Multiphase reinforced ultrahigh-strength maraging stainless steel and preparation method thereof

A technology of stainless steel and martensite, which is applied in the field of multiphase strengthening ultra-high strength maraging stainless steel and its preparation, can solve the problems of complex preparation process and low corrosion resistance mechanical properties, and achieve simple preparation method and corrosion resistance Good, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

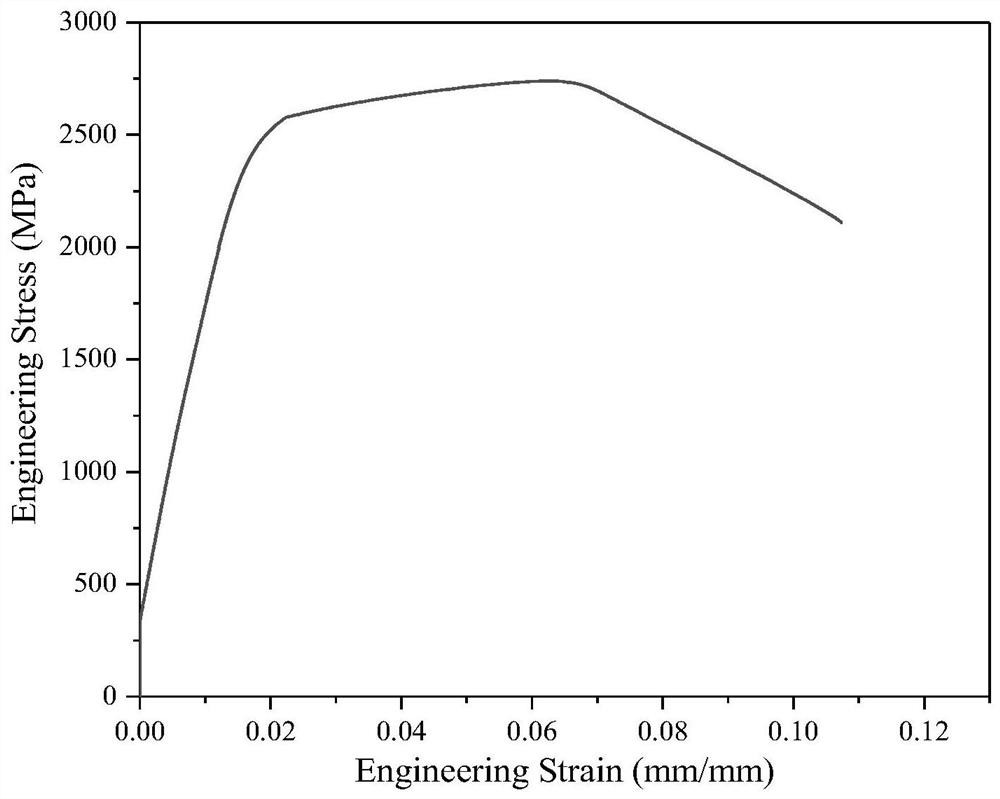

Embodiment 1

[0050] Select pure iron, metal chromium, metal nickel, metal manganese, metal molybdenum, metal cobalt, metal titanium, and iron-silicon raw materials. The composition of stainless steel is as follows (mass percentage): Co=3.0, Cr=11.0, Mn=0.08, Mo =5.0, Ni=8.0, Si=0.4, Ti=2.0, Fe balance.

[0051] Vacuum melting is used throughout the process to prepare ingots.

[0052] High-temperature homogenization treatment, heating in air, the heating method is heating with the furnace, the heating rate is 100°C / h, holding at 700°C for 4 hours, then raising the temperature to 1100°C for 20 hours, and cooling to room temperature with the furnace.

