Patents

Literature

112results about How to "Low precious metal content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

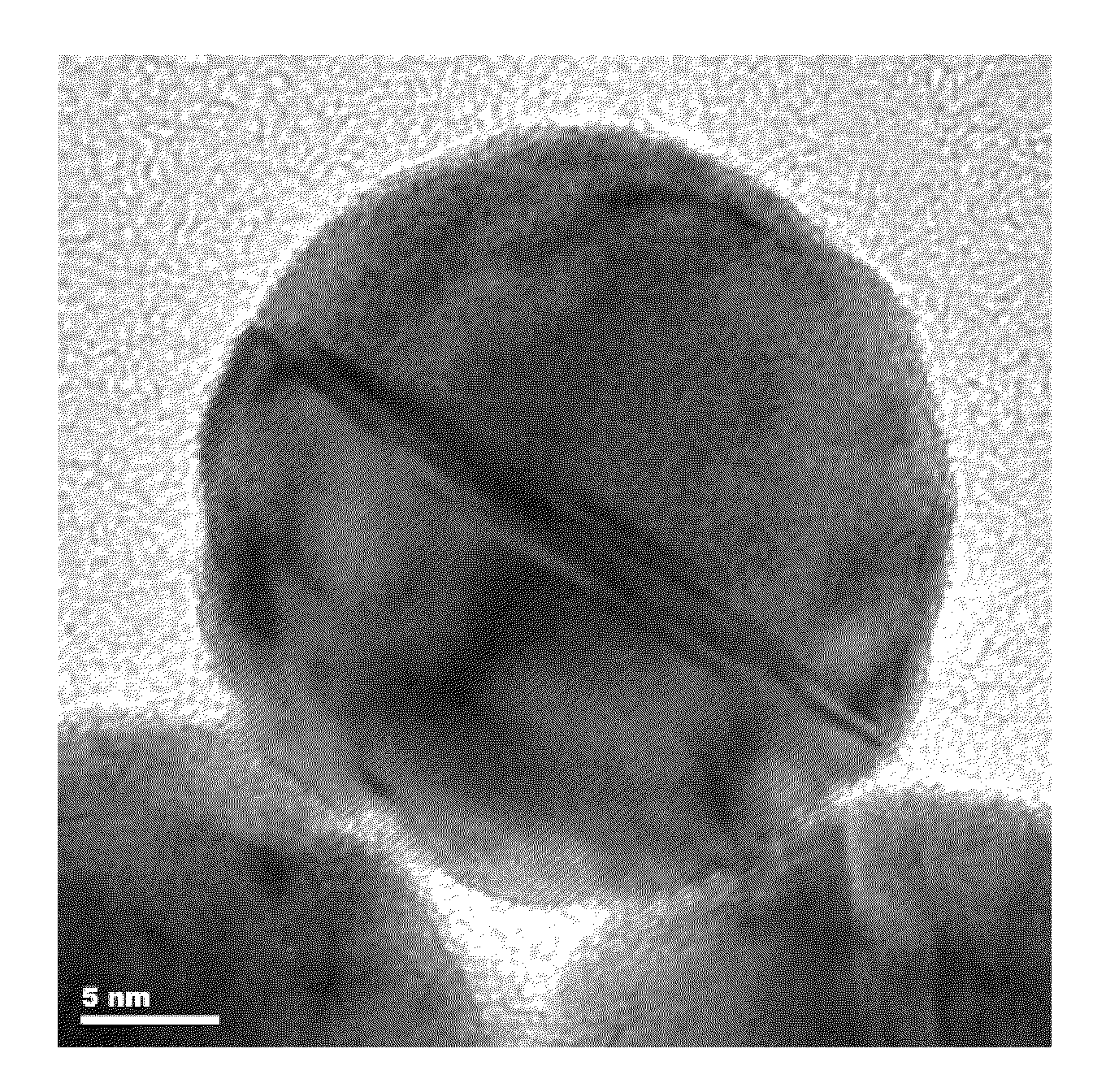

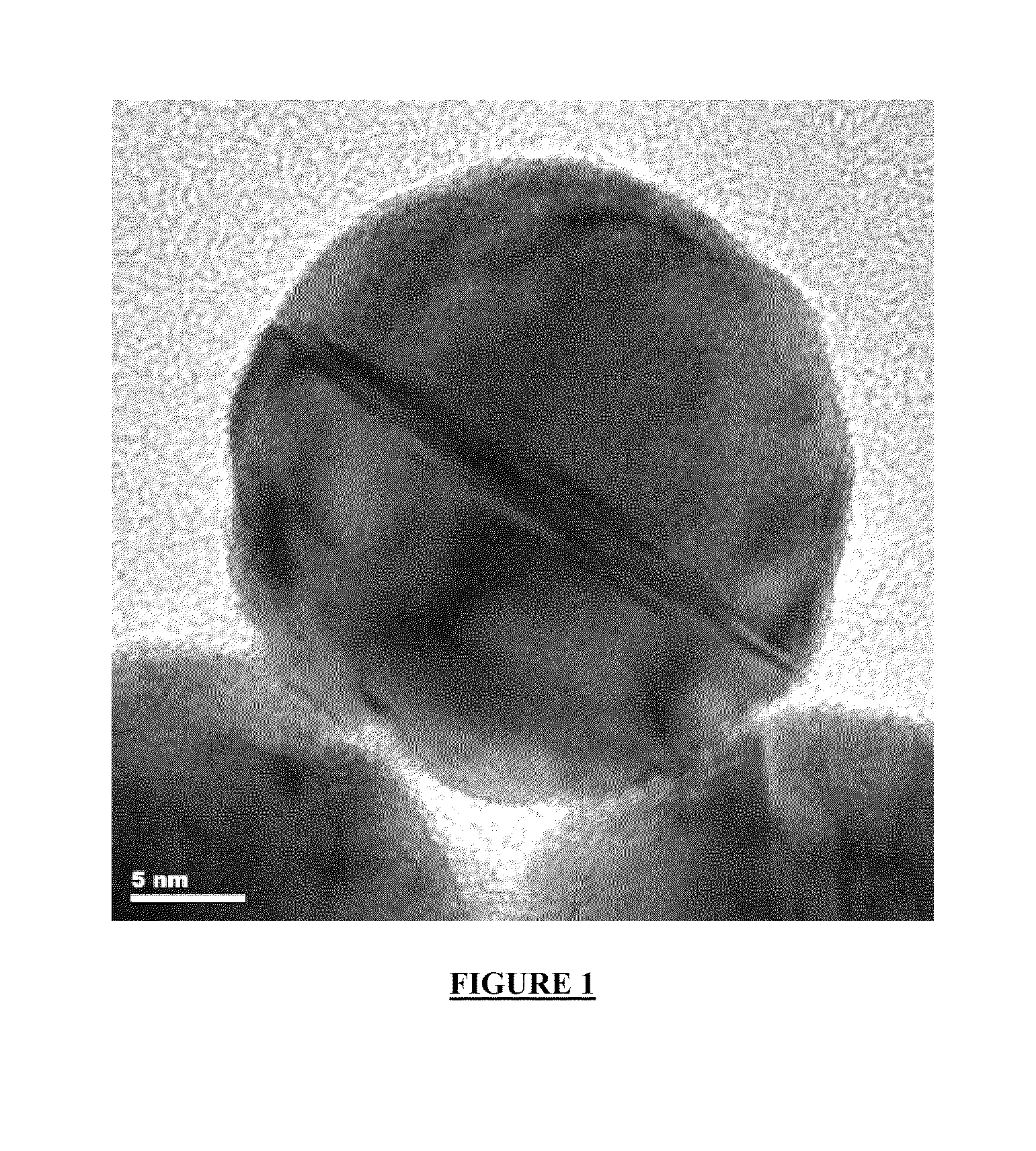

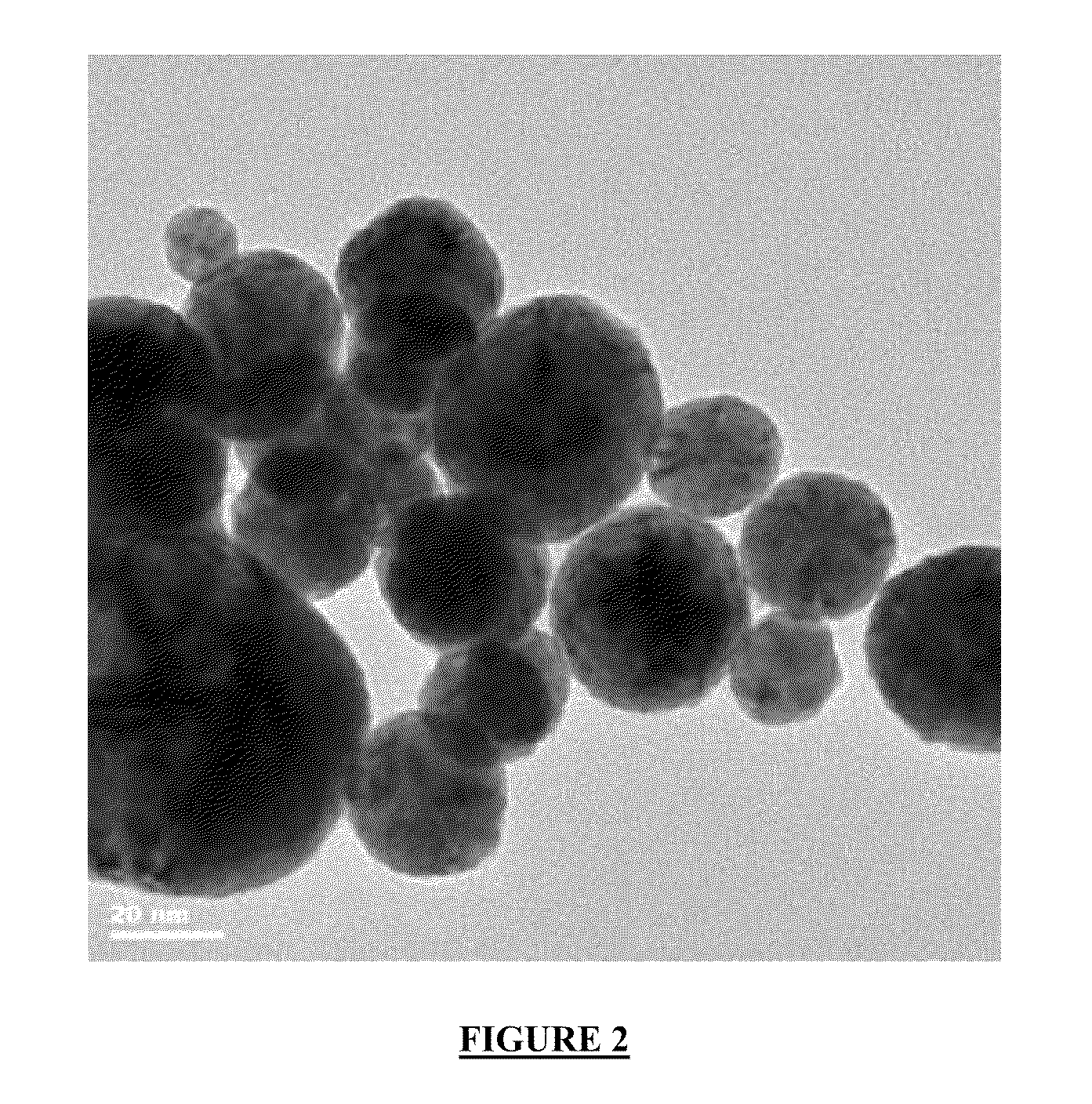

Core / shell-type catalyst particles comprising metal or ceramic core materials and methods for their preparation

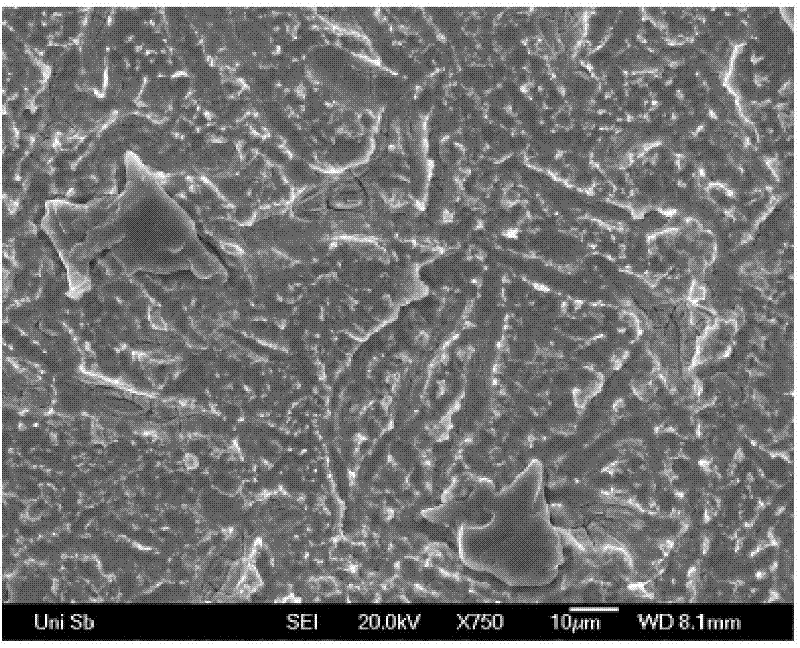

ActiveUS20100092841A1High specific activityLow precious metal contentMaterial nanotechnologyCell electrodesFuel cellsAlloy

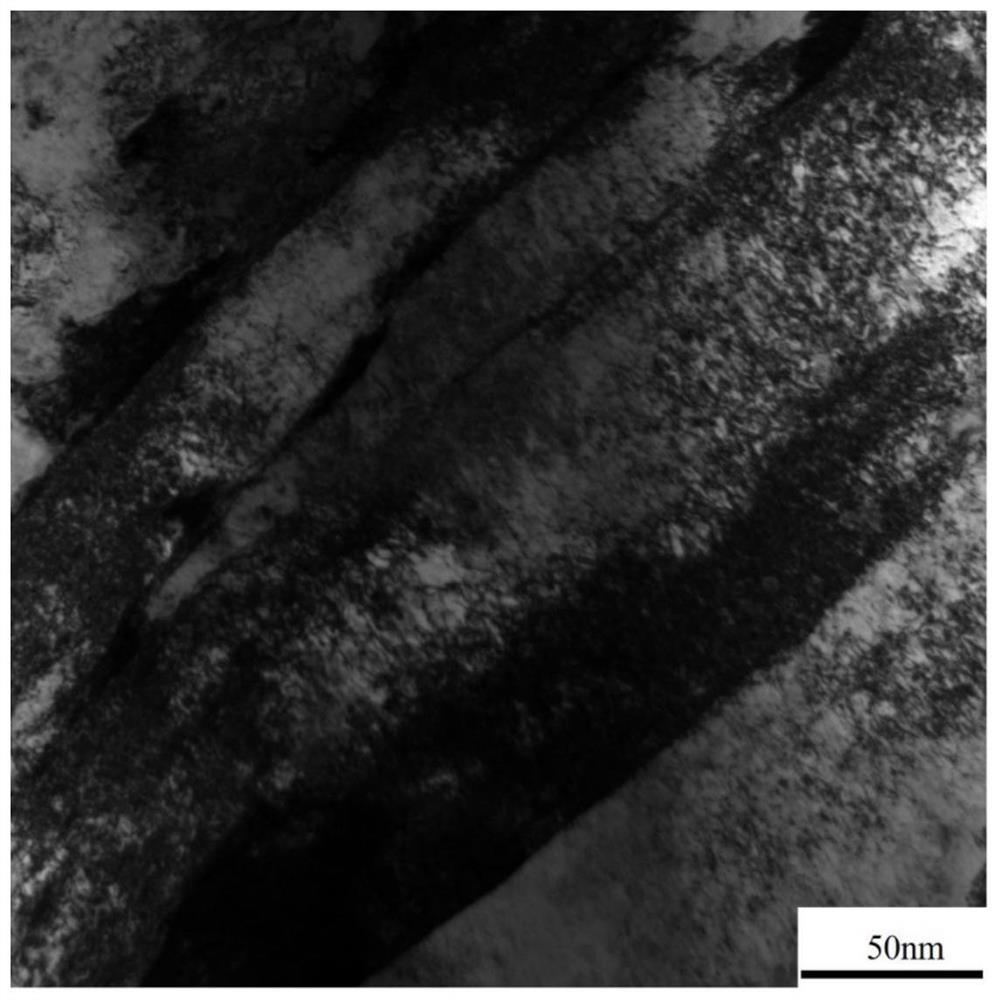

The invention is directed to core / shell type catalyst particles comprising a Mcore / Mshell structure with Mcore=inner particle core and Mshell=outer particle shell, wherein the medium diameter of the catalyst particle (dcore+shell) is in the range of 20 to 100 nm, 5 preferably in the range of 20 to 50 nm. The thickness of the outer shell (tshell) is about 5 to 20% of the diamet the inner particle core of said catalyst particle, preferably comprising at least 3 atomic layers. The inner particle core (Mcore) of the particles comprises metal or ceramic materials, whereas the material of the outer shell (Mshell) comprises precious metals and / or alloys thereof. The core / shell type catalyst particles are preferably supported on suitable support materials such as carbon black and can be used as electrocatalysts for fuel cells and for other catalytic applications.

