Patents

Literature

34results about How to "Realize enrichment recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

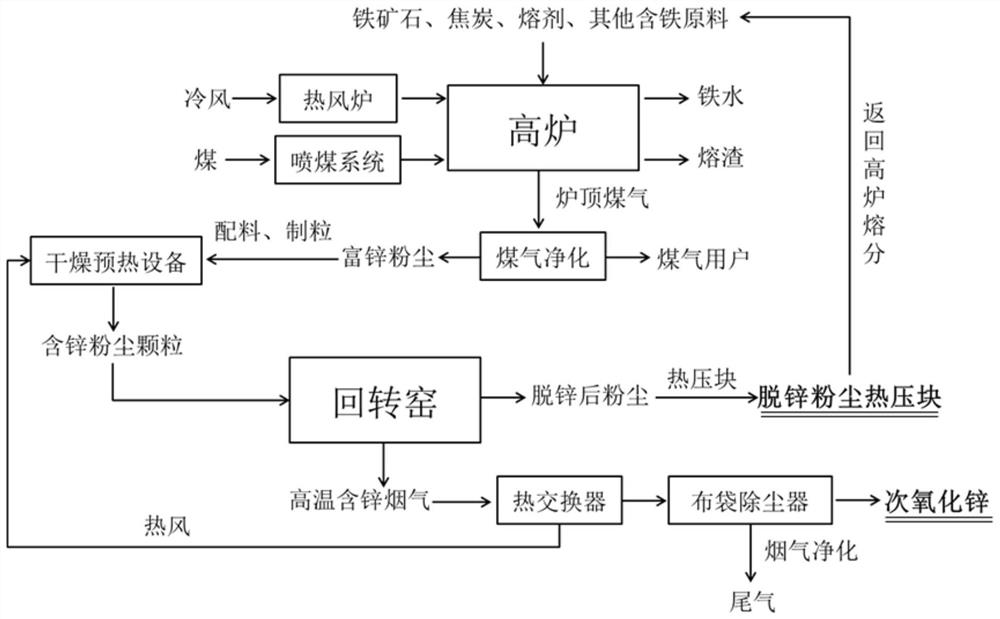

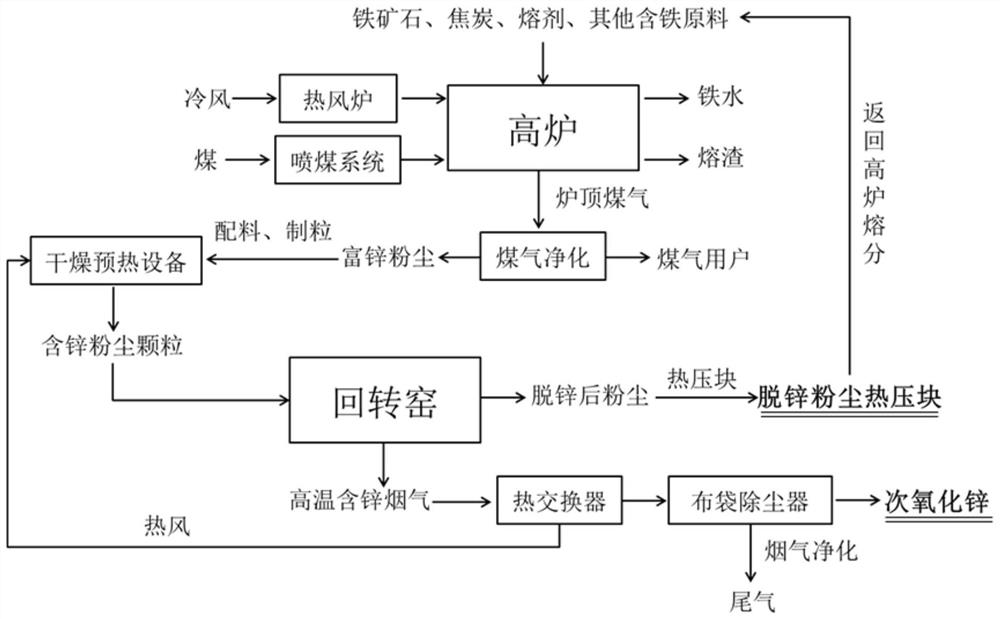

Method for treating dust containing zinc and iron through cooperation of blast furnace and rotary kiln

ActiveCN112111656AEfficient use ofEfficient recyclingBlast furnace detailsRecycling and recovery technologiesFlue gasHot blast

The invention provides a method for treating dust containing zinc and iron through cooperation of a blast furnace and a rotary kiln. According to the method, the rotary kiln is used and cooperates with the blast furnace; and the dust containing zinc and iron is treated by an open-loop circulation mode. The rotary kiln is used for taking the dust containing zinc and iron of the blast furnace as a main raw material and preparing zinc-containing dust particles through processes of mixing, granulating, drying and preheating; hot air used in the drying process is from hot air obtained by high-temperature flue gas of the rotary kiln through heat exchange equipment; then the dried zinc-containing dust particles are added into the rotary kiln and are reduced and roasted at high temperature; the reduced metal zinc is volatilized at the temperature about 907 DEG C and is changed into zinc vapor; the zinc vapor leaves the rotary kiln along with the flue gas; zinc oxide is formed in a recycling system, so that zinc can be enriched and recycled; high-temperature dust particles after dezincification are instantly changed into directly reduced iron; then the directly reduced iron is prepared intodezincification hot-pressing blocks through a hot block pressing process; the dezincification hot-pressing blocks are returned to an iron recycling system and then enter the blast furnace for high-temperature melting treatment; and the metal iron can be fully recycled.

Owner:UNIV OF SCI & TECH BEIJING

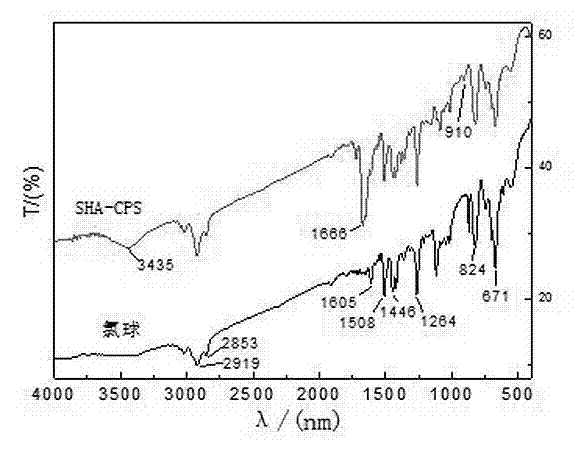

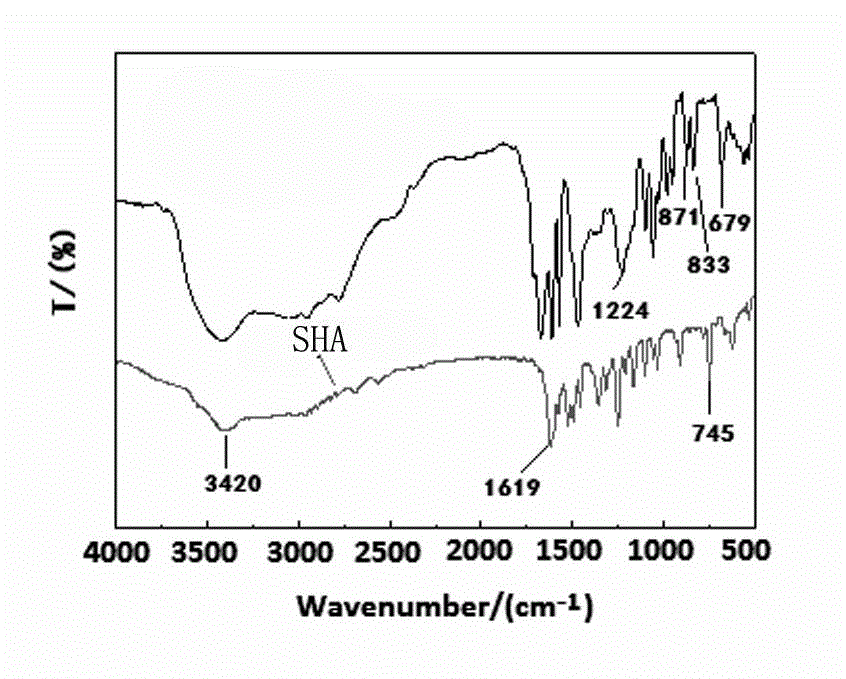

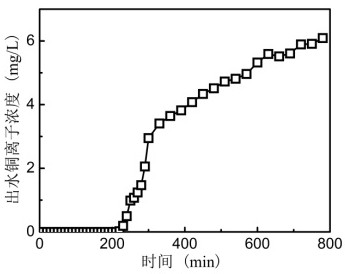

Salicyhydroximic acid type chelate resin and preparation method thereof

InactiveCN103087231ASimple preparation processThe preparation process is simple and controllableOther chemical processesWater contaminantsMicrosphereChelating resin

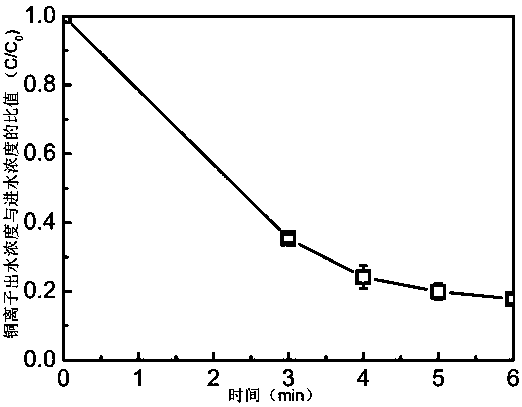

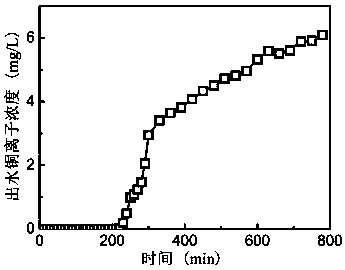

The invention belongs to the field of chelate resin materials and provides a salicyhydroximic acid type chelate resin and a preparation method thereof for solving the problem that the existing hydroximic acid can not be repeatedly used in sewage treatment. The preparation method comprises that a ligand salicyhydroximic acid is bonded to the surface of a chloromethylated polystyrene microsphere to obtain the salicyhydroximic acid type chelate resin, and bonding quantity of the ligand salicyhydroximic acid is 0.38-0.43g / g. The salicyhydroximic acid type chelate resin has strong coordination complexing power to metal ions, can realize enrichment recycling of multiple precious metal ions, especially has excellent adsorbability and selectivity to heavy metal ions such as copper, nickel, lead, iron, zinc and chromium and can be effectively applied to treatment of sewage in the industries such as electroplating, electronics and heavy metals and extraction of rare earth minerals; besides, the bonding quantity of salicyhydroximic acid is high, a synthetic process is simple, conditions are mild, time is short, and synthesis is easy to control; and the chelate resin provided by the invention is convenient to use and easy to separate and recycle and can be recycled for 10 times while the adsorbability is basically constant.

