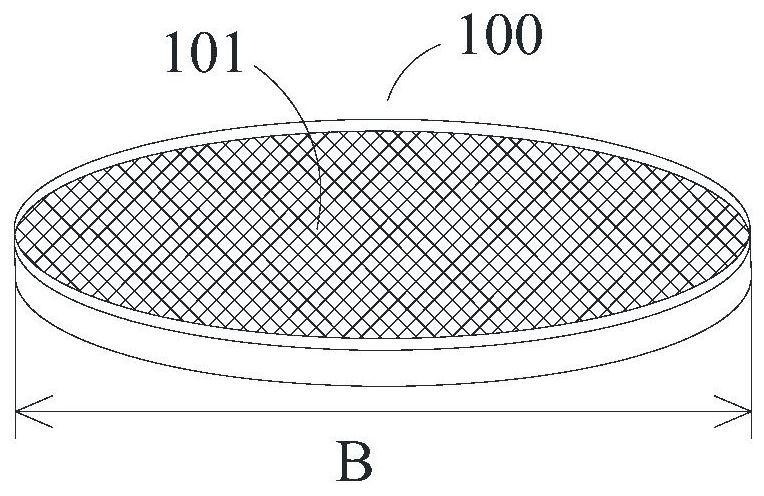

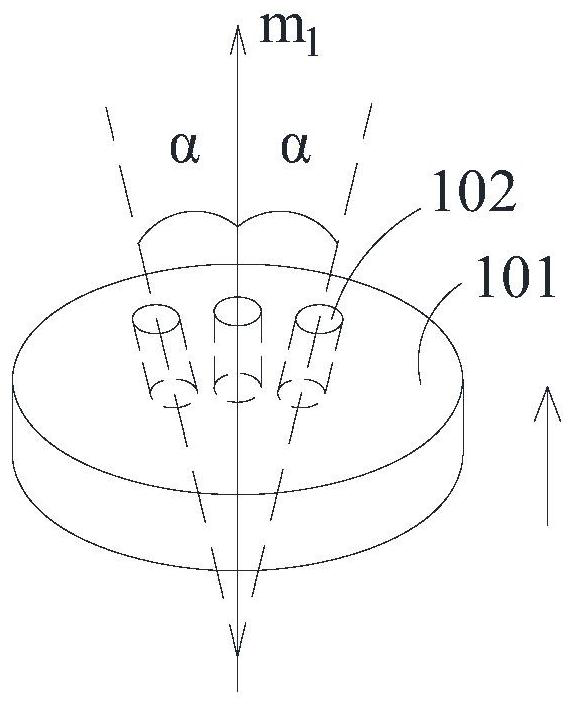

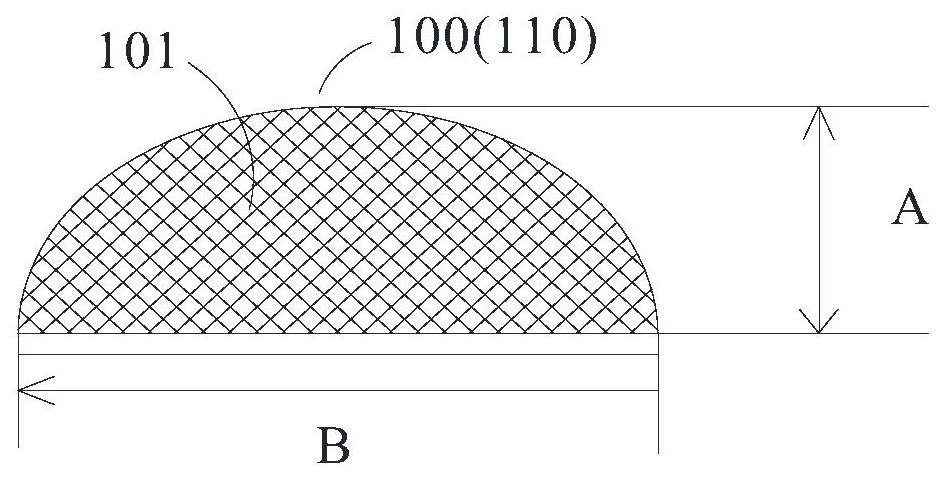

Semiconductor manufacturing method

ActiveUS6916373B2Excellent uniformityFew differencePolycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method for manufacturing a semiconductor using a wafer carrier, wherein the temperature of a wafer can be made uniform with few differences in surface composition distribution. A plurality of grooves are formed at the bottom of a wafer pocket of a wafer carrier, to make uniform the temperature of the wafer surface by diffusing heat. The grooves are deeper at the peripheral part of the wafer than at the central part, and groove density is higher at the peripheral part than at the central part. The groove patterns may include a plurality of wedge-shaped grooves widening from the central part toward the peripheral part, a plurality of circular grooves with narrowing interval therebetween from the central part toward the peripheral part, circular grooves with the diameter shortened from the central part toward the peripheral part, and square grooves with shortened sides from the central part toward the peripheral part.

Owner:NEOPHOTONICS SEMICON GK

Mother strain culture medium formula of wood-rotting edible fungi and preparation method of mother strain culture medium

InactiveCN104311257AExcellent growth densityExcellent uniformityFungiFertilizer mixturesBiotechnologyEdible mushroom

The invention discloses a mother strain culture medium formula of wood-rotting edible fungi and a preparation method of a mother strain culture medium. The formula comprises the following raw materials in parts by weight: 60-100 parts of peach twigs, 40-60 parts of wheat grains, 40-60 parts of soybean curd, 15-25 parts of multi-vitamin glucose powder, 15-25 parts of agar and 1000 parts of water. The invention further provides the preparation method of the mother strain culture medium and the preparation method comprises the following steps: selecting the raw materials, preparing, subpackaging, sealing, tying up, sterilizing and placing on a slant. After the mother strain culture medium is used for many years, regardless of purification, rejuvenation or subculture, the growth density of mycelia, uniformity and growth speed of hyphae of the wood-rotting edible fungi which are transferred to and cultured in the mother strain culture medium are better than those of edible fungi cultured in a traditional culture medium PDA (potato dextrose agar); and particularly, under the situation of using a silica gel plug, for a mother strain which is preserved at a low temperature in a refrigerator and then transferred after being preserved for 1-2 years, the survival rate can still be more than 95%, and the occurrence of phenomena of variety degeneration, variation and the like can be avoided.