Owner:UMICORE AG & CO KG

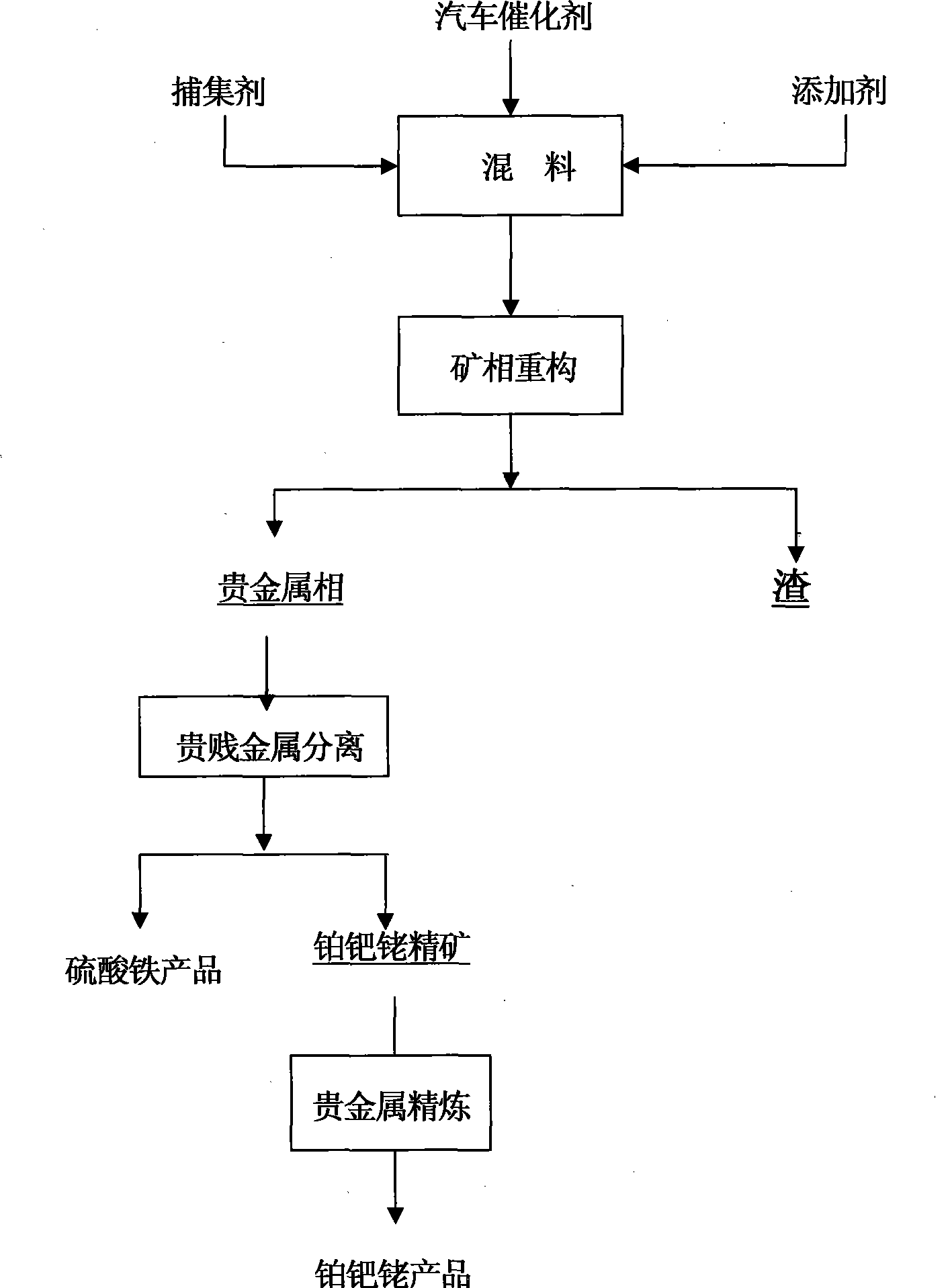

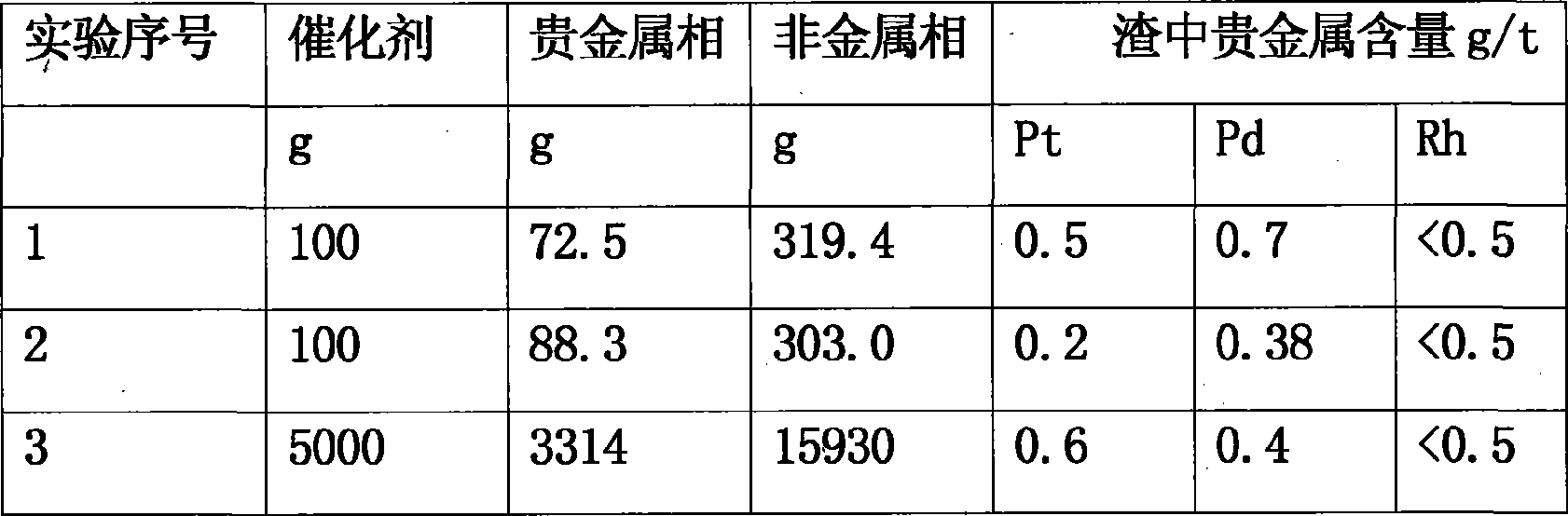

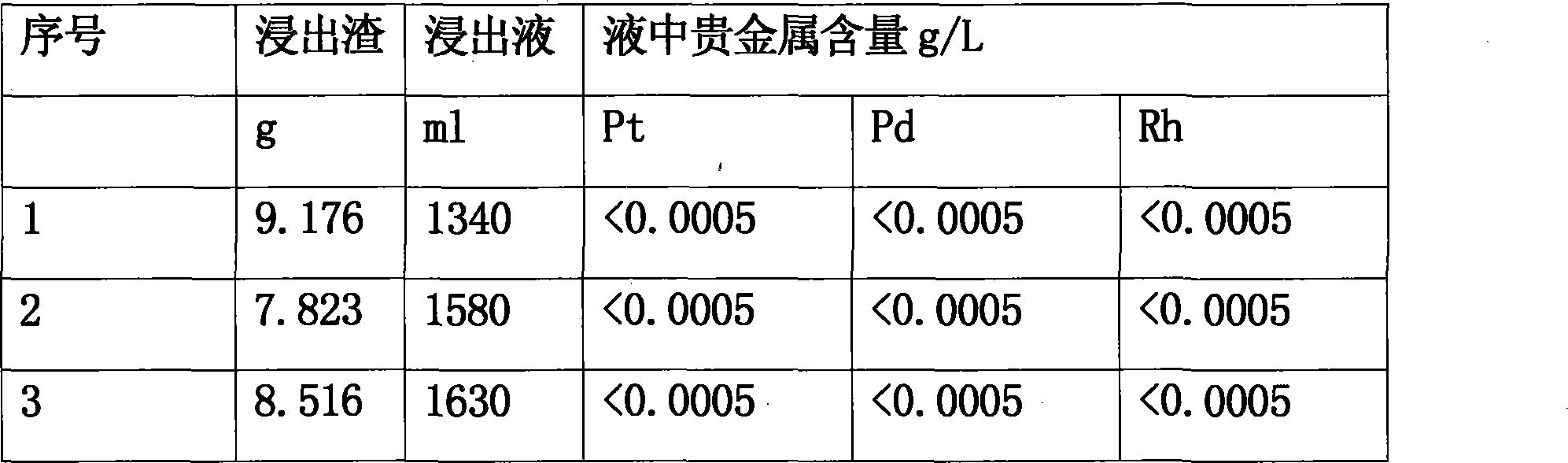

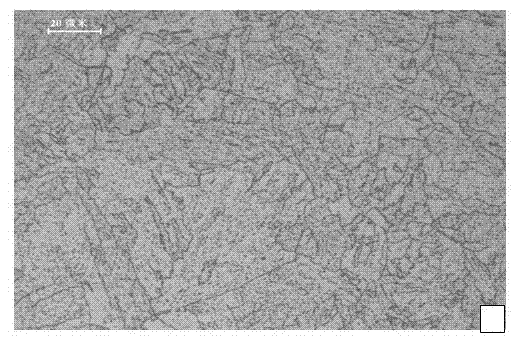

Method for extracting platinum, palladium, rhodium from automotive catalyst of ore phase reconstruction

InactiveCN101509077AEfficient captureReduce corrosionProcess efficiency improvementElectric arc furnaceSlag

The invention relates to a method for recovering noble metals from spent automotive exhaust catalysts, comprising the following processes: 1. mixing the spent automotive exhaust catalyst with a reducing agent, an additive and a trapping agent; 2. putting the mixed materials into a clay graphite crucible, and putting the clay graphite crucible into an electric furnace or an electric arc furnace for smelting, thus obtaining a noble metal phase; 3. selectively leaching base metals from the noble metal phase, thus obtaining the enrichment of the noble metal, refining the enrichment of the noble metal to produce platinum, palladium and rhodium products. The method is characterized by simple process flow and high recovery rates of noble metals. The platinum, palladium and rhodium in the waste slag are less than 1g / t and the product purity is 99.95%.

Owner:KUNMING INST OF PRECIOUS METALS

Superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and manufacture method thereof

The invention relates to a superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and a manufacture method thereof, and belongs to the technical field of ferrous metallurgy. A technical scheme is as below: the steel plate comprises the following components by weight: no more than 0.15% of C, no more than 0.10% of Si, 0.300.60% of Mn, no more than 0.007% of P, no more than 0.005% of S, 2.00-2.50% Cr, 0.90-1.10% of Mo, no more than 0.02% of Nb, no more than 0.20% of Cu, no more than 0.20% of Ni, no more than 0.003% of Sb, no more than 0.005% of Sn, no more than 0.016% of As, no more than 0.003% of O, N no more than 0.008%, no more than 0.0002% of H, no more than 0.03 of Ti and the balance of Fe and unavoidable impurities; a round steel ingot with piece weight of 80 tons is produced by electric arc furnace smelting and casting; and the steel ingot is subjected to forging cogging, rolling and a heat treatment process including normalizing, accelerated cooling and tempering to prepare the superlarge thickness chromium molybdenum steel plate with a maximum thickness of 256mm for hydrogenation equipment. A finished steel plate has maximum single weight reaching 60 tons, good cold bending property, no cracking during material manufacture and good resilience. The method provided by the invention reduces labor intensity, saves time and improves the utilization rate of materials.

Owner:WUYANG IRON & STEEL +1

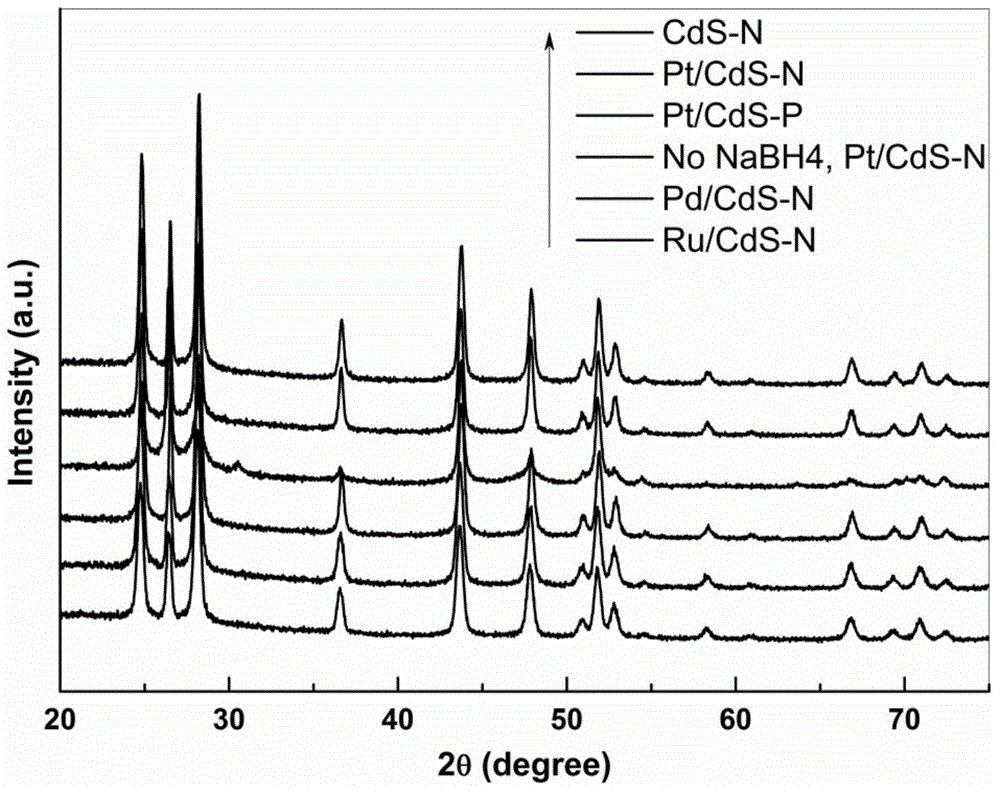

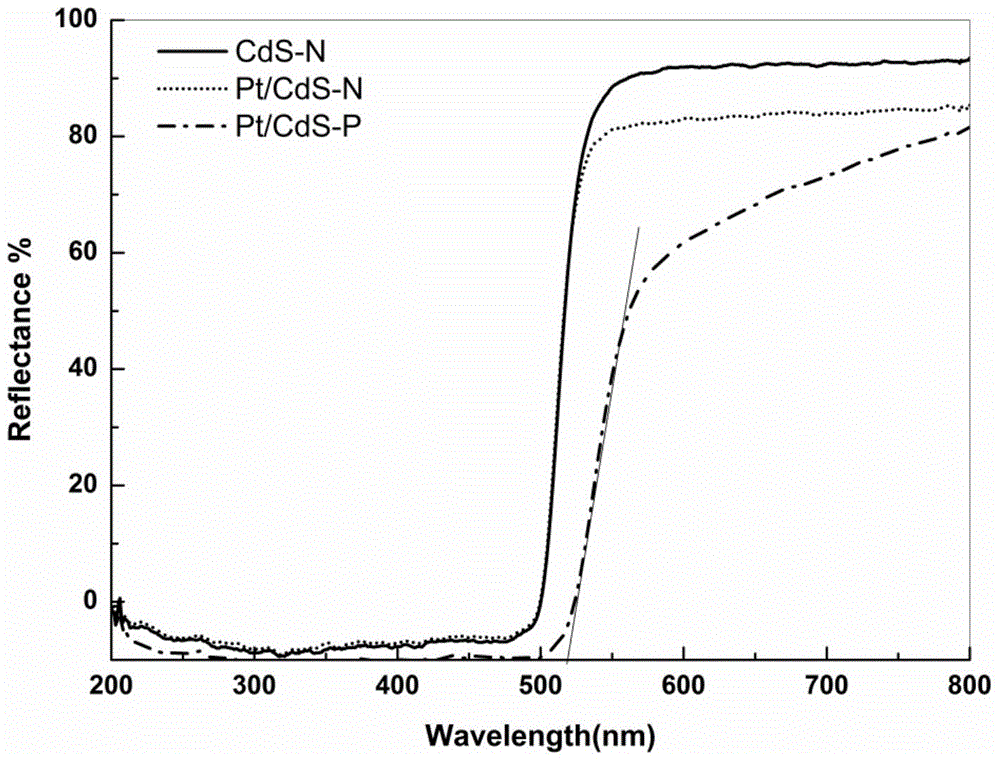

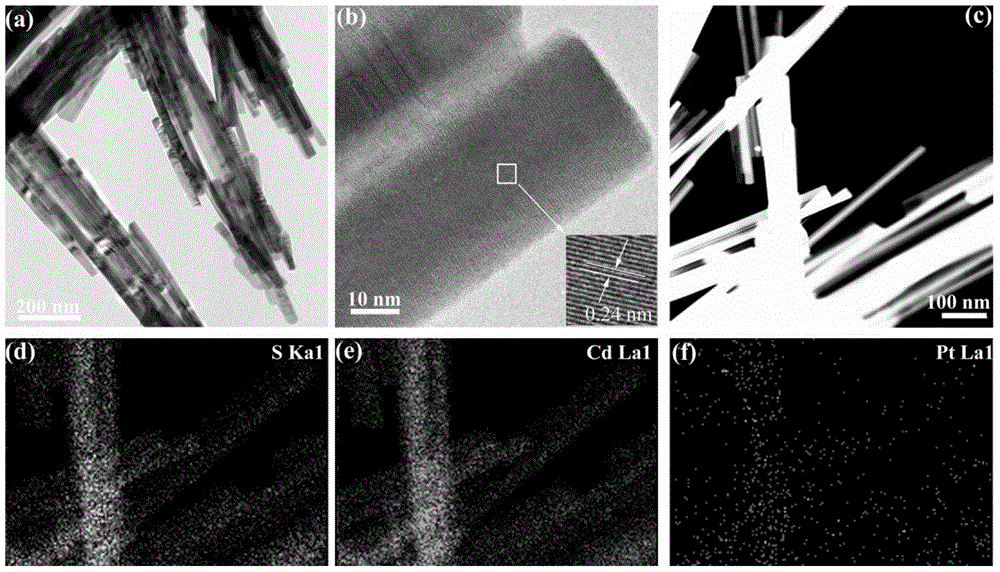

Preparation method and application of precious metal-modified CdS nanorod photocatalyst

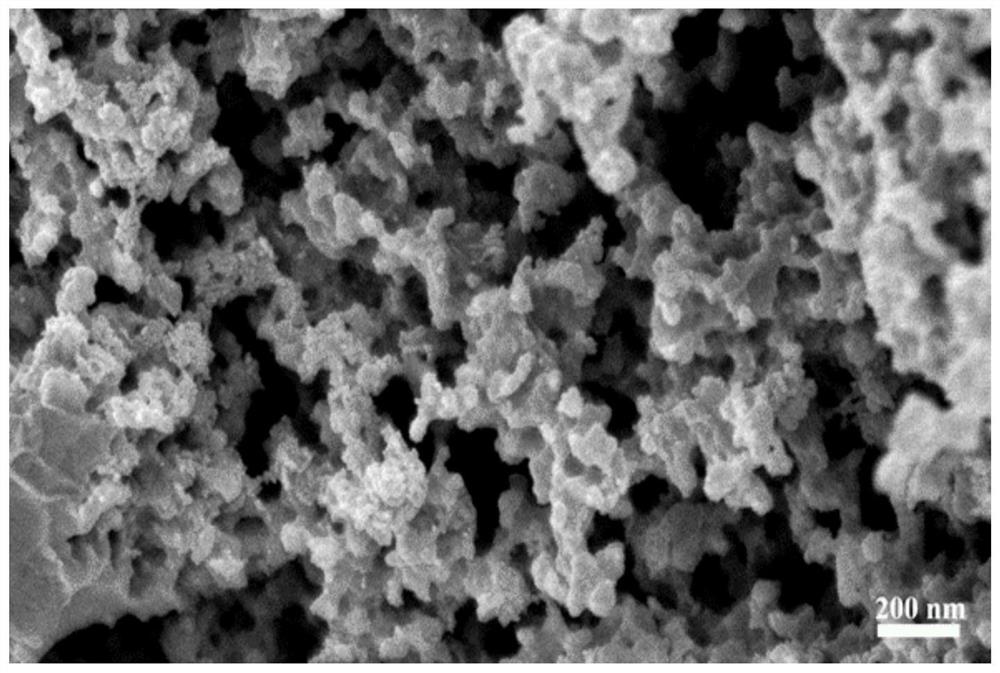

ActiveCN104923264ANo reunionEfficient and stable decompositionPhysical/chemical process catalystsHydrogen productionHydrogenPhotochemistry

The invention discloses a preparation method and an application of a precious metal-modified CdS nanorod photocatalyst. The photocatalyst consists of precious metal (Pt, Pd or Ru) and nanorod-shaped CdS, and the formation of nanorod-shaped CdS and the depositional modification of precious metal are implemented by a one-pot solvothermal method. The photocatalyst disclosed by the invention has a nanorod-shaped morphology, and can show high-efficient, stable activity in producing hydrogen by decomposing water under visible light when the precious metal content is only 0.06wt.percent. The catalyst preparation process is simple, the required precious metal content is far lower than the precious metal contents of reported products, the catalyst cost is greatly reduced, and the obtained sample has high-efficient, stable activity in producing hydrogen by decomposing water under visible light.

