Carbon nitride quantum dot/oxide nano fiber composite photocatalytic material and preparation method thereof

A technology of composite photocatalysis and nanofibers, which is applied in the field of preparation of composite photocatalytic materials, can solve the problems of uneven distribution of quantum dots, long time-consuming mechanical mixing method, poor dispersion of quantum dots, etc., and achieves simple and easy method and uniform composite The effect of improved efficiency and low cost of sex and compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

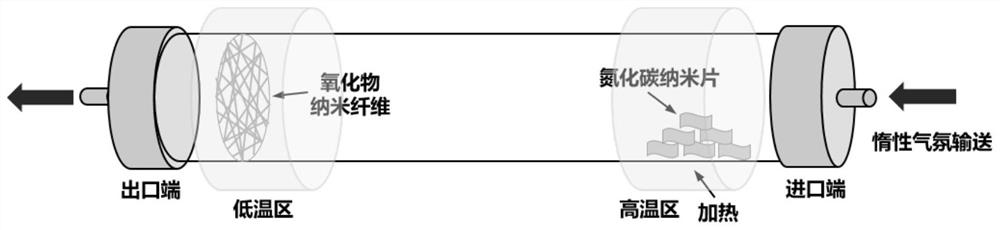

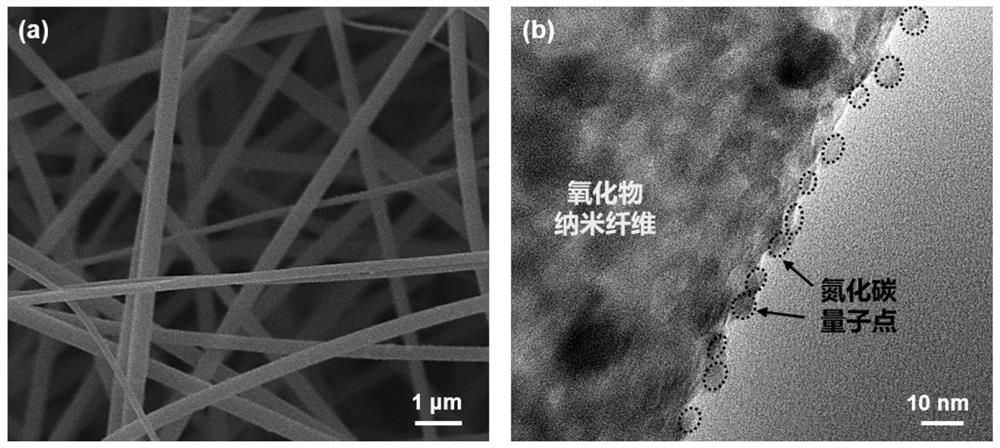

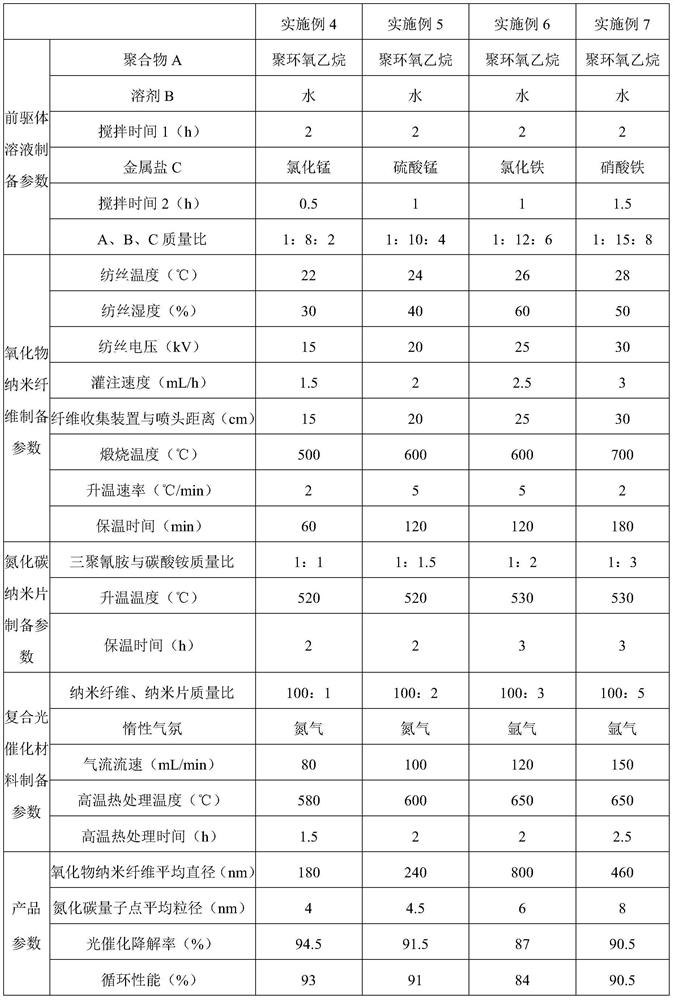

[0045]Preparation method of a carbon nitride quantum dot / oxide nanofiber composite photocatalytic material of the present invention, including the following steps:

[0046](1) Preparation of precursor solution

[0047]After mixing the polymer and the solvent was stirred for 1 to 6 h (e.g., 1H, 2H, 3H, 4H, 5H, 6H), and then slowly added a metal salt, stirring was continuously stirred at room temperature or ice water bath (for example, 0.5h, 1H, 1.5H, 2H), where the mass ratio of the polymer, solvent and the metal salt is 1: (5 ~ 20): (, 1 to 10) (for example, 1: 5: 1, 1: 20: 10, 1: 12: 5, 1: 8: 2, 1: 10: 4, 1: 12: 6), polymers are polyvinylpyrrolidone, polyacrylonitrile, polyvinyl butyral, polyethylene oxide, polystyrene At least one of the medium, the solvent is water, ethanol, acetic acid, acetone, N, N-dimethylformamide; metal salt is isopropyl titanate, tetrabutyl titanate, titanium tetrachloride , Manganese chloride, manganese sulfate, iron chloride, iron nitrate, cobalt chloride, c...

Embodiment 1

[0059]The method of preparing the carbon nitride quantum dot / oxide nanofiber composite photocatalytic material of the present embodiment includes the following steps:

[0060](1) Preparation of precursor solution

[0061]The polymer polyvinylpyrrolidone was mixed with the solvent ethanol for 1 h, then the metal saline titanate was slowly added, and the precursor solution was stirred for 0.5 h, wherein the mass ratio of the polymer, solvent, and metal salt is 1: 5: 1;

[0062](2) Preparation of oxide nanofibers

[0063]The precursor solution was prepared by electrostatic spinning, followed by calcination under the air atmosphere, to obtain oxide nanofibers, wherein the conditions of electrostatic spinning are: temperature 20 ° C, relative humidity is 20%, The spinning voltage is 50 kV, the perfusion speed is 10 ml / h, the fiber collecting device and the nozzle distance are 40 cm, and the conditions of calcination are: calcination temperature is 0.5 ° C / min, the temperature is 300 min;

[0064]...

Embodiment 2

[0074](1) Preparation of precursor solution

[0075]The polymer polypropylene nitrile was mixed with solvent N, N-dimethylformamide was mixed after 6 h, and then the tetrabutyl titanate titanate was slowly added, and the agitate for 2 h. The precursor solution was continuously stirred, wherein the polymer, solvent, metal The mass ratio of the salt is 1:20:10;

[0076](2) Preparation of oxide nanofibers

[0077]The above precursor solution was prepared by electrostatic spinning, followed by calcination under the air atmosphere, to obtain oxide nanofibers, wherein the conditions of electrostatic spinning: temperature 30 ° C, relative humidity of 70%, The spinning voltage is 10 kV, the perfusion speed is 0.1 ml / h, the fiber collecting device and the nozzle distance are 10 cm; the calcination conditions are: calcination temperature 1000 ° C, the temperature of the temperature is 10 ° C / min, the holding time is 10 min;

[0078](3) Preparation of a carbon nitride nanoflake

[0079]The mixture was mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com