Owner:ZHONGBEI UNIV

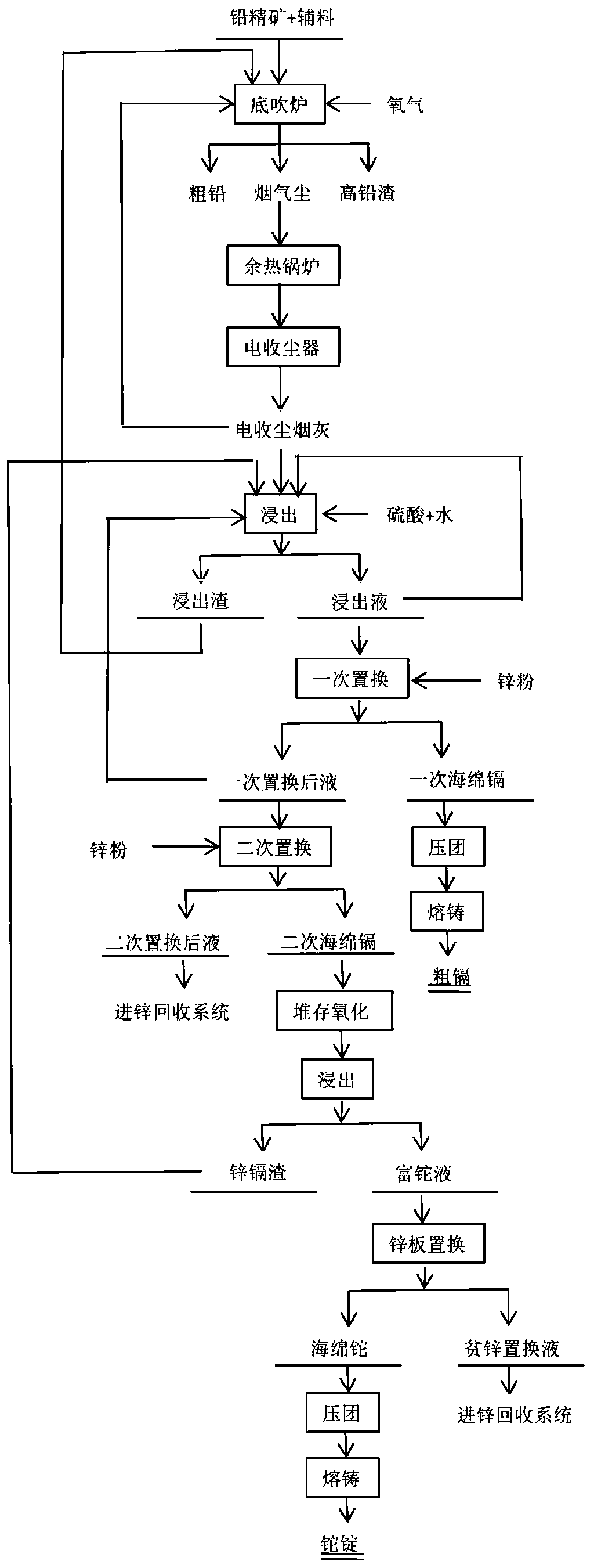

Method for enriching and recovering thallium from lead smelting system

InactiveCN111088433ALow costGood for recycling and recyclingProcess efficiency improvementSodium carbonateOre concentrate

The invention discloses a method for enriching and recovering thallium from a lead smelting system. The method comprises the following steps of: collecting thallium-cadmium soot from a lead concentrate smelting system; leaching the obtained thallium-cadmium soot in water or dilute sulfuric acid, and collecting a leaching solution; carrying out primary replacement and secondary replacement on the collected leaching solution by using a metal monomer; carrying out standing oxidation on thallium-containing sponge cadmium obtained after secondary replacement, leaching by using a sodium carbonate solution after oxidation, and obtaining a thallium-rich leaching solution after leaching; and adjusting the pH value of the obtained thallium-rich leaching solution, and then carrying out replacement toobtain sponge thallium, thereby completing the enrichment of thallium. According to the method for enriching and recovering thallium from the lead smelting system, thallium in the lead concentrate smelting system is well enriched and recovered by using a simple and easy-to-operate method, no toxic or harmful reagent is used in the whole treatment process, the used reagent is non-toxic and low incost, the materials in the whole treatment process are well recycled and recovered, no waste is generated, and the production cost is further reduced. Moreover, thallium is well enriched and recovered. The method has outstanding social and economic benefits.

Owner:HENAN YUGUANG GOLD & LEAD

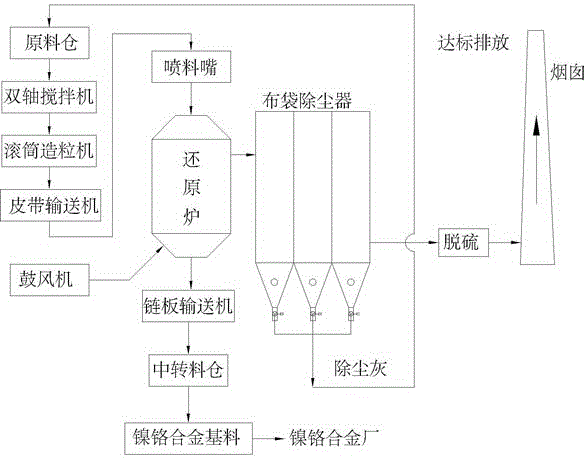

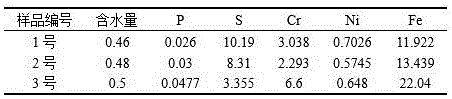

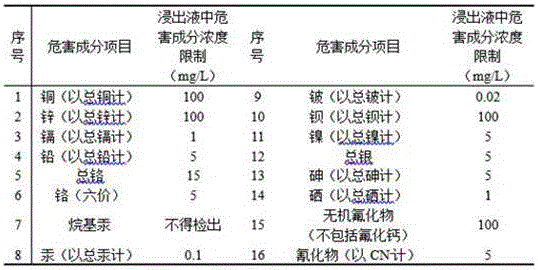

Method for reduction and detoxification of stainless steel acid pickling sludge

InactiveCN105734297AAchieving detoxificationRealize enrichment recoveryProcess efficiency improvementSocial benefitsAdhesive

The invention provides a method for reduction and detoxification of stainless steel acid pickling sludge, and belongs to the field of metallurgy and environmental protection. The method comprises the following steps that 1, after the stainless steel acid pickling sludge is produced, water can be reduced to 50% after stockpiling and natural drying; 2, the sludge, coke and an adhesive are added into a vertical curing furnace after batching, mixing and pelleting, meanwhile, a proper amount of air is blown in for high-temperature reducing roasting curing, reduction is achieved through the water reduced by 50%, Cr6+ is reduced, decomposed and converted into Cr3+, thorough detoxification is carried out, and a nichrome basic material is obtained and conveyed to a smelting plant for producing nichrome; and 3, smoke generated in the roasting process is subjected to bag dedusting and then is discharged after wet desulphurization and defluorination are carried out to meet the standard, and a small quantity of desulphurization and defluorination byproducts are used as common solid waste to be used as backfill materials of building roadbeds and the like or abandoned. Reduction, detoxification and efficient resource recycling of the stainless steel acid pickling sludge are achieved, and remarkable economic, environmental and social benefits are achieved.

Owner:SICHUAN UNIV

Method for copper slag tailings pulp smoke desulfurization cooperating with copper resource efficient recovery

InactiveCN110423892ASimple processLow costProcess efficiency improvementPrecipitationFlue-gas desulfurization

The invention discloses a method for copper slag tailings pulp smoke desulfurization cooperating with copper resource efficient recovery. Copper slag tailings are adopted as a smoke desulfurizer. Firstly, the slag tailings and water are added into a pulp mixing tank according to a ratio, stirring and mixing are conducted, the mixture is evenly added into a desulfurization tower, smoke reacts withan absorbent through the desulfurization tower, Fe and Cu leached out from pulp liquid can significantly promote the smoke desulfurization effect, the purified smoke is discharged through a chimney, and acid desulfurization liquid is introduced into a zinc production section. Pulp liquid entering a zinc sulfate or electrolytic zinc purification section can be subjected to iron precipitation undercertain pH through iron leached out from the slag tailings, afterwards, cadmium is removed through replacement, zinc sulfate is prepared with copper, and copper can be recovered from filter residues.According to the method, the removal rate of 95% or above is achieved for low-concentration SO2 through the copper slag tailings of smelting tailings, and valuable metal copper with high additional value in the copper slag tailings is leached out and recovered. The method is simple in process, the used desulfurization absorbent is low in cost, energy consumption is low, benefits of an enterprise can be increased, and the method is an efficient utilization method integrating smoke desulfurization and slag tailings recycling comprehensive recovery.

Owner:肖功明

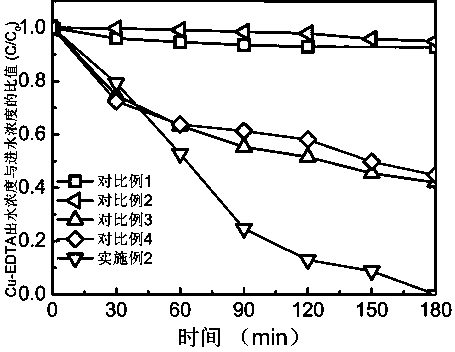

Treatment method of Cu-EDTA heavy metal complex wastewater

ActiveCN108529797AWith piezoelectric effectAdsorptivePiezoelectric/electrostrictive device manufacture/assemblyWater/sewage treatment by electrochemical methodsChemical effectsBarium titanate

The application discloses a treatment method of Cu-EDTA heavy metal complex wastewater. The treatment method comprises the following steps: firstly, synthesizing a piezoelectric composite of barium titanate / graphene by a hydrothermal method; under pressure provided by ultrasonication, breaking down heavy metal complexation and degrading organic matter obtained after breakdown by virtue of the piezoelectric chemical effect of piezoelectric material; and further adsorbing and recovering free Cu<2+> or weak complex Cu<2+> by graphene in a solution obtained by breakdown and degradation, so as to effectively remove Cu-EDTA heavy metal complex wastewater. According to the application, by coupling the piezoelectric effect and the chemical process as well as the adsorption and electric desorptioneffects, the situation of high cost, cumbersome process, serious secondary pollution and secondary recovery of a traditional heavy metal wastewater treatment method is broken through, the effective removal of EDTA and the efficient recovery of Cu<2+> are implemented, the shortcomings of traditional technology are overcome, and as a green and efficient processing technology, the treatment method provides a new development direction for novel water treatment technology.