Owner:HUAIBEI NORMAL UNIVERSITY

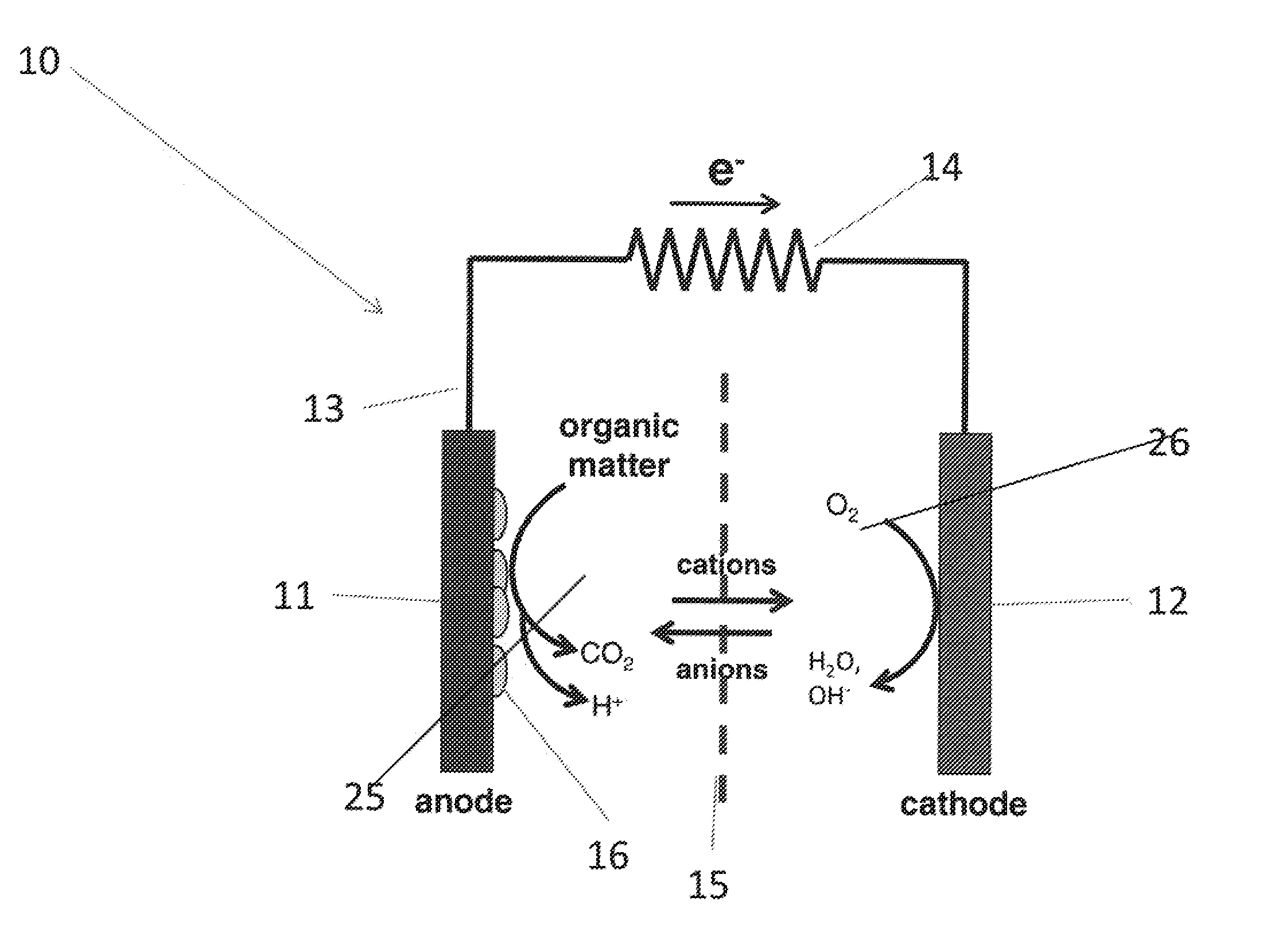

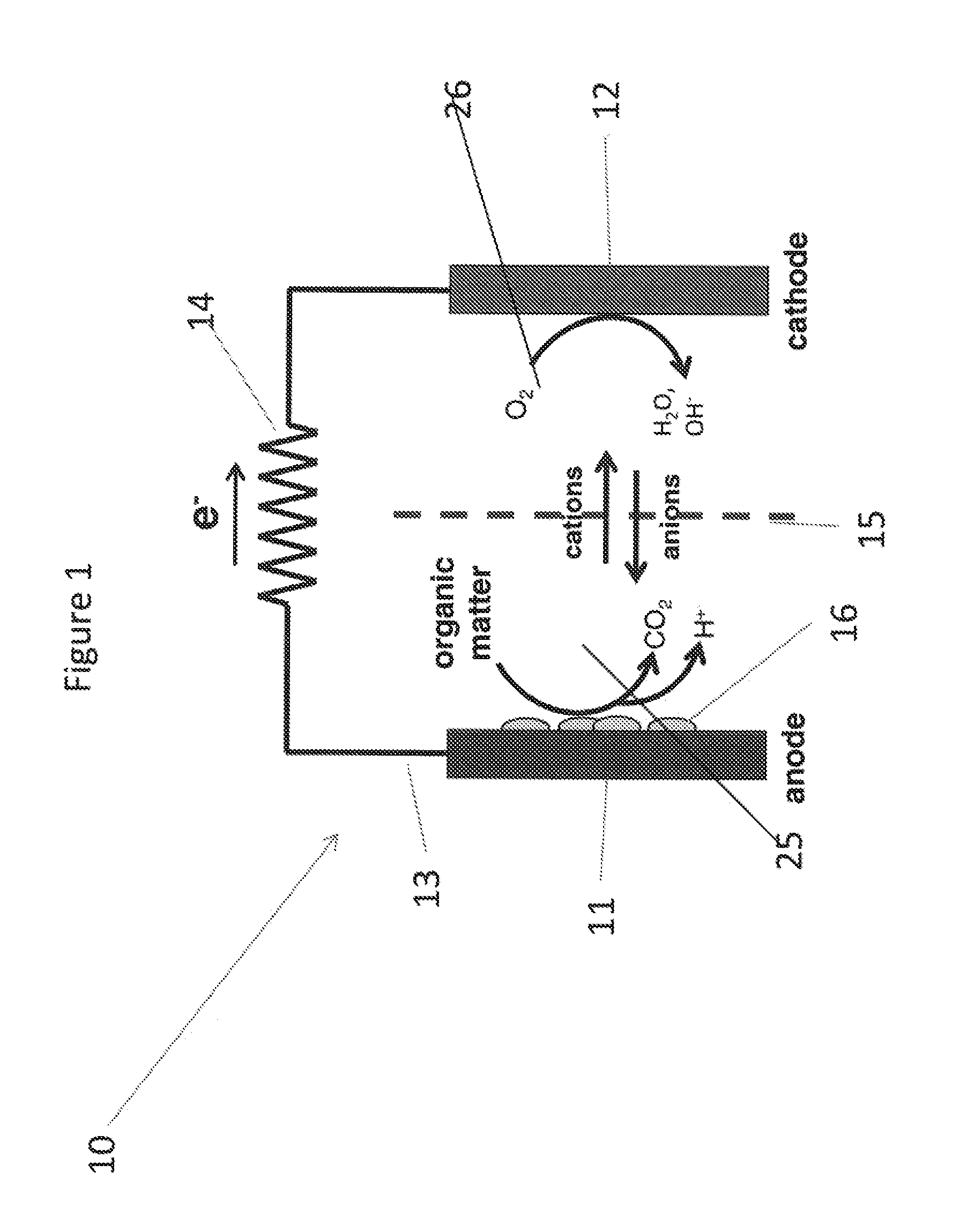

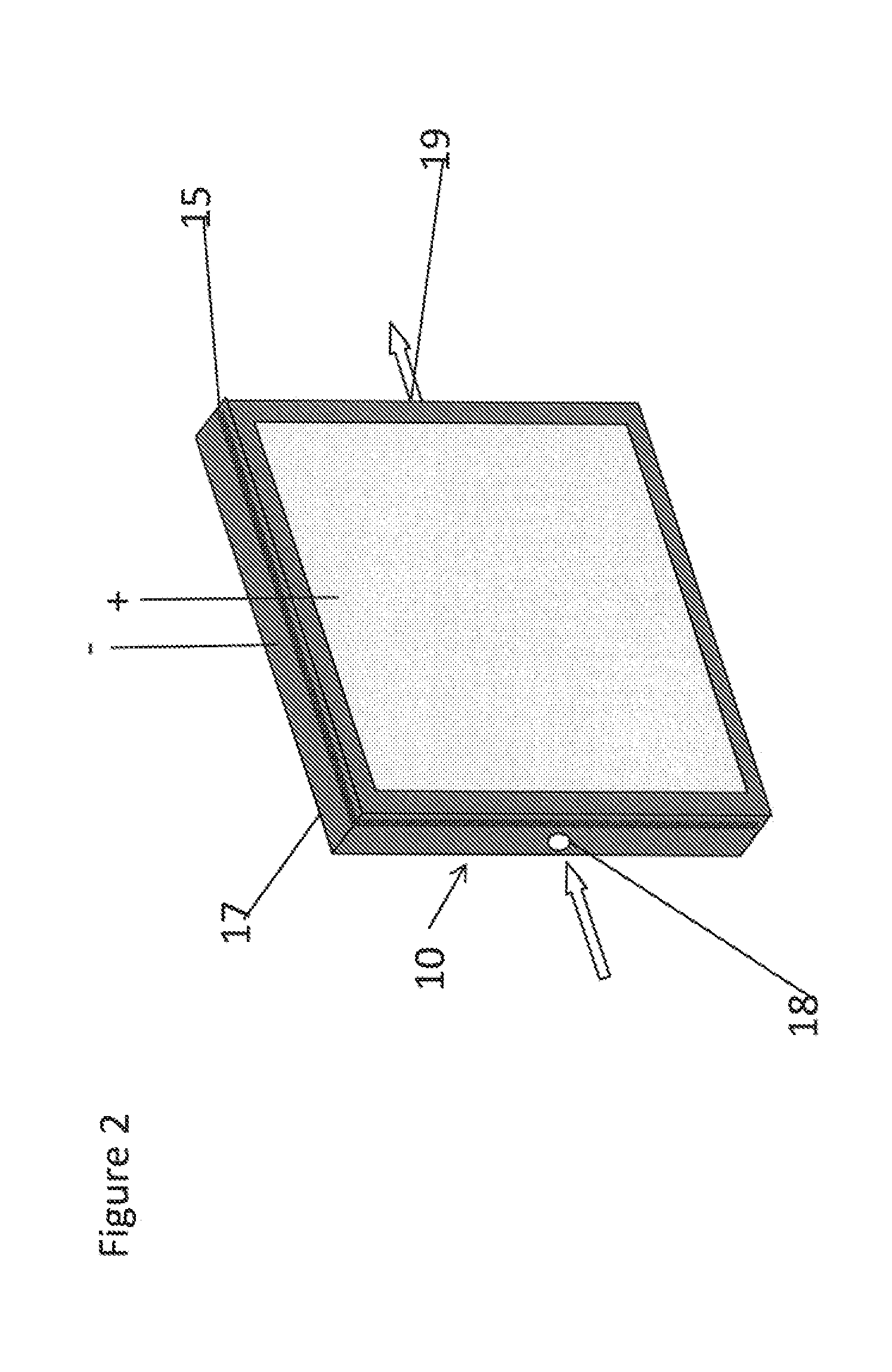

Electrolyte Enhanced Microbial Fuel Cell

InactiveUS20120321966A1Easy to useEfficient energy productionBiochemical fuel cellsMicrobial fuel cellElectricity

The present invention relates to a process comprising A) providing a microbial fuel cell comprising i) an anode containing one or more electrically conductive materials which is arranged to provide flow paths for electrons through the electrically conductive material, ii) microbes in electrical contact with the anode iii) a cathode containing one or more electrically conductive materials iv) a catholyte, v) a conduit for electrons in contact with both the anode and the cathode which is a part of a circuit; B) introducing a mixture of one or more electrolytes or one or more electrolytes dissolved in a first fluid with a second fluid containing biodegradable material; C) contacting the mixture of B) with the anode in the presence of microbes; D) contacting the cathode with a catholyte; E) removing from the microbial fuel cell the fluid mixture.

Owner:DOW GLOBAL TECH LLC

Catalyst for treating organic wastewater and preparation method thereof

InactiveCN102101053AHigh activityHigh removal rateMetal/metal-oxides/metal-hydroxide catalystsChemical oxygen demandRuthenium

The invention discloses a catalyst for treating organic wastewater and a preparation method thereof. The catalyst is a metal carbonyl loaded catalyst, a precursor of the catalyst is one or a combination of ruthenium carbonyl and cobalt carbonyl, a second component Ce or Fe is added at the same time, and a carrier of the catalyst is selected from one or a compound oxide of active carbon, gamma-Al2O3 and TiO2. The catalyst can be used for oxidizing and degrading different organic matters with various concentrations in water under a milder condition so as to greatly reduce COD (Chemical Oxygen Demand) in wastewater and improve the removal efficiency of the COD in the wastewater.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

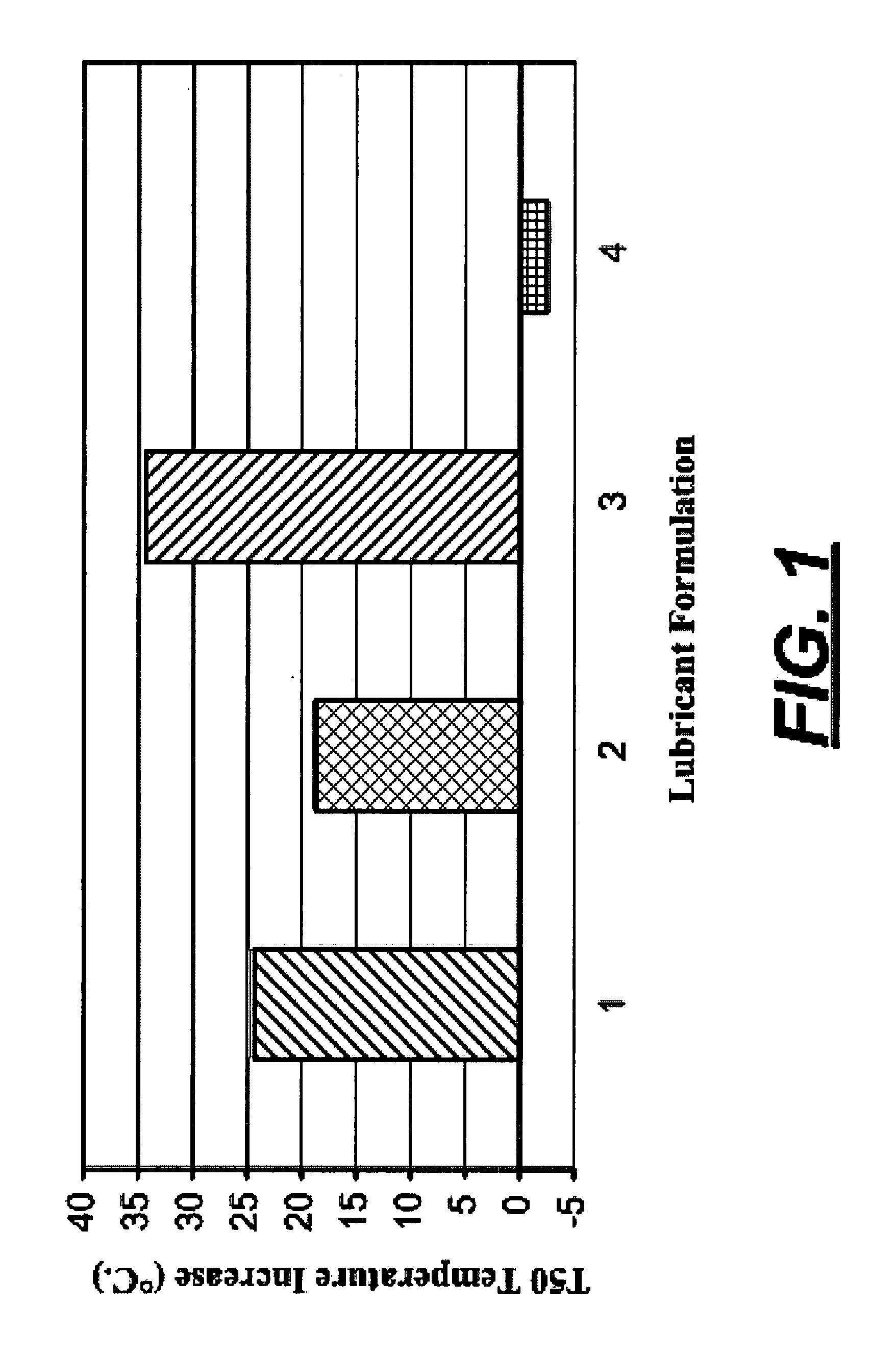

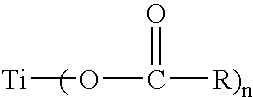

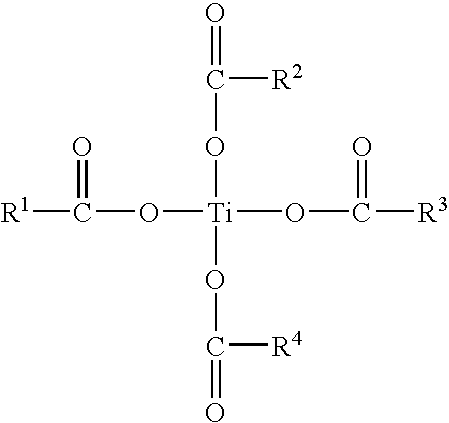

Additives and lubricant formulations for improved catalyst performance

ActiveUS20080280796A1Low of oxidationLow level of wearLiquid carbonaceous fuelsMachines/enginesTitaniumBase oil

A method and compositions for lubricating surfaces with lubricating oils exhibiting increased phosphorous retention. The lubricated surface includes a lubricant composition containing a base oil of lubricating viscosity, an amount of a phosphorus-containing compound and an amount of at least one hydrocarbon soluble titanium compound that is effective to provide an aged catalyst temperature that converts at least fifty percent of exhaust gas hydrocarbons, carbon monoxide, and NOx that is lower than an aged catalyst temperature that converts at least fifty percent of exhaust gas hydrocarbons, carbon monoxide, and NOx of the lubricant composition devoid of the hydrocarbon soluble titanium compound.

Owner:AFTON CHEMICAL

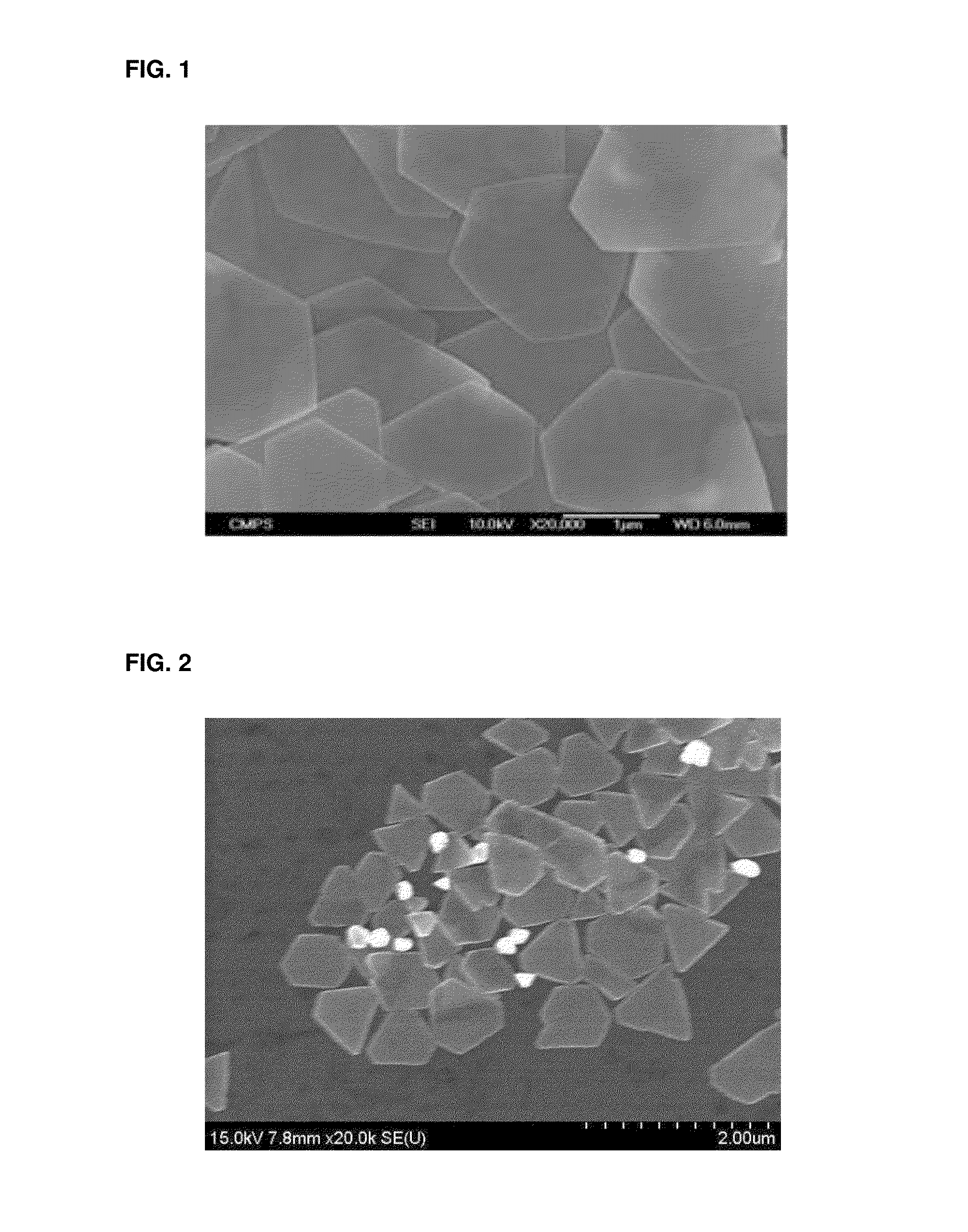

Metal nanoplate, a method for preparing the same, a conductive ink composition, and a conductive film comprising the same

ActiveUS20160137865A1Excellent conductivityExcellent activityTransportation and packagingConductive materialHigh pressureSemiconductor components

The present invention relates to a metal nanoplate, a method for manufacturing same, and a conductive ink composition and a conductive film comprising metal nanoplate. The metal nanoplate does not require application of a high temperature and high pressure and thus can be easily manufactured at a low temperature and at normal pressure, and a conductive film or a conductive pattern, among others, having excellent conductivity can be formed even when the conductive ink composition comprising the metal nanoplate is printed on a substrate and then heat-treated or dried at a low temperature. As a result, the metal nanoplate and the conductive ink composition comprising same can be very appropriately applied to various semiconductor elements, display devices, or when forming a conductive pattern or a conductive film for a solar cell in an environment requiring low-temperature firing.

