Ceramic material of middle-low temp. sintered temp stable type multirayer ceramic capacitor

A temperature-stable capacitor ceramic technology, applied in the field of capacitor materials, can solve problems such as inability to produce and use, and achieve the effects of narrow particle size distribution, cost reduction, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

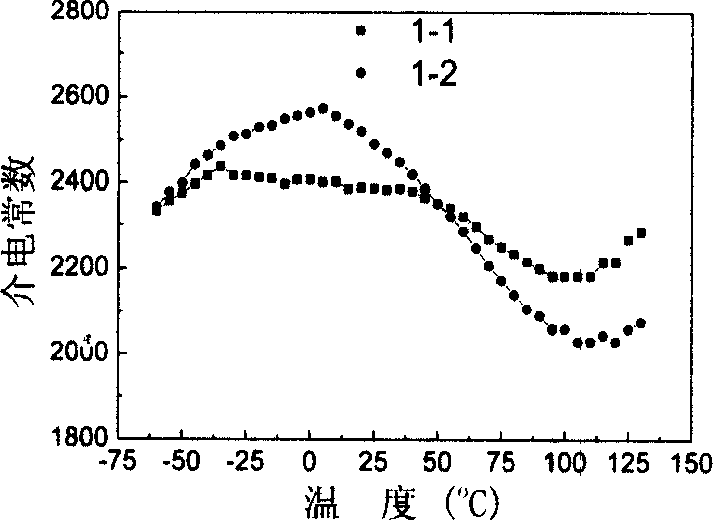

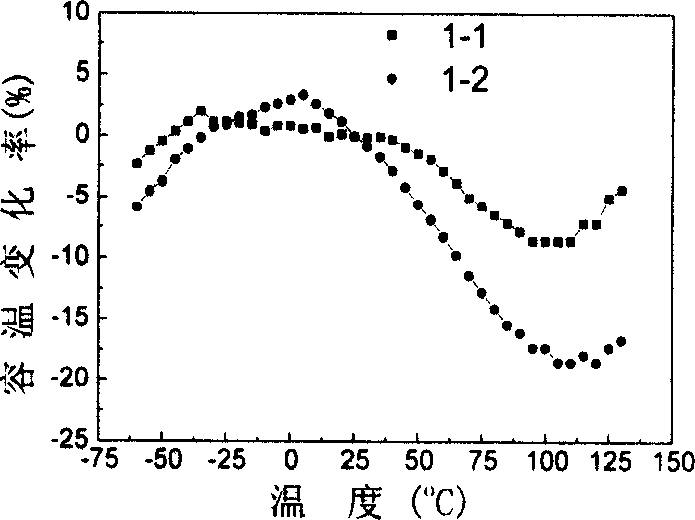

[0031] Barium titanate BaTiO 3The main material is synthesized by hydrothermal method, and the initial particle size is about 300nm. First, solid solutions with Nb / Co atomic ratios of 3:1 and 2:1 were synthesized by solid-state method. Add secondary additives to 20g of barium titanate powder material respectively according to the formula, the solid solution content of Nb / Co in the formula is 1.5wt%, and the content of neodymium oxide is 0.9wt%, recorded as 1-1, 1- 2. The ingredients are mixed by ball milling, and after drying, they are pressed into shape under a pressure of 2MPa, with a diameter of 10mm and a thickness of 1mm. Sinter at 1150°C for 4h with a heating rate of 6°C / min. The dielectric properties of the fired ceramic pieces were measured after firing silver on the surface. The dielectric properties of the obtained ceramic samples are shown in Table 1. figure 1 The curve shows the dielectric temperature characteristic curve of the sample. figure 2 Give the vol...

Embodiment 2

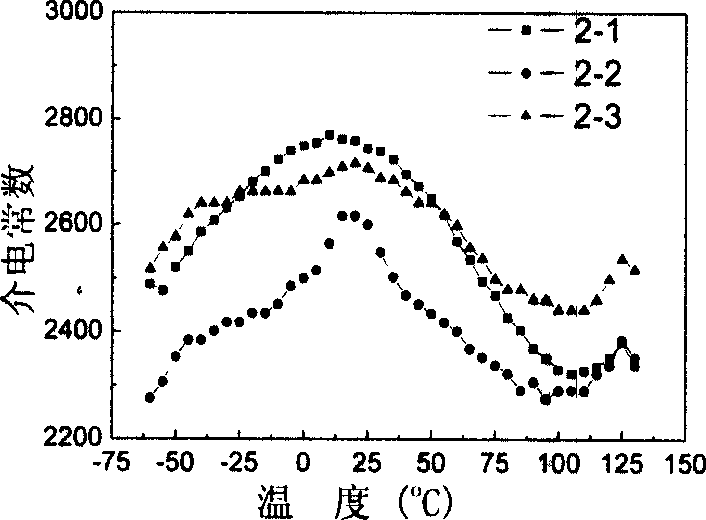

[0033] Barium titanate BaTiO 3 The main material is synthesized by hydrothermal method, and the initial particle size is about 300nm. In 20g of barium titanate powder material, add secondary additives according to the formula respectively. In the formula, the content of solid solution with Nb / Co atomic ratio of 3:1 is 1.2wt%, and the content of lanthanum oxide is 0.8wt% and 0.9wt%, respectively. %, 1.0wt%, recorded as 2-1, 2-2, 2-3. The ingredients are mixed by ball milling, and after drying, they are pressed into shape under a pressure of 2MPa, with a diameter of 10mm and a thickness of 1mm. Sinter at 1150°C for 4h with a heating rate of 6°C / min. The dielectric properties of the fired ceramic pieces were measured after firing silver on the surface. The dielectric properties of the obtained ceramic samples are shown in Table 1. image 3 The curve shows the dielectric temperature characteristic curve of the sample. Figure 4 Give the volumetric temperature change rate curv...

Embodiment 3

[0035] Barium titanate BaTiO 3 The main material is synthesized by hydrothermal method, and the initial particle size is about 300nm. Add secondary additives to 20g of barium titanate powder material according to the formula. In the formula, the solid solution content of Nb / Co atomic ratio is 3:1 is 1.5wt%, neodymium oxide and samarium oxide are co-doped, and the content is respectively 0.6 wt%, 0.3wt%, recorded as 3-1. The ingredients are mixed by ball milling, and after drying, they are pressed into shape under a pressure of 2MPa, with a diameter of 10mm and a thickness of 1mm. Sinter at 1150°C for 4h with a heating rate of 6°C / min. The dielectric properties of the fired ceramic pieces were measured after firing silver on the surface. The dielectric properties of the obtained ceramic samples are shown in Table 1. Figure 5 The curve shows the dielectric temperature characteristic curve of the sample. Image 6 Give the volumetric temperature change rate curve of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com