Owner:TANGYIN EDIBLE FUNGUS RES INST

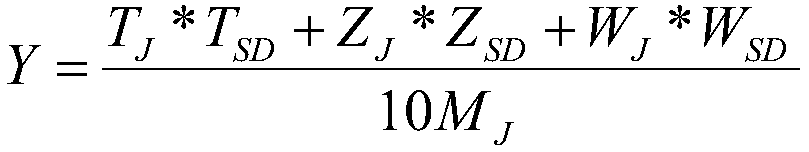

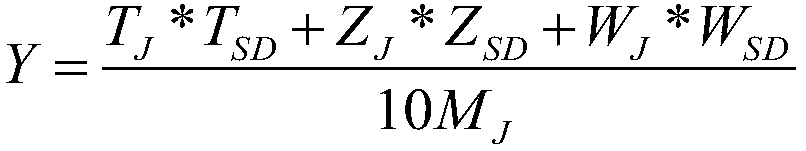

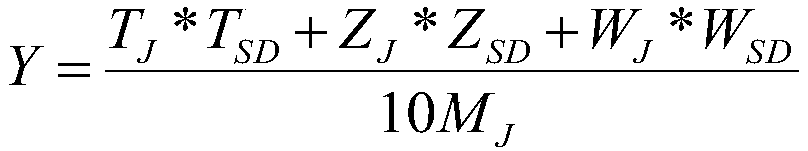

Method of rapidly predicting smoking uniformity of cigarette

ActiveCN109100263AExcellent suction uniformityExcellent uniformitySpecific gravity measurementDensity distributionEngineering

The invention discloses a method of rapidly predicting smoking uniformity of a cigarette. Smoking uniformity of a cigarette is predicted according to a cigarette density distribution characteristic Y,if Y is within (1.2,3.0), the cigarette of the specification is qualified in smoking uniformity, and the smaller the Y, the better the smoking uniformity of the cigarette. The method is easy and rapid to operate, can measure online, and delivers an accurate, reliable result.

Owner:CHINA TOBACCO YUNNAN IND

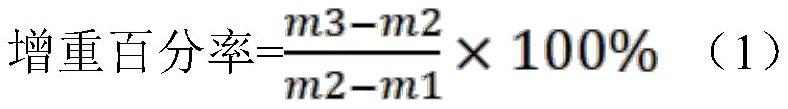

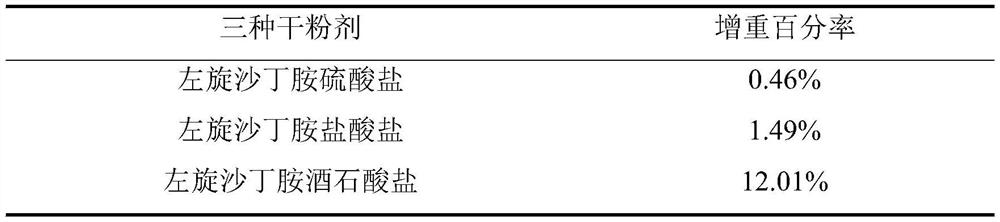

Method for delivering levosalbutamol to lung in inhaled dry powder

PendingCN112691088AExcellent efficiencyExcellent deliveryPowder deliveryOrganic active ingredientsBiochemistryBiomedical engineering

The invention discloses a preferable method for preparing a dry powder preparation and device by using levosalbutamol sulfate.

Owner:SUZHOU JUNNING NEW MEDICINE DEV CENT CO LTD

Photopolymerization type photosensitive lithographic printing plate precursor

ActiveUS20080081291A1Excellent uniformityImprove uniformityPhotosensitive materialsSemiconductor/solid-state device manufacturingPhotochemistryLight sensitive

A negative-working photopolymerization type photosensitive lithographic printing plate precursor for exposing with laser, includes: a hydrophilic support; at least one photopolymerizable photosensitive layer; and a protective layer, provided in this order, wherein the photopolymerizable photosensitive layer contains a sensitizing dye, a dye or pigment capable of absorbing light having a wavelength of a laser emission wavelength ±50 nm, which is different from the sensitizing dye; and a photopolymerization initiator.

