Method and device for scarifying soil and picking up plastic film residues sequentially in tobacco field

A residual film, loosening technology, applied in shovels, plows, collectors, etc., can solve the problems of difficult degradation, difficult work, low pick-up rate, etc., and achieve the effect of simple device structure, ideal use effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a limitation to the present invention.

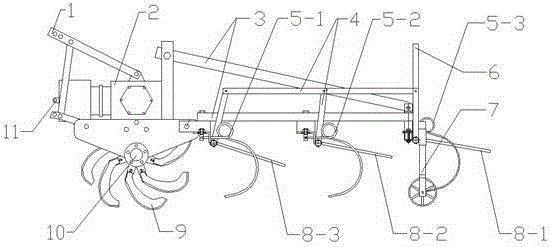

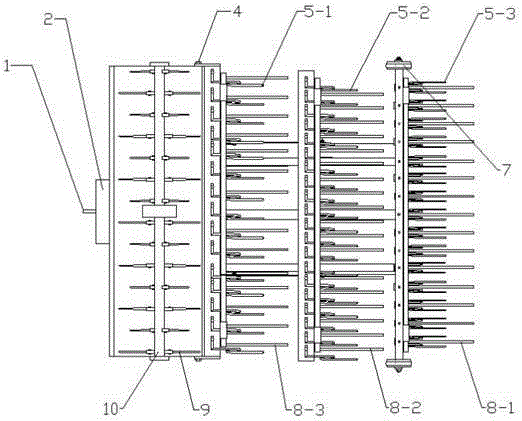

[0013] Embodiments of the present invention: the method of picking up residual film after loosening the ground first in the tobacco field, utilizing the tractor's power traction loosening device to make the loosening device loosen the soil with a depth of 10-15 cm in the tobacco ground, and remove the soil in the soil The residual film is turned over to the surface, and the residual film is picked up by the film picking mechanism, and the picked up residual film is sent to the designated place for cleaning, which realizes the picking and recycling of the residual film.

[0014] The device for picking up the residual film after first loosening the ground includes a suspension frame 1, a soil loosening device 10 is connected to the suspension frame 1, and a soil loosening knife 9 is arranged at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com