Thick film resistor slurry

A technology of thick-film resistors and resistor pastes, which is applied in thick-film resistors, resistors, resistor manufacturing, etc., and can solve problems such as deterioration of electrical properties, size effect of electrical properties, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

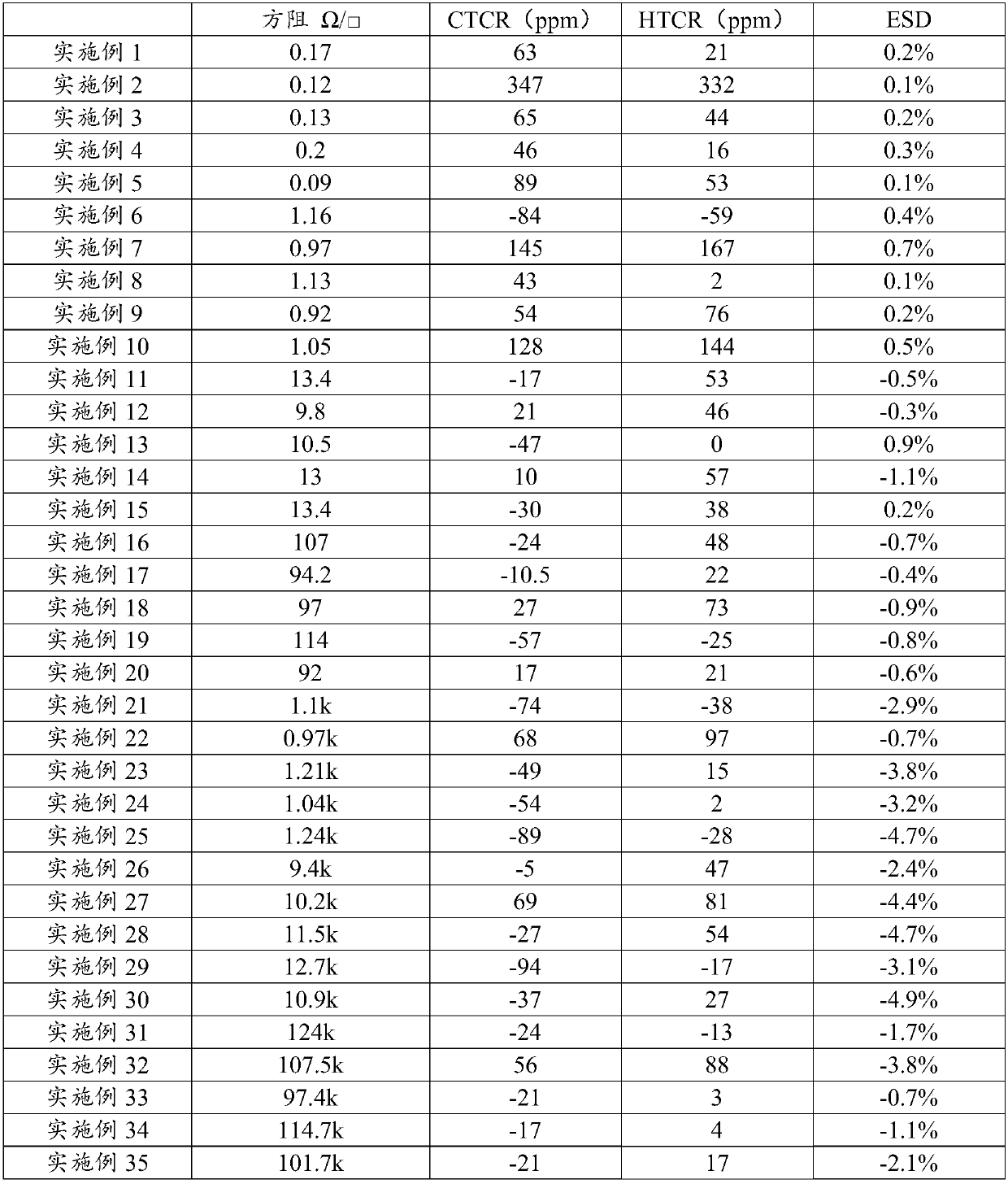

Examples

Embodiment 1

[0137] An embodiment of the 0.1Ω / □ thick film resistor paste of the present invention, the thick film resistor paste described in this embodiment includes solid phase components and organic phase components, and the weight of the solid phase components and organic phase components is The ratio is: solid phase composition: organic phase composition=35:65;

[0138] The solid phase components comprise the following components in weight percentage: Ag 20%, Pd 65% and glass composition 15%; the glass composition comprises glass composition A, glass composition B, glass composition C and glass composition Object D; in the glass composition, the weight percentage of the glass composition A is 5%, the weight percentage of the glass composition B is 24%, and the weight percentage of the glass composition C is component content is 70%, and the weight percentage content of the glass composition D is 1%;

[0139] The glass composition A comprises the following components in weight percen...

Embodiment 2

[0144] An embodiment of the 0.1Ω / □ thick film resistor paste of the present invention, the thick film resistor paste described in this embodiment includes solid phase components and organic phase components, and the weight of the solid phase components and organic phase components is The ratio is: solid phase composition: organic phase composition=75:25;

[0145] The solid phase composition contains the following components in weight percentage: Ag 60%, Pd 5%, RuO 2 20% and glass composition 15%; said glass composition comprises glass composition A, glass composition B, glass composition C and glass composition D; in said glass composition, said glass composition A The weight percentage is 20%, the weight percentage of the glass composition B is 50%, the weight percentage of the glass composition C is 20%, and the weight percentage of the glass composition D is 10%;

[0146] The glass composition A comprises the following components in weight percentage: PbO 50%, SiO 2 35...

Embodiment 3

[0151] An embodiment of the 0.1Ω / □ thick film resistor paste of the present invention, the thick film resistor paste described in this embodiment includes solid phase components and organic phase components, and the weight of the solid phase components and organic phase components is The ratio is: solid phase composition: organic phase composition=75:25;

[0152] The solid phase composition contains the following components in weight percentage: Ag 60%, Pd 15%, RuO 2 20% and glass composition 5%; said glass composition comprises glass composition A, glass composition B, glass composition C and glass composition D; in said glass composition, said glass composition A The weight percentage is 20%, the weight percentage of the glass composition B is 50%, the weight percentage of the glass composition C is 20%, and the weight percentage of the glass composition D is 10%;

[0153] The glass composition A comprises the following components in weight percentage: PbO 30%, SiO 2 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com