High-performance low-cost fuel cell anti-reverse anode catalyst and preparation method thereof

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing anti-reversal ability, easy falling off or agglomeration of alloys, high cost, etc., to avoid falling off and agglomeration, and enhance the life of membrane electrodes , Improve the effect of anti-reverse ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A high-performance and low-cost fuel cell anti-counterpolar anode catalyst, the preparation method of which comprises the following steps:

[0029] 1) Add 2 mL of phytic acid, 0.03 g of chloroplatinic acid, 0.01 g of chloroiridic acid, 60 mg of melamine and 250 mg of silica nanospheres into 100 mL of deionized water in sequence, and stir for 1 hour to prepare a mixed solution;

[0030] 2) Put the mixed solution in a drying oven at 80°C and dry it into a solid, then put it into an argon-protected tube furnace, raise the temperature to 880°C at a rate of 5°C / min, and keep it for 2 hours;

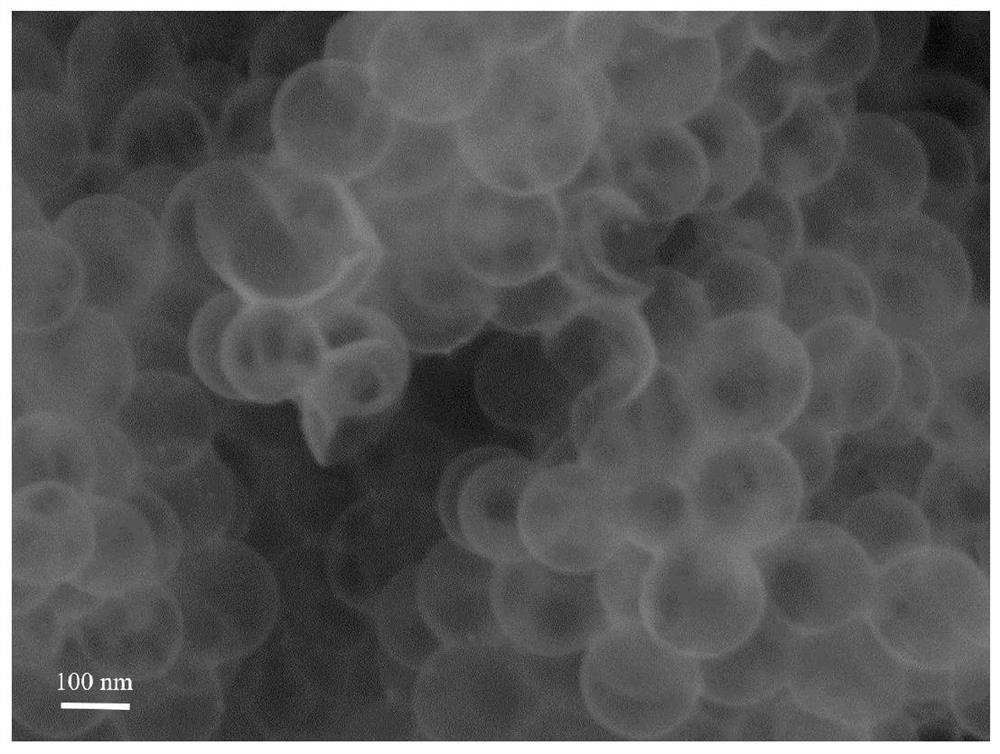

[0031] 3) The calcined product was etched with 10 mL of HF solution with a solute volume ratio of 1:10 for 12 hours to remove the silica nanospheres, and then washed by centrifugation and vacuum dried overnight to obtain the anode anti-reverse catalyst Pt 0.7 Ir 0.3 P 2 @NPC;

[0032] At the same time, this embodiment further uses Pt 0.7 Ir 0.3 P 2 Prepared as an anode catalyst la...

