Magnetic ion liquid micro-emulsion extraction agent for treating printing and dyeing wastewater

A magnetic ionic liquid, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, extraction water/sewage treatment, special compound water treatment, etc., to achieve the effect of improving extraction efficiency, broad application prospects, and rapid phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

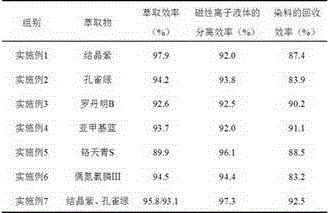

Examples

Embodiment 1

[0023] Components of a magnetic ionic liquid microemulsion type extractant for treating printing and dyeing wastewater and their weight percentages: calculated in weight percentages, the composition includes magnetic ionic liquid benzyl trioctylimidazolium bromide iron trichloride ( [N 888Bn ][FeCl 3 Br]) 26%, crystal violet aqueous solution 3%, the concentration of crystal violet is 2 mg / L, surfactant polyoxyethylene lauryl ether (Brij 30) 40%, co-surfactant ethanol 31%.

[0024] at 20 o Under C temperature conditions, with the stirring speed of 1200 rev / mins, surfactant and co-surfactant were stirred for 20 minutes to obtain a clear and transparent mixture; at 20 o Under the temperature condition of C, add the aqueous dye solution, stir for 5 minutes with a stirring speed of 1200 rpm, and prepare a clear and transparent aqueous solution mixture containing the dye; finally, at 20 o Under the temperature condition of C, the magnetic ionic liquid was added dropwise to the mi...

Embodiment 2

[0027] A magnetic ionic liquid microemulsion type extractant for treating printing and dyeing wastewater and its weight percentage: calculated in weight percentage, its composition includes magnetic ionic liquid trihexyltetradecyl phosphorus tetrachloride ferric salt ([P 66614 ][FeCl 4 ]) 14%, malachite green aqueous solution 15%, the concentration of malachite green is 10 mg / L, surfactant octylphenyl polyoxyethylene ether (TX-100) 40%, co-surfactant isopropanol 31% .

[0028] at 100 o Under the temperature condition of C, with the stirring speed of 300 rev / min, surfactant and co-surfactant were stirred for 10 minutes to obtain a clear and transparent mixture; at 100 o Under the temperature condition of C, add the aqueous dye solution, stir for 10 minutes at a stirring speed of 300 rpm, and prepare a clear and transparent aqueous dye-containing mixture; finally, at 100 oUnder the temperature condition of C, the magnetic ionic liquid was added dropwise to the mixture contain...

Embodiment 3

[0031] A magnetic ionic liquid microemulsion type extractant for treating printing and dyeing wastewater and its weight percentage: calculated by weight percentage, its composition includes magnetic ionic liquid methoxybenzyl trioctyl imidazolium bromide trichloride Iron salt ([N 888MBn ][FeCl 3 Br]) 19%, rhodamine B aqueous solution 15%, wherein the concentration of rhodamine B is 24 mg / L, surfactant bis(2-ethylhexyl) succinate sodium sulfonate (AOT) 35%, surface aid Active agent n-butanol 31%.

[0032] at 60 o Under C temperature conditions, with the stirring speed of 750 revs / min, surfactant and co-surfactant were stirred for 5 minutes to obtain a clear and transparent mixture; at 60 o Under the temperature condition of C, add the aqueous dye solution, stir for 5 minutes with a stirring speed of 750 rev / min, and prepare a clear and transparent mixture containing the aqueous dye solution; finally at 60 o Under the temperature condition of C, the magnetic ionic liquid was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com