Owner:FUJIFILM CORP

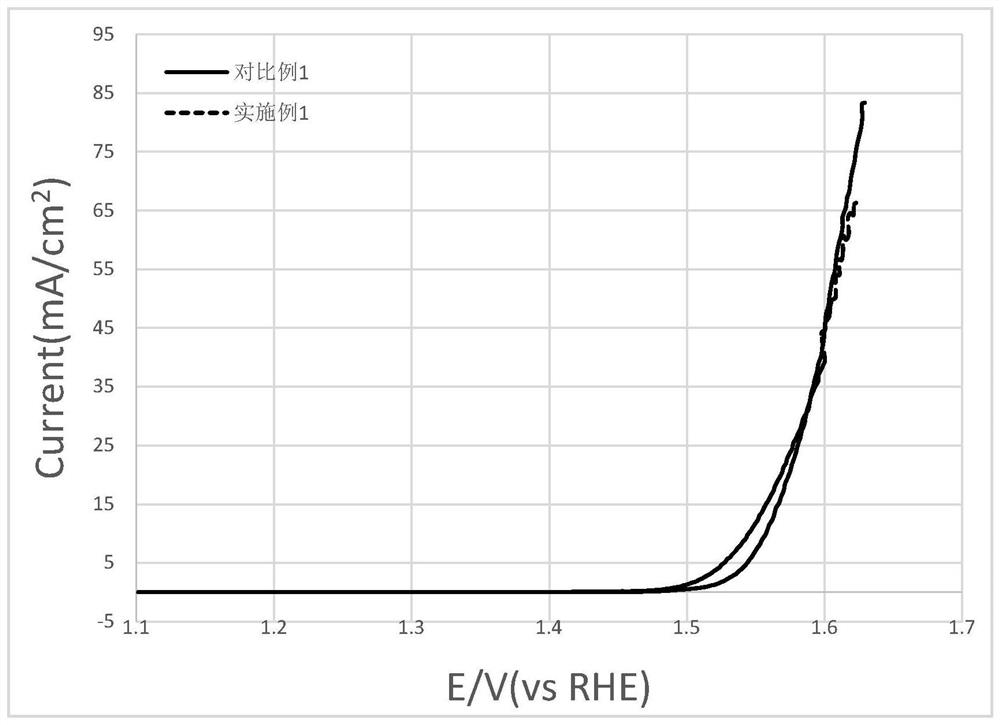

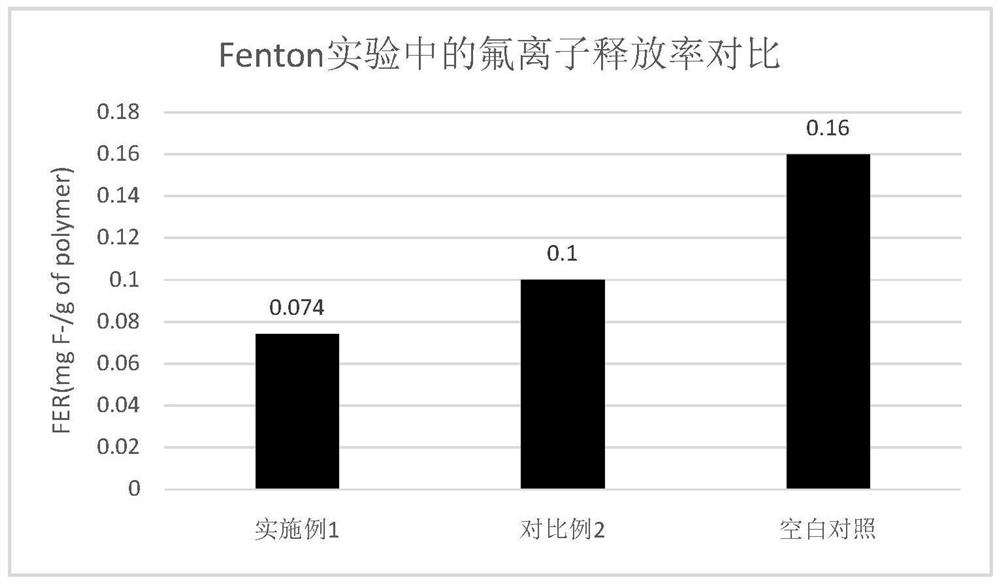

Mixed oxide multifunctional electro-catalytic material as well as preparation method and application thereof

ActiveCN113363512AImprove anti-reverse abilityImprove stabilityCell electrodesPtru catalystFuel cells

The invention provides a mixed oxide multifunctional electro-catalytic material, and belongs to the technical field of electro-catalytic materials and is composed of a metal oxide A with oxygen storage capacity and a metal oxide B with oxygen evolution reaction catalytic activity. Through cooperation of the metal oxide A with oxygen storage capacity and the metal oxide B with oxygen evolution reaction catalytic activity, the poisoning of carbon monoxide to the catalyst can be alleviated, damage of free radicals to a proton exchange membrane can be weakened, and the protection can be provided for a carbon carrier and a catalytic layer through electrolyzed water when an electric fuel cell stack is subjected to pole reversal; the stability of the catalytic material can also be improved, and a positive effect on improving the catalytic performance of the catalytic material is also achieved; the invention also provides a preparation method and application of the mixed oxide multifunctional electro-catalytic material.

Owner:SINOHYKEY TECH CO LTD

Method of manufacturing semiconductor device and non-transitory computer-readable recording medium

ActiveUS20170092647A1Excellent uniformitySuppress oxidation of surfaceTransistorElectric discharge tubesOxideSemiconductor

A semiconductor manufacturing method includes preparing a substrate having a metal film formed on a surface thereof; forming an oxide layer by oxidizing a surface of the metal film by plasma of a mixed gas of an oxygen-containing gas and a hydrogen-containing gas; and forming a thin film on the oxide layer by supplying at least an oxidizing gas to the substrate.

