Ordered anode catalyst layer of PEM water electrolysis membrane electrode and preparation method and application thereof

An electrode catalyst layer, electrode catalyst layer technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of catalyst preparation method limitation, more cracks on the surface uniformity of the catalyst layer, expensive catalyst, etc., to achieve the preparation method Simple and easy to operate, widely used value, dispersibility and quantitative activity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

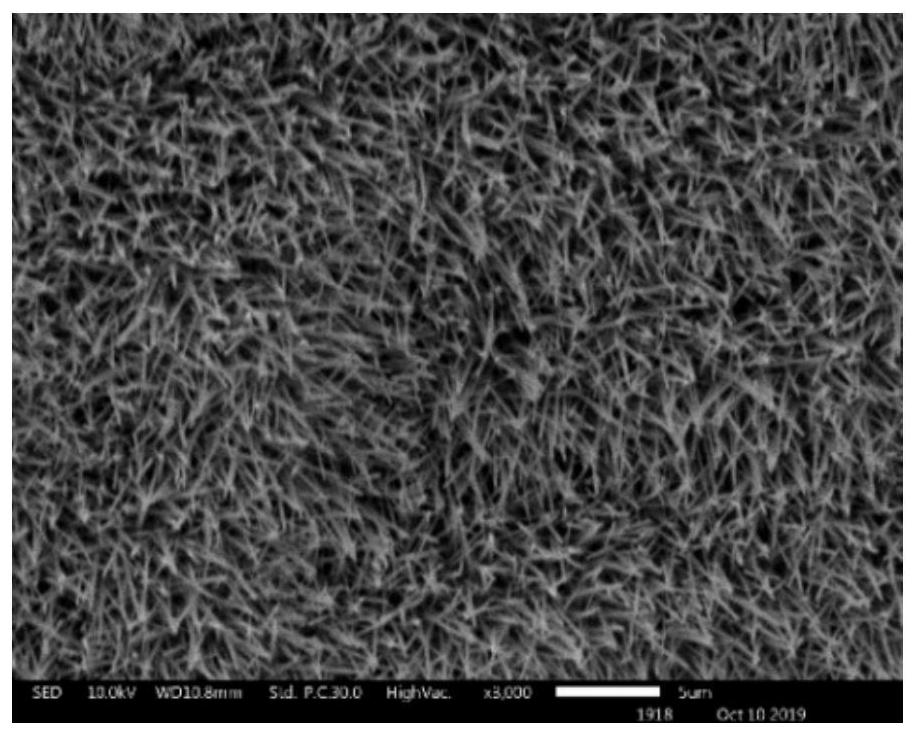

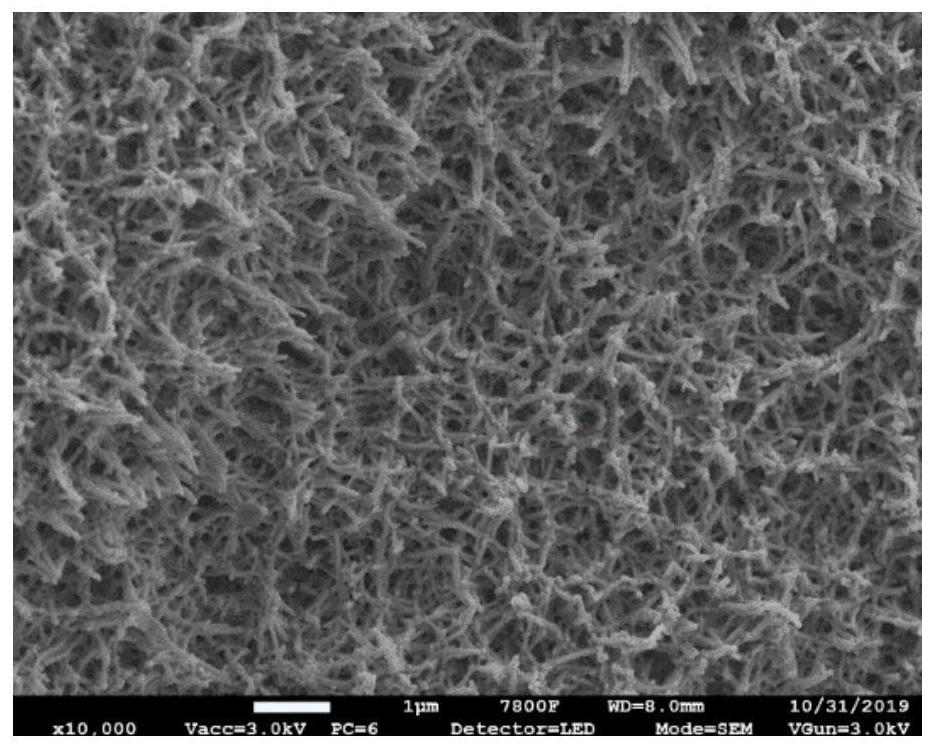

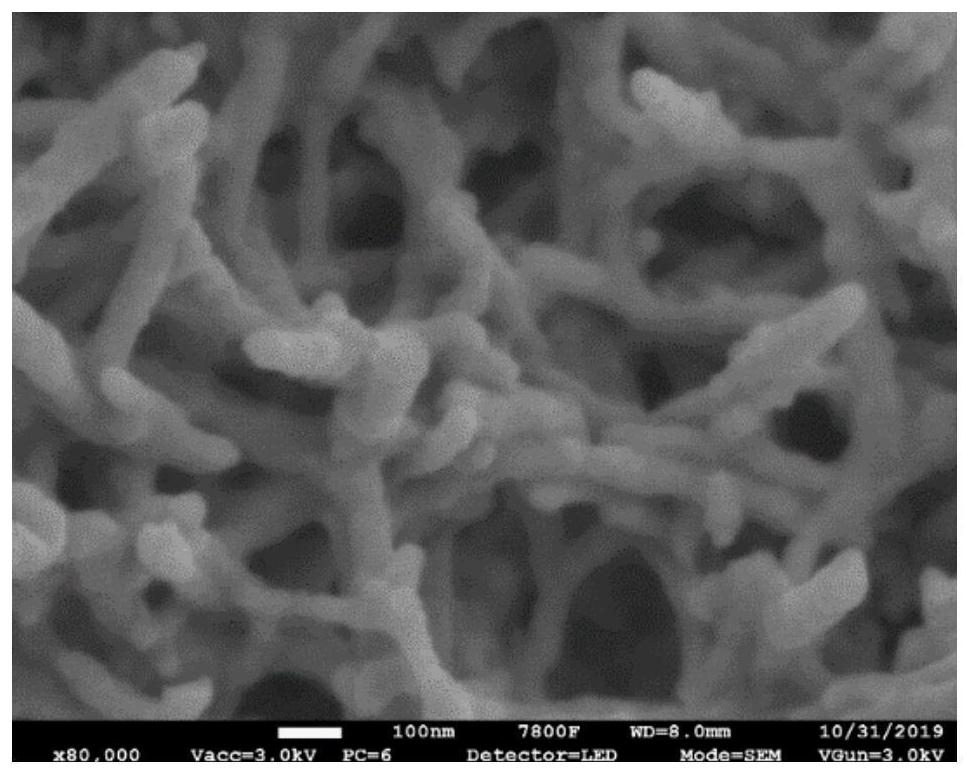

[0043] Preparation of ordered WO by hydrothermal method 3 carrier

[0044] To prepare a tungstic acid solution, first weigh 1.25g of tungstic acid, add 10ml of 30 wt% hydrogen peroxide, add water to dissolve 30ml of water, stir at 85°C for 30min to form a milky white tungstic acid solution, add water to dilute, so that the concentration of tungstic acid is 0.05molL -1 .

[0045] Prepare the solution for hydrothermal reaction: weigh 0.056g thiourea and 0.064g maleic acid in sequence, measure 3.2mL 3M hydrochloric acid solution, add 4.8mL water and 30.4mL acetonitrile as solvent, and stir for 30min. Add the prepared tungstic acid solution and continue to stir for 60 minutes to complete the preparation of the reaction solution.

[0046] Cut pure tungsten sheet into 2.5*5.0cm 2 Size, ultrasonic in sequence with ethanol and deionized water for 20 minutes, then placed in 80°C, 25% hydrochloric acid solution to remove the oxide layer on the surface, take it out and rinse it with ...

Embodiment 2

[0056] 1. Preparation of ordered WO by hydrothermal method 3 carrier