Owner:NANJING UNIV

Method of recovering manganese, lead and silver from electrolytic zinc anode mud

The invention relates to the technical field of hydrometallurgy, and in particular to a method of recovering manganese, lead and silver from electrolytic zinc anode mud. Manganese in the electrolytic zinc anode mud of a cathode region is reduced and leached by means of a diaphragm electrolysis method, and hydrogen is generated on a cathode. Under the stirring action of the cathode region, reduction leaching of manganese dioxide can be enhanced, so that the leaching efficiency of manganese dioxide reaches 95% above; lead sulfate and a compound of silver enter cathode leaching residues to be enriched. In an anode region of a diaphragm electrolyzer, almost leached manganese sulfate is electrolytically oxidized to manganese dioxide and is deposited on an anode plate or in the bottom of the anode region, and a small part of manganese sulfate residues are left in the electrolyte and are returned to an electrolytic zinc system to supplement manganese ions. In the electrolytic process, graphite is taken as the anode, so that the purity of manganese dioxide reaches 80% above.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

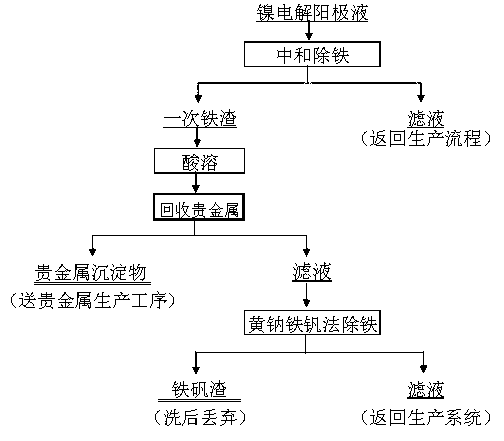

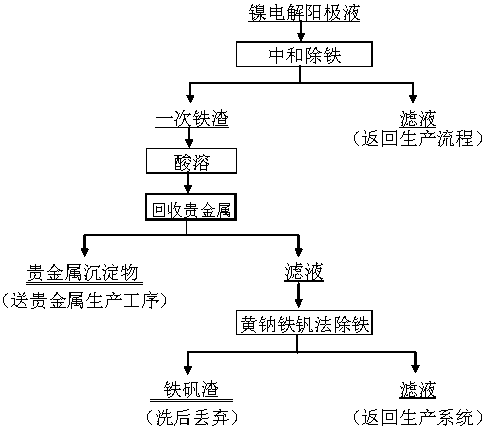

Method for recovering platinum group metal from ferrous nickel electrolysis anolyte

ActiveCN102994773ASolve difficult to recycleRealize enrichment recoveryProcess efficiency improvementElectrolysisSlag

The invention relates to a method for recovering platinum group metal from ferrous nickel electrolysis anolyte, which comprises the following steps of: firstly neutralizing the nickel electrolysis anolyte to remove iron; returning the filtrate to a production system; performing acid dissolution on the obtained primary iron slag at 20-50 DEG C, and then adding a vulcanizing agent; performing precision filtering, wherein over 96% of precious metal is enriched in the filter residue; and removing iron of the filtrate by a sodium jarosite method, wherein the content of precious metal in the obtained sodium jarosite slag is less than 1.0g / t. The method provided by the invention solves the problem that precious metal is lost in anolyte and hard to recover in an electrolytic refining process of a nickel anode containing precious metal, prevents influence on the existing production, and can guarantee the quality of electrolytic nickel; and moreover, the technology is simple, the production cost is low, and the implementation is easy.

Owner:JINCHUAN GROUP LIMITED

Preparation method and applications of graphene aerogel

ActiveCN108341410ARealize enrichment recoveryLarge adsorption capacityOther chemical processesWater contaminantsDesorptionSolvent

The invention discloses a preparation method and applications of graphene aerogel. The preparation method comprises following steps: a graphene oxide aqueous solution is subjected to centrifugation, and absolute ethyl alcohol is added continuously so as to obtain a graphene alcohol gel; 4 to 12h of in-suit hydro-thermal reaction is carried out at 100 to 180 DEG C so as to obtain a graphene hydrogel; the graphene hydrogel is immersed in a mixed solvent of ethanol and acetone, distilled water is added, the mixed solvent is removed via suction, an obtained product is introduced into liquid nitrogen for 20 to 60h of drying, is introduced into a tubular furnace for 2 to 10h of heat treatment in 400 to 600 DEG C Ar, and then is treated in ozone atmosphere for 5 to 30min so as to obtain the graphene aerogel. The graphene aerogel can be used for absorbing heavy metal ions in waste water, is large in specific surface area, adsorption capacity, and excellent in conductivity, is capable of realizing electrochemical desorption, realizing enrichment recovery of heavy metal ions, and is low in energy consumption; the pH value of discharged water is close to 7, and is in an environmentally acceptable range; and no secondary pollution is caused.

Owner:NANJING UNIV

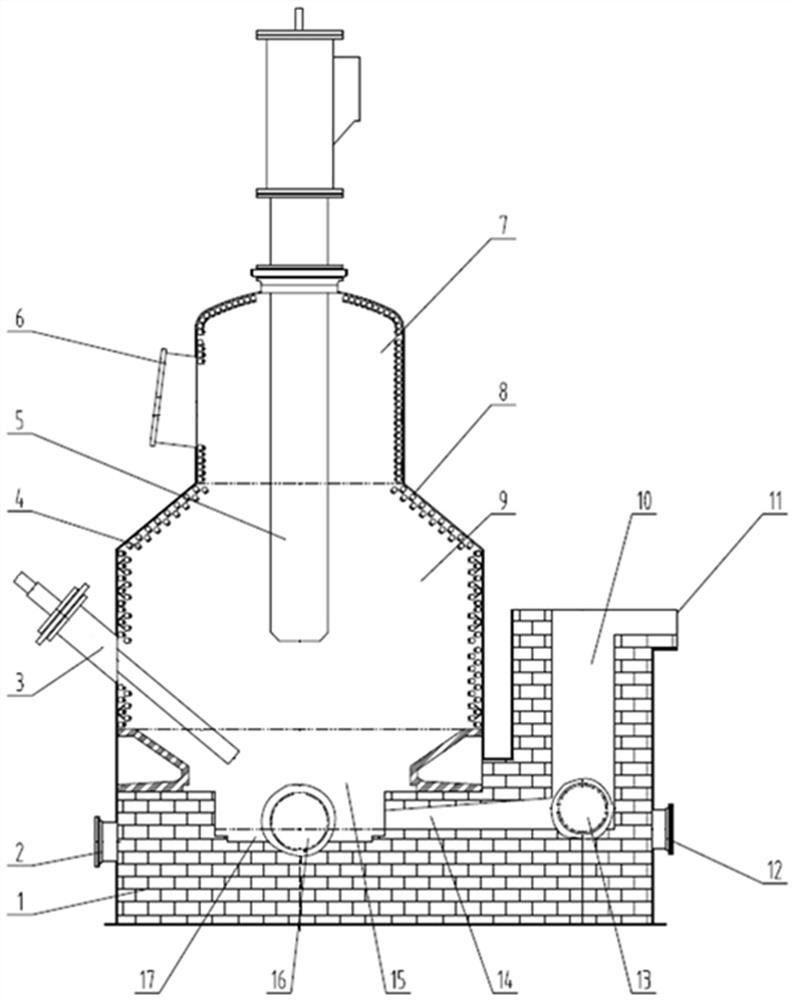

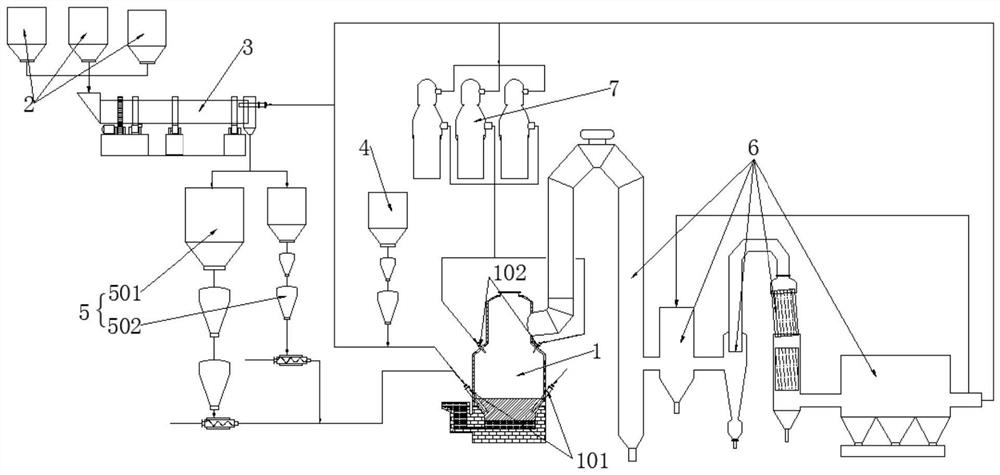

Design method of wide-screening powder phase change composite furnace applied to solid waste treatment

ActiveCN114264150ARealize enrichment recoveryDifficult to handleGlass furnace apparatusCrucible furnacesWaste treatmentHot blast

The invention provides a design method of a wide-screening powder phase change composite furnace applied to solid waste treatment. The wide-screening powder phase change composite furnace comprises a melting furnace and a homogenizing furnace, wherein the melting furnace is communicated with the homogenizing furnace through a throat; the inner wall of the melting furnace adopts a fire-resistant lining protected by a water-cooled wall; a hot air spray gun and a plurality of material spray guns are arranged on a furnace body; and the top end of the homogenizing furnace is provided with an overflow port for discharging molten liquid. The wide-screening powder phase change composite furnace is particularly suitable for solid waste treatment, and a new thought is provided for large-scale, high-valued and green utilization of solid waste.