Owner:LG CHEM LTD

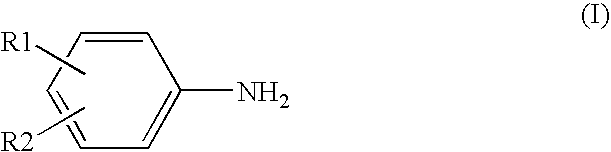

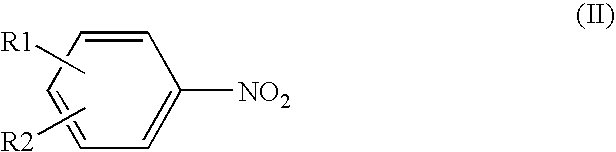

Process for producing aromatic amines

ActiveUS20080234518A1Long cycleHigh selectivityOrganic compound preparationAmino compound preparationHydrogenGas phase

Aromatic amines are produced by adiabatic hydrogenation of nitroaromatic compounds in the gas phase on one or more fixed catalysts. The nitroaromatic reactant is passed over the catalyst under pressure and at elevated temperature with hydrogen, water, optionally nitrogen and substantially in the absence of the aromatic amine produced from the nitroaromatic.

Owner:COVESTRO DEUTSCHLAND AG

Method for preparing toluene catalytic combustion monolithic catalysts and application

InactiveCN105688904AReduce the temperatureImprove catalytic oxidation performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystPhysical chemistry

The invention provides a method for preparing toluene catalytic combustion monolithic catalysts and application. The toluene catalytic combustion monolithic catalysts are Pd-based catalysts, a carrier for the toluene catalytic combustion monolithic catalysts is CeO2-Pr6O11 / Al2O3, CeO2-Pr6O11 mixed oxide with different Ce / Pr molar ratios is researched, accordingly, the optimal Ce / Pr proportions of the CeO2-Pr6O11 mixed oxide with the highest activity are found, and the toluene catalytic combustion monolithic catalysts are optimal in toluene catalytic oxidation activity when the Ce / Pr proportions are equal to 4:1. The method and the application have the advantages of excellent catalytic performance, low precious-metal content, good thermal stability and uniform coating.

Owner:NINGBO YUANXIANG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Core/shell-type catalyst particles and methods for their preparation

ActiveUS8288308B2High specific activityLow precious metal contentSynthetic resin layered productsCellulosic plastic layered productsFuel cellsHigh specific activity

The invention discloses core / shell type catalyst particles comprising a Mcore / Mshell structure with Mcore=inner particle core and Mshell−outer particle shell, wherein the medium diameter of the catalyst particle (dcore+shell) is ≧20 nm. The thickness of the outer shell (tshell) comprises at least 3 atomic layers. The core / shell type catalyst particles, particularly the particles comprising a Pt-based shell, reveal a high specific activity. The catalyst particles are preferably supported on suitable support materials such as carbon black and are used as electrocatalysts for fuel cells.

Owner:UMICORE AG & CO KG

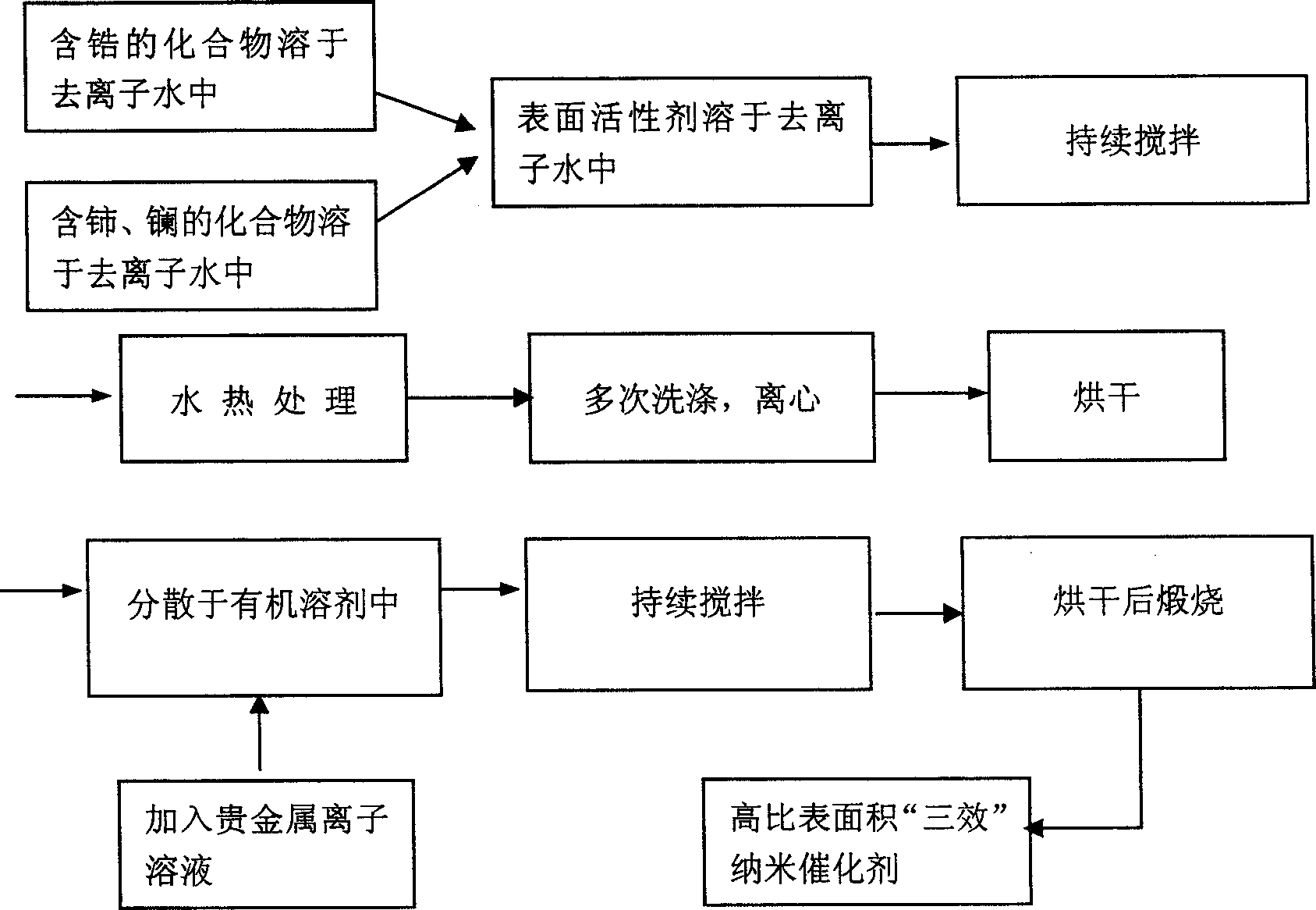

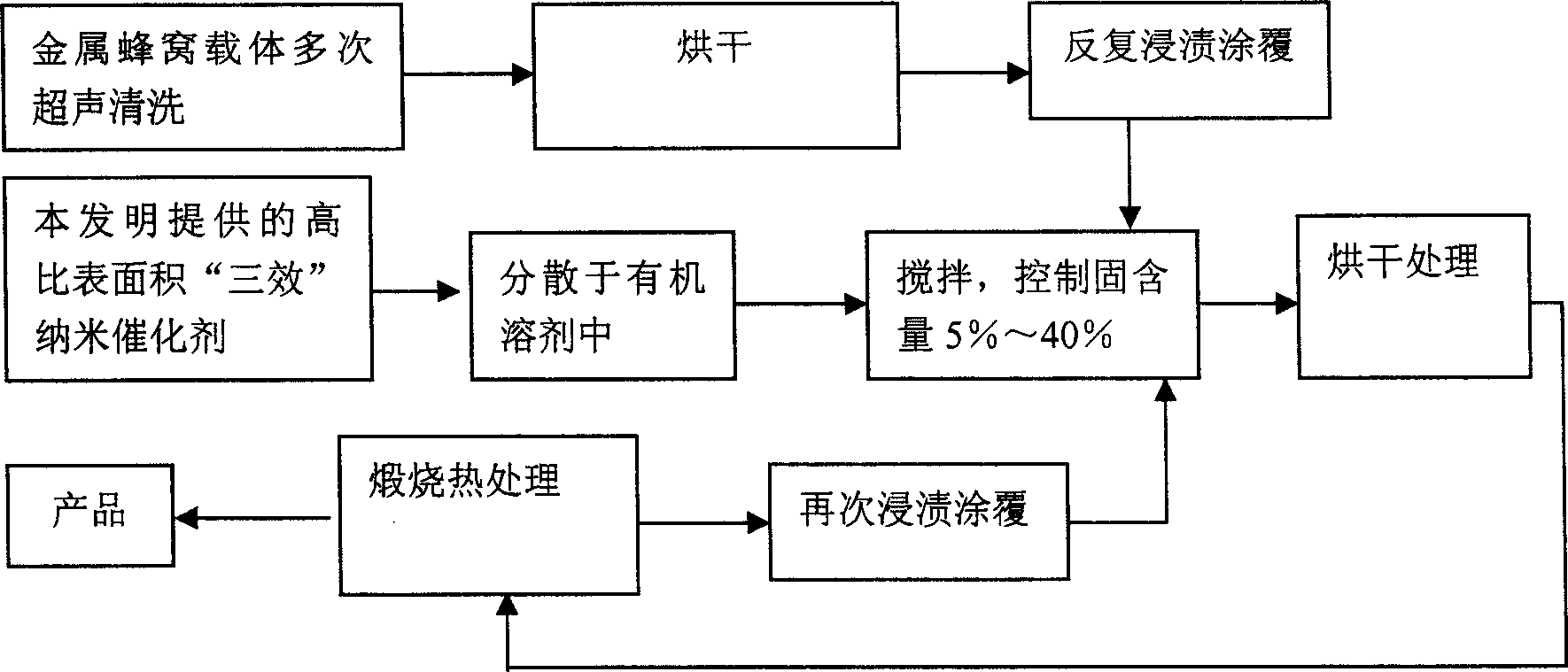

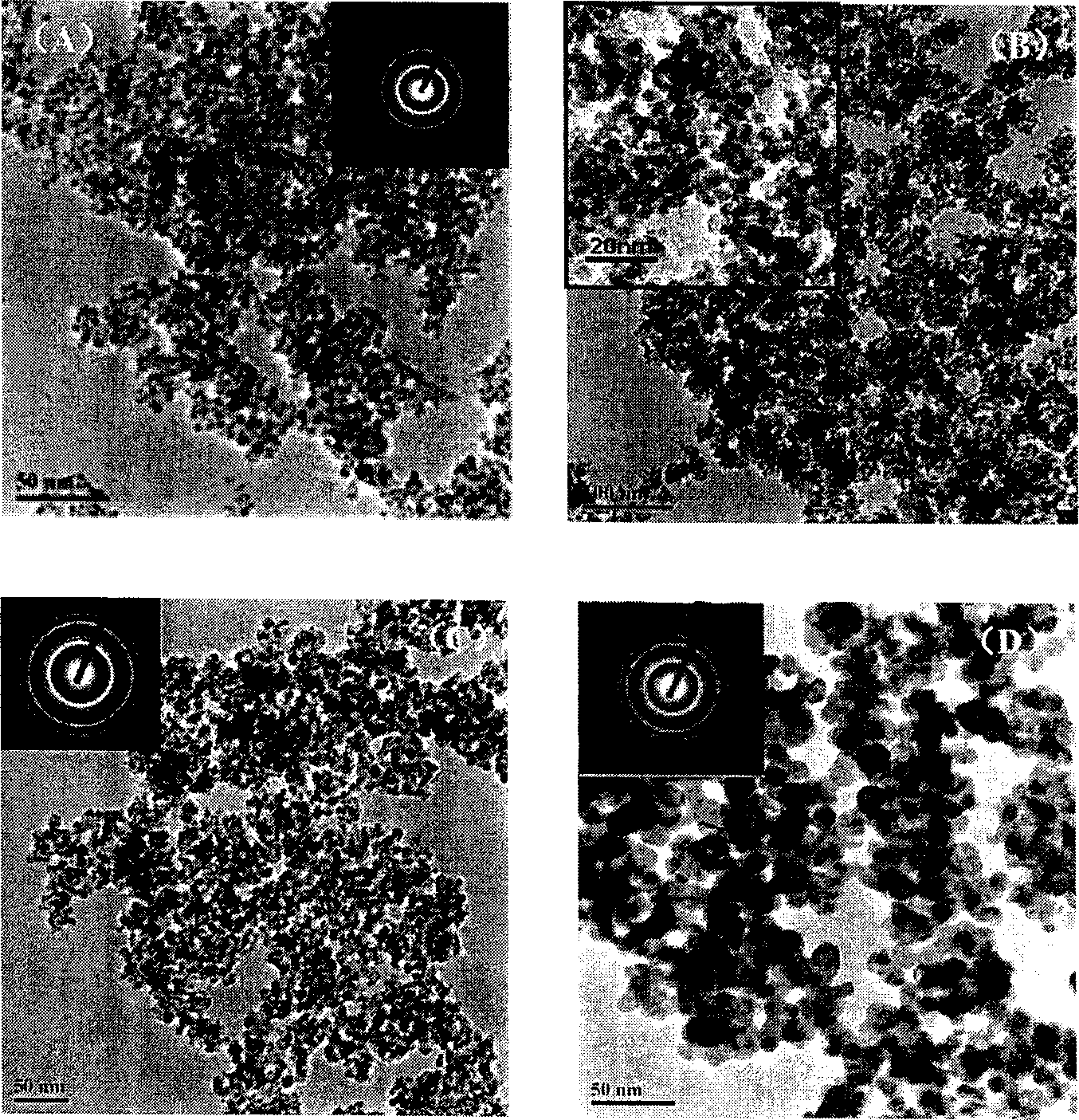

Ternary Nano catalyst in use for cellular carrier of full metal, preparation method and coating process

InactiveCN1915489ACoating Process AdvantagesGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNano catalystOrganic solvent

A three-element nano-catalyst for the metallic cellular carrier used to treat the tail gas of car is proportionally prepared from lanthanum oxide, zirconium oxide and cerium oxide through dissolving them in deionized water, adding surfactant, hydrothermal treating, washing, filtering, dispersing it in organic solvent, adding the solution of noble metal, stirring, baking and calcining. Its coating technology includes such steps as ultrasonic cleaning of metallic cellular carrier multiple times, dispersing said nano-catalyst in organic solvent, stirring, baking, coating and calcining.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Lubricant formulations and methods for improved exhaust catalyst performance

InactiveUS20080125336A1Multiple functionsLower levelGroup 5/15 element organic compoundsAdditivesPtru catalystPhysical chemistry

A lubricant composition for improved phosphorus retention of a used oil and a method for decreasing catalyst deactivation in a catalytic system for an engine exhaust. The lubricant composition is provided by a base oil and an additive composition that contains a phosphorus-containing additive mixture. The phosphorus-containing additive mixture includes an ash-containing phosphorus compound and an ash-free phosphorus compound. A phosphorus retention value provided by the lubricant composition is greater than about 85 percent after oil aging based on an amount of phosphorus initially present in the lubricant composition.

Owner:AFTON CHEMICAL

Pretreatment method for platinum palladium concentrate

ActiveCN103045849AEasy to extract and handleLow precious metal contentProcess efficiency improvementPretreatment methodSlag

The invention provides a pretreatment method for platinum palladium concentrate. The pretreatment method comprises the following steps: mixing the platinum palladium concentrate, sodium carbonate, sodium hydroxide and sodium chlorate uniformly according to a certain ratio; roasting at certain temperate; transforming impurity elements such as copper, selenium and tellurium into corresponding oxide or corresponding salt; and adding the roasting slag into water according to a certain ratio and leaching, wherein impurities such as copper, selenium and tellurium enter the alkaline leachate, and gold, platinum and palladium are enriched in the alkaline leaching slag. Compared with the traditional pretreatment method for the platinum palladium concentrate, the pretreatment method for the platinum palladium concentrate has the advantages that oxidation roasting and water leaching are adopted, so the noble metal content of the alkaline leachate is low; the leaching rate of the impurities such as copper, selenium and tellurium is high, the copper leaching rate reaches over 95 percent, the selenium leaching rate reaches over 88 percent, and the tellurium leaching rate reaches over 95 percent; the enrichment rate of the noble metal such as gold, platinum and palladium is high, so the extraction treatment on gold, platinum and palladium in the next step is promoted; and equipment is low in corrosivity, safe in operation, good in comprehensive recycling benefit and good in operating environment.