experiment example 1

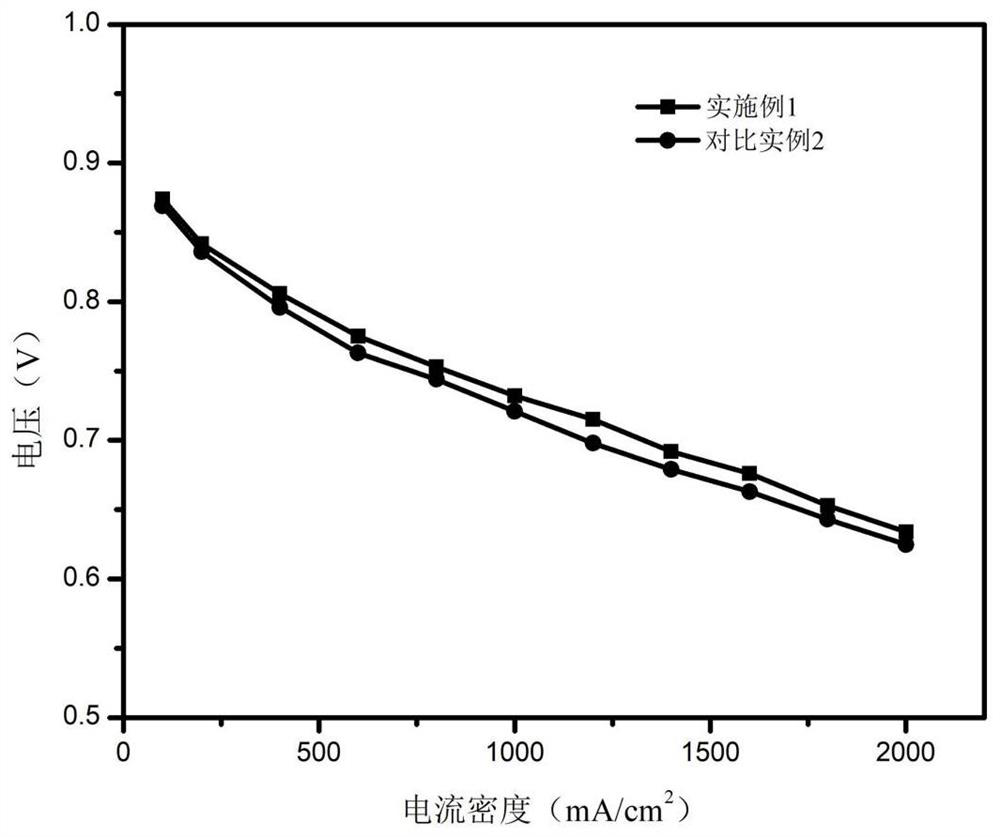

[0048] Membrane electrode performance test:

[0049] The prepared membrane electrode (Example 1, Comparative Example 2) was subjected to an electrochemical performance test: the operating temperature of the battery was 80°C, the gas humidity was 100%, the stoichiometric ratio of cathode and anode was 2 and 1.8 respectively, and the back pressure was 120kPa; figure 2 For the Pt prepared in Example 1 0.7 Ir 0.3 P 2 The polarization curves of @NPC and commercial Pt / C, from figure 2 It can be seen that the prepared anode anti-reverse catalyst is at 1800.12mA / cm 2 It can reach 0.653V, and the catalytic performance is better than that of commercial Pt / C.

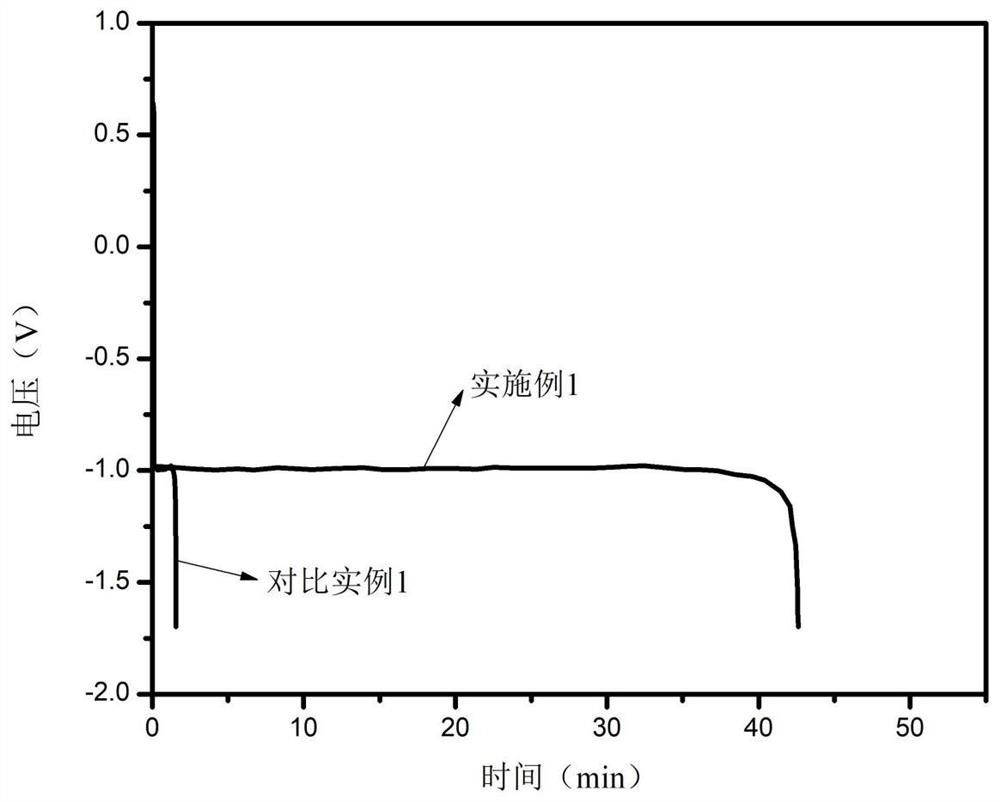

[0050] Anti-reverse polarity performance test:

[0051] The prepared membrane electrode (Example 1, Comparative Example 1) was tested for anti-reversal performance: the operating temperature of the battery was 80°C, and the gas flow rate of the anode and cathode was 0.5L / min; image 3 Pt prepared for the present invention ...

Embodiment 2

[0053] A high-performance and low-cost fuel cell anti-counterpolar anode catalyst, the preparation method of which comprises the following steps:

[0054] 1) Add 2 mL of phytic acid, 0.04 g of platinum chloride, 0.01 g of ruthenium chloride, 60 mg of melamine and 250 mg of silica nanospheres into 100 mL of deionized water in sequence, and stir for 1 hour to obtain a uniform mixed solution;

[0055] 2) Put the mixed solution in a drying oven at 80°C and dry it into a solid, then put it into an argon-protected tube furnace, raise the temperature to 900°C at a rate of 5°C / min, and keep it for 2 hours;

[0056] 3) The calcined product was etched with 10 mL of HF solution with a solute volume ratio of 1:10 for 8 hours to remove the silica nanospheres, and then washed by centrifugation and vacuum dried overnight to obtain the anode anti-reverse catalyst Pt 0.8 Ru 0.2 P 2 @NPC;

[0057] At the same time, this embodiment further uses Pt 0.8 Ru 0.2 P 2 Prepared as an anode cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com