Owner:山西智博环化工程有限公司

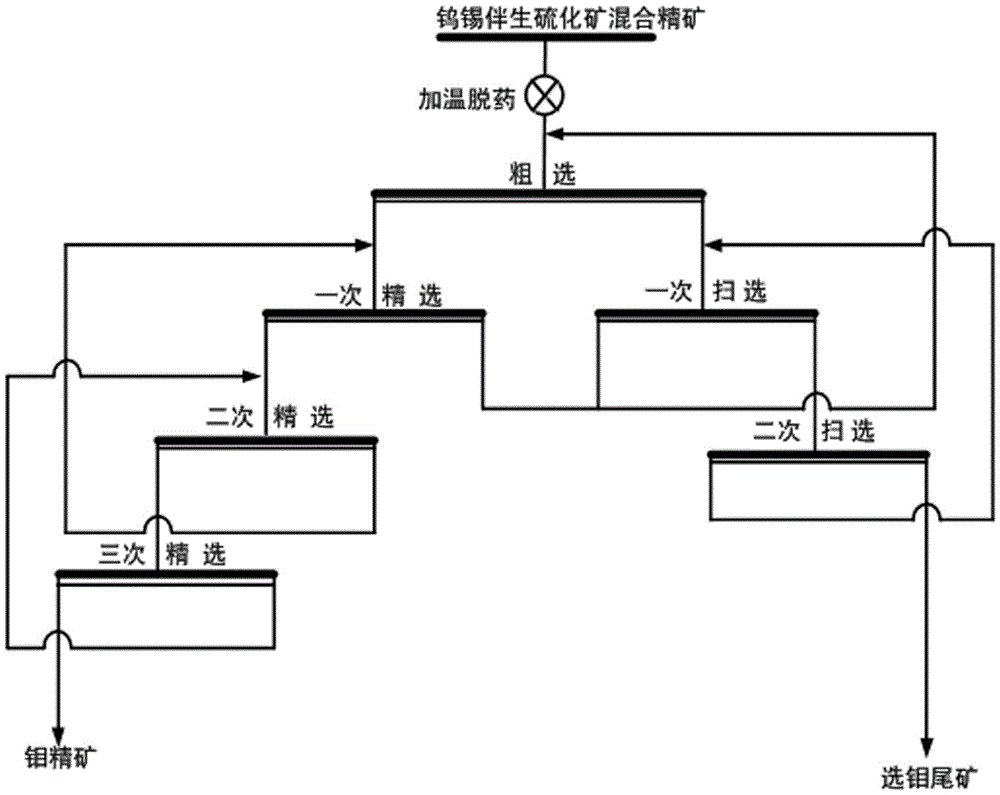

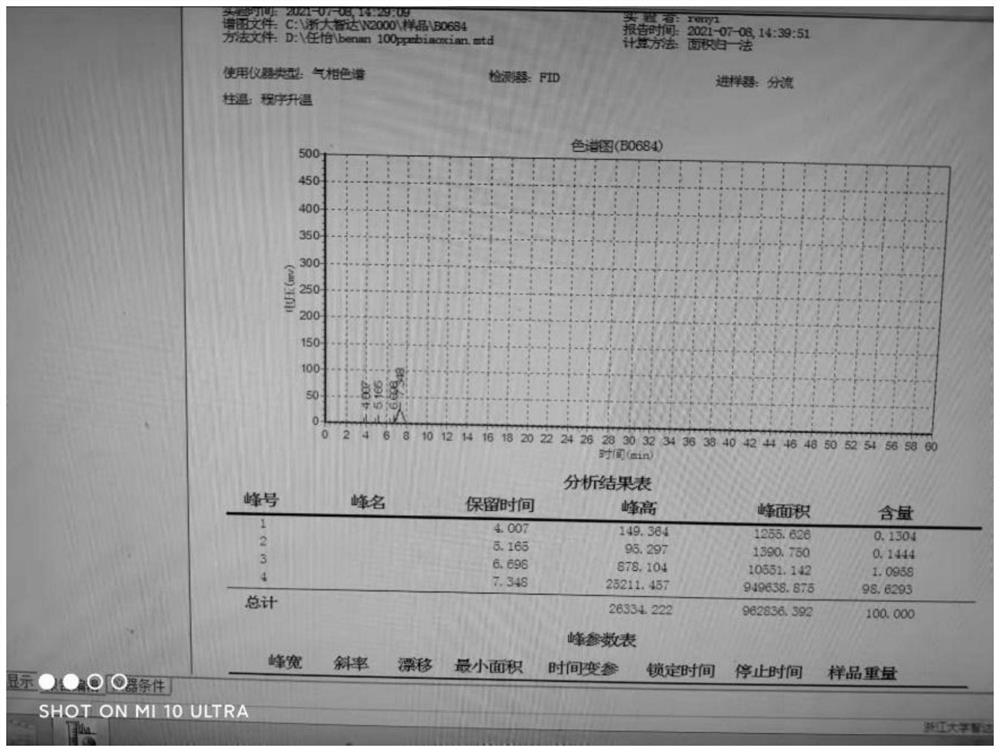

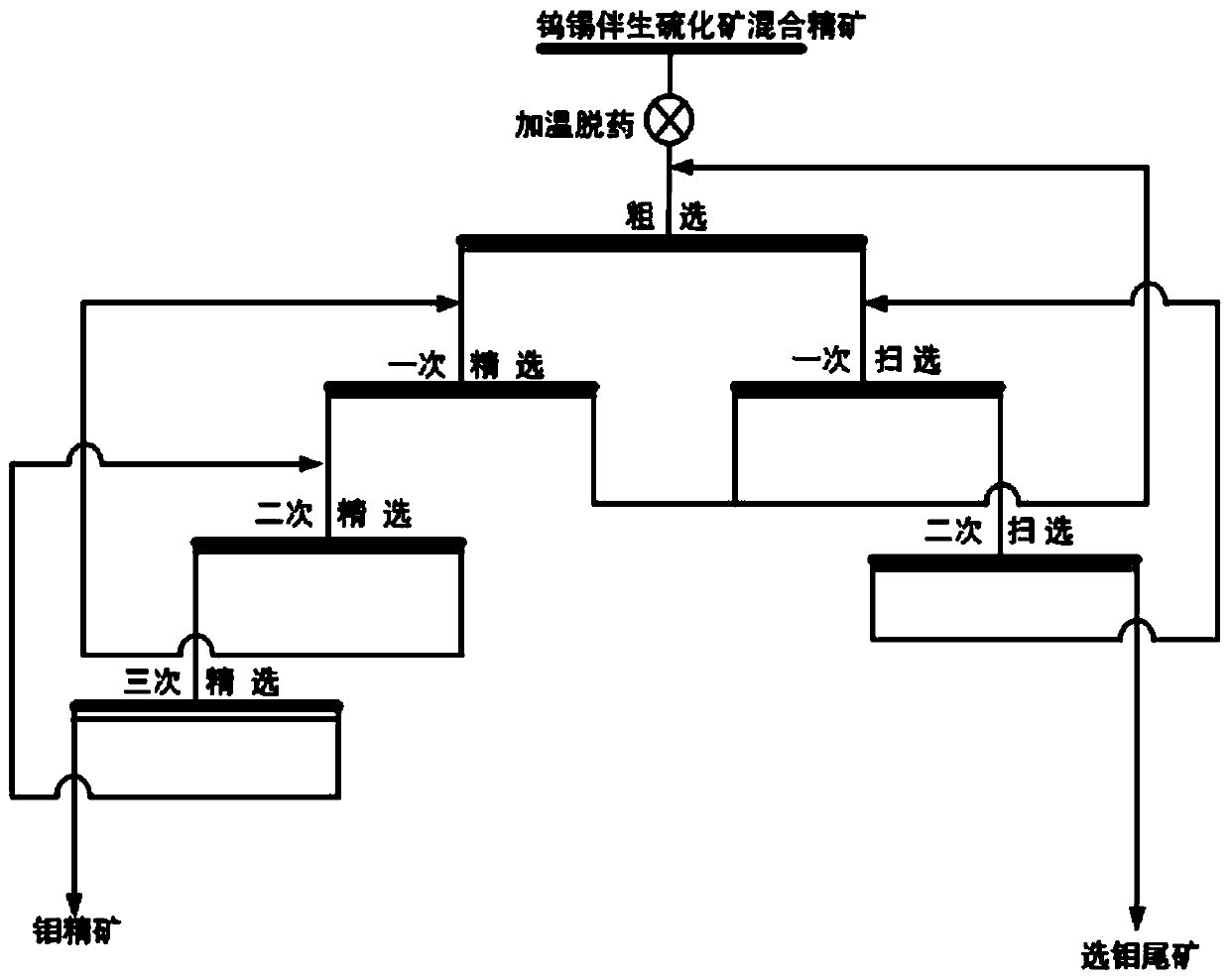

Beneficiation method for recovering molybdenum from tungsten tin associated sulfide ore bulk concentrate

InactiveCN105537005AIncrease floatability differenceGood hydrophobicityFlotationOre concentrateTungsten

The invention discloses a beneficiation method for recovering molybdenum from a tungsten tin associated sulfide ore bulk concentrate. The beneficiation method is characterized by comprising the following steps: after the heating reagent removal is performed for a sulfide ore bulk concentrate obtained from a tungsten tin associated sulfide ore; water is added for mixing pulp; quicklime is added for stirring to adjust the pulp; an inhibitor and a collecting agent are added for primary roughing to obtain a primary roughing concentrate and a primary roughing tailing; the collecting agent is added in the primary roughing tailing for secondary selection to obtain a secondary selection concentrate and a secondary selection tailing; and three times of blank selection are performed for the secondary selection concentrate to obtain a molybdenum concentrate. The method obtains the molybdenum concentrate with a molybdenum grade of 48-52% and a molybdenum recovery rate of 87-93%, reduces the molybdenum selection cost, generates no waste water and other substances harmful to the environment, and is an environment-friendly beneficiation method. The method is suitable for recovering molybdenum from the tungsten tin associated sulfide ore bulk concentrate.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