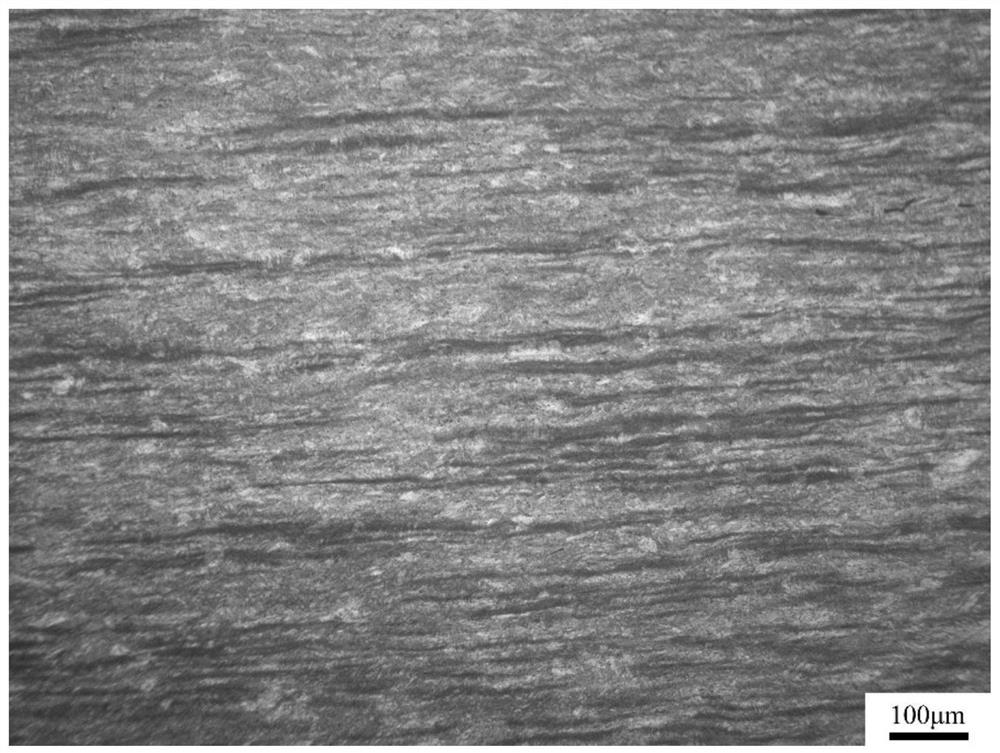

[0053] The process conditions for hot rolling blanking are: the cast billet is heated to 1100°C, held for 10 hours and then rolled out of the furnace; the hot rolling start temperature is 1100±20°C, the final rolling temperature is ≥950°C, the total amount of sheet hot rolling is 50%, ice The water mixture is cooled.

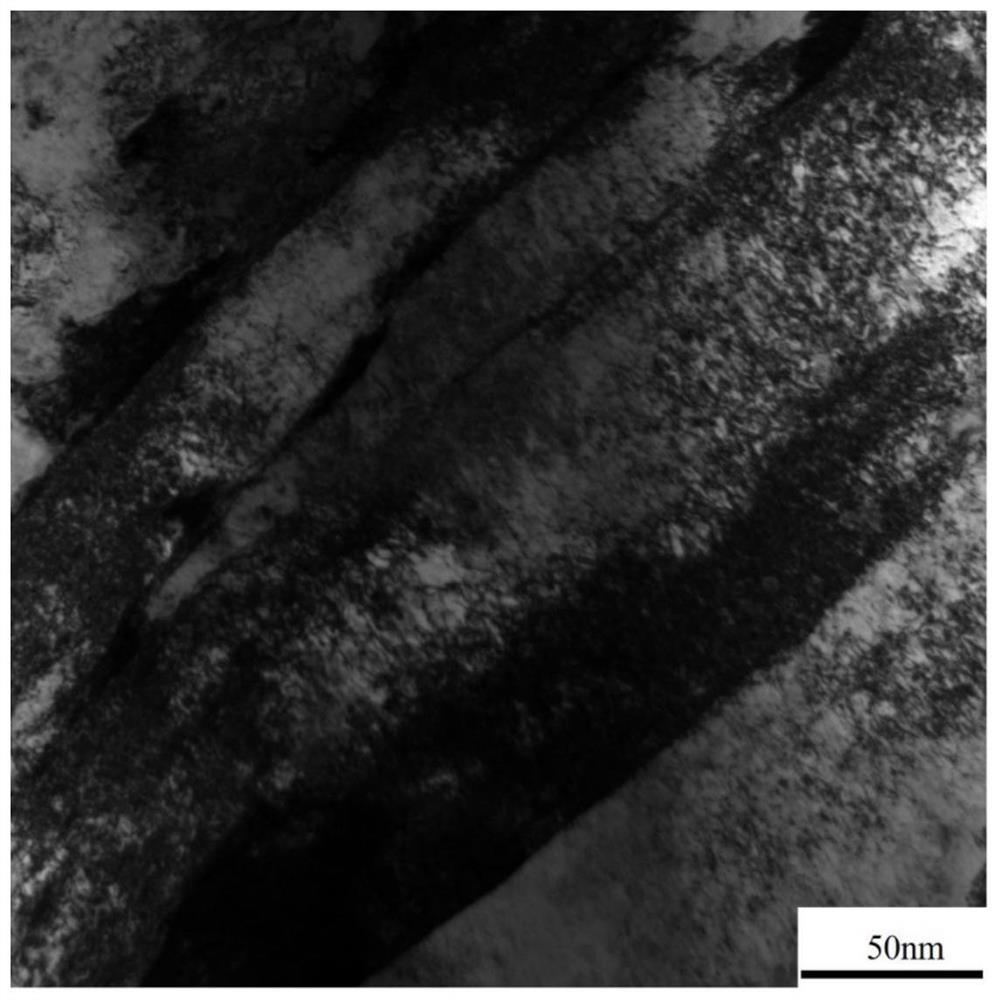

[0054] The sheet was co...

Embodiment 2

[0058] Select pure iron, metal chromium, metal nickel, metal manganese, metal molybdenum, metal cobalt, metal titanium, and iron-silicon raw materials. The stainless steel composition is as follows (mass percentage): Co=1.0, Cr=12.0, Mn=0.5, Mo =6.0, Ni=9.0, Si=0.5, Ti=1.5, Fe balance.

[0059] Vacuum melting is used throughout the process to prepare ingots.

[0060] High-temperature homogenization treatment, heating in air, the heating method is heating with the furnace, the heating rate is 100°C / h, holding at 700°C for 4 hours, then raising the temperature to 1150°C for 20 hours, and cooling to room temperature with the furnace.

[0061] The process conditions for hot rolling blanking are: the cast billet is heated to 1200°C, held for 30 hours and then rolled out of the furnace; the hot rolling start temperature is 1150±20°C, the final rolling temperature is ≥950°C, the total amount of sheet hot rolling is 50%, ice The water mixture is cooled.

[0062] The sheet was cold r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com