Owner:KOKUSA ELECTRIC CO LTD

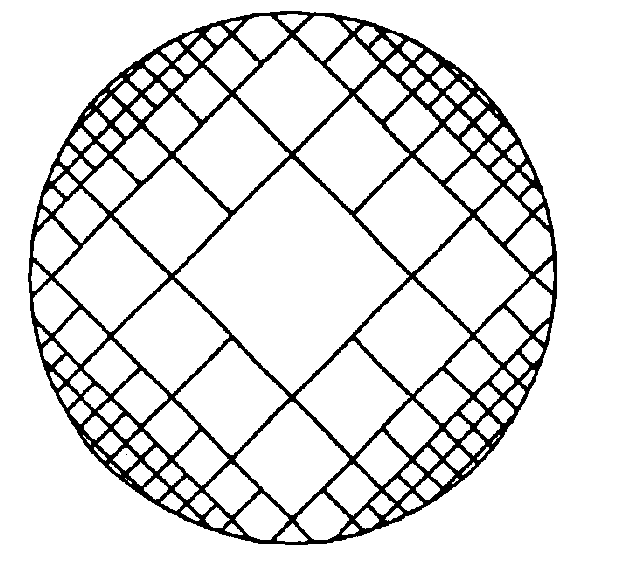

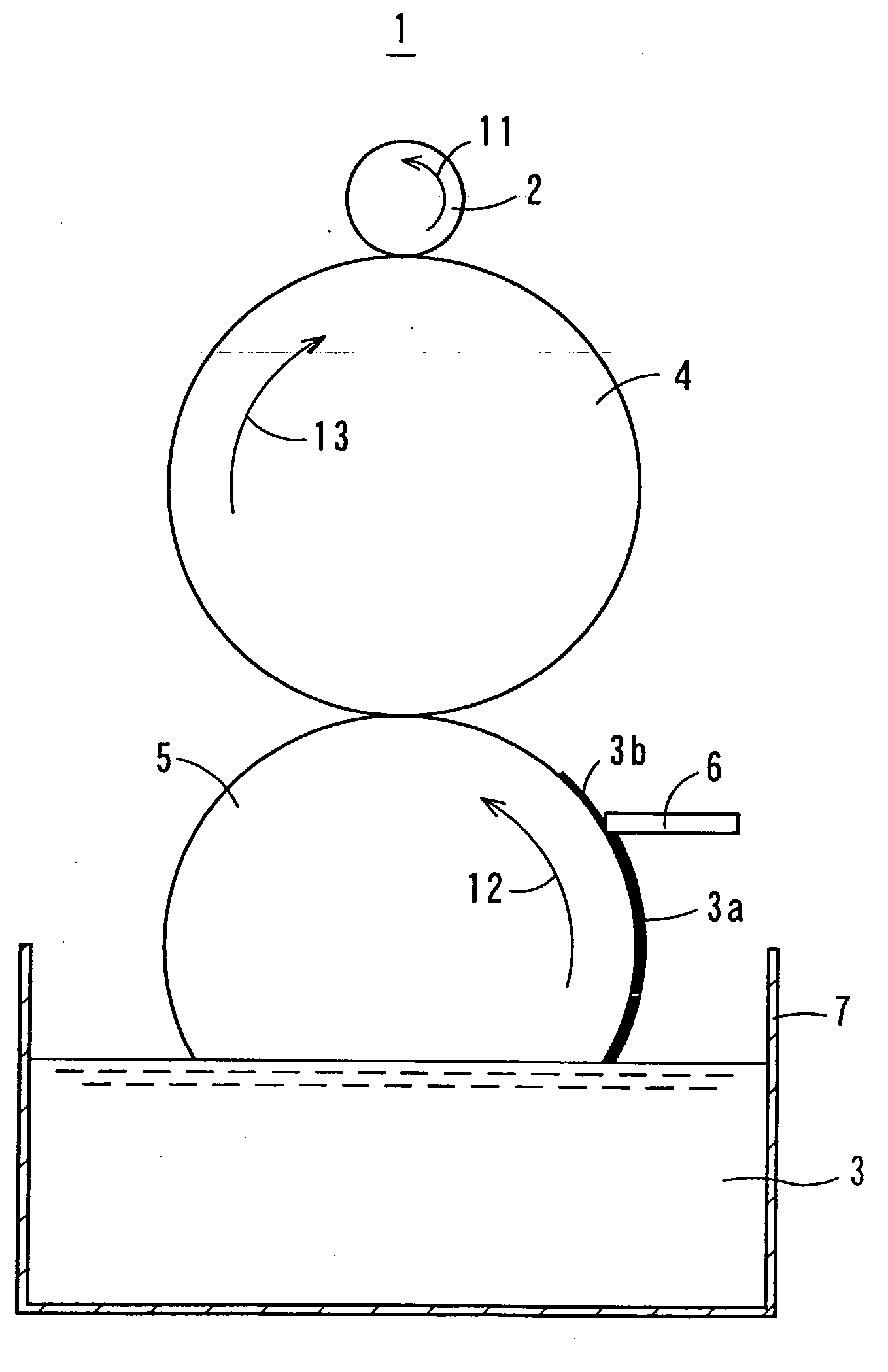

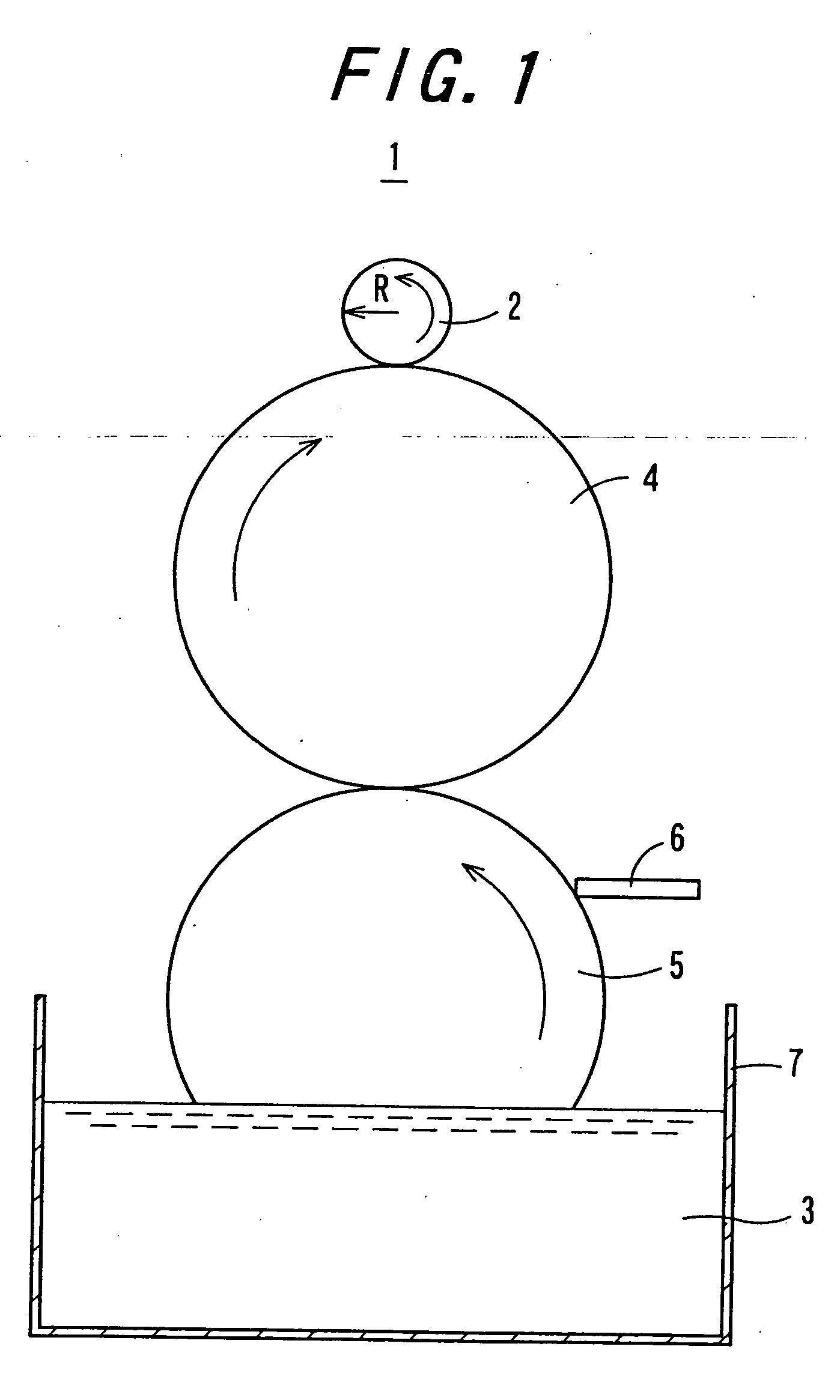

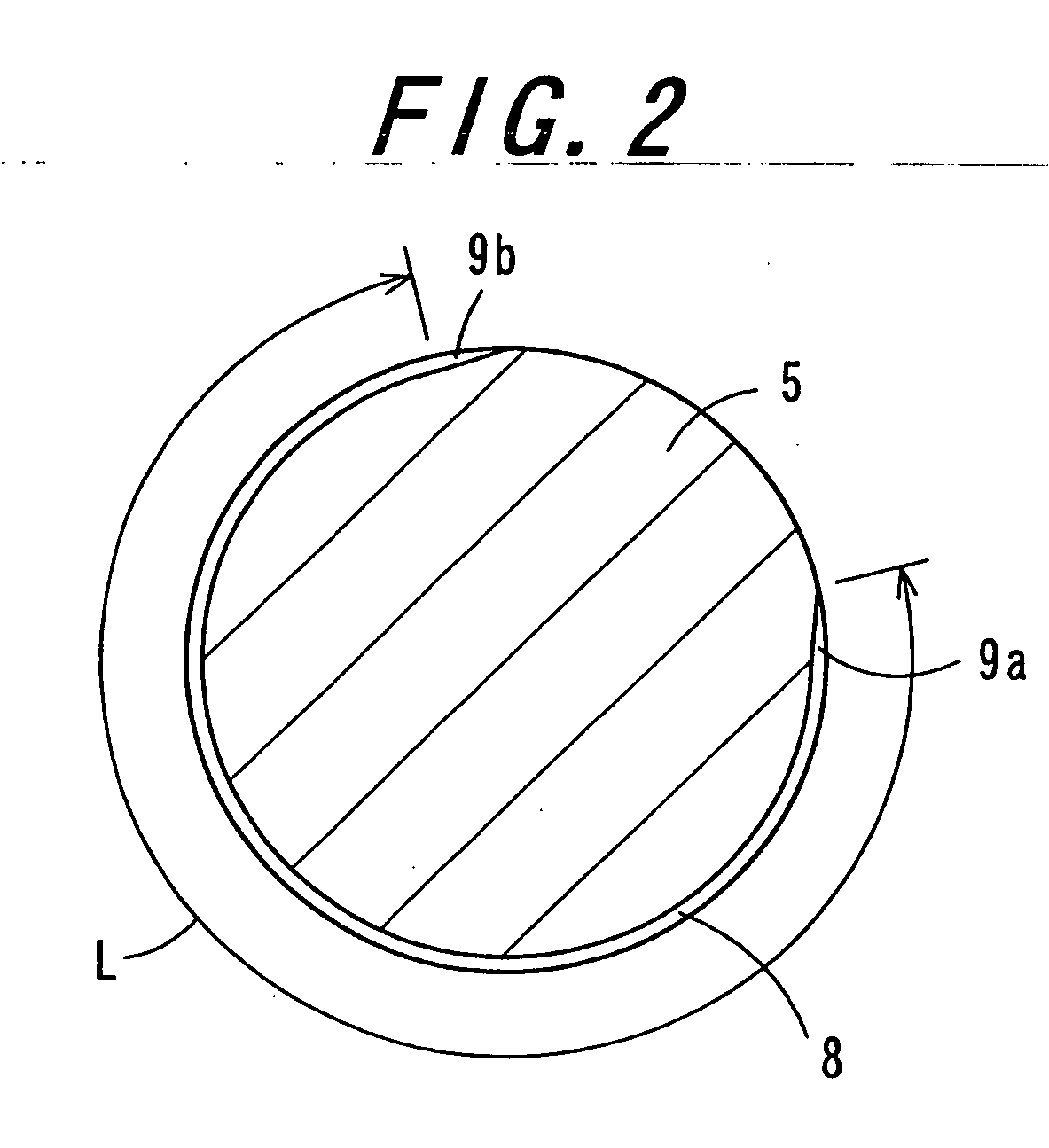

Apparatus and method for applying coating liquid to cylindrical substrate, and electrophotographic photoreceptor produced by that method and electrophotographic apparatus provided with the same

ActiveUS20070054206A1Excellent uniformityEfficiently carry outPretreated surfacesElectrographic process apparatusEngineeringCoating

A coating liquid to be used for coating has a loss tangent tan δ of from 1 to 10 at a frequency of 6.28 radians / sec. A coating liquid supplying roll has a fine concave portion in at least a part of the circumferential length thereof, and in the vicinities of the both circumferential ends of the fine concave portion, the fine concave portion 8 has concave depth decreasing portions formed in such a manner that the depth of a fine concave decreases. The fine concave portion is constructed in such a manner that the sum L (=L1+L2) of a circumferential length L1 of a portion in which the fine concaves are formed in substantially the same depth and a circumferential length L2 of one concave depth decreasing portion becomes an integral multiple (1 or more) of a circumference Lc of the cylindrical substrate.