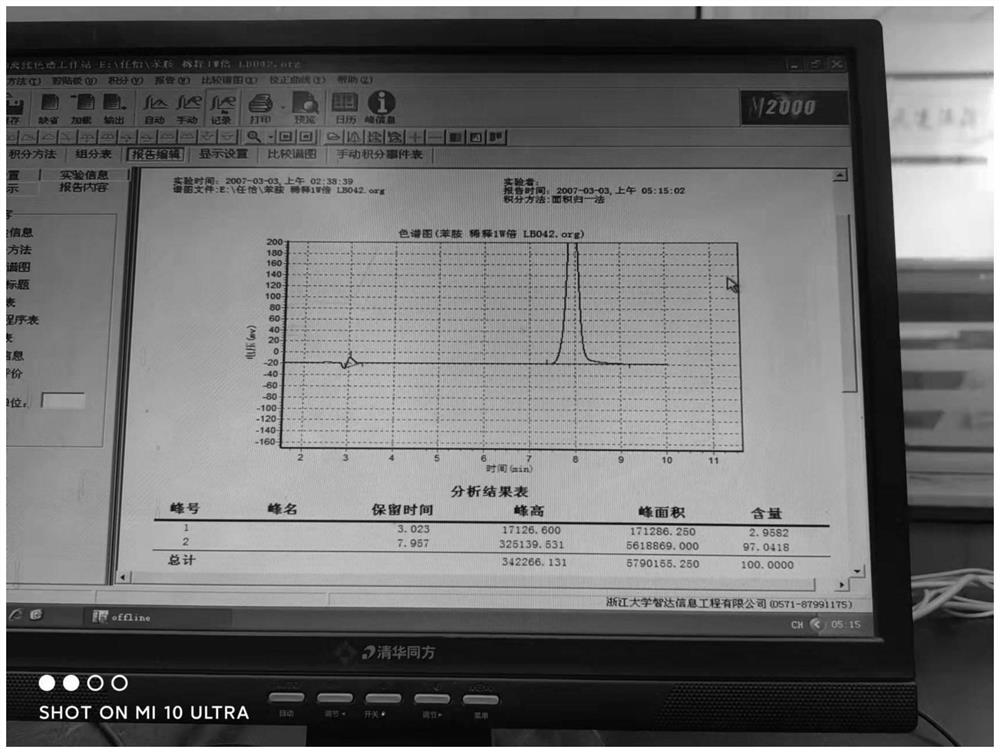

Method for selective flotation separation of molybdenum and rhenium acid radicals in alkaline leaching liquid

The invention discloses a method for selective flotation separation of molybdenum and rhenium acid radicals in an alkaline leaching liquid. The method comprises the following steps that a pH value ofthe alkaline leaching liquid containing molybdate acid radicals and rhenium acid radicals is adjusted to 7.1-12, then an organic matter modified activated carbon collecting agent composed of triethylenetetramine, tetraethylenepentamine, methyl violet 10B and cocamidopropyl betaine and a surface active agent are added into the alkaline leaching liquid, pneumatic flotation is carried out, a foam product is a rhenium-rich component, and a liquid core is a molybdenum-rich solution. The method has the advantages that the selective separation effect is good on molybdenum and rhenium, the technological process is simple, and the cost is low, and is especially suitable for separation between the rhenium and the molybdenum in the alkaline leaching liquid with low rhenium content and high molybdenumcontent.

Owner:ZHENGZHOU UNIV

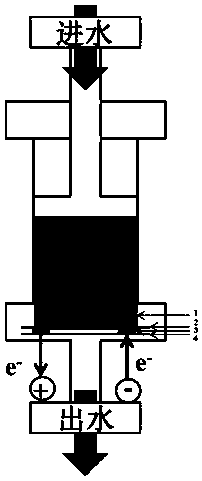

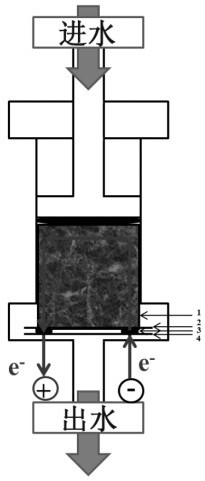

Polluted soil in-situ circulation leaching treatment method adopting electrochemical treatment leacheate

PendingCN114309031ASpread evenlyFacilitated DiffusionContaminated soil reclamationElectrochemical responseChemical reaction

A contaminated soil in-situ circulation leaching treatment method adopting an electrochemical treatment leacheate comprises the following steps that firstly, an electrochemical reactor is arranged on a contaminated soil ground, the upper portion of the chemical reactor is open, the leacheate enters from the upper portion, and the upper portion of the chemical reactor is open; the bottom of the electrochemical reactor is communicated with a leacheate discharge pipe network arranged in the polluted soil through a discharge pipe; 2, after entering the contaminated soil, the leacheate absorbs pollutants in the soil and then is enriched in a water collecting well, and then the leacheate in the water collecting well is sent back into the electrochemical reactor through a sewage pump, so that circulation of the leacheate is achieved; and step 3, after the leacheate is circulated stably, electrifying the positive electrode plate and the negative electrode plate to enrich heavy metal ions in the leacheate and degrade organic pollutants so as to realize efficient circulating operation of the leacheate. The leacheate subjected to electrochemical treatment enters the leacheate discharge pipe network system below again, so that efficient cyclic utilization of the leacheate is realized.

Owner:QILU UNIV OF TECH

A kind of beneficiation method for recovering molybdenum from tungsten-tin associated sulfide ore mixed concentrate

InactiveCN105537005BMineral processing method to solve recoveryIncrease floatability differenceFlotationWastewaterTungsten

The invention discloses a beneficiation method for recovering molybdenum from a tungsten tin associated sulfide ore bulk concentrate. The beneficiation method is characterized by comprising the following steps: after the heating reagent removal is performed for a sulfide ore bulk concentrate obtained from a tungsten tin associated sulfide ore; water is added for mixing pulp; quicklime is added for stirring to adjust the pulp; an inhibitor and a collecting agent are added for primary roughing to obtain a primary roughing concentrate and a primary roughing tailing; the collecting agent is added in the primary roughing tailing for secondary selection to obtain a secondary selection concentrate and a secondary selection tailing; and three times of blank selection are performed for the secondary selection concentrate to obtain a molybdenum concentrate. The method obtains the molybdenum concentrate with a molybdenum grade of 48-52% and a molybdenum recovery rate of 87-93%, reduces the molybdenum selection cost, generates no waste water and other substances harmful to the environment, and is an environment-friendly beneficiation method. The method is suitable for recovering molybdenum from the tungsten tin associated sulfide ore bulk concentrate.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

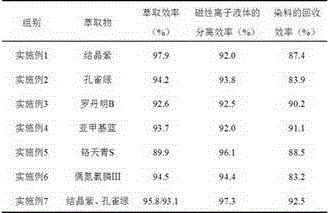

Magnetic ion liquid micro-emulsion extraction agent for treating printing and dyeing wastewater

InactiveCN106315732AImprove extraction efficiencyEasy to handleWater treatment compoundsWater contaminantsEmulsionDyeing wastewater

The invention discloses a magnetic ion liquid micro-emulsion extraction agent for treating printing and dyeing wastewater. The extraction agent takes a magnetic ion liquid as a polar phase and a dyeing aqueous solution as a nonpolar phase; a micro-emulsion technique is adopted for preparing the magnetic ion liquid micro-emulsion; the defects of easiness in agglomeration and high ionic liquid viscosity of the magnetic material in a process of treating printing and dyeing wastewater can be effectively overcome; the preparation method is simple; the operation is convenient; the control is easy; the production cost is low. The magnetic ion liquid micro-emulsion extraction agent prepared according to the invention can be used for quickly and efficiently treating the dyes in the printing and dyeing wastewater and obviously increasing the extraction efficiency and reuse efficiency of the extraction agent; the magnetism of the extraction agent is utilized and a magnet is adopted for quickly separating the ion liquid from the dyes after the completion of the extraction, the recycle of the ion liquid and the enriching recycle of the dye molecules are realized and the application prospect is wide.

Owner:LUDONG UNIVERSITY

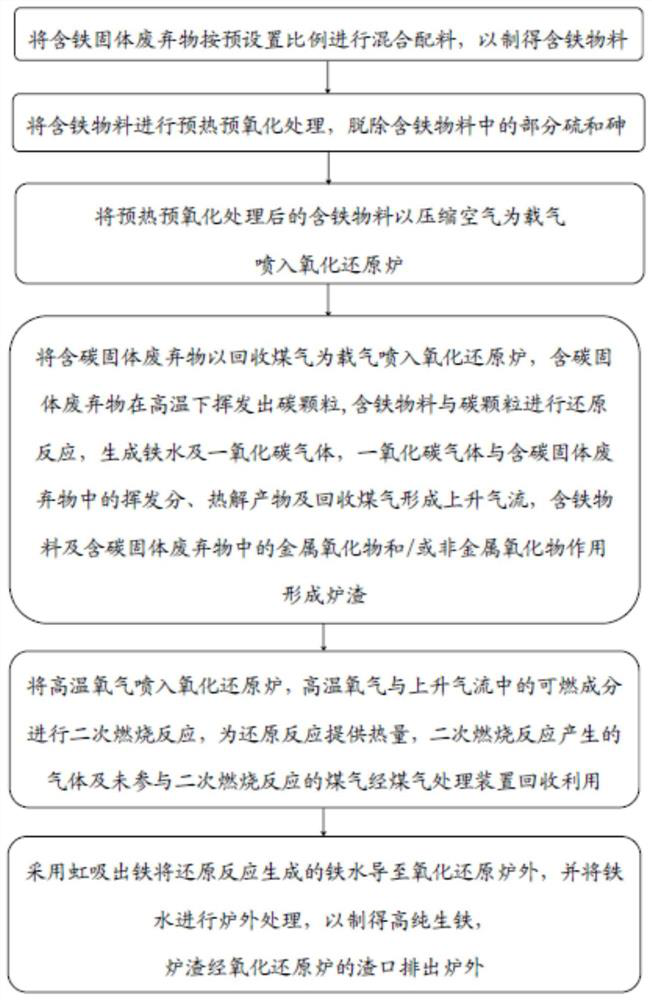

Method and system for treating solid waste through smelting reduction process

InactiveCN112708713ARealize resourcesAchieving Scale UtilizationProcess efficiency improvementCombustionSlag

The invention provides a method and system for treating solid waste through a smelting reduction process. The method comprises the following steps of mixing and batching iron-containing solid waste to prepare an iron-containing material; preheating and pre-oxidizing the iron-containing material; spraying the preheated and pre-oxidized iron-containing material into an oxidation-reduction furnace by taking compressed air as carrier gas; spraying carbon-containing solid waste into the oxidation-reduction furnace by taking recycled coal gas as carrier gas, and reacting the carbon-containing solid waste with the iron-containing material to generate molten iron, carbon monoxide and furnace slag; and spraying high-temperature oxygen into the oxidation-reduction furnace, carrying out a secondary combustion reaction on the high-temperature oxygen and combustible components in ascending gas flow, and recycling coal gas generated by the secondary combustion reaction and coal gas which does not participate in the secondary combustion reaction. According to the method, traditional fuel, lime, dolomite and other fluxing agents do not need to be added, compressed air and recycled coal gas are adopted as carrier gas to convey materials, high-temperature oxygen is adopted as a combustion improver, and solid waste recycling and large-scale comprehensive utilization are achieved.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

