Tightly-coupled exhaust manifold assembly

An exhaust manifold, tightly coupled technology, used in exhaust devices, mufflers, engine components, etc., can solve problems affecting mass production speed, difficulty, and increasing the number of engine parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

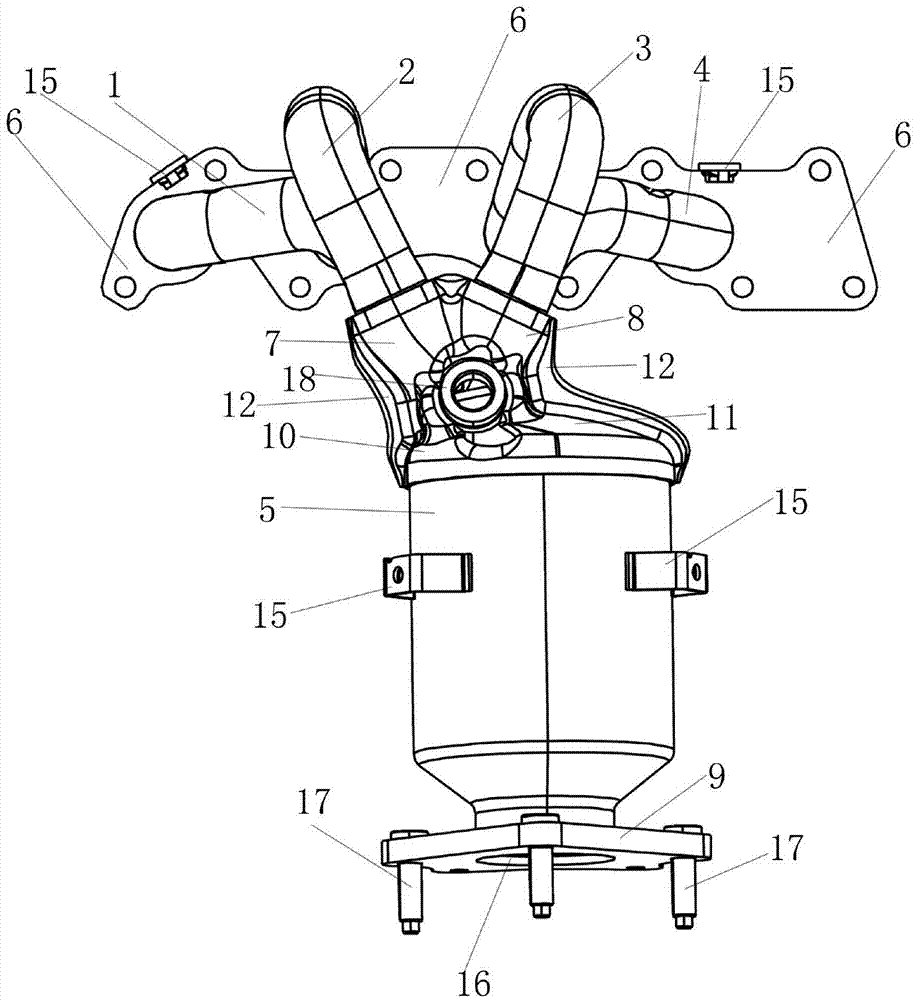

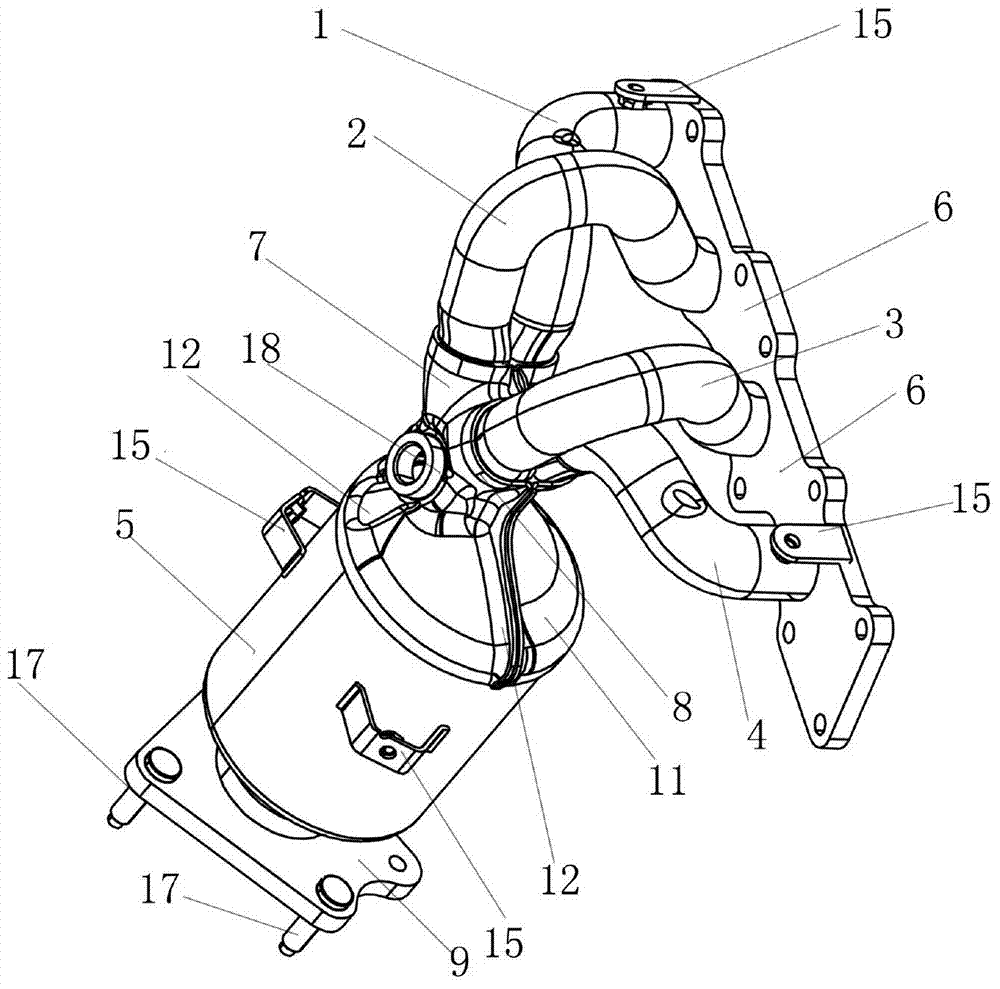

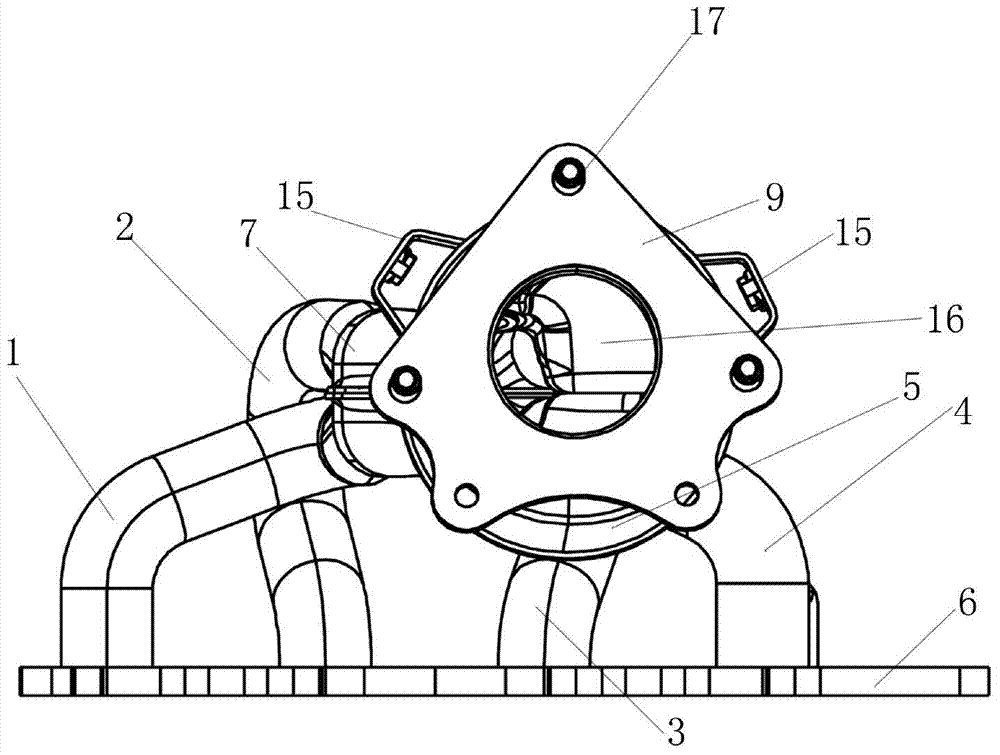

[0025] The following with attached Figure 1 to Figure 6 A close-coupled exhaust manifold assembly of the present invention is further described in detail.

[0026] A close-coupled exhaust manifold assembly of the present invention, please refer to Figure 1 to Figure 6 , including an exhaust manifold assembly and a three-way catalytic converter 5 that is conductively coupled to the exhaust manifold assembly, and the three-way catalytic converter 5 is connected to the exhaust manifold assembly through clam shells, so The exhaust manifold assembly includes a first manifold 1, a second manifold 2, a third manifold 3 and a fourth manifold 4, which are installed on the intake flange 6 at the front end and arranged in sequence from one side to the other. The ends of the first manifold 1 and the second manifold 2 extend into the front end of the first converging pipe 7, and the ends of the third manifold 3 and the fourth manifold 4 extend into the front end of the second converging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com