Owner:SHARP KK

Flow dividing element and fluid distributor

PendingCN113007929ASimple structureEasy to processFluid circulation arrangementMixed flowEngineering

The invention relates to the technical field of fluid distribution, and discloses a flow dividing element which comprises an element body. A plurality of flow dividing through holes are distributed on the element body; the porosity of the element body is 60 percent to 78 percent; and the included angle between the axis of each flow dividing through hole and the normal of the plane where the flow dividing through hole is located is 0 degree to 15 degrees. By controlling the porosity of the flow dividing through holes and setting the forming directions of the flow dividing through holes, a better flow mixing effect can be achieved on fluid, and the fluid flowing through the flow dividing through holes can be evenly and stably mixed; the fluid distributor comprising the flow dividing element is uniform in liquid distribution, so that good uniformity and stability are achieved, and the uniformity and the stability of the fluid distributor can be even superior to the uniformity and the stability of an existing venturi distributor; and furthermore, a heat exchanger adopting the fluid distributor is uniform in flow distribution, and the energy efficiency is improved. Meanwhile, the flow dividing element provided by the embodiment of the invention is simple in structure, easy to machine and form and low in machining cost. The invention further discloses the fluid distributor.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Atomic layer deposition technology and method used for preparing iridium thin film

PendingCN111254412AEasy to store and transportExcellent uniformityChemical vapor deposition coatingThin membraneIridium

