Dual-shell phase change stored energy micro-capsule and preparation method thereof

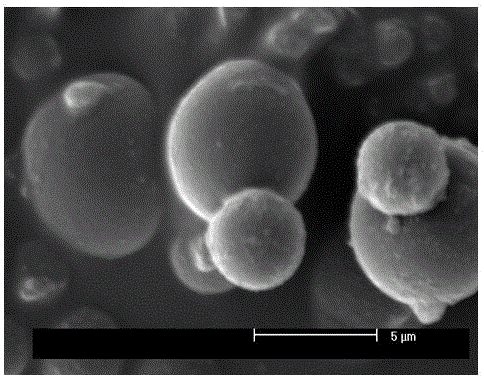

A phase change energy storage and microcapsule technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of lack of standards and specifications, few synthesis methods, and many evaluation indicators, and achieve the latent heat of phase change. High, uniform particle size, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Core material emulsification and polyurea wrapping: first heat n-octadecane to 60 ℃ Form the core material solution, then join 20 parts of the core material solution into 20 parts of deionized water dissolved with 0.15 part of toluene diisocyanate and 0.8 part of sodium dodecylbenzenesulfonate, stir Emulsified Emulsify for 20 min at 7000 r / min , then phacoemulsification 15 minutes to form a core emulsion, in 40 ℃ and The speed is 400 r / min Add 2.5 parts of ethylenediamine dropwise to the core material emulsion under the condition of mechanical stirring, and react after the dropwise addition 1 hour An aqueous solution of microcapsules wrapped in polyurea can be obtained;

[0036] (2) Preparation of monomer prepolymer: in at 40°C, Mix 10 parts of deionized water, compound reactive milk agent stir until well Dissolve to obtain emulsifier aqueous solution, then add 5 parts of methyl methacrylate, 5 parts of butyl acrylate and magnetically stir for 30 ...

Embodiment 2

[0039] (1) Core material emulsification and polyurea wrapping: first heat n-octadecane to 70 ℃ Form the core material solution, then join 30 parts of core material solution into 20 parts of deionized water that are dissolved with 0.2 part of toluene diisocyanate and 1.2 parts of sodium dodecylbenzene sulfonate, exist control Emulsify for 30 min at 8000 r / min , then phacoemulsified for 20 min to form a core emulsion, in 45 ℃ and The speed is 450r / min Add 3.75 parts of ethylenediamine dropwise to the core material emulsion under the condition of mechanical stirring, and react after the dropwise addition 1.5 hours can Obtain the aqueous solution of the microcapsule of polyurea wrapping;

[0040] (2) Preparation of monomer prepolymer: at 45 °C, Mix 25 parts of deionized water, compound reactive milk agent stir until well Dissolve to obtain emulsifier aqueous solution, then add 10 parts of methyl methacrylate, 10 parts of butyl acrylate and magnetically stir at...

Embodiment 3

[0043] (1) Core material emulsification and polyurea wrapping: first heat n-octadecane to 75 ℃ Form the core material solution, then join 35 parts of the core material solution into 30 parts of deionized water dissolved with 0.25 parts of toluene diisocyanate and 1.2 parts of sodium dodecylbenzenesulfonate, stir Emulsified Emulsify at 9000 r / min for 30 min , then phacoemulsification 20 minutes to form a core emulsion, in 50 ℃ and The speed is 450r / min Add 3.75 parts of ethylenediamine dropwise to the core material emulsion under the condition of mechanical stirring, and react after the dropwise addition 1.5 hours An aqueous solution of microcapsules wrapped in polyurea can be obtained;

[0044] (2) Preparation of monomer prepolymer: in at 50°C, Mix 30 parts of deionized water, compound reactive milk agent stir until well Dissolve to obtain emulsifier aqueous solution, then add 10 parts of methyl methacrylate, 10 parts of butyl acrylate and magnetically stir a...

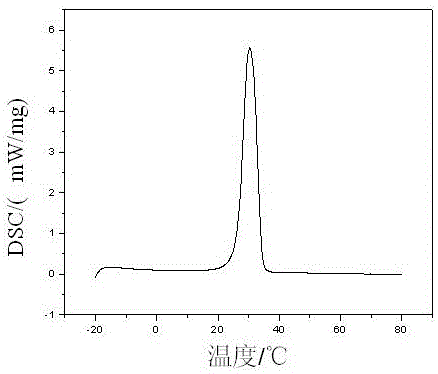

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com