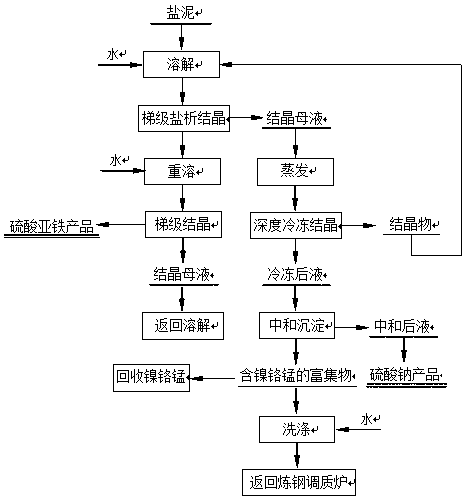

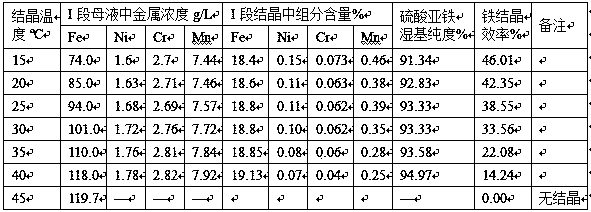

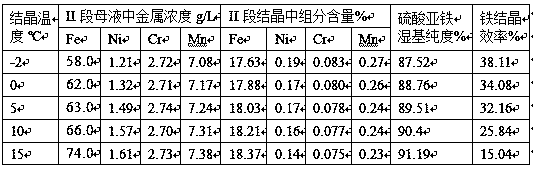

Resource utilization method of stainless steel pickling waste water crystallized salt sludge

InactiveCN110791651AReduce iron concentrationEfficient enrichment and recoveryAlkali metal sulfite/sulfate dehydrationProcess efficiency improvementManganeseProcess engineering

The invention relates to a resource utilization method of stainless steel pickling waste water crystallized salt sludge, and belongs to the technical field of comprehensive utilization of resources. After the salt sludge is dissolved, efficient separation between iron and nickel, chromium and manganese is realized with a cascade salting-out crystallization method, and crystallization mother liquorwith lower iron concentration and higher nickel, chromium and manganese concentrations and ferrous sulfate crystallized coarse salt are obtained. By aiming at further realizing separation between iron and nickel, chromium and manganese, the crystallization mother liquor is subjected to evaporation-freezing crystallization treatment, nickel, chromium and manganese are enriched while the iron concentration of the liquor is further reduced, then nickel, chromium and manganese are recovered in a hydroxide precipitate form with a sodium carbonate neutralization method, and effective enrichment ofnickel, chromium and manganese is realized. The precipitate residues can be taken as raw materials for recovering nickel, chromium and manganese or are returned to a tempering furnace in a stainless steel production process for self-use. According to the method, enrichment and recovery of valuable metals such as nickel, chromium and manganese with low content in the salt sludge are realized, and meanwhile, resource utilization of iron as a main impurity element in the salt sludge is realized.

Owner:KUNMING UNIV OF SCI & TECH

Method for recovering platinum group metal from ferrous nickel electrolysis anolyte

ActiveCN102994773BSolve difficult to recycleRealize enrichment recoveryProcess efficiency improvementElectrolysisSlag

The invention relates to a method for recovering platinum group metals from iron-containing nickel electrolysis anolyte. The process flow is as follows: first neutralize and remove iron from the nickel electrolysis anolyte, return the filtrate to the production system, and obtain primary iron slag Add vulcanizing agent after acid dissolution at 20℃~50℃, after precision filtration, more than 96% of the precious metals are enriched in the filter residue, and the jarosite slag obtained after the filtrate removes iron by the jarosite method has a precious metal content of less than 1.0g / t. The invention solves the problem that the noble metal is lost in the anolyte and is difficult to recover during the electrolytic refining process of the nickel anode containing the noble metal, and has no influence on the existing production, can ensure the quality of the electrolytic nickel, and has simple process, low production cost, and easy implement.

Owner:JINCHUAN GROUP LIMITED

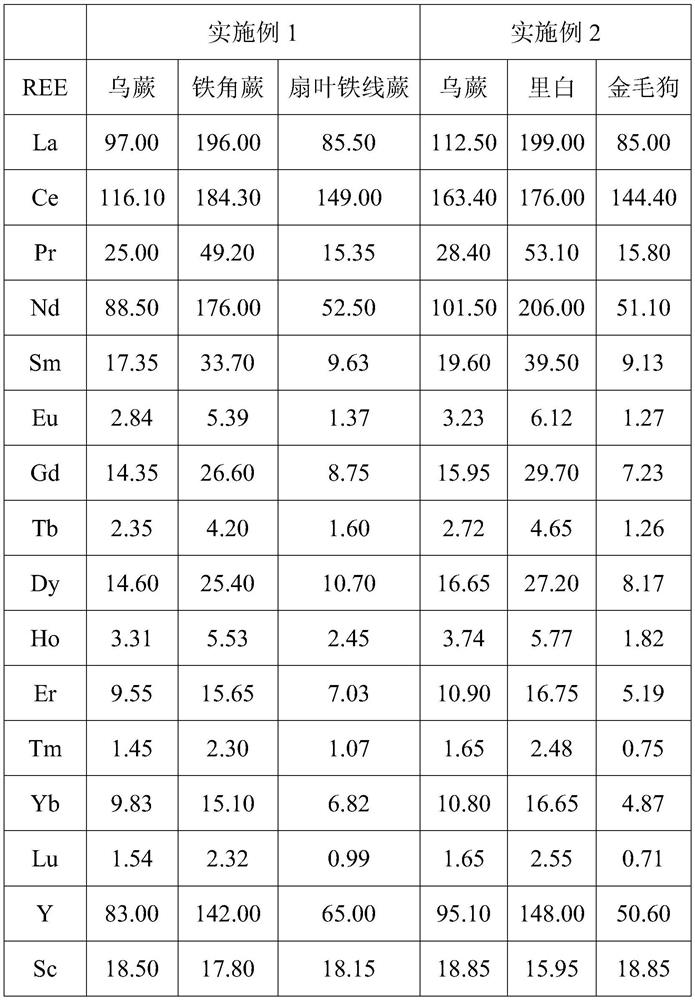

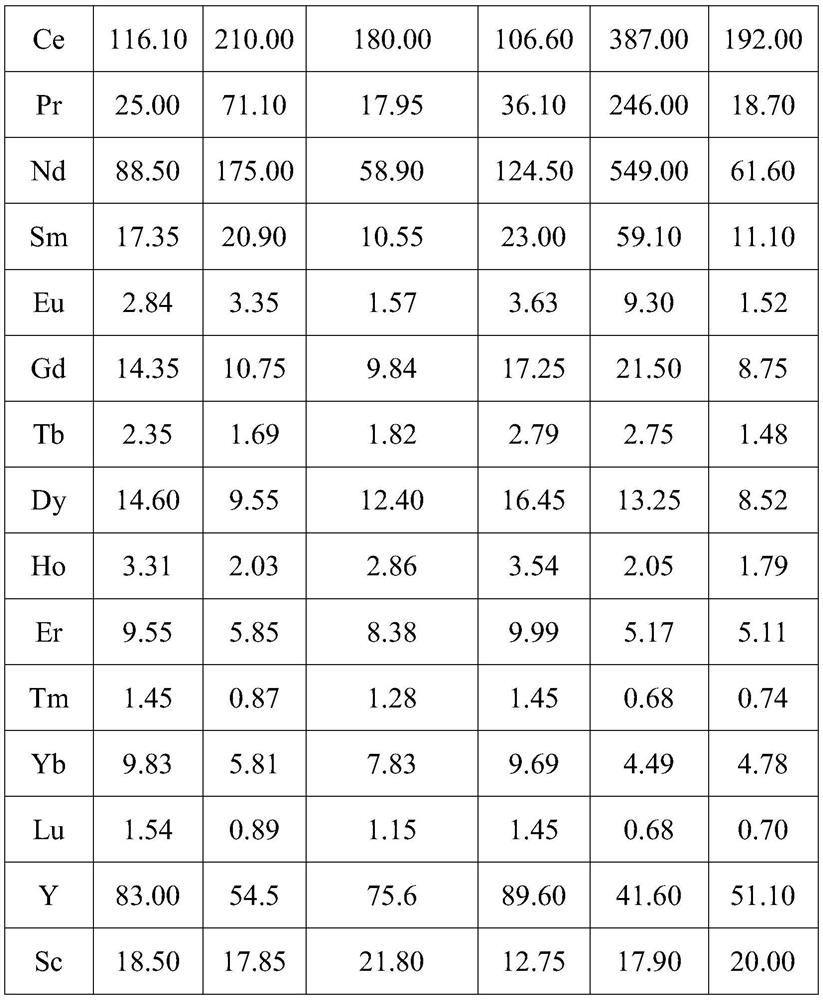

Method for enriching rare earth elements in weathered crust by using pteridophytes

ActiveCN113234943ARealize enrichment recoveryImprove the ecological environmentPteridophyteEcological environment

The invention belongs to the technical field of weathered crust rare earth enrichment, and particularly relates to a method for enriching rare earth elements in a weathered crust by using pteridophytes. The method comprises the following steps of 1) soil pretreatment; and 2) pteridophyte planting, wherein the pteridophytes are planted on the weathered crust, and the pteridophytes comprise one or more of blechnum orientale, dicranopteris pedata, athyrium filix-femina, dryopteris filix-mas, asplenium trichomanes, diplopterygium glaucum, lindsaea odorata, woodwardia japonica, stenoloma chusana, adiantum flabellulatum, cibotium barometz, microlepia strigosa and diplazium donianum. Different pteridophytes are planted on different structural layers of the weathered crust in different modes to be used for adsorbing rare earth elements in soil, so that the rare earth resources can be effectively utilized; and the effect of improving the surrounding ecological environment can be achieved by planting the pteridophytes in the weathered crust soil. Compared with an existing rare earth mining technology, the method cannot cause secondary pollution. The method provides an economical and effective solution way for realizing ecological management of rare earth polluted land and rare earth reclamation.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

