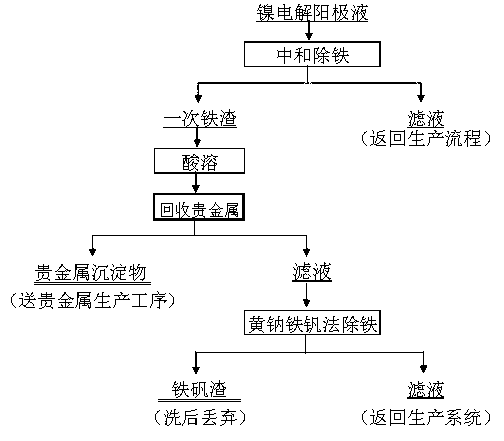

Method for recovering platinum group metal from ferrous nickel electrolysis anolyte

A technology of platinum group metals and anolyte, applied in the direction of improving process efficiency, etc., can solve the problem of difficult recovery of precious metals, achieve the effects of reducing the content of precious metals, wide application range of the process, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Containing Ni68g / L, Cu0.23g / L, Co0.31g / L, Fe0.7g / L and a small amount of platinum group metals, the pH of the nickel electrolysis anolyte of 1.0 and the primary iron slag slurry obtained after iron removal and filtration are as follows Ni13.52%, Cu8.76%, Fe10.45%, platinum group metals total 8.58g / t. Based on the weight of the primary iron slag slurry, add sulfuric acid 100kg / t, acid dissolve the primary iron slag slurry at 30°C for 10 minutes, control the pH at the end point of acid dissolution between 1.0 and 2.0, then add sodium sulfide, add Amount of 8.0kg / t (based on the weight of primary iron slag ore slurry), react at 30°C for 30 minutes, and then use a filter medium with a pore size of 0.5 to 10 microns for precision filtration; the obtained filter residue has a platinum, palladium, and gold content of 123 g / t , enriched by 15 times, the precious metal yield was 97.6%, and the precious metal content of the jarosite slag obtained by removing iron from the filtrat...

Embodiment 2

[0018] Containing Ni63g / L, Cu0.18g / L, Co0.24g / L, Fe0.5g / L and a small amount of platinum group metals, the nickel electrolysis anolyte with a pH of 1.2 and the primary iron slag slurry obtained after iron removal and filtration are as follows: Ni16.11%, Cu9.35%, Fe8.78%, platinum group metals total 7.89g / t. Based on the weight of the primary iron slag slurry, add sulfuric acid 95kg / t, acid-dissolve the primary iron slag slurry at 20°C for 15 minutes, and control the pH at the end point of acid dissolution between 1.0 and 2.0, then add ammonium sulfide, add Amount of 4kg / t (based on the weight of primary iron slag ore slurry), reacted at 40°C for 180min, and then used a filter medium with a pore size of 0.5 to 10 microns for precision filtration; the obtained filter residue had a platinum, palladium, and gold content of 118 g / t. The enrichment was 15 times, the yield of precious metal was 98.1%, and the precious metal content of jarosite slag obtained by removing iron from the ...

Embodiment 3

[0020] Containing Ni73g / L, Cu0.35g / L, Co0.27g / L, Fe0.48g / L and a small amount of platinum group metals, the nickel electrolysis anolyte with a pH of 1.0 and the primary iron slag slurry obtained after iron removal and filtration are as follows Ni10.67%, Cu8.68%, Fe13.01%, platinum group metals total 10.37g / t. Based on the weight of the primary iron slag slurry, add sulfuric acid 108kg / t, acid-dissolve the primary iron slag slurry at 40°C for 20 minutes, and control the pH at the end point of acid dissolution between 1.0 and 2.0, then add sodium sulfide, add Amount of 12kg / t (based on the weight of primary iron slag ore slurry), after reacting at 50°C for 60 minutes, use a filter medium with a pore size of 0.5 to 10 microns for precision filtration; the obtained filter residue has a platinum palladium content of 138g / t, rich in The concentration is 13.3 times, the precious metal yield is 96.11%, and the precious metal content of the jarosite slag obtained by removing iron from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com