Owner:JIANGXI COPPER

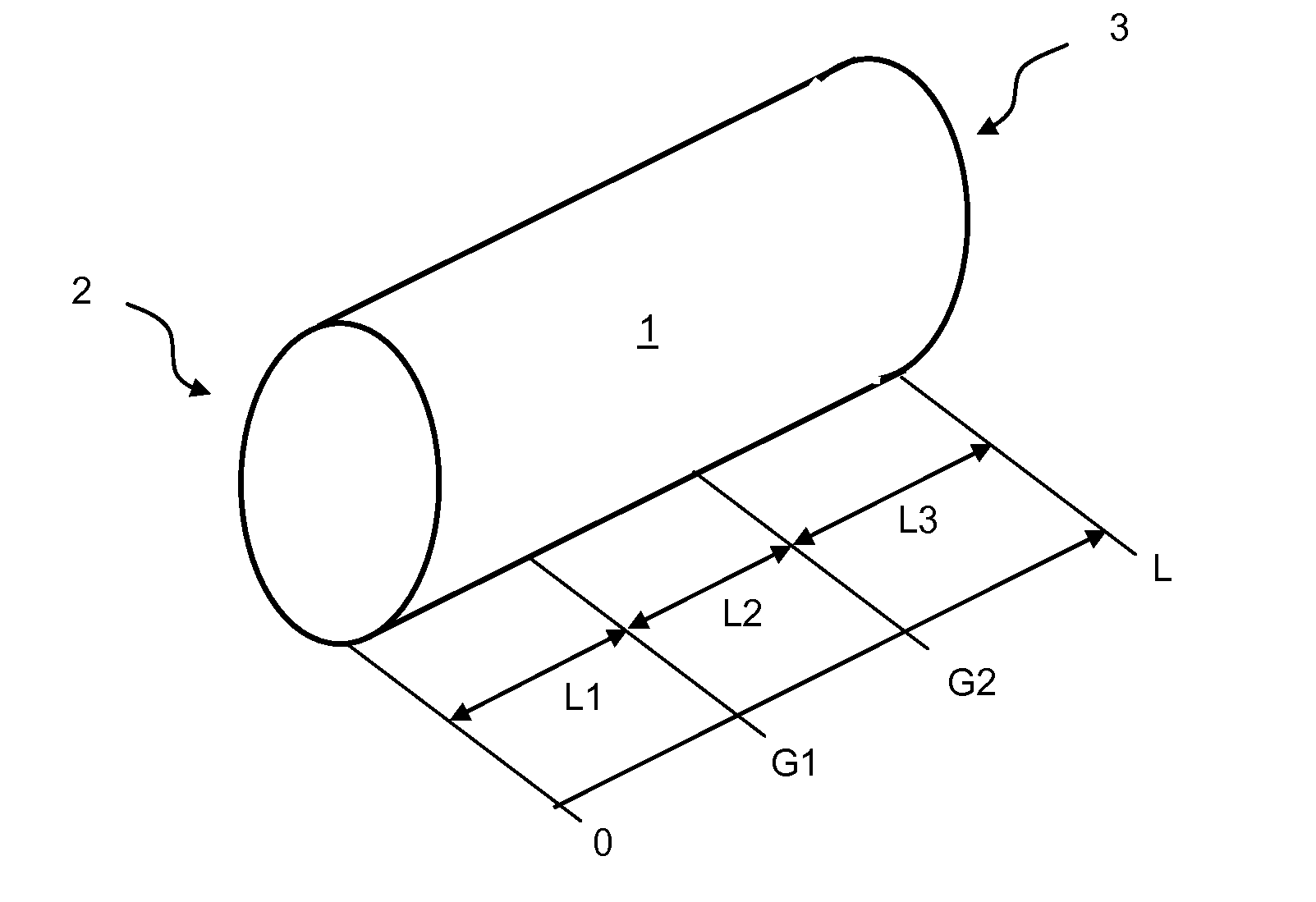

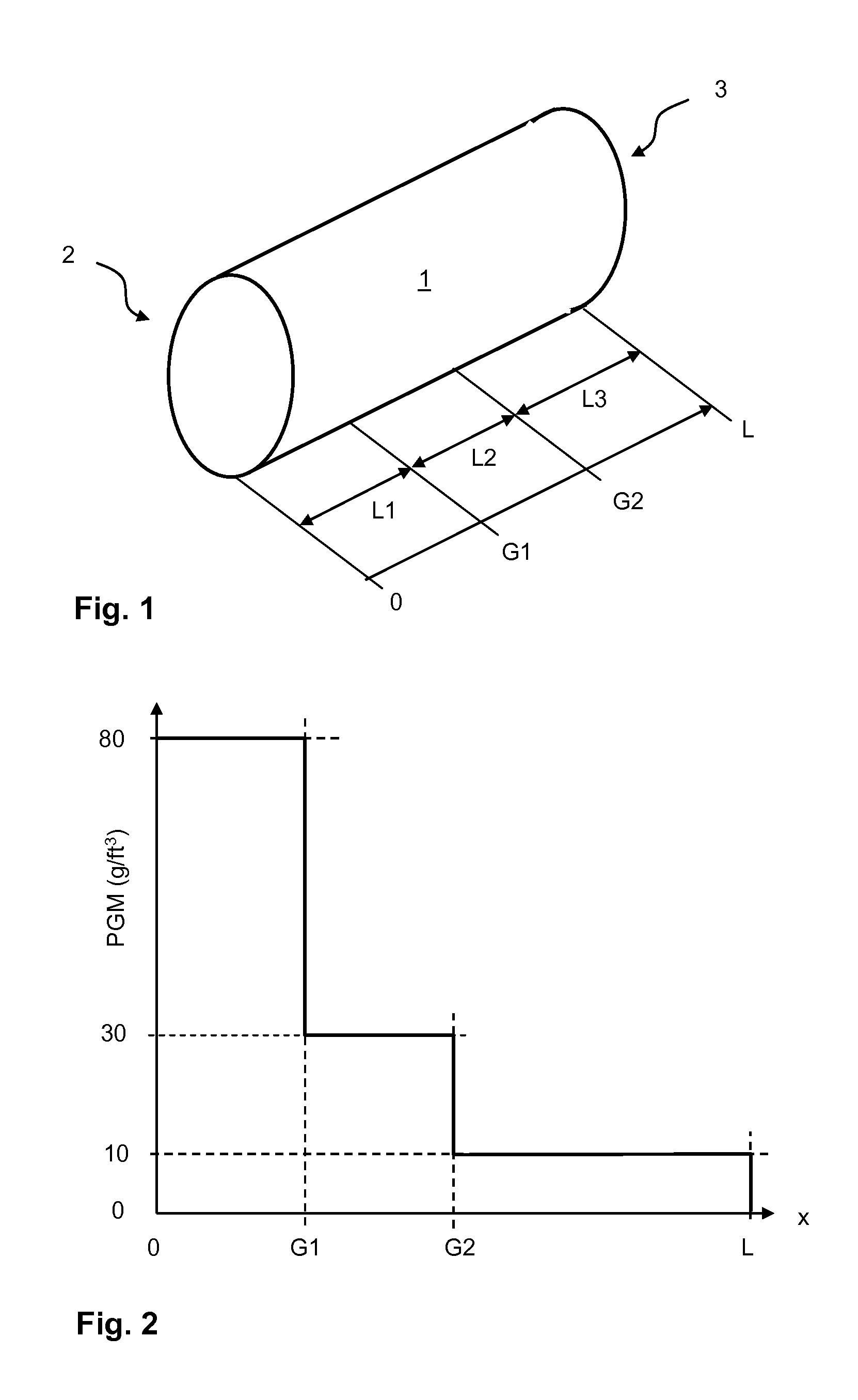

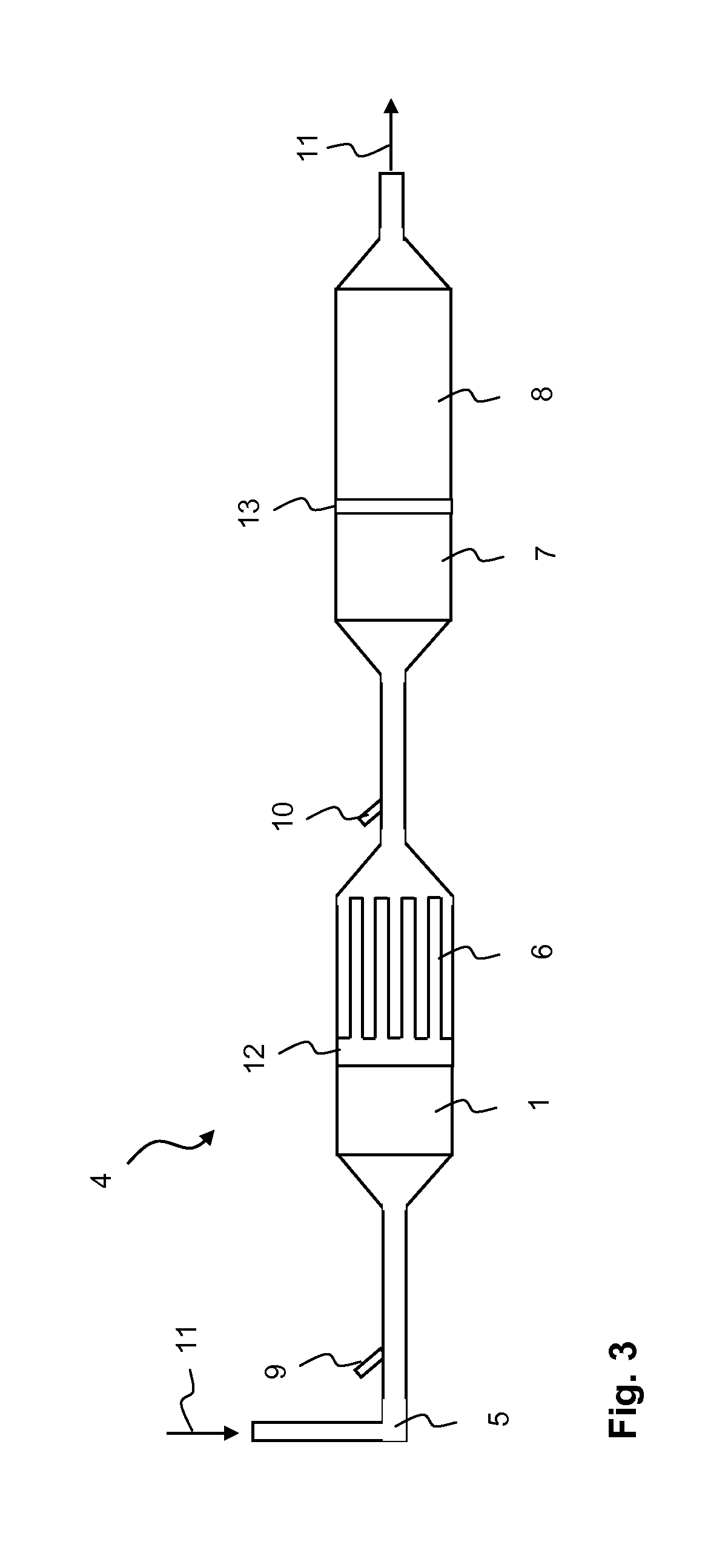

Catalyst Component of a Motor Vehicle Exhaust Gas Cleaning System and Use of a Catalyst Component

ActiveUS20150071839A1High level of cost savingEvenly distributedNitrogen compoundsInternal combustion piston enginesHoneycombEngineering

A motor vehicle emission control system includes a three zone catalytic converter component having a honeycomb support body with catalytically active coating having a precious metal content applied on the channel walls. The first coating zone extends in the longitudinal direction from the inlet-side end to a first coating boundary and has a first precious metal content. The second coating zone extends in the longitudinal direction from the first coating boundary to a second coating boundary situated downstream from the first coating boundary and has a second precious metal content that is lower than the first precious metal content. The third coating zone extends from the second coating boundary to the outlet-side end and has a third precious metal content that is lower than the second precious metal content. The coating has oxidation catalyst activity and is free of rhodium.

Owner:DAIMLER TRUCK AG

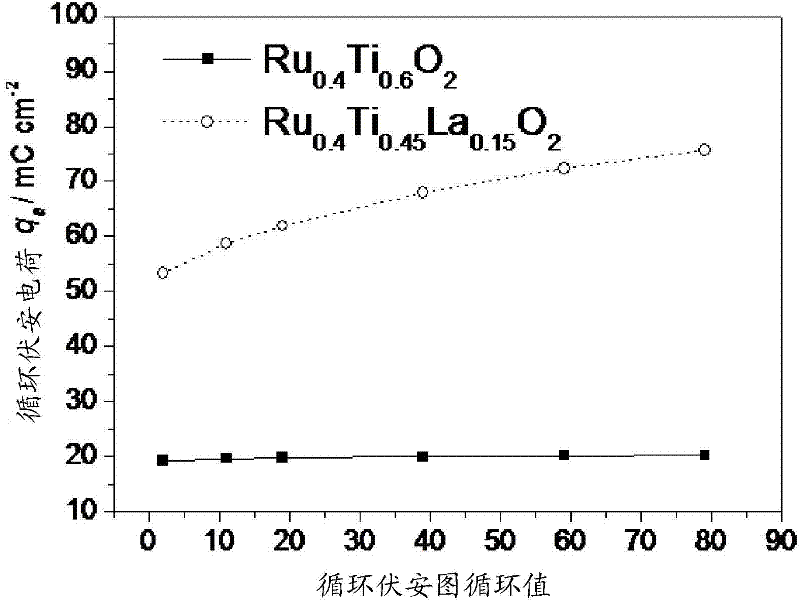

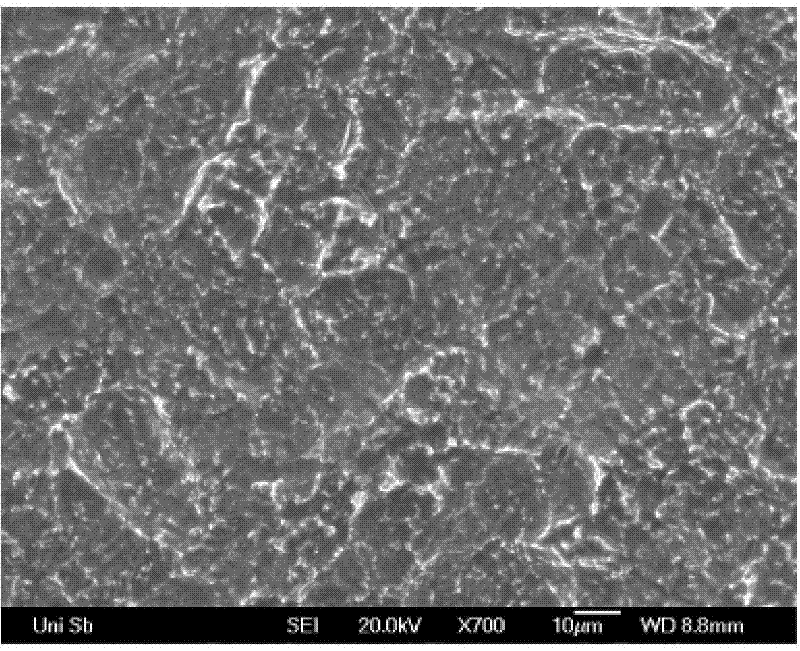

Electrode for producing chlorine through electrolysis

InactiveCN102465312AReduce overvoltageLow precious metal contentMultiple component coatingsIridiumElectrolysis

The present invention relates to an electrode comprising an electrically conductive substrate and a catalytically active layer, wherein the catalytically active layer is based on two catalytically active components and comprises iridium, ruthenium or titanium as metal oxide or mixed oxide or mixtures of the oxides, wherein the total content of ruthenium and / or iridium based on the sum of the elements iridium, ruthenium and titanium is at least 10 mol %, and wherein the electrode comprises at least one oxidic base layer which is applied to the electrically conductive substrate and is impermeable to aqueous electrolytes comprising NaCl and / or NaOH and / or HCl.

Owner:BAYER MATERIALSCIENCE AG

Ctalyst for treating high concentrated organic wastewater and method for preparing the same

InactiveCN1197781CLow precious metal contentLow costWater/sewage treatment by oxidationPtru catalystManganese

Owner:YUNNAN UNIV

Carbon monoxide oxidation catalyst and preparation method thereof

InactiveCN102101054AHigh catalytic activityImprove water resistanceCarbon compoundsCatalyst activation/preparationActive componentWater vapor

The invention provides a carbon monoxide oxidation catalyst and a preparation method thereof. A carrier of the catalyst is attapulgite clay, active components of the catalyst are Cu and Pd, the loading capacity of the Cu is 8-12 wt percent, and the loading capacity of the Pd is 0.2-1 wt percent. The preparation method comprises the steps of: preparing Cu(NO3)2.3H2O, CuCl2.2H2O and PdCl2 in a mol ratio of (2-4):(1-2):(1.5-3) into a solution; and dipping equivalent or excessive solution to the carrier of the attapulgite clay, drying and tabletting to obtain the catalyst. The catalyst has higher catalysis activity, stability and water resistance, and can be used for carrying out effective catalytic oxidation on steam saturated CO under the reaction conditions of normal temperature, space velocity of 2500-10000h<-1> and CO content of 2000-10000ppm, wherein the activity duration of the catalyst is not lower than 120min.

Owner:SHANXI UNIV

Monolithic catalyst for catalytic oxidation of CO at normal temperature and preparation method thereof

ActiveCN107376935AEfficient removalImprove water resistanceGas treatmentHeterogenous catalyst chemical elementsAir volumeCatalytic oxidation

The present invention belongs to the technical field of environmental protection, and in particular relates to a monolithic catalyst for catalytic oxidation of CO at normal temperature and a preparation method thereof. The monolithic catalyst comprises precious metal Pt as an active component, a composite metal oxide as an auxiliary agent coating, and honeycomb ceramic as a carrier; the mass ratio of the precious metal Pt, the composite metal oxide coating and the honeycomb ceramic carrier is 0.01-2:5-20:80-90. The composite metal oxide coating is a mixture of a cobalt-based composite metal oxide, pseudoboehmite and gamma-Al2O3 in a mass ratio of 10-15: 1-5: 1-5. The catalyst prepared by the method has high activity at normal temperature, lowers the energy consumption of CO removal process, has good water and sulfur resistance and stability, can achieve CO effective removal under the conditions of high space velocity, CO concentration and air volume change, and is applicable to normal temperature elimination of CO in all types of combustion tail gases and closed and semi-enclosed places.