Owner:江苏迈纳德微纳技术有限公司

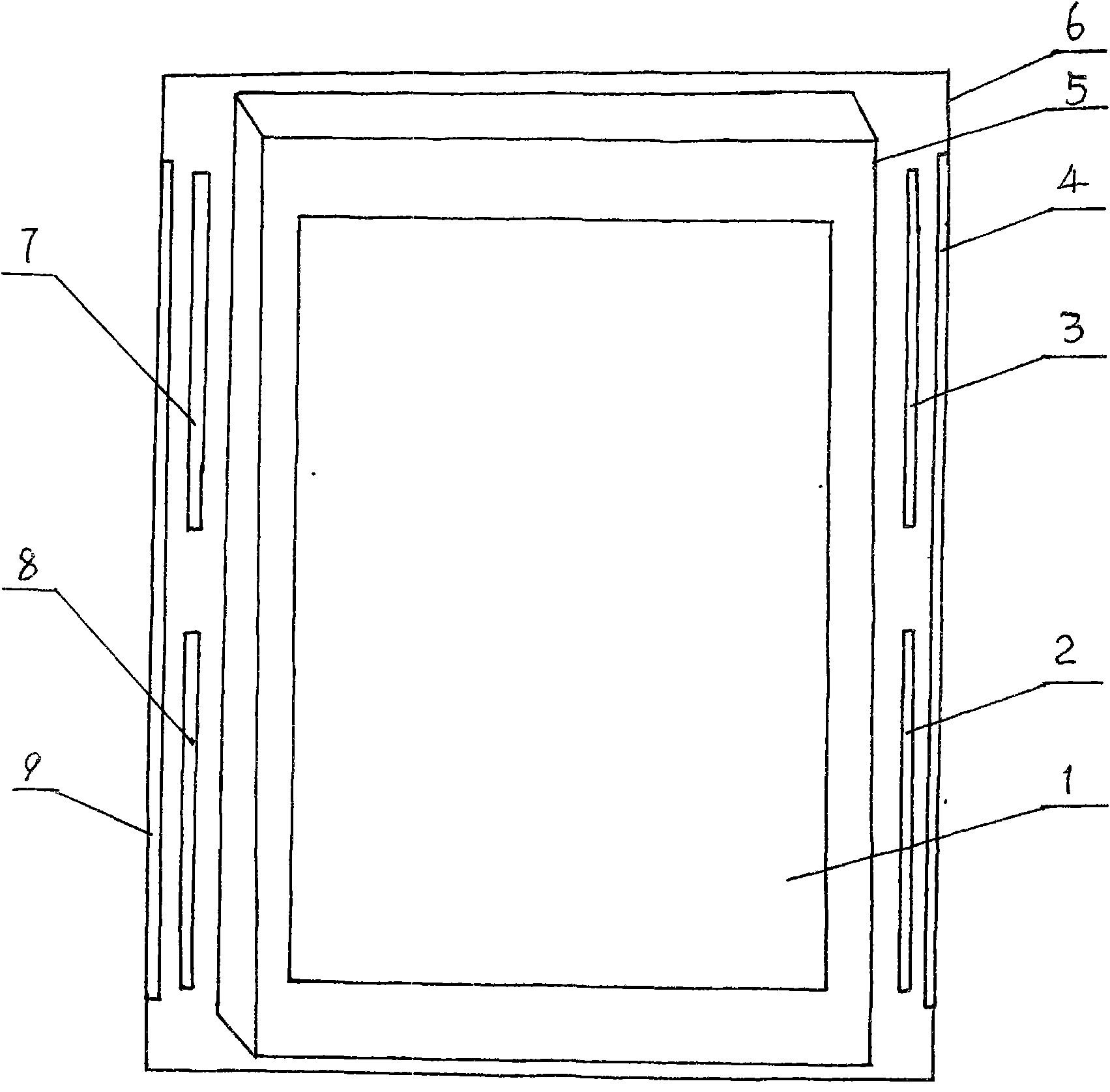

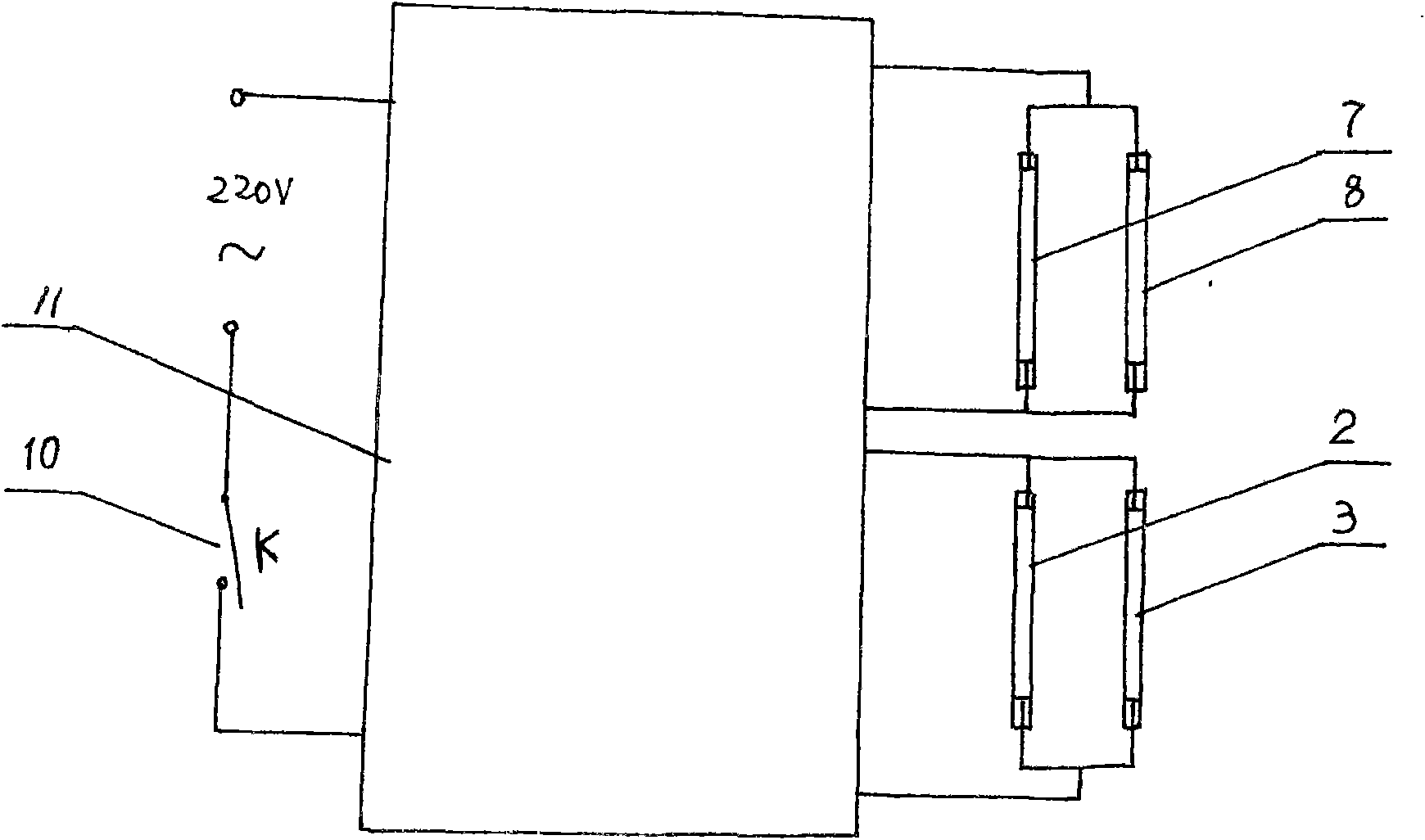

Liquid crystal logarithmic vision detector

InactiveCN101627895AExcellent UniformityAccurate vision test resultsEye diagnosticsNon-linear opticsNoise pollutionLighting system

The invention relates to a liquid crystal logarithmic vision detector. A sighting target panel (1) marked with a logarithmic visual chart is fixed to the front face of a liquid crystal plate (5); both sides of the liquid crystal plate (5) are respectively provided with two cold cathode strip lamps moving up and down, namely a first cold cathode strip lamp (7) arranged at top left, a second cold cathode strip lamp (8) arranged at bottom left, a third cold cathode strip lamp (3) arranged at upper right, and a fourth cold cathode strip lamp (2) arranged at bottom right; and outer sides of the cold cathode strip lamps of both sides are respectively provided with reflex housings, namely a first reflex housing (9) arranged at the left side and a second reflex housing (4) arranged at the right side. The liquid crystal logarithmic vision detector selects a liquid crystal backlight plate and a novel design of light path transmission and combines the technology of high-frequency contravariance so as to achieve the aims of stable light source of the visual chart, flicker-free luminance, good bright screen uniformity, noise pollution prevention and longer service life of an illuminating system.

