Superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and manufacture method thereof

A technology of hydrogenation equipment and production methods, which is applied in the field of iron and steel metallurgy, can solve the problems of performance degradation, large-thickness steel plates cannot meet the performance parameters, etc., achieve good plate shape, good hydrogen corrosion resistance and embrittlement resistance, and reduce equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

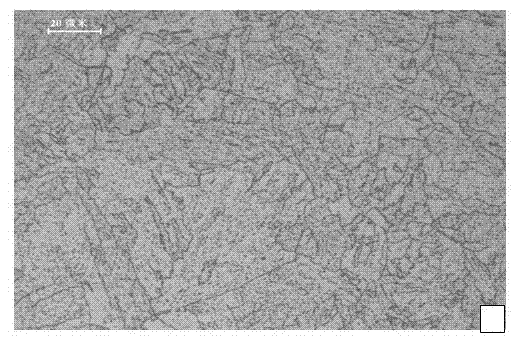

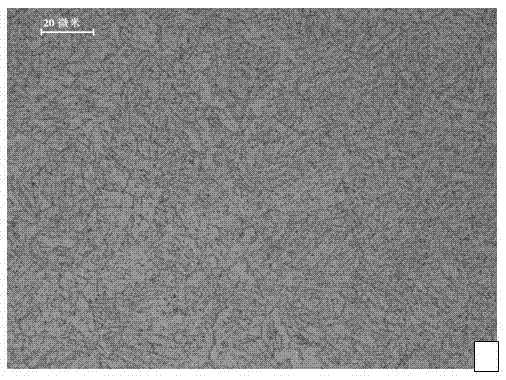

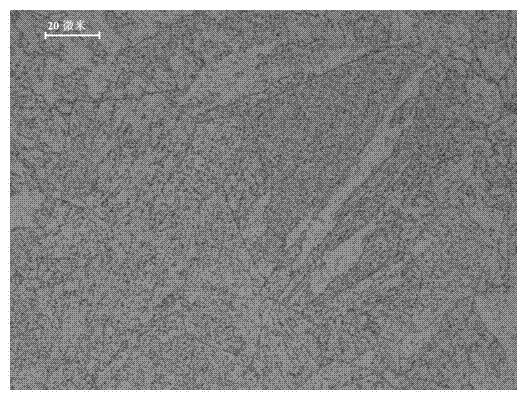

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through embodiment.

[0025] The large-thickness chromium-molybdenum steel plate for hydrogenation equipment of the example is composed of the following components in weight percentage: 0.12%≤C≤0.15%, 0.02%≤Si≤0.07%, Mn: 0.50-0.60%, P≤0.007%, S≤0.005%, Cr: 2.35-2.50%, Mo: 0.95-1.10%, 0.012%≤Nb≤0.02%, Cu≤0.20%, Ni≤0.20%, Sb≤0.003%, Sn≤0.005%, As≤0.016 %, O ≤ 0.003%, N ≤ 0.008%, H ≤ 0.0002%, Ti ≤ 0.03, the J coefficient of the large-thickness chromium-molybdenum steel plate for hydrogenation equipment in this embodiment is 41.3, and the P+Sn content is 0.007%. The thickness is 256mm.

[0026] The production method of the super-thickness chromium-molybdenum steel plate for the hydrogenation equipment of the present embodiment, the specific steps are:

[0027](1) Smelting steps: first smelt with a 100T ultra-high power electric arc furnace, use a large amount of slag flow during the melting period, vacuum decarburizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com