Owner:SHANGHAI RES INST OF CHEM IND

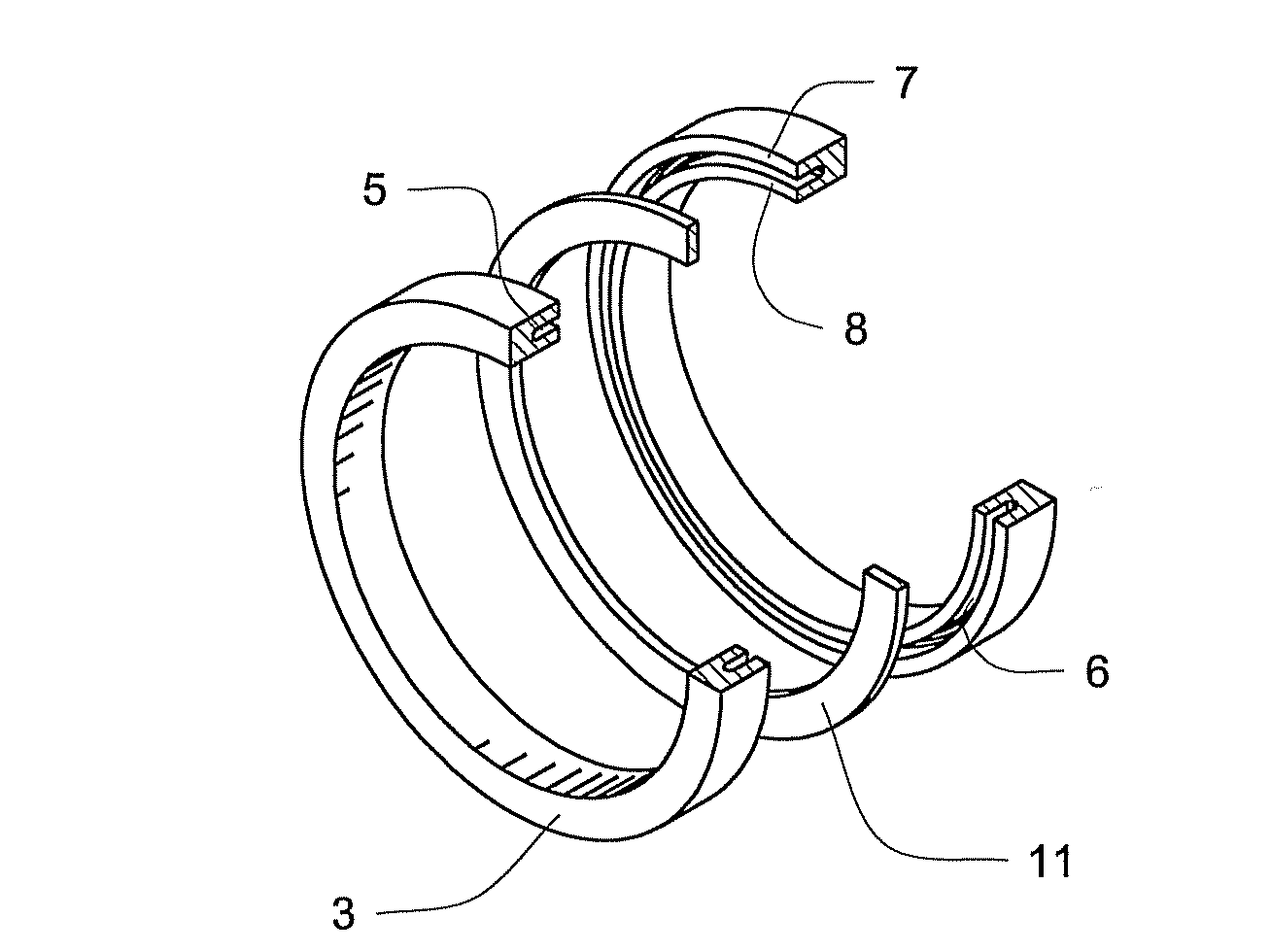

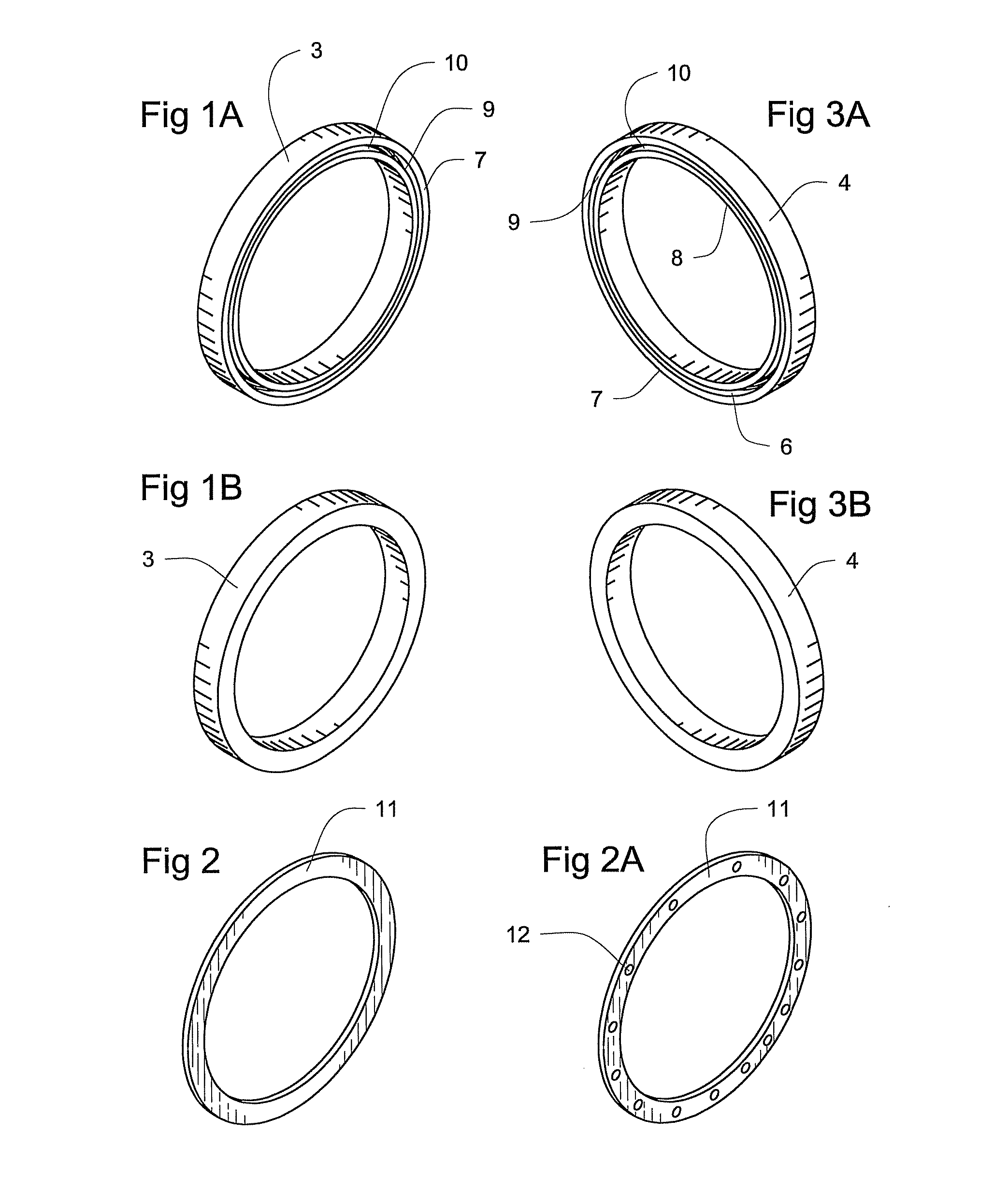

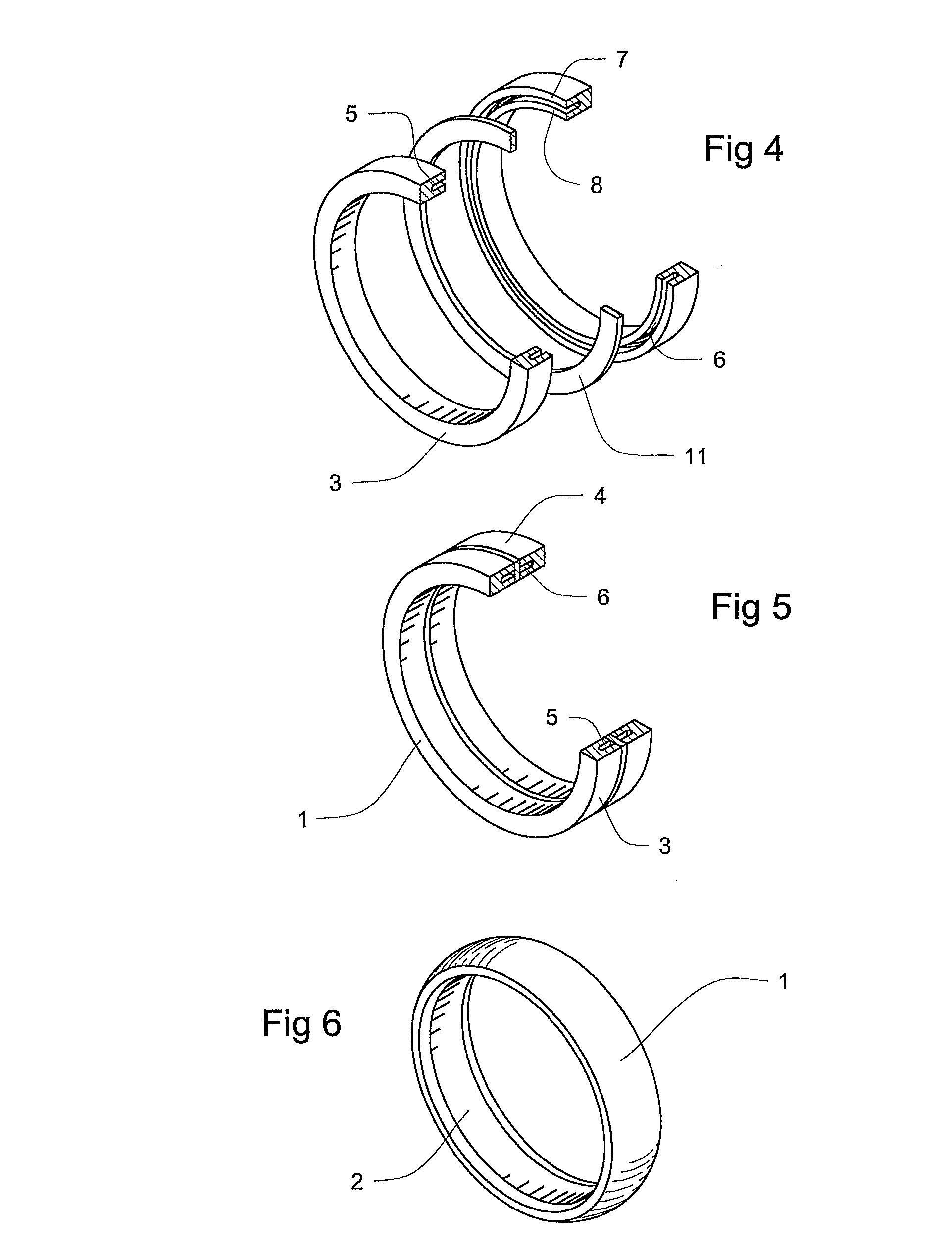

Jewelry Item Having Reduced Weight and Enhanced Strength

InactiveUS20090293541A1Eliminate any visible seamReduce the amount requiredBraceletsWrist-watch strapsPrecious metalMaterials science

A reduced weight enhanced strength jewelry piece. In the preferred embodiment, the piece is comprised of a left section and a right section, each preferably containing a substantially hollow channel. A central section is also provided. All three sections are preferably formed of the same precious metal, though different metals could be used if contrast is desired in the finished piece. In the preferred embodiment, the central section is a substantially solid piece fitted to match both the left section and the right section. The three sections are joined together to form a jewelry piece. The resultant jewelry piece will have two substantially hollow chambers transected by a substantially solid piece. The substantially solid piece will serve as a brace to the hollow chambers, such that if a force were applied to the jewelry piece transverse to the hollow chambers of the piece, the central section would resist deformation.

Owner:STULLER MFG

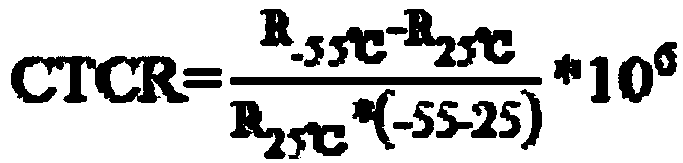

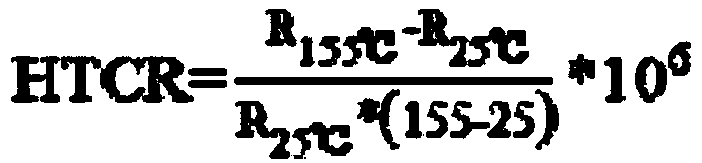

Thick film resistor slurry

ActiveCN108053960AWell mixedElectrical performance will not deteriorateResistor manufactureThick film resistorsSlurryElectrical performance

The invention discloses a thick film resistor slurry, and further provides a thick film resistor slurry with a resistance range of 0.1-10 M[omega] / , and a preparation method thereof. According to thepresent invention, the thick film resistor slurry with the any resistance between the adjacent resistances can be obtained by mixing nine thick film resistor slurries with the adjacent resistances of0.1 [omega] / , 1 [omega] / , 10 [omega] / , 100 [omega] / , 1 k[omega] / , 10 k[omega] / , 100 k[omega] / , 1 M[omega] / and 10 M[omega] / in the range of 0.1 [omega] / to 10 [omega] / , the mixture of the slurries with the adjacent resistances has the good mixing performance, the electrical performance cannot be deteriorated after the mixing, and the resistor slurry obtained by mixing the resistor slurries with the adjacent resistances according to the any ratio does not contain the middle-range transition section so as to greatly reduce the production cost.

Owner:CHAOZHOU THREE CIRCLE GRP

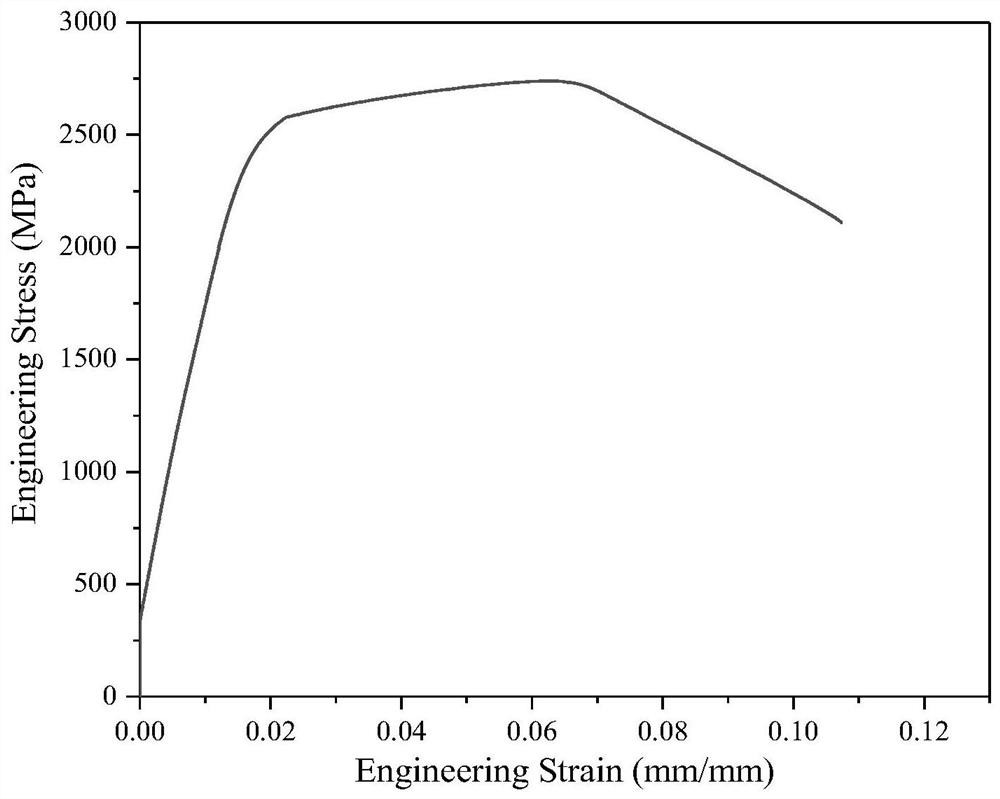

690 Mpa-grade low-cost high-toughness bainitic steel plate and production process thereof

InactiveCN109055657ALow precious metal contentLow weld crack susceptibility factorProcess efficiency improvementElectric furnaceChemical compositionHeavy load

The invention discloses a 690 Mpa-grade low-cost high-toughness bainitic steel plate and a production process thereof. The steel plate comprises the following chemical components of, by mass percentage, 0.03-0.09% of C, 0.10-0.30% of Si, 1.50-1.80% of Mn, 0.030-0.070% of Nb, less than or equal to 0.02% of Ti, 0.10-0.40% of Mo, 0.20-0.30% of Ni, less than or equal to 0.045% of Alt, less than or equal to 0.002% of Bt and the balance Fe and inevitable impurities; and the production process comprises the processes of smelting, continuous casting, heating, rolling and heat treatment. The steel plate has the characteristics of low welding crack sensitivity coefficient, low carbon content, low cost and the like, the problems that the carbon content and the carbon equivalent of the tempered steelare high, and the welding performance is poor are solved, and the steel plate can meet the requirements of steel in the fields of engineering machinery, heavy-load bridges, energy-saving vehicles, pipelines, ships, ocean platforms and the like in China.

Owner:HEBEI IRON AND STEEL

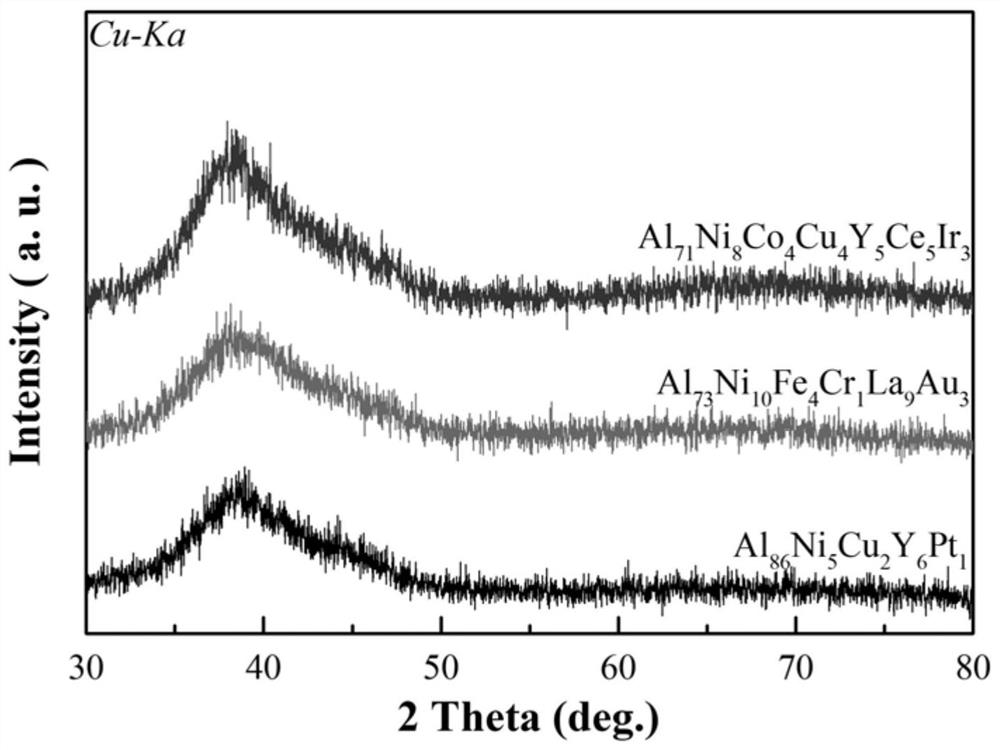

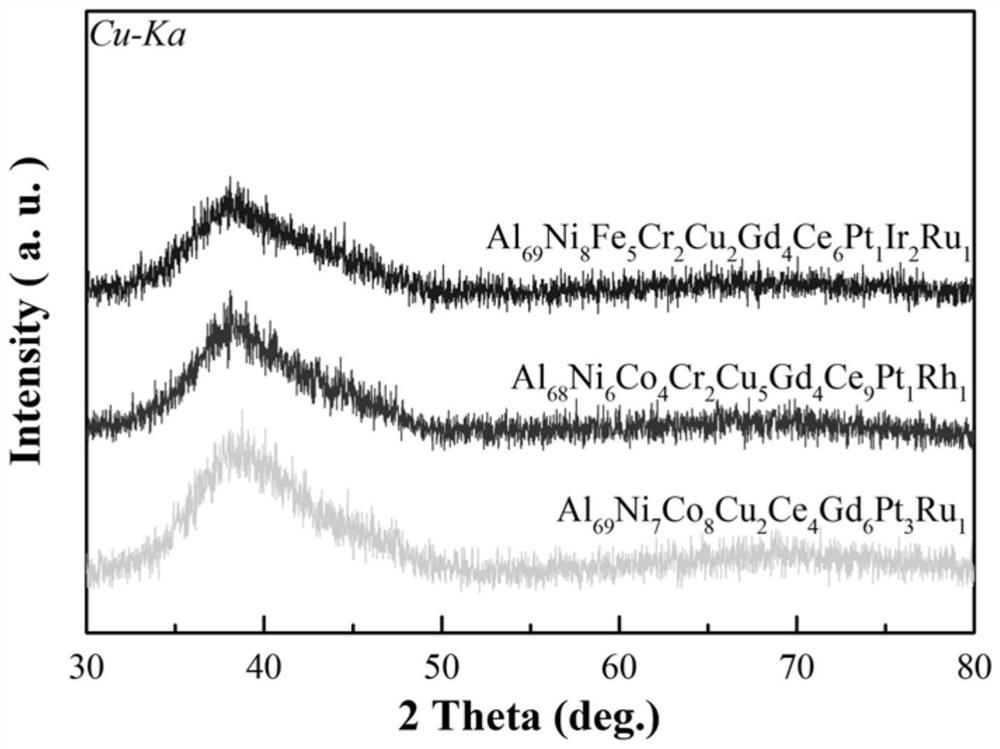

Nano-porous Al-Ni-M-RE-R amorphous alloy used as hydrogen evolution catalytic electrode, and preparation method thereof

ActiveCN112064058AWide range of ingredientsSolve the problem of difficult preparation of nanoporous structuresElectrode shape/formsRare-earth elementElectrolysis

The invention discloses a nano-porous Al-Ni-M-RE-R amorphous alloy used as a hydrogen evolution catalytic electrode, wherein a transition metal element M is Fe, Co, Cr and Cu, a rare earth element REis Y, La, Gd and Ce, a precious metal R is Pt, Ru, Pd, Rh, Au and Ir, and a hydrogen evolution catalytic electrode comprises the following components in percentage by mass: Al, 2-12% of Ni, 1-13% of M, 2-13% of RE, and 0.2-7% of R, and is treated by adopting a constant current method, a corrosion method or a pulse corrosion current method, so that the prepared nano porous amorphous alloy is stablein structure, large in specific surface area, adjustable in component, structure and morphology and high in catalytic activity. According to the invention, when the nano-porous amorphous alloy hydrogen evolution electrode is used as a water electrolysis hydrogen evolution catalytic electrode, the hydrogen evolution overpotential is 40-65 mV and the Tafel slope is 10-60 mV / dec under the current density of 10 mA.cm<-2>, so that the nano-porous amorphous alloy hydrogen evolution electrode has excellent hydrogen evolution catalytic activity.

