Spinel-coated layered positive electrode material and preparation method and application thereof

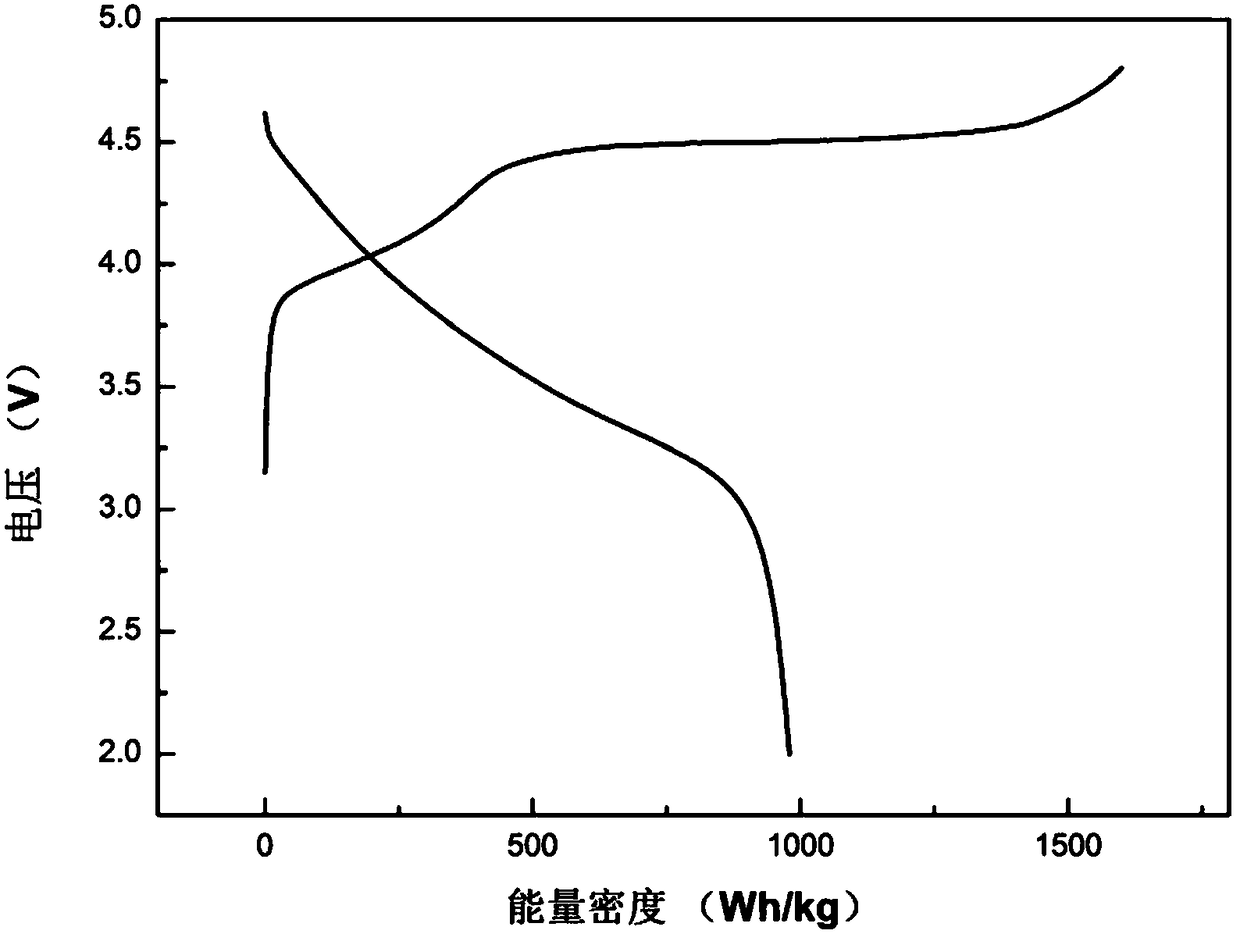

A technology of positive electrode materials and coating layers, which is applied in the field of modified layered positive electrode materials and lithium-ion batteries containing the materials, can solve the problems of low heat release, inability to exert the surface protection effect of spinel phase, and the continuity of the coating layer Poor and other problems, to achieve high safety, meet high energy density, long cycle high stability, and improve cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Lithium-rich layered material 0.5Li 2 MnO 3 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Preparation method of surface-coated spinel lithium manganate

[0052] Weigh nickel sulfate, cobalt sulfate, and manganese sulfate in a molar ratio of x:y:1-x-y=1 / 6:1 / 6:2 / 3, dissolve them in deionized water and mix evenly, and the concentration is 2mol / L, volume 2L is called A component, mix 2mol / L sodium carbonate solution with a volume of 2L and 30mL complexing agent ammonia water, called B component. Then A component and B component are simultaneously added in the reactor with the feed rate of 8.3mL / min, and are stirred with the speed of 800rpm, and the pH value of controlling this reaction is at 8.0, and the temperature of the solution in the reactor remains at 60 ℃ for about 4 hours, then wash the obtained precursor with pure water three times, filter it with suction, and then dry it for 3 days in a blast drying oven at a temperature of about 100 ℃ to obtain the precursor material, w...

Embodiment 2

[0059] Steps 1.1, 1.3, 2, 3, and 4 are exactly the same as in Example 1, except for 1.2: the added KMnO 4 Solution concentration is 0.02mol / L, at this moment product a and KMnO 4 The molar ratio of is about 3.2:1, hydrochloric acid is still added to adjust the pH value to 4, the mixture is stirred at room temperature for 40 min, washed and dried to obtain the intermediate product b.

Embodiment 3

[0061] Steps 1.1, 1.3, 2, 3, and 4 are exactly the same as in Example 1, except for 1.2: the added KMnO 4 Solution concentration is 0.06mol / L, at this moment product a and KMnO 4 The molar ratio of the mixture is about 1.05:1, hydrochloric acid is still added to adjust the pH value to 4, the mixture is stirred at room temperature for 40 minutes, washed and dried to obtain the intermediate product b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com