Preparation method and application of precious metal-modified CdS nanorod photocatalyst

A technology of photocatalysts and precious metals, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve the problems of complex preparation process of photocatalysts for splitting water and low utilization rate of precious metals, and achieve mild conditions and easy preparation The effect of simple process and low precious metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

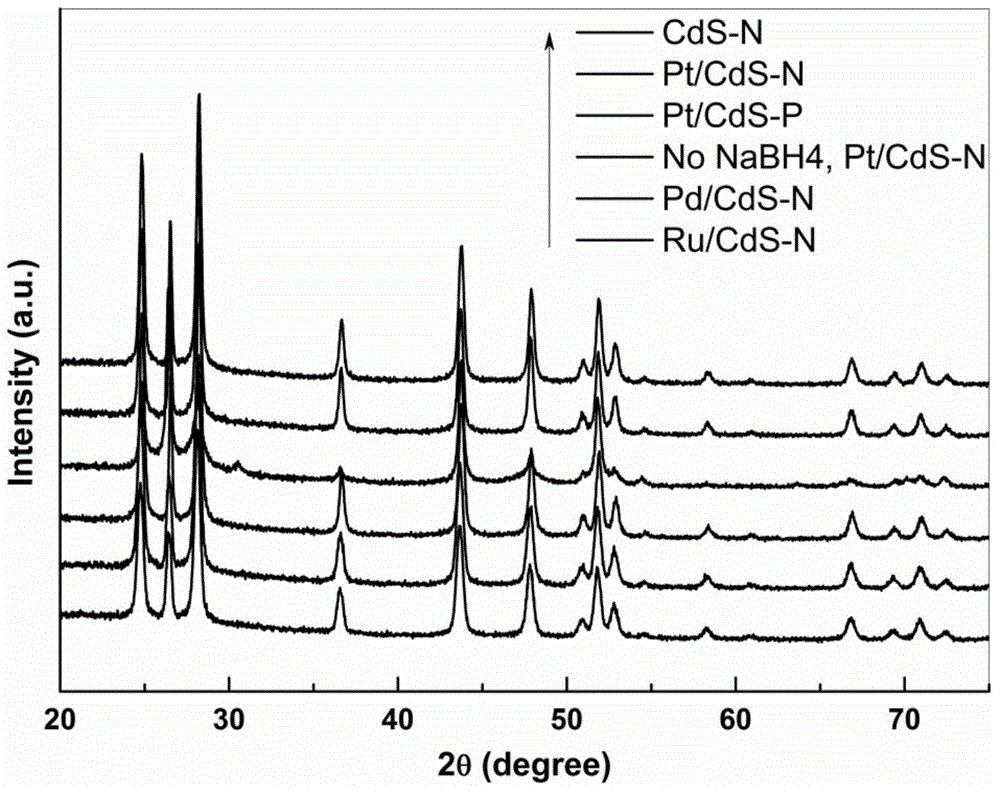

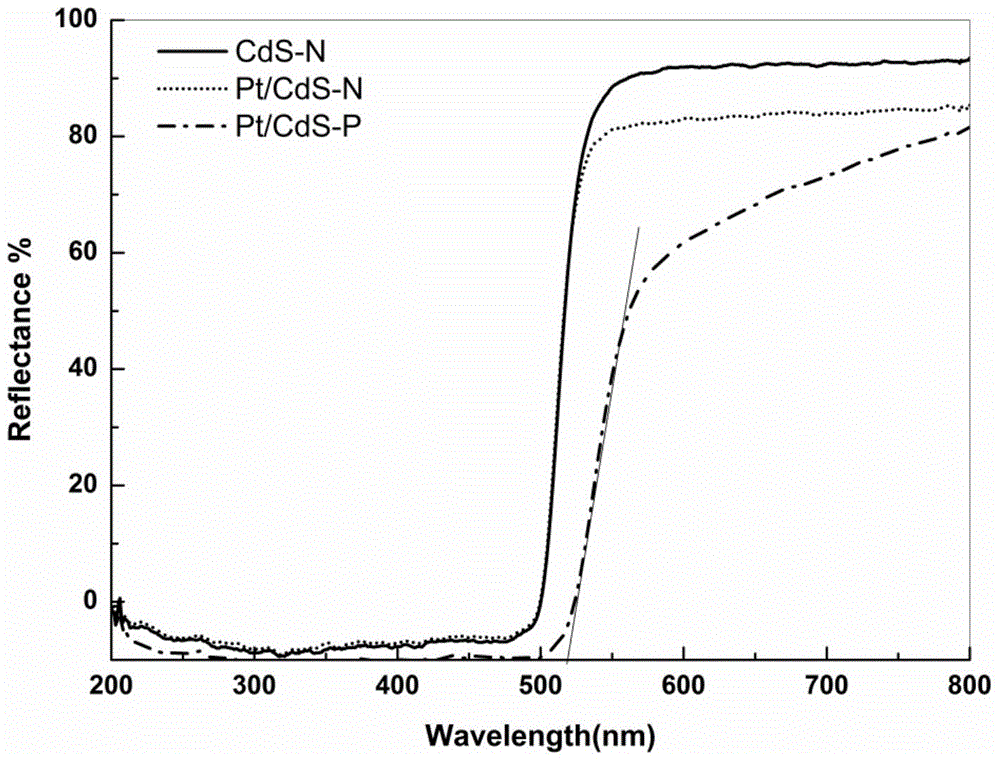

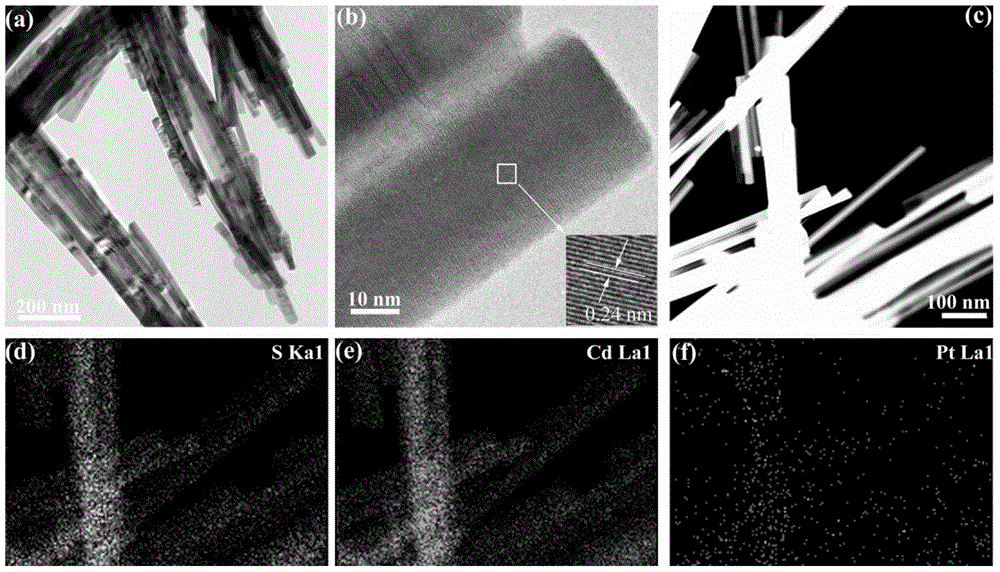

[0054] In this example, Pt (0.06wt.%) modified CdS nanorods were synthesized in one step as follows:

[0055] Take 1g H 2 PtCl 6 ·6H 2 O reagent was dissolved in 37.5mL water to obtain a Pt precursor solution (0.0515mol / L);

[0056] Weigh 4.66g of analytically pure cadmium nitrate tetrahydrate and 3.45g of thiourea into a 100mL cylindrical polytetrafluoroethylene container with an electronic balance, then add 60mL of analytically pure ethylenediamine, stir vigorously until dissolved, and obtain a raw material solution;

[0057] While stirring, use a pipette to pipette a certain amount of 130 μL of the above Pt precursor solution into the raw material solution, and then quickly add 0.20 g of analytically pure NaBH while continuing to stir 4 Reagent, a light yellow solution was obtained. Finally, seal the polytetrafluoroethylene container, put it into a stainless steel hydrothermal kettle, and heat-treat it in a blast drying oven at 160°C for 48h. After naturally cooling to...

Embodiment 2

[0060] This example synthesizes Pt (0.06wt.%) modified CdS nanorods according to the following steps:

[0061] The specific steps of this embodiment are the same as in Example 1, the only difference is that NaBH is not added in the preparation process 4 .

[0062] The sample obtained in this embodiment is marked as No NaBH 4 , Pt / CdS-N.

Embodiment 3

[0064] This embodiment synthesizes CdS nanorods without noble metal modification according to the following steps:

[0065] The specific steps of this embodiment are the same as those in Example 1, the only difference being that no precious metal solution and NaBH were added during the preparation process. 4 .

[0066] The sample obtained in this example is denoted as CdS-N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com