Owner:BEIHANG UNIV

Preparation method of filled composite catalyst for CO gas-phase coupling synthesizing of oxalate and application of catalyst

ActiveCN108187691AHigh activityAvoid sintering deactivationCatalyst activation/preparationPreparation by carbon monoxide or formate reactionOxalateActive component

The invention relates to a preparation method of a filled composite catalyst for CO gas-phase coupling synthesizing of oxalate and application of the catalyst. The catalyst comprises an aluminum oxideframework, a filled composite carrier which is composed of a filler that fills the framework, an active component Pd which is loaded on the surface of the carrier, and additives Fe and Cu. Compared with the prior art, the catalyst shows outstanding catalyzing performance in the CO gas phase coupling synthesizing of dimethyl oxalate, and the catalyst has the advantages of being low in noble metalPd content, high in utilization rate, and low in cost.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

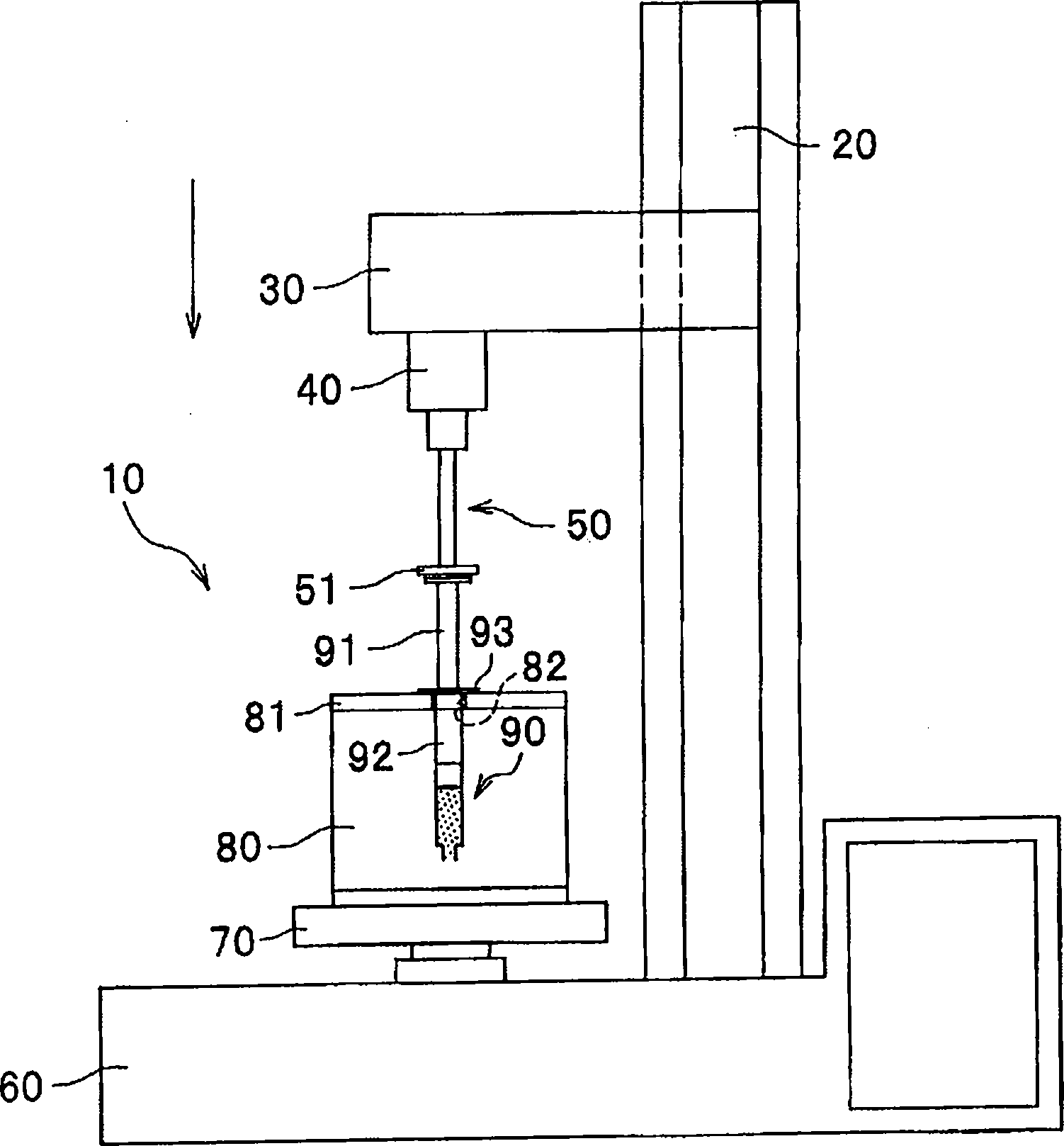

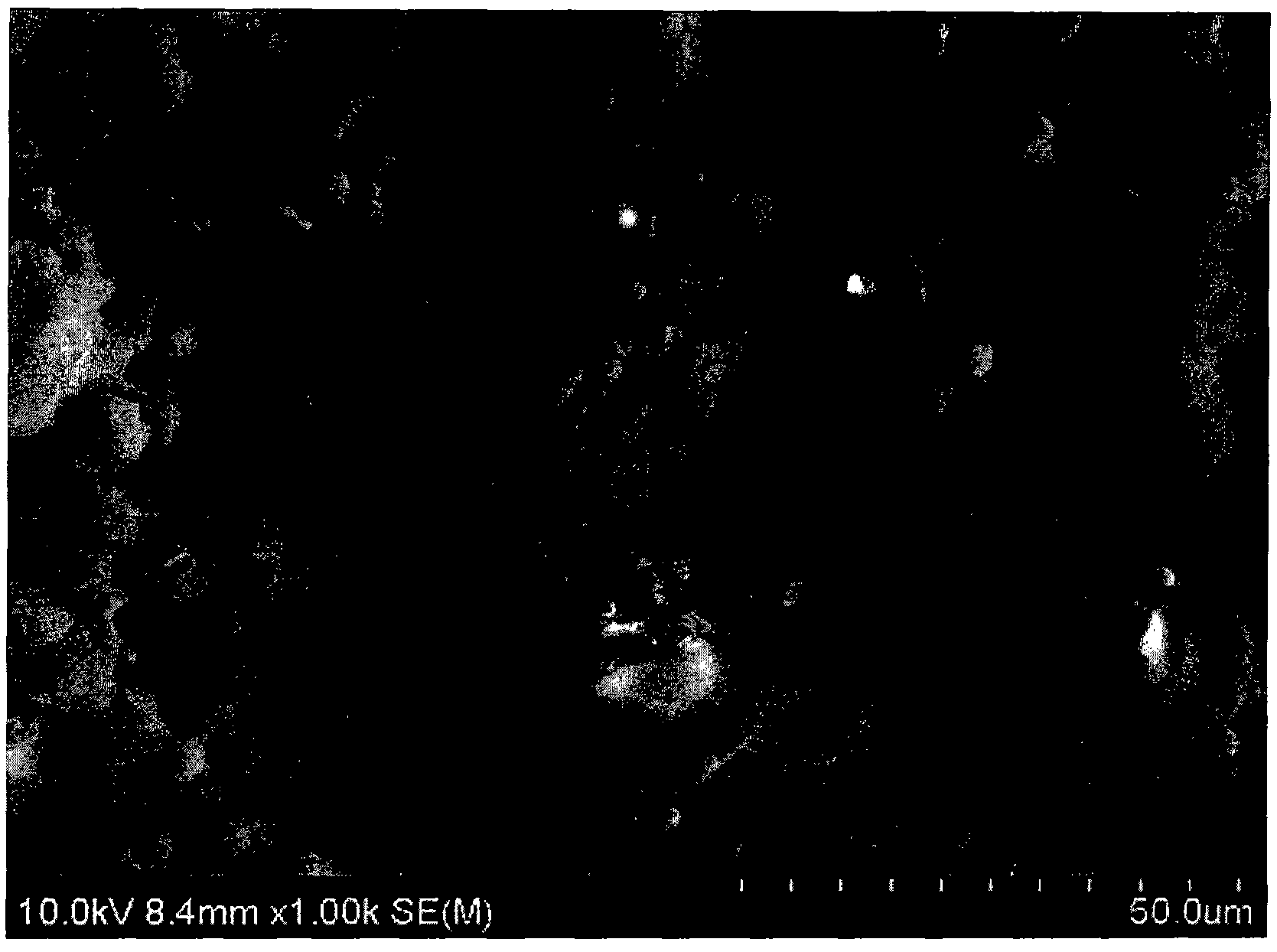

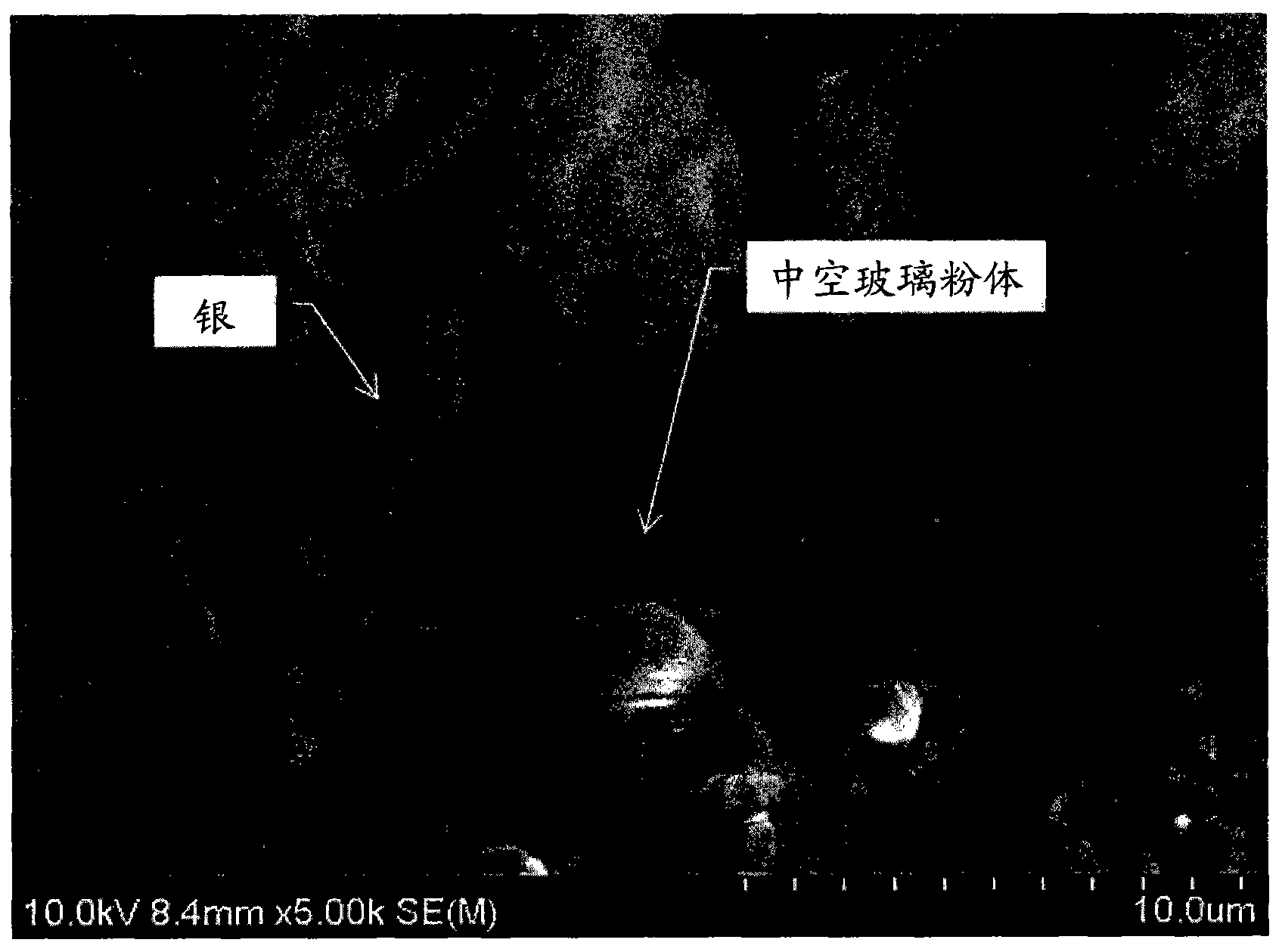

Composition for precious metal sintering, process for producing precious metal sinter and precious metal sinter

InactiveCN102015165ALow precious metal contentReduce dosageThin material handlingMetal powderOrnaments

A composition for precious metal sintering that, by firing, yields a precious metal sinter for use in jewelry, ornaments, accessories, etc., especially that realizes not only production of a precious metal sinter even when the precious metal content per volume of the composition for precious metal sintering is reduced but also striking reduction of the weight of the precious metal sinter. Further, there are disclosed a process for producing the precious metal sinter and the precious metal sinter. This composition for precious metal sintering is characterized by consisting of a mixture of precious metal powder, hollow glass powder and organic binder solution.

Owner:AIDA CHEM IND

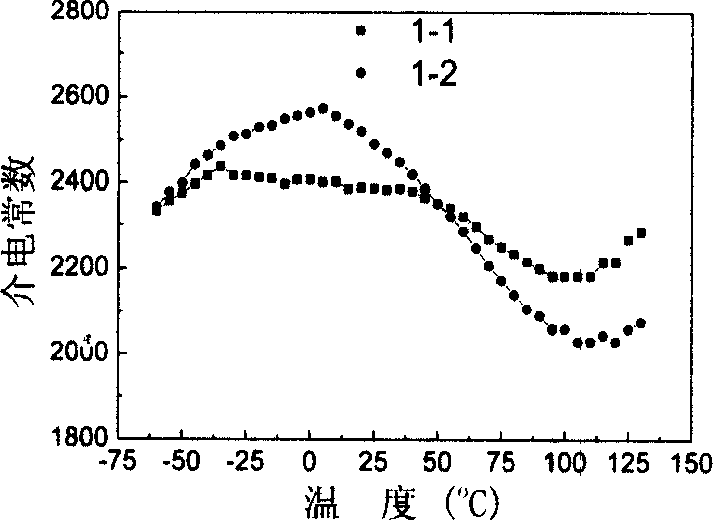

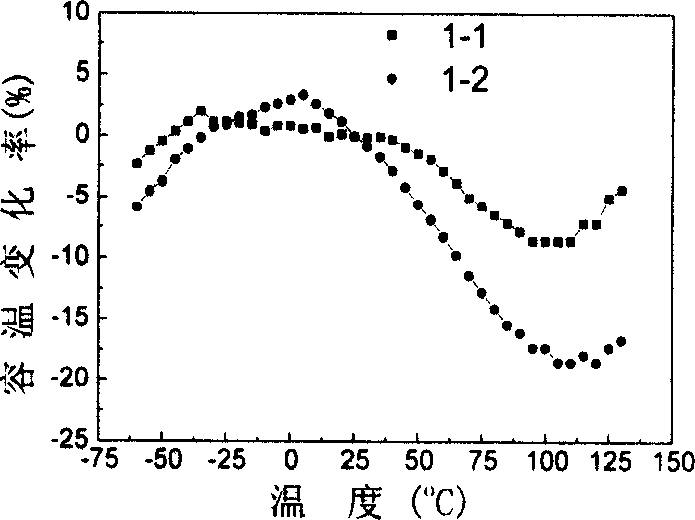

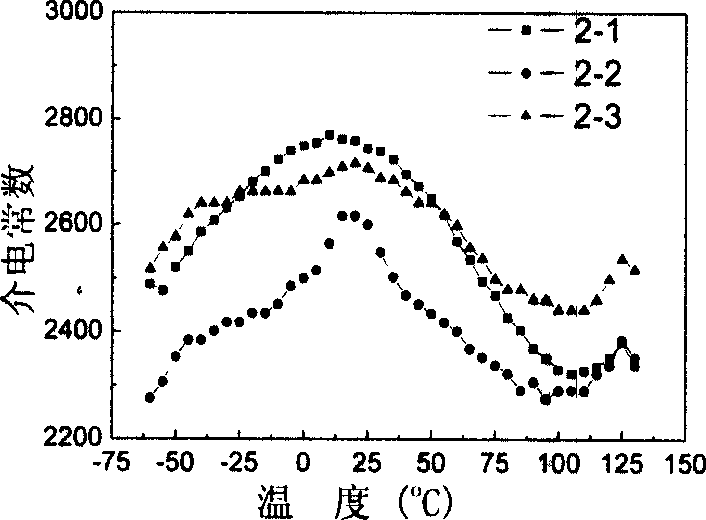

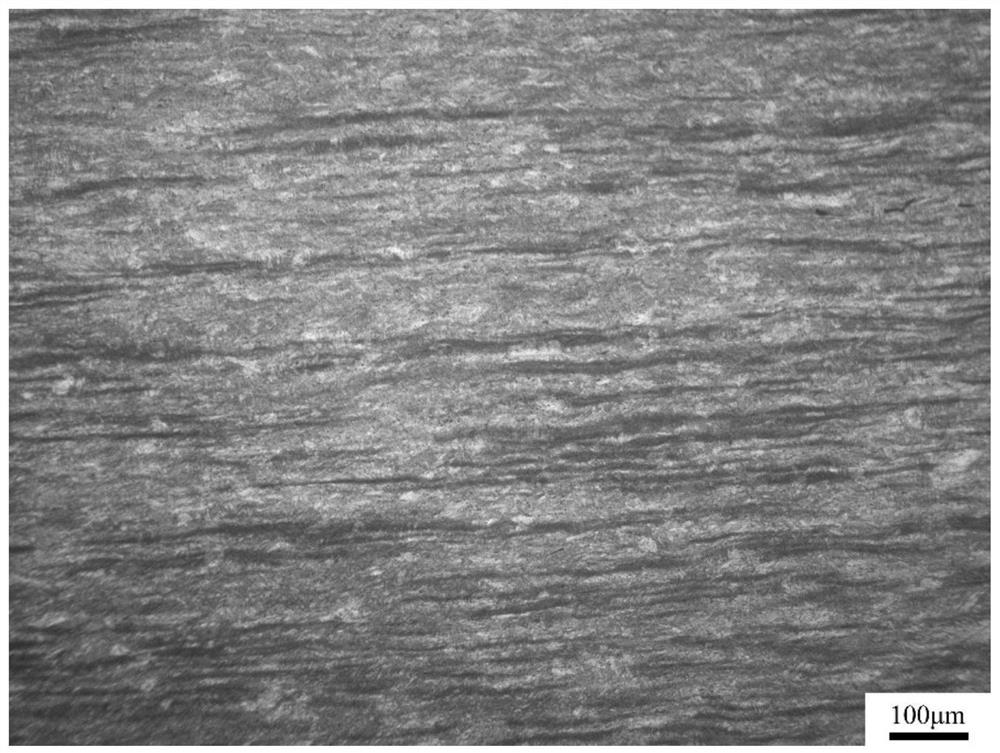

Ceramic material of middle-low temp. sintered temp stable type multirayer ceramic capacitor

A ceramic material used for X7R-model multi-layer ceramic capacitor with medium or low sinter temp and high temp stability is prepared from barium titanate and the additive chosen from cobalt oxide and niobium oxide, or their compound, yttrium oxide, RE oxide, Ag, zinc oxdie and boron oxide, or their compound. It has dielectric constant of 1800-5600, capacitance-temp variation rate less than + / -15%, and sinter temp of 900-1150 deg.C.

Owner:TSINGHUA UNIV

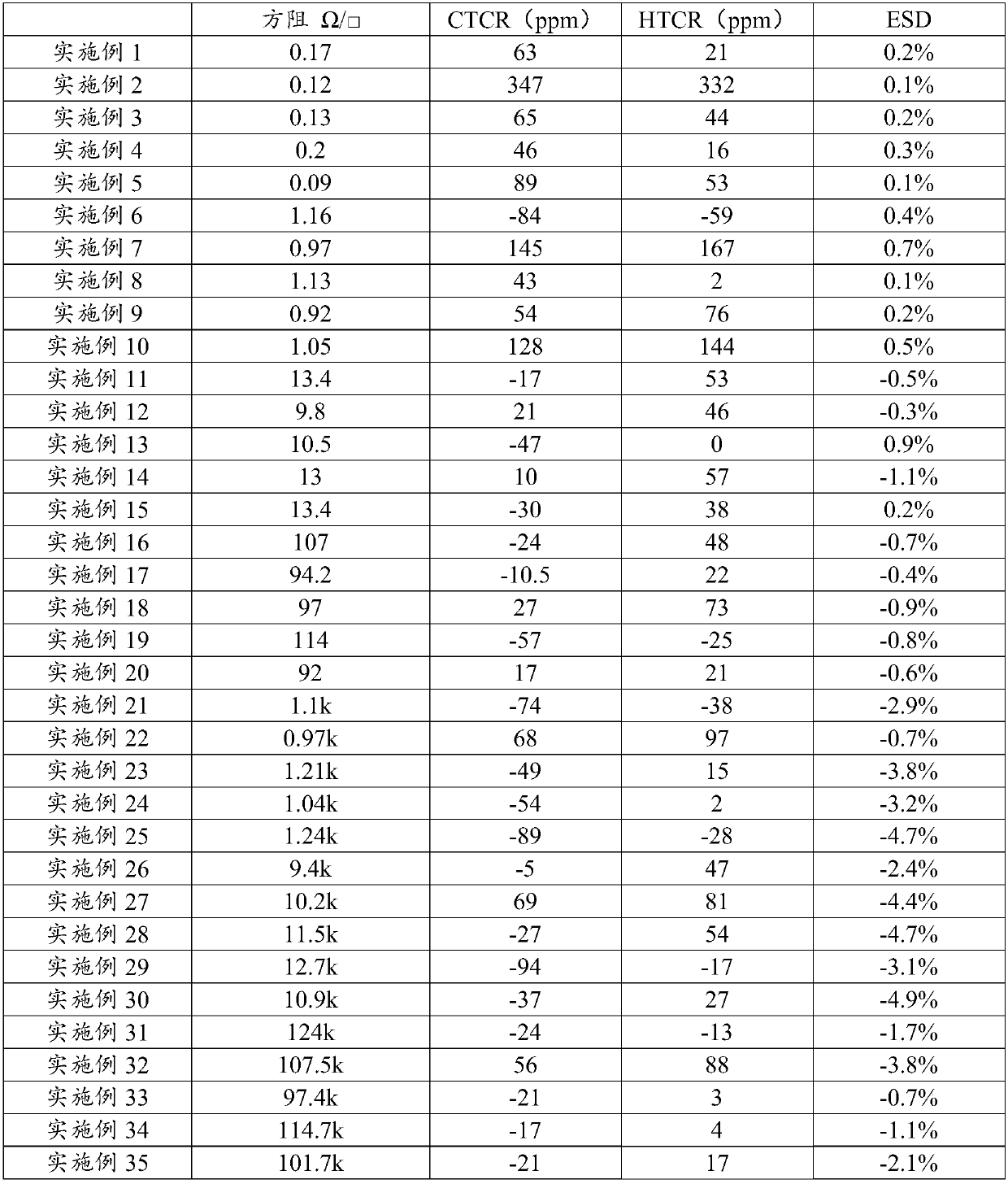

Multiphase reinforced ultrahigh-strength maraging stainless steel and preparation method thereof

InactiveCN113699463AEasy to prepareImprove corrosion resistanceFurnace typesIncreasing energy efficiencySS - Stainless steelAustenite

The invention discloses multiphase reinforced ultrahigh-strength maraging stainless steel and a preparation method thereof. The multiphase reinforced ultrahigh-strength maraging stainless steel is prepared from the following components in percentage by mass: 1.0 to 5.0 percent of Co, 6.0 to 10.0 percent of Ni, 11.0 to 17.0 percent of Cr, 0.3 to 2.0 percent of Ti, 3.0 to 7.0 percent of Mo, 0.08 to 1.0 percent of Mn, 0.08 to 0.5 percent of Si, less than or equal to 0.02 percent of C, less than or equal to 0.003 percent of P, less than or equal to 0.003 percent of S and the balance of Fe. The preparation method comprises the following steps: (1) proportioning alloy elements; (2) carrying out vacuum smelting on an electrode in a vacuum induction smelting furnace; (3) carrying out vacuum consumable remelting; (4) carrying out high-temperature fire homogenizing treatment; (5) carrying out forging or hot rolling cogging; (6) carrying out cold rolling deformation; and (7) carrying out heat treatment. According to the multiphase reinforced ultrahigh-strength maraging stainless steel and the preparation method, a precipitation phase and inverted austenite are uniformly and finely distributed, and the partition efficiency of the inverted austenite forming elements is higher.

