Mixed oxide multifunctional electro-catalytic material as well as preparation method and application thereof

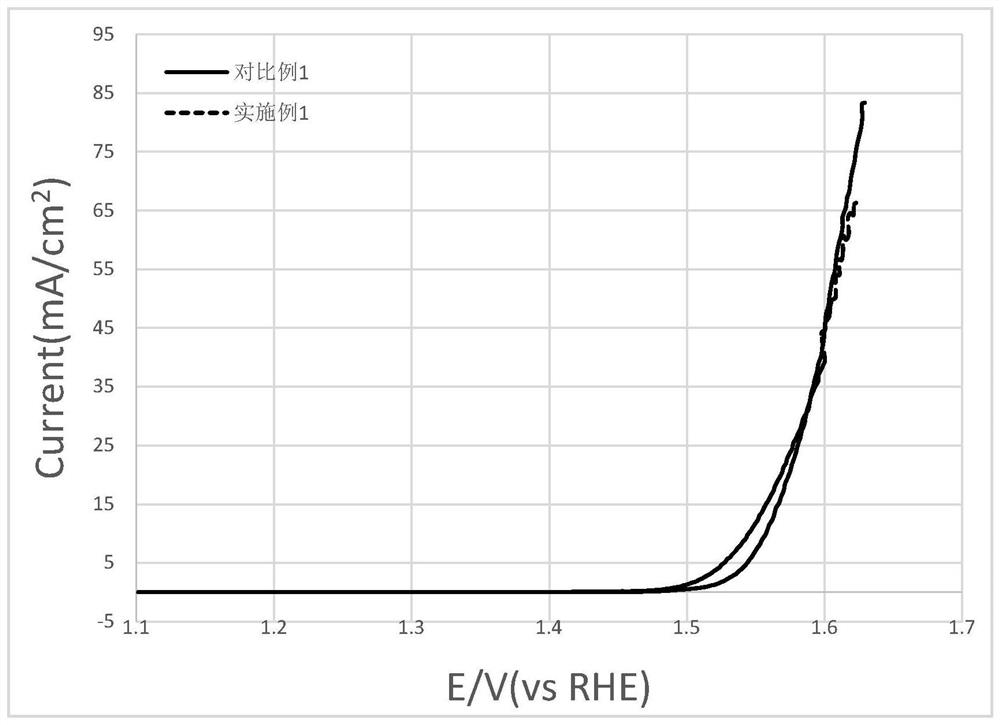

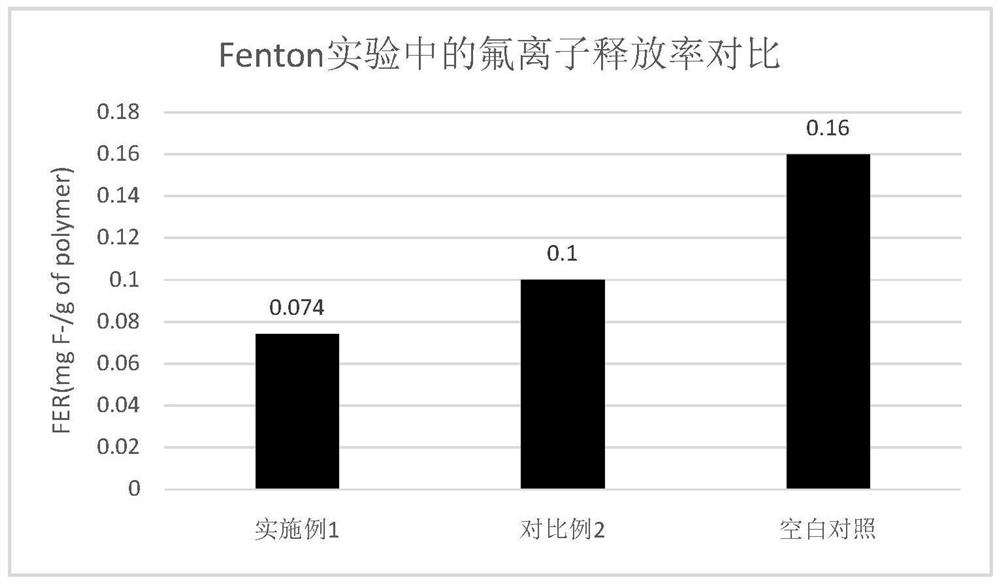

A technology of electrocatalytic materials and mixed oxides, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of insufficient stability of pure ceria, achieve improved anti-reversal ability, excellent dispersion and uniformity, The effect of improving the elimination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of mixed oxide multifunctional electrocatalytic material of the present invention:

[0045] 0.868g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 5mL of water, and a certain amount of 0.21g NaOH was dissolved in 35mL of water. The two solutions were mixed in a polytetrafluoroethylene reactor and stirred magnetically for 30 min. Then the reactor was placed in an oven and kept at 100 °C for 24 h. After the hydrothermal reaction, the product was washed and filtered three times with water and ethanol, and then dried in an oven at 60° C. for about 30 minutes. Then 30 mg of the product was weighed and added to 20 mL of 0.1 M NaOH solution, and the mixture was sonicated for at least 30 min to ensure uniform mixing. Then 0.0735g of H 2 IrCl 6 ·6H 2 O (35wt% Ir) precursor was added to the solution. The solution was transferred to a 40 mL polytetrafluoroethylene reactor, and then sonicated for about 10 min to form a homogeneous solution. The reaction kettle was placed...

Embodiment 2

[0047] 0.868g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 5mL of water, and a certain amount of 0.21g NaOH was dissolved in 35mL of water. The two solutions were mixed in a polytetrafluoroethylene reactor and stirred magnetically for 30 min. Then the reactor was placed in an oven and kept at 100 °C for 24 h. After the hydrothermal reaction, the product was washed and filtered three times with water and ethanol, and then dried in an oven at 60° C. for about 30 minutes. Then 30 mg of the product was weighed and added to 20 mL of 0.1 M NaOH solution, and the mixture was sonicated for at least 30 min to ensure uniform mixing. Then 0.0558g of H 2 IrCl 6 ·6H 2 O (35wt% Ir) precursor was added to the solution. The solution was transferred to a 40 mL polytetrafluoroethylene reactor, and then sonicated for about 10 min to form a homogeneous solution. The reaction kettle was placed in an oven and kept at 150°C for 720min. The precipitate was obtained by suction filtration and washing...

Embodiment 3

[0049] 0.868g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 5mL of water, and a certain amount of 0.21g NaOH was dissolved in 35mL of water. The two solutions were mixed in a polytetrafluoroethylene reactor and stirred magnetically for 30 min. Then the reactor was placed in an oven and kept at 100 °C for 24 h. After the hydrothermal reaction, the product was washed and filtered three times with water and ethanol, and then dried in an oven at 60° C. for about 30 minutes. Then 30 mg of the product was weighed and added to 20 mL of 0.1 M NaOH solution, and the mixture was sonicated for at least 30 min to ensure uniform mixing. Then 0.0882g of H 2 IrCl 6 ·6H 2 O (35wt% Ir) precursor was added to the solution. The solution was transferred to a 40 mL polytetrafluoroethylene reactor, and then sonicated for about 10 min to form a homogeneous solution. The reaction kettle was placed in an oven and kept at 150°C for 720min. The precipitate was obtained by suction filtration and washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com