[0057] To prepare a tungstic acid solution, first weigh 1.25g of tungstic acid, add 10ml of 30 wt% hydrogen peroxide, add water to dissolve 30ml of water, stir at 85°C for 30min to form a milky white tungstic acid solution, add water to dilute, so that the concentration of tungstic acid is 0.05molL -1 .

[0058] Prepare the solution for hydrothermal reaction: weigh 0.056g thiourea and 0.064g maleic acid in sequence, measure 3.2mL 3M hydrochloric acid solution, add 4.8mL water and 30.4mL acetonitrile as solvent, and stir for 30min. Add the prepared tungstic acid solution and continue to stir for 60 minutes to complete the preparation of the reaction solution.

[0059] Cut pure tungsten sheet into 2.5*5.0cm 2 Size, ultrasonic in sequence with ethanol and deionized water for 20 minutes, then placed in 80°C, 25% hydrochloric acid solution to remove the oxide layer on the surface, take it out and rinse it wi...

Embodiment 3

[0068] 1. Preparation of ordered WO by hydrothermal method 3 carrier

[0069] To prepare a tungstic acid solution, first weigh 1.25g of tungstic acid, add 10ml of 30 wt% hydrogen peroxide, add water to dissolve 30ml of water, stir at 85°C for 30min to form a milky white tungstic acid solution, add water to dilute, so that the concentration of tungstic acid is 0.05molL -1 .

[0070] Prepare the solution for hydrothermal reaction: weigh 0.056g thiourea and 0.064g maleic acid in sequence, measure 3.2mL 3M hydrochloric acid solution, add 4.8mL water and 30.4mL acetonitrile as solvent, and stir for 30min. Add the prepared tungstic acid solution and continue to stir for 60 minutes to complete the preparation of the reaction solution.

[0071] Cut pure tungsten sheet into 2.5*5.0cm 2 Size, ultrasonic in sequence with ethanol and deionized water for 20 minutes, then placed in 80°C, 25% hydrochloric acid solution to remove the oxide layer on the surface, take it out and rinse it wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com