Owner:孟繁华

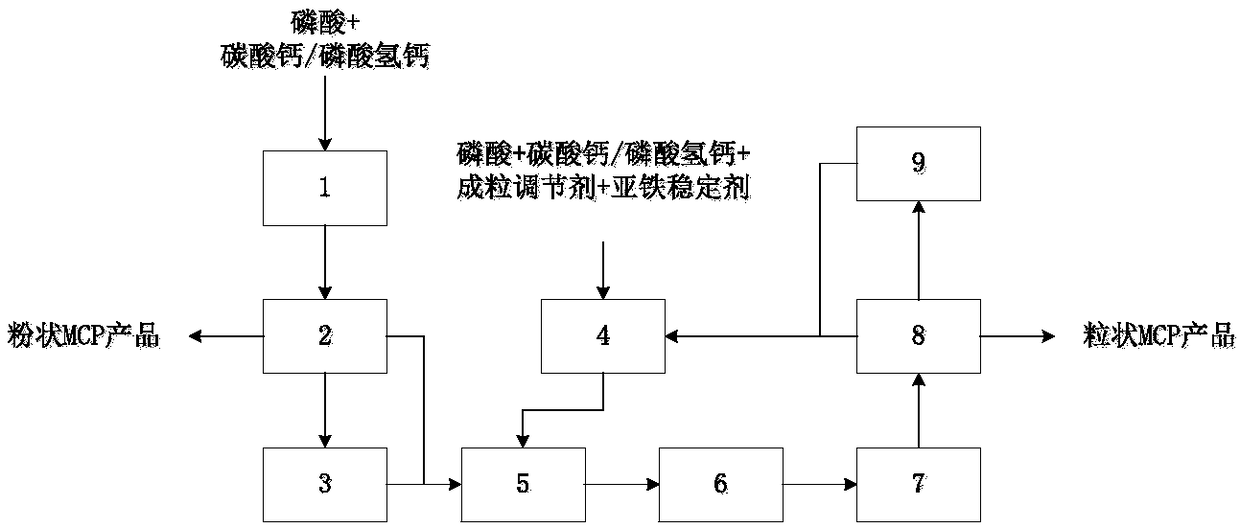

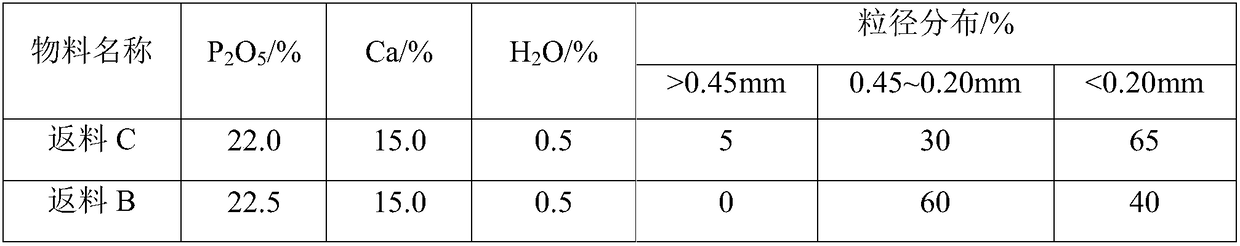

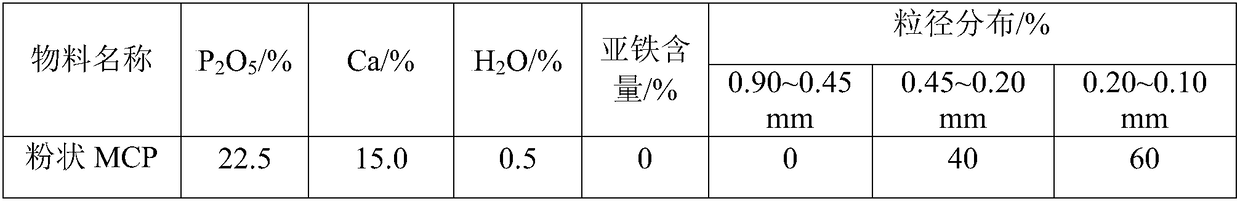

Method and device for processing monocalcium phosphate

ActiveCN108249415AReaction HomogenizationSolve the recycling problemAccessory food factorsPhosphorus compoundsPhosphoric acidMonocalcium phosphate

The invention discloses a method for processing monocalcium phosphate. The method comprises the following steps: enabling defluorinated phosphoric acid to react with calcium carbonate or calcium hydrophosphate slurry, drying through a spray drying tower to obtain a powdery MCP product, and taking a part of the powdery product and collected powder as backward materials for producing a granular MCPproduct; using defluorinated phosphoric acid to directly react with calcium carbonate or calcium hydrophosphate powder, adding the backward materials and a small amount of a granulating modifier and aferrous stabilizer, and carrying out drying and sieving after pelleting of a pelletizer so as to obtain the granular MCP product. The cooperative production of powdery and granular feed grade MCP isrealized, dust material is efficiently recycled, the intensity and uniformity of particles are improved, the pulverization of particles is avoided, and material sieving and crushing equipment blockageare effectively reduced. Moreover, the granular MCP product with the effect of supplementing phosphorus, calcium and iron is also obtained.

Owner:SINOCHEM YUNLONG

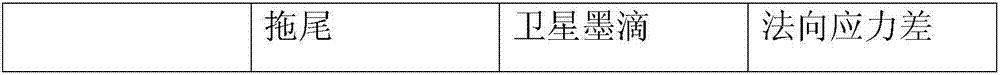

Ink-jet printing ink prepared from mixed solvents and preparation method of ink-jet printing ink

ActiveCN107880650AImprove inkjet statusExcellent uniformityInksZirconium oxychloride octahydratePrinting ink

The invention belongs to the field of printing electronics, and discloses ink-jet printing ink prepared from mixed solvents and a preparation method of the ink-jet printing ink. The ink-jet printing ink is composed of the good solvent of a polymer, the bad solvent of the polymer, the polymer and zirconium oxychloride octahydrate, wherein the polymer is polyacrylamide or polyvinyl alcohol. The preparation method comprises the steps that the polymer is added into the good solvent of the polymer and stirred, so that the polymer is sufficiently dissolved, then the bad solvent of the polymer is added for stirring and uniform mixing, then the zirconium oxychloride octahydrate is added for stirring and dissolving, and the ink-jet printing ink is obtained after ageing. In the ink-jet printing inkand the preparation method, a mixed solvent system containing the good solvent of the polymer and the bad solvent of the polymer is selected, the ink-jet state of the ink containing the polymer is improved to a certain extent, the functionality of the ink is little affected, and the obtained ink-jet printing ink has an excellent uniformity even in high-dosage application.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com