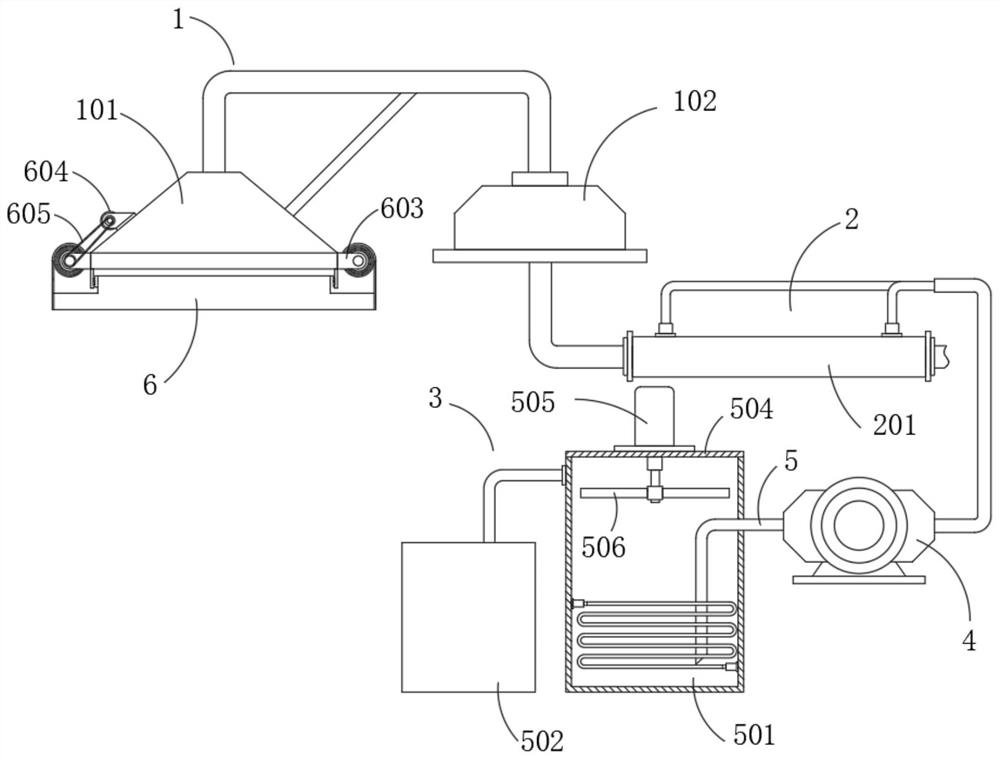

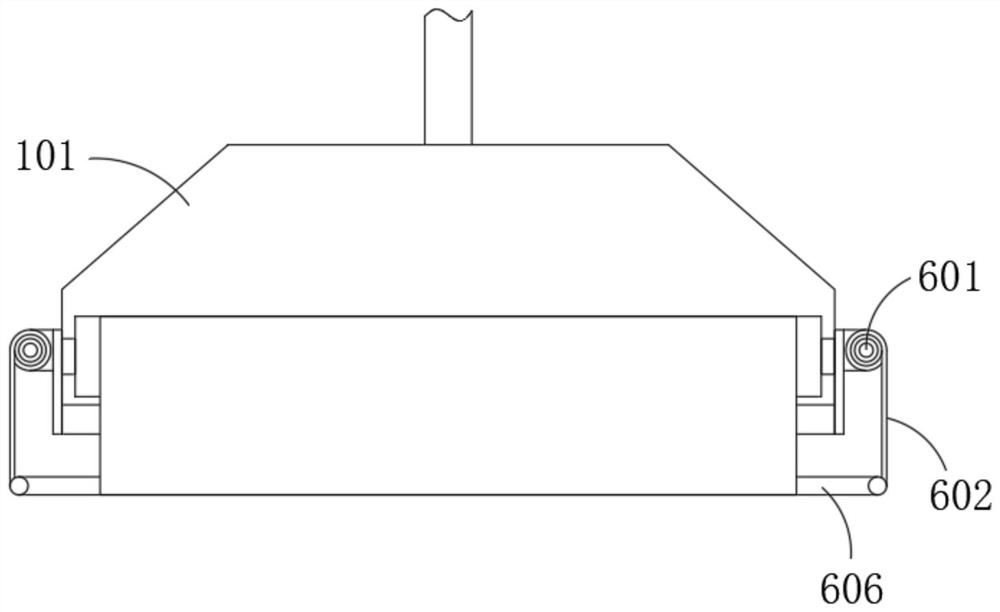

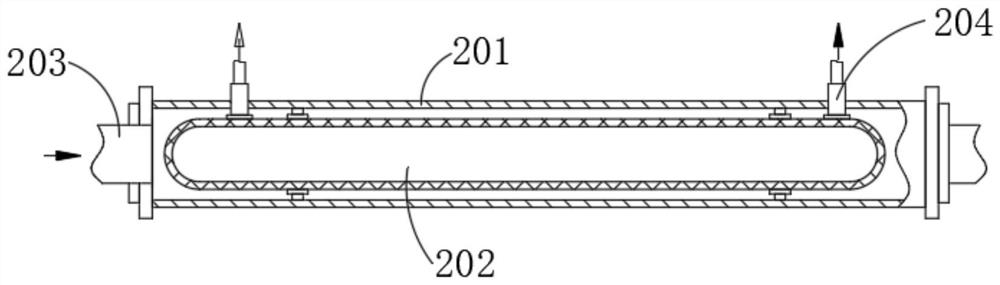

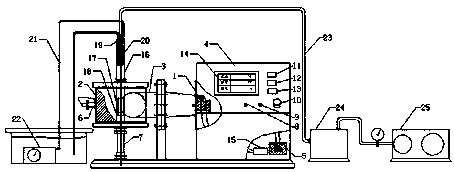

Recovery device and recovery method for volatile organic solvent gaseous membrane of electrophoresis tank

PendingCN113385000AAchieve separationRealize enrichment recoveryDispersed particle separationDirt cleaningOrganic solventElectrophoresis

The invention discloses a recovery device for a volatile organic solvent gaseous membrane of an electrophoresis tank; the recovery device comprises an air suction assembly, a degassing membrane assembly and a recovery assembly; one end of the degassing membrane assembly is fixedly communicated with the air suction assembly, a vacuum pump is fixedly communicated between the recovery assembly and the degassing membrane assembly, and the air suction assembly comprises an air suction cover and an air suction fan; and the air suction cover and an air inlet of the air suction fan are fixedly communicated through an air pipe; the degassing film assembly comprises a shell and a degassing film air bag arranged in the shell, an air inlet pipe is fixedly mounted at one end of the shell, two sets of air outlet pipes are symmetrically mounted on one side of the degassing film air bag, and the two sets of air outlet pipes extend out of the shell. The air suction assembly, the degassing membrane assembly and the recovery assembly are sequentially arranged, gas is collected and filtered, the device is simple and high in practicability, and the treatment cost is reduced.

Owner:吉安特膜分离设备(长春)有限公司

A device for extracting indium by microwave chlorination of waste liquid crystal panels

ActiveCN108677019BAvoid shadow effectReduce heat lossProcess efficiency improvementIndiumHigh energy

The invention discloses a microwave chlorination indium-extraction device for a waste liquid crystal display panel. The device comprises a microwave heating device composed of a microwave generator, amicrowave heating cavity, a microwave communication pipe, an electronic control panel and the like, a quartz reaction device composed of a quartz reaction pipe, a material crucible, a quartz sand core layer and a ground glass sealing plug, a condensation recovery device composed of a quartz condensation pipe, a condensation water pipe and a circulation water pump, and a vacuum device composed ofa vacuum pipeline, activated carbon adsorption equipment and a diaphragm vacuum pump. According to the device disclosed by the invention, chlorination recovery is carried out on indium material in thewaste liquid crystal display panel by taking microwave as heating means, so that high energy utilization efficiency and shadow-free effect are achieved, the heating effect is improved, and the recovery cost and difficulty are lowered; and the device disclosed by the invention is simple in structure, and capable of realizing long-time safe and stable running, and has the advantages of resourcefuland harmless treatment.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

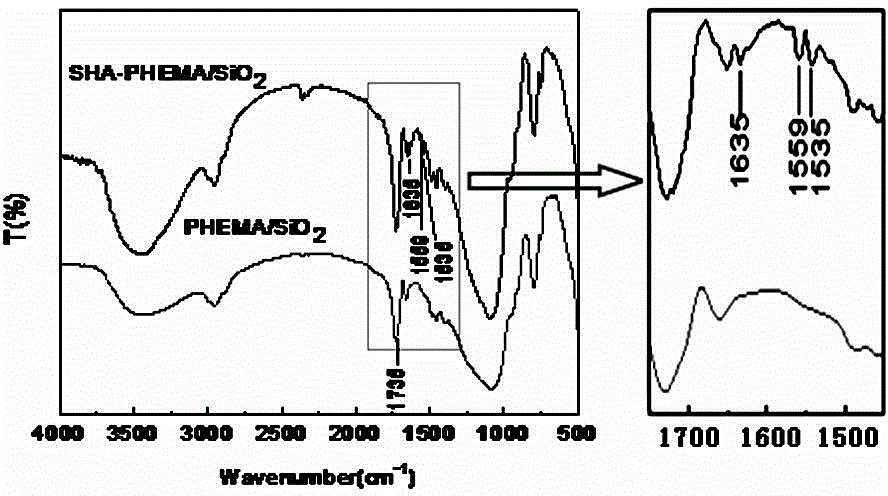

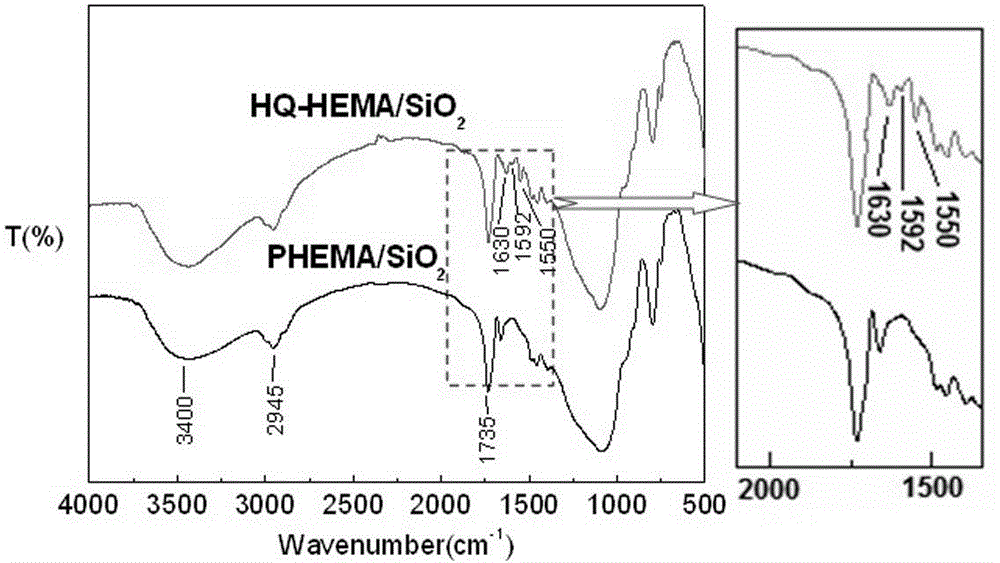

Hydroximic acid functionalized polymer/inorganic composite chelating adsorption material and preparation method thereof

InactiveCN103586001BExcellent adsorption and desorption performanceEasy to separateOther chemical processesWater/sewage treatment by sorptionChemistryChelating resin

The invention belongs to the technical field of the treatment of heavy metal ions in industrial waste water and the extraction of rare earth ions in rare earth mines, and aims to solve the problem that existing hydroxamic acid materials cannot produce polymer effects, such as high adsorption characteristics, separable, reusable and other characteristics, and The invention does not have the advantages of good physical and chemical stability and simple operation of chelating resins, and provides a hydroxamic acid functionalized polymer / inorganic composite chelating adsorption material and a preparation method thereof. It is composed of carrier micron-level silica and hydroxamic acid functionalized polymer that selectively recognizes and adsorbs heavy metal ions and rare earth ions. The particle size of the micron-level silica is 90-125 μm. The adsorption material of the present invention can effectively remove heavy metal ions in industrial wastewater and extract rare earth ions from rare earth ores. The preparation method is simple, the performance is stable, and it has strong selective recognition and adsorption capabilities for heavy metal ions and rare earth ions. It is fast and easy to regenerate, so it can be used repeatedly.

Owner:ZHONGBEI UNIV

A kind of preparation method of graphene aerogel and application thereof

ActiveCN108341410BRealize enrichment recoveryLarge adsorption capacityOther chemical processesWater contaminantsElectrochemistryHeat treated

The application discloses a preparation method of graphene airgel and its application. The preparation method of the graphene airgel is as follows: first, centrifuge the graphene oxide aqueous solution, and continuously add absolute ethanol to obtain graphene alcohol gel, and then 100 ~180°C, conduct in situ hydrothermal reaction for 4~12 h to obtain graphene hydrogel, then immerse in a mixed solvent of ethanol and acetone, add distilled water, suck out the mixed solvent, and then dry in liquid nitrogen for 20~60 h, then placed in a tube furnace for heat treatment in Ar at 400-600°C for 2-10 h, and finally placed in an ozone atmosphere for 5-30 min to obtain the graphene airgel; this material can be used for adsorption Heavy metal ions in wastewater have a large specific surface area, large adsorption capacity, and good conductivity, which can realize electrochemical desorption, enrichment and recovery of heavy metal ions, low energy consumption, and the pH of the effluent is close to neutral, which is within the environmental tolerance range. No secondary pollution.

Owner:NANJING UNIV

Novel immobilized 8-hydroxyquinoline type chelate adsorption material and preparation method thereof

InactiveCN102773082BImprove the coordination effectHigh bonding capacityOther chemical processes(Hydroxyethyl)methacrylateIndustrial waste water

The invention belongs to the field of chelate resin materials, and particularly relates to a novel immobilized 8-hydroxyquinoline type chelate adsorption material and a preparation method thereof. 0.95-1.85mmol / g of ligand 8-hydroxyquinoline is bonded to the surface of a silica gel micro-particle modified by hydroxyethyl methacrylate (HEMA). The preparation method includes the steps: grafting the hydroxyethyl methacrylate on the surface of the silica gel micro-particle modified by amino containing silane coupling agents; and fixing the ligand 8-hydroxyquinoline on the surface of the silica gel micro-particle modified by polymer. The material is large in 8-hydroxyquinoline bonding quantity, simple in synthesis process, moderate in condition, short in time, easy to control and fine in mechanical property, is repeatedly used, has a high coordinated complexing capacity for metal ions, can enrich and recycle various precious metal ions, particularly has excellent adsorption and selection performances for heavy metals such as copper, nickel and lead, and can be used for purifying industrial wastewater.

Owner:ZHONGBEI UNIV

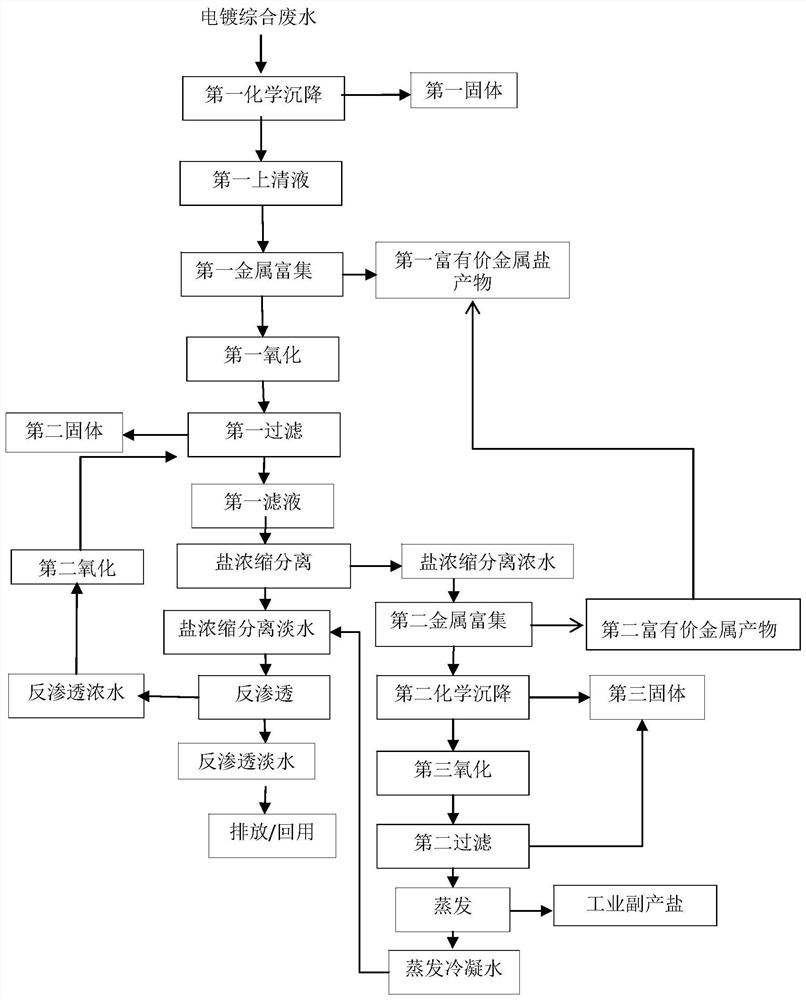

Method for comprehensively treating electroplating comprehensive wastewater

PendingCN113292193AAchieve zero emissionsReach resourcesTreatment involving filtrationWaste water treatment from metallurgical processFiltrationReverse osmosis

The invention provides a method for comprehensively treating electroplating comprehensive wastewater, and belongs to the technical field of sewage treatment. The electroplating comprehensive wastewater is treated by comprehensively applying various treatment methods such as electrochemical sedimentation treatment, metal enrichment, oxidation, filtration, salt concentration and separation, reverse osmosis and the like, so that enrichment and recovery of valuable metal ions in the comprehensive electroplating wastewater, reduction of mud and deep purification treatment of chemical pollutants are realized; and the recycling of water resources is effectively ensured, and meanwhile, industrial salt, valuable metal products and mud are separated, so that zero discharge of wastewater and recycling of resources are achieved.

Owner:苏州融和福天宝环保科技有限责任公司

Blast furnace-rotary kiln co-processing method for dust containing zinc and iron

ActiveCN112111656BEfficient use ofEfficient recyclingBlast furnace detailsRecycling and recovery technologiesFlue gasBriquette

Owner:UNIV OF SCI & TECH BEIJING

A method for selective flotation separation of molybdenum rhenate in alkaline leaching solution

ActiveCN110777270BEfficient and selective separationHigh recovery rateFlotationActivated carbonMeth-

The invention discloses a method for selective flotation separation of molybdenum-rhenate in alkaline leaching solution. The method is to adjust the pH value of the alkaline leaching solution containing molybdate and rhenate to 7.1-12, and then add triethylenetetramine , Tetraethylenepentamine, methyl violet 10B and cocamidopropyl betaine are organic modified activated carbon collectors and surfactants, inflated flotation, the foam product is a rhenium-rich component, and the remaining liquid is a molybdenum-rich solution . The method has good selective separation effect on molybdenum and rhenium, simple process flow and low cost, and is especially suitable for separating rhenium and molybdenum in alkaline leaching solutions with low rhenium content and high molybdenum content.

Owner:ZHENGZHOU UNIV

A method for enriching zirconium and titanium from waste acid discharged from zirconium oxychloride production

ActiveCN112921182BRealize enrichment recoveryAchieve reductionProcess efficiency improvementOrganic acidO-Phosphoric Acid

The invention relates to resource comprehensive utilization of waste acid, and specifically discloses a method for enriching zirconium and titanium from waste acid discharged from zirconium oxychloride production. The process of the present invention mainly includes the method of adding organic acid or organic acid salt to waste acid to enrich zirconium and titanium, which can realize the effective separation of zirconium, titanium and other elements such as sodium, iron, aluminum, yttrium and so on in waste acid, and obtain The enriched product can be used as the secondary raw material for extracting zirconium and titanium, which can be directly applied to the existing zirconium oxychloride process, and can also be used for the comprehensive utilization of waste acid resources after solvent extraction to extract scandium. Compared with the reported extraction, phosphate, and phosphoric acid precipitation methods, the present invention has the advantages of simple process and high enrichment rate, and is also conducive to the reduction of subsequent neutralization waste residue.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

A kind of purification method of zinc hydrometallurgy leachate

ActiveCN106191463BRealize enrichment recoveryHigh affinityProcess efficiency improvementSlurryPrecipitation

The invention discloses a method for purifying a zinc hydrometallurgy leaching solution. The method is particularly suitable for a zinc sulfate solution or zinc oxide soot sulfate leaching solution obtained after high acid leaching-jarosite (ammonium alum) process iron removal. The method includes the steps that ferroporphyrin in an oxidation solution or a supplement iron source is used for guaranteeing the ferric iron concentration of the solution at first; then seed crystal-lepidocrocite (gamma-FeOOH) slurry is added into a reaction still; afterwards, a zinc sulfate leaching solution with impurities to be removed is added slowly; and meanwhile, a neutralizer is added, the reaction pH value and temperature are controlled, most of ions of ferric iron, arsenic, germanium, fluorine and the like in the solution or all the ions are precipitated, and obtained precipitation sludge is easy to filter and wash. The technological process is simple, and cost is low. Detrimental impurities (like iron, arsenic, fluorine and germanium) generated in the zinc electroanalysis process can be removed, and meanwhile effective enrichment of the germanium is realized, so that the method is suitable for industrialized application.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

A kind of lead-thallium alloy and its production method

Owner:HULUDAO ZINC IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com