Owner:HARBIN ENG UNIV

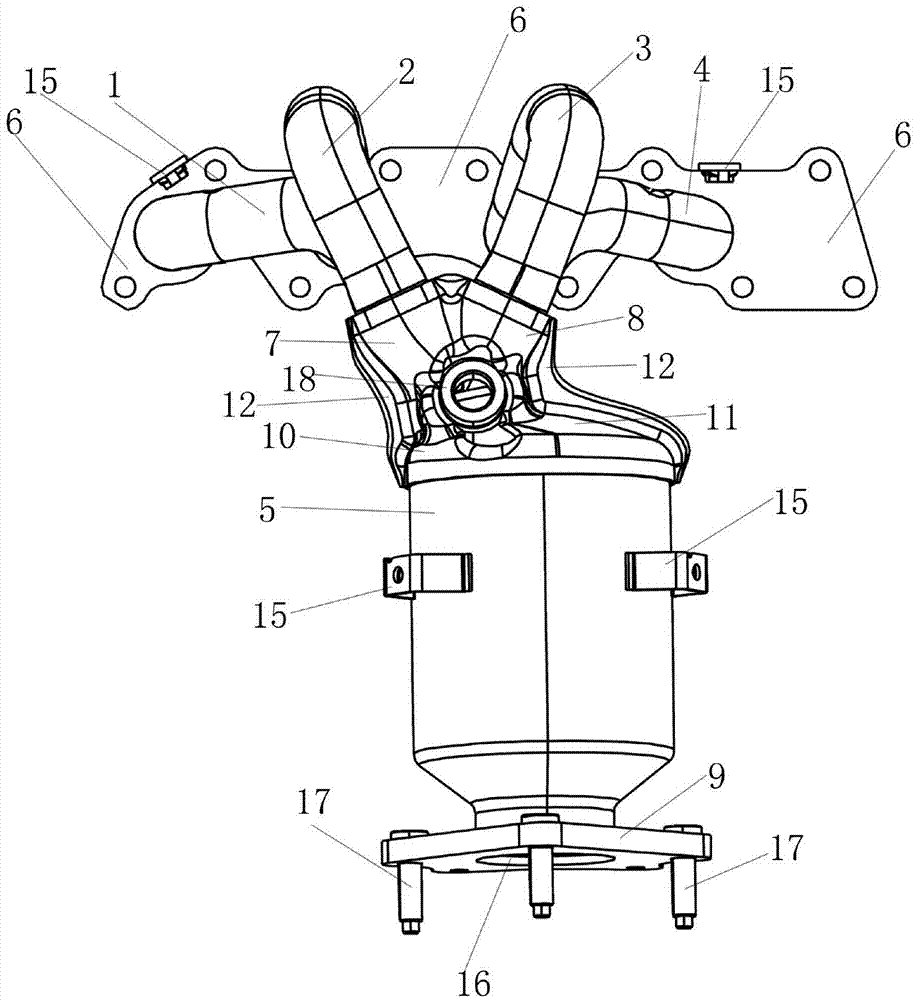

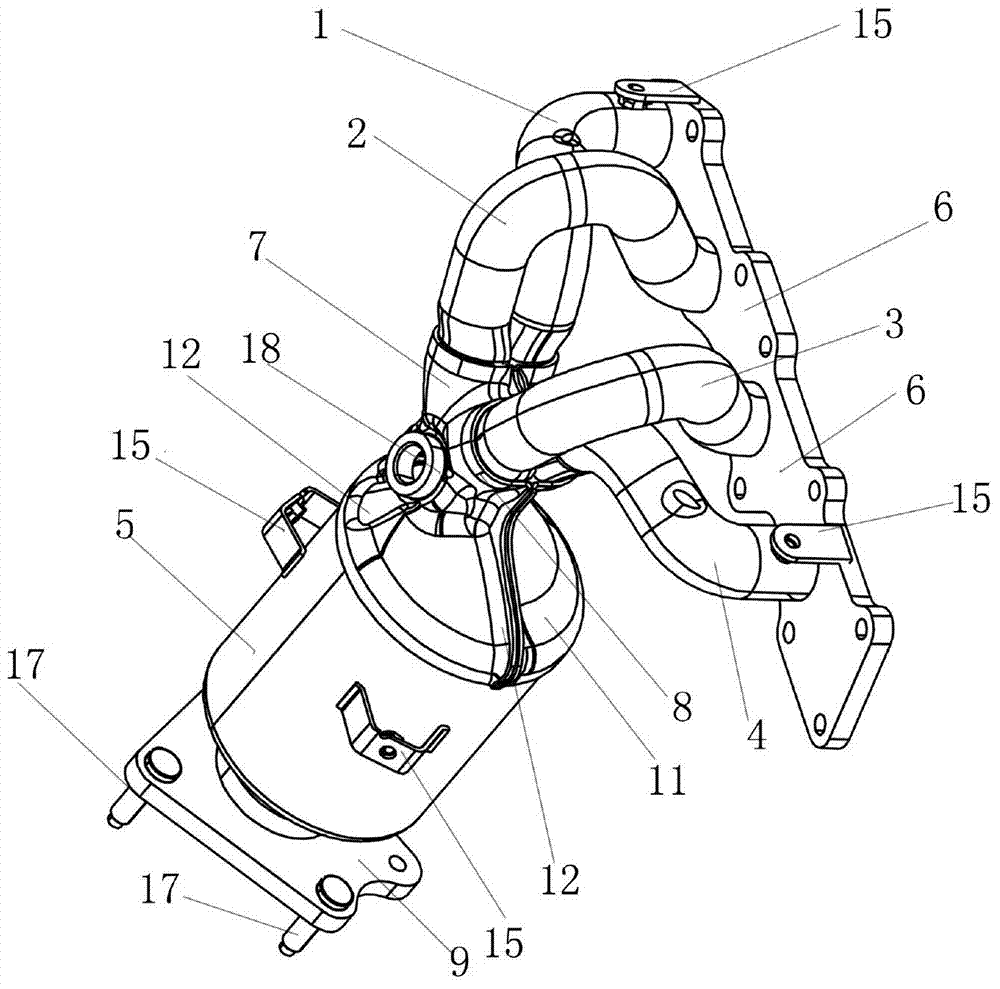

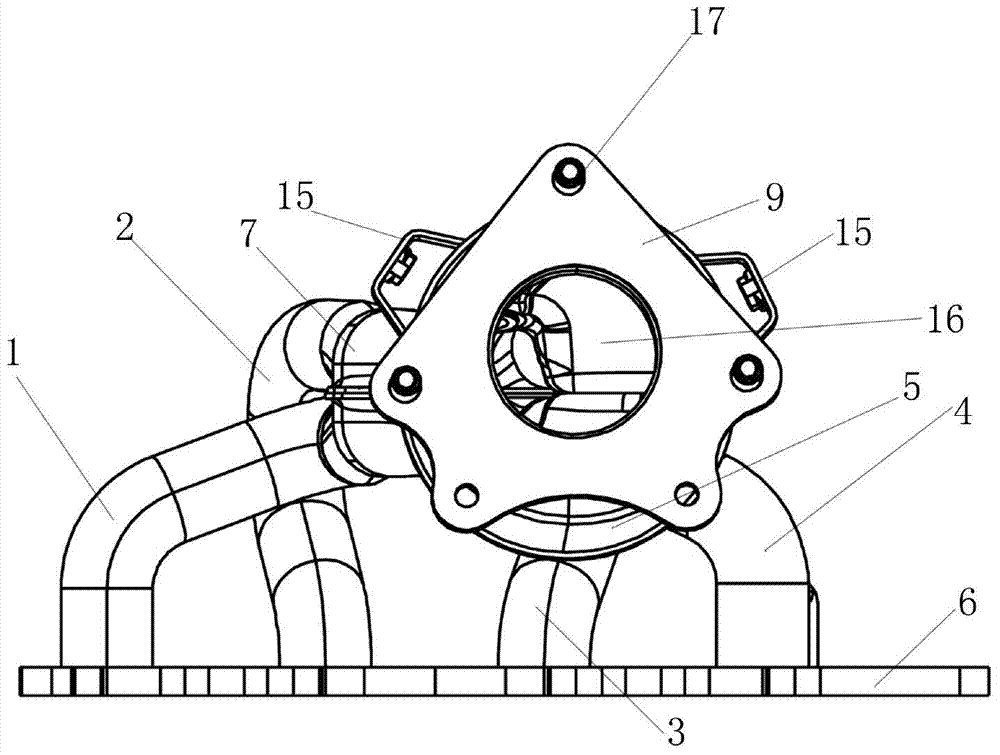

Tightly-coupled exhaust manifold assembly

InactiveCN103244249AReduce weightLow precious metal contentExhaust apparatusSilencing apparatusEngineeringOil consumption

The invention discloses a tightly-coupled exhaust manifold assembly which comprises an exhaust manifold component and a three-way catalytic converter conducted and coupled with the exhaust manifold component. The three-way catalytic converter and the exhaust manifold component are connected through a clamshell. The exhaust manifold component comprises a first manifold, a second manifold, a third manifold and a third manifold with front ends mounted on an air inlet flange and arranged from one side to the other side sequentially. The tail ends of the first and second manifolds extend into the front end of a first convergence pipeline, the tails of the third and fourth manifolds extend into the front end of a second convergence pipeline, the tail ends of the first and second convergence pipelines extend into the clamshell, the tail end of the clamshell is connected with the three-way catalytic converter, and the bottom of the three-way catalytic converter is connected with the air inlet flange. The tightly-coupled exhaust manifold assembly is simple in structure and light in weight, number of parts is reduced, oil consumption and production cost are lowered, the temperature of the three-way catalytic converter is increased, airflow interference is avoided and engine performance is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

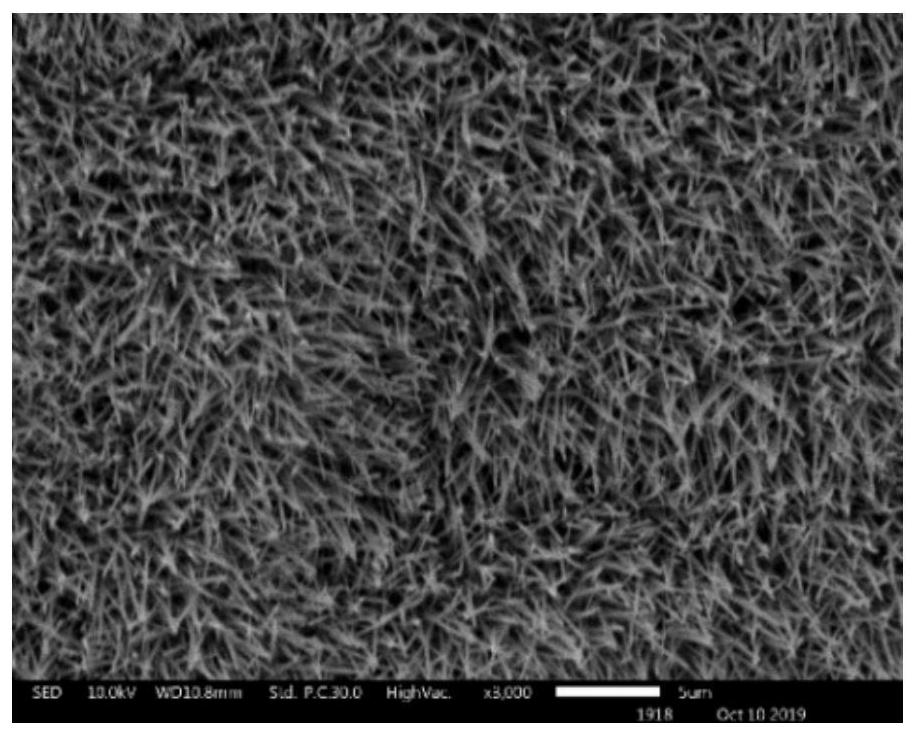

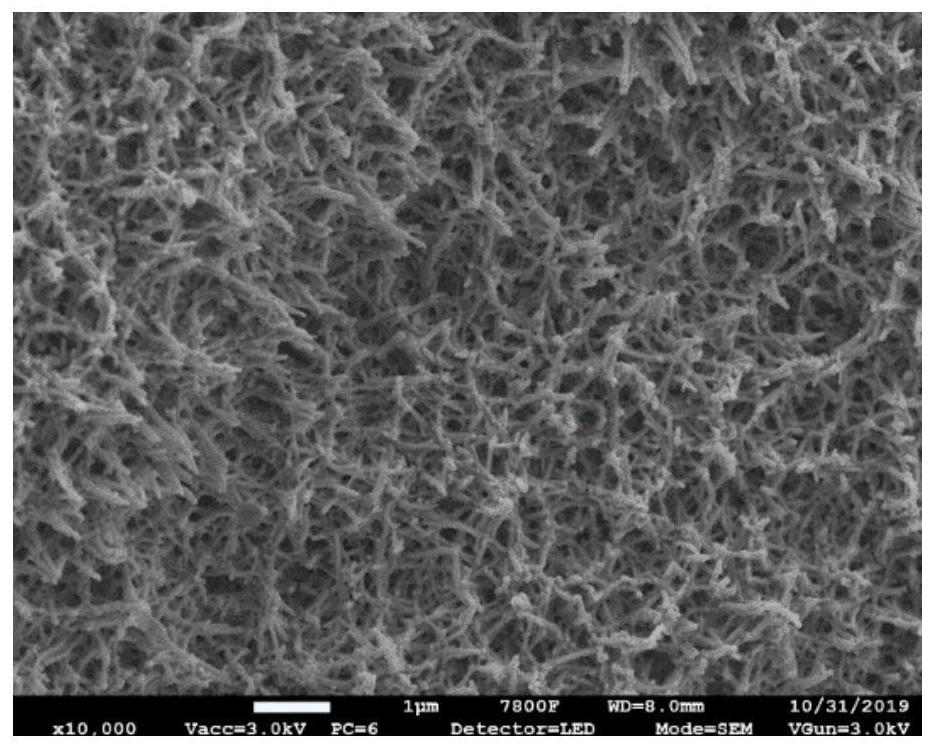

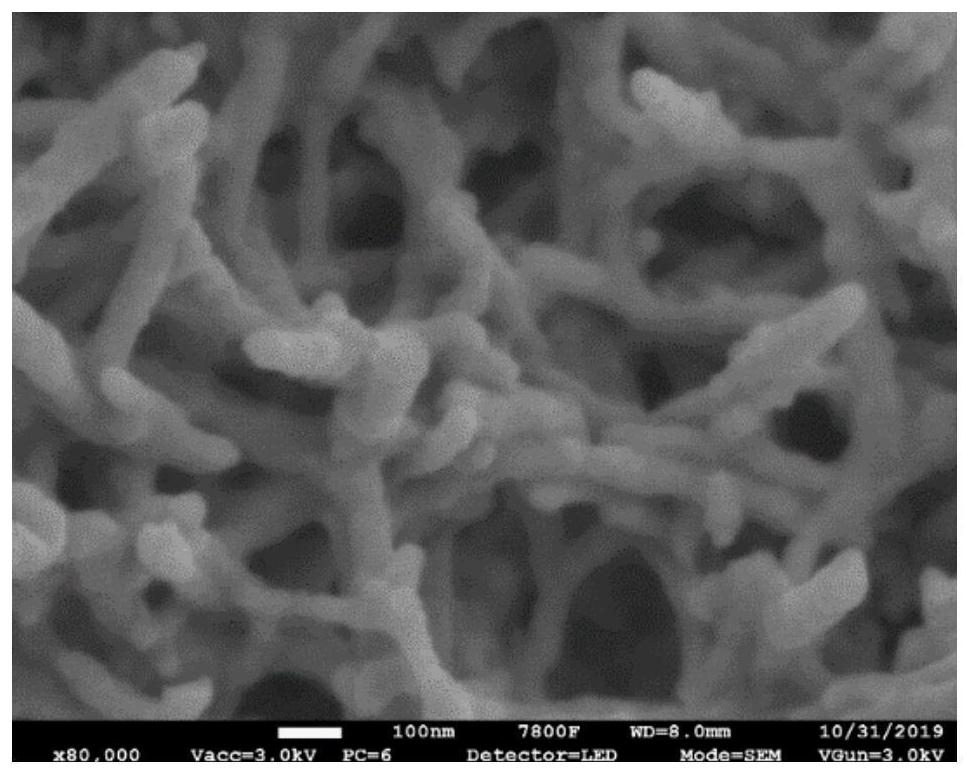

Ordered anode catalyst layer of PEM water electrolysis membrane electrode and preparation method and application thereof

The invention relates to a preparation method of an ordered anode catalyst layer of a PEM water electrolysis membrane electrode. A catalyst layer array provided by the invention is of a double-layer structure, a transition metal oxide array serves as a catalyst layer carrier, and a catalyst wraps the surface layer of the array. The catalyst layer has the characteristics of an ordered structure, a low noble metal catalyst loading amount and high-current-density stable operation. Specifically, a hydrothermal method is adopted to prepare a non-noble metal oxide which serves as an array carrier, a thin catalyst shell is prepared on the surface of the array through an electro-deposition technology, and an ordered oxygen evolution electrode is obtained. The membrane electrode catalyst layer has the advantages of simple and reliable preparation method and uniform structure. The prepared catalyst layer can be used for preparing a PEMWE (proton exchange membrane water electrolysis) membrane electrode, and low-cost, efficient and stable operation of PEM water electrolysis hydrogen production is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

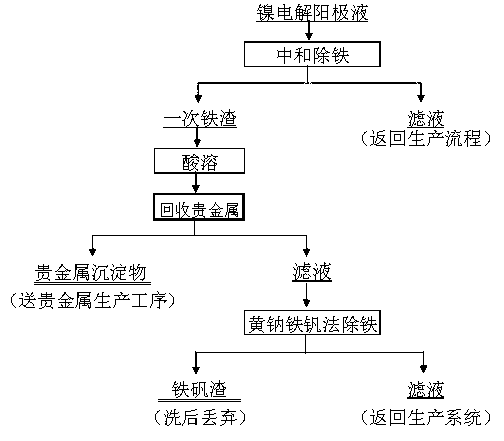

Method for recovering platinum group metal from ferrous nickel electrolysis anolyte

ActiveCN102994773ASolve difficult to recycleRealize enrichment recoveryProcess efficiency improvementElectrolysisSlag

The invention relates to a method for recovering platinum group metal from ferrous nickel electrolysis anolyte, which comprises the following steps of: firstly neutralizing the nickel electrolysis anolyte to remove iron; returning the filtrate to a production system; performing acid dissolution on the obtained primary iron slag at 20-50 DEG C, and then adding a vulcanizing agent; performing precision filtering, wherein over 96% of precious metal is enriched in the filter residue; and removing iron of the filtrate by a sodium jarosite method, wherein the content of precious metal in the obtained sodium jarosite slag is less than 1.0g / t. The method provided by the invention solves the problem that precious metal is lost in anolyte and hard to recover in an electrolytic refining process of a nickel anode containing precious metal, prevents influence on the existing production, and can guarantee the quality of electrolytic nickel; and moreover, the technology is simple, the production cost